Environment-friendly high-durability epoxy mortar

An epoxy mortar and durability technology, applied in the field of building materials, can solve the problems of impact wear, damage to the health of construction workers, performance degradation, etc., achieve excellent impact and wear resistance, be conducive to environmental protection and safety, reduce shrinkage and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An embodiment of the environment-friendly high-durability epoxy mortar of the present invention, the mortar is composed of component A and component B with a weight ratio of component A: component B=100:11.5;

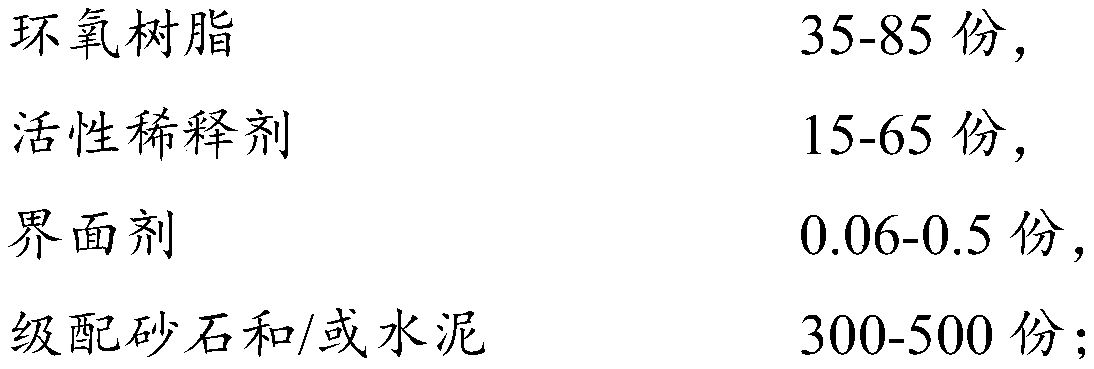

[0037] Wherein the first component is made up of the composition of following weight part:

[0038]

[0039] B component comprises the composition of following weight part:

[0040] Diethylenetriamine (amine curing agent) 5 parts,

[0041] Polymercaptan (humid environment functional curing agent) 35 parts,

[0042] DMP-30 (curing accelerator) 2 parts.

Embodiment 2

[0044] An embodiment of the environment-friendly high-durability epoxy mortar of the present invention, the mortar is composed of component A and component B with a weight ratio of component A: component B=100:8.5;

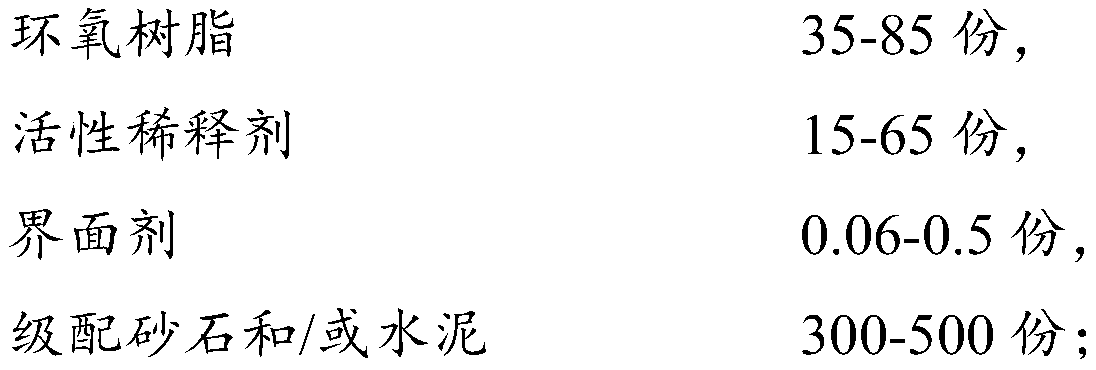

[0045] Wherein the first component is made up of the composition of following weight part:

[0046]

[0047] B component comprises the composition of following weight part:

[0048] Amine curing agent 593 (amine curing agent) 10 parts,

[0049] Polymercaptan (humid environment functional curing agent) 40 parts,

[0050] 3 parts of benzyldimethylamine (curing accelerator).

Embodiment 3

[0052] An embodiment of the environment-friendly high-durability epoxy mortar of the present invention, the mortar is composed of component A and component B with a weight ratio of component A: component B=100:3;

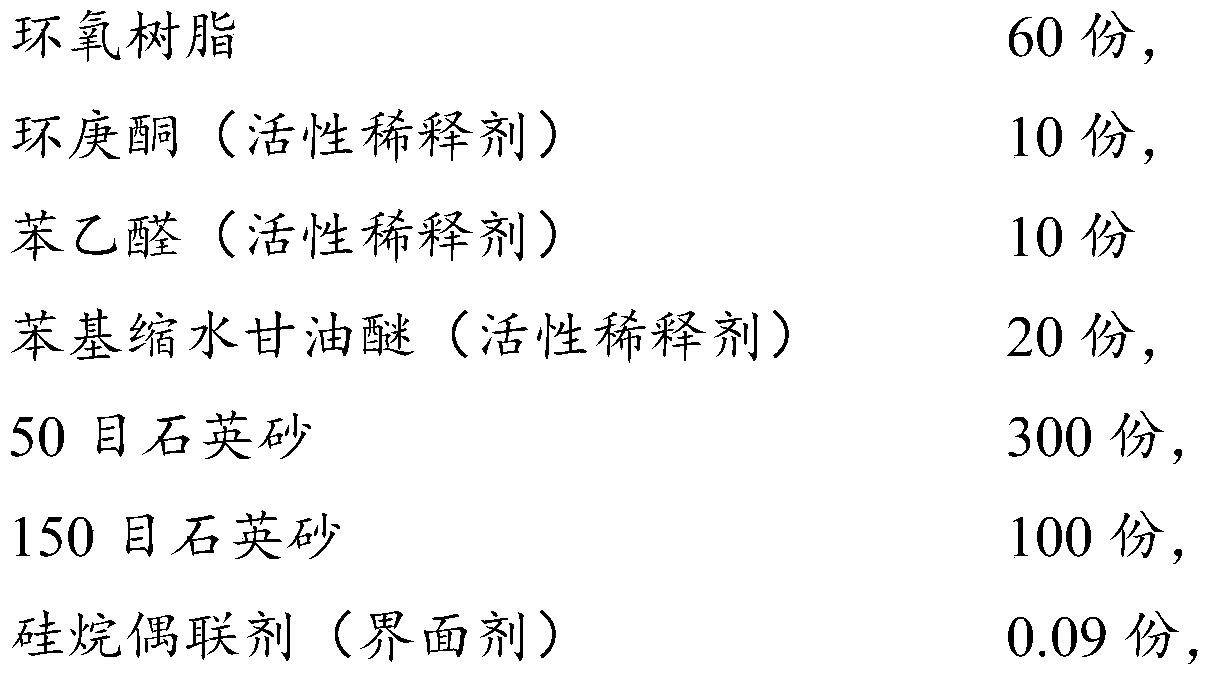

[0053] Wherein the first component is made up of the composition of following weight part:

[0054]

[0055]

[0056] B component comprises the composition of following weight part:

[0057] 25 parts of polyamide (amine curing agent),

[0058] Mannich modified amine (humid environment functional curing agent) 22.5 parts,

[0059] 12 parts of triethanolamine (curing accelerator).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com