Multiple crosslinking ultraviolet light solidifying water polyurethane dispersoid and its preparation method and application

A water-based polyurethane and multiple cross-linking technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve product safety and hygiene and long-term adverse effects on performance, environment and human harmful organic volatiles, and active diluents to increase the coating film Shrinkage and other issues, to achieve the effect of mature and stable production process, good molecular structure, and increase hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The multi-crosslinking UV-curable waterborne polyurethane wood coating was prepared according to the following steps.

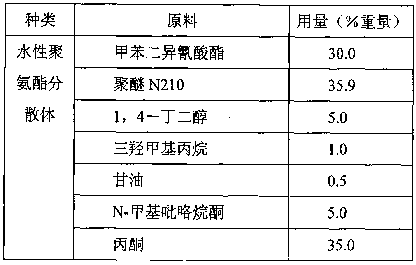

[0052] Prepare raw materials: Prepare materials according to the formula in Table 1.

[0053] Table 1

[0054]

[0055]

[0056] Synthesis of polyurethane primary polymer I: firstly add polyether N210 into the reaction vessel, heat up to 70°C, then add toluene diisocyanate, stir and react for 2 hours to obtain reactive primary polymer I;

[0057] Synthesis of polyurethane prepolymer II: Add dropwise a mixture of 1,4-butanediol, trimethylolpropane, glycerol, N-methylpyrrolidone and acetone to the resulting initial polymer I, and control the dropping time Control within 2 hours; after the dropwise addition is completed, react for 1 hour in the temperature range of 80°C, and the polyurethane prepolymer II is obtained after the reaction is completed;

[0058] Synthesis of polyurethane prepolymer III: dissolve the dried 2,2-dimethylolpropionic ac...

Embodiment 2

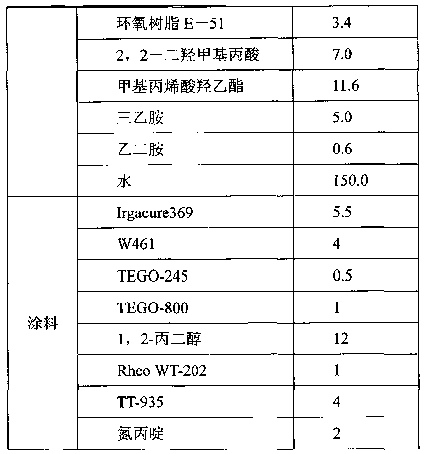

[0065] Raw materials were prepared according to the ratio in Table 2 below, and then the same steps as in Example 1 were used to prepare multiple cross-linked UV-curable water-based polyurethane wood coatings.

[0066] Table 2

[0067]

[0068]

[0069] Synthesis of polyurethane primary polymer I: firstly add polyether N220 into the reaction vessel, heat up to 90°C, then add toluene diisocyanate, stir and react for 1 hour to obtain reactive primary polymer I;

[0070] The synthesis of polyurethane prepolymer II: dropwise the mixture of 1,4-butanediol, pentaerythritol, N-methylpyrrolidone and acetone in the initial polymer I of gained, control dropping time is controlled at 1.5 hours; After the addition is completed, react for 2 hours in the temperature range of 70°C, and the polyurethane prepolymer II is obtained after the reaction is completed;

[0071] Synthesis of Polyurethane Prepolymer III: Dissolve the dried 2,2-dimethylol propionic acid and epoxy resin E-20 mixt...

Embodiment 3

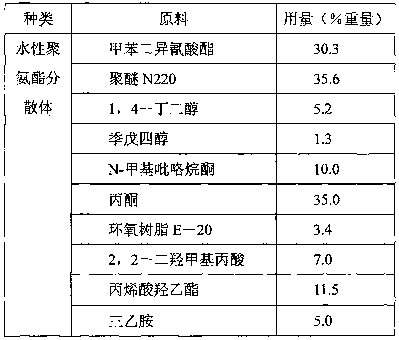

[0078] Raw materials were prepared according to the ratio in Table 3 below, and then the multiple cross-linked UV-curable waterborne polyurethane wood coating was prepared according to the same steps as in Example 1.

[0079] table 3

[0080]

[0081]

[0082] Synthesis of polyurethane primary polymer I: firstly add polyether N230 into the reaction vessel, heat up to 80°C, then add toluene diisocyanate, stir and react for 1.5 hours to obtain reactive primary polymer I;

[0083] The synthesis of polyurethane prepolymer II: dropwise the mixture of 1,4-butanediol, glycerol, N-methylpyrrolidone and acetone in the obtained primary polymer I, control the time of dropping and control at 1 hour; drop After the addition is completed, react within the temperature range of 80°C for 1 hour, and the polyurethane prepolymer II is obtained after the reaction is completed;

[0084] Synthesis of Polyurethane Prepolymer III: Dissolve the dried 2,2-dimethylol propionic acid and epoxy r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com