High-toughness impact-resistant and wear-resistant repairing material

A repairing material and high-toughness technology, applied in the field of high-toughness impact-resistant and wear-resistant repairing materials, can solve the problems of high operating technical requirements, easy cracking of the repairing layer, and high product price, so as to improve crack resistance, eliminate harmful bubble defects, The effect of improving compactness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

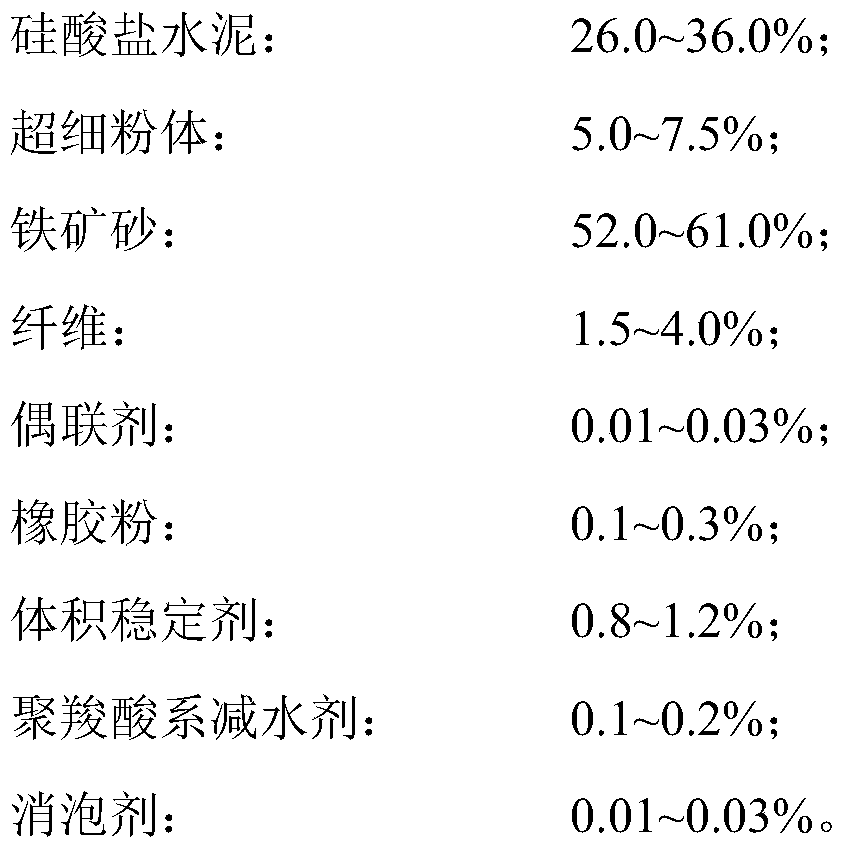

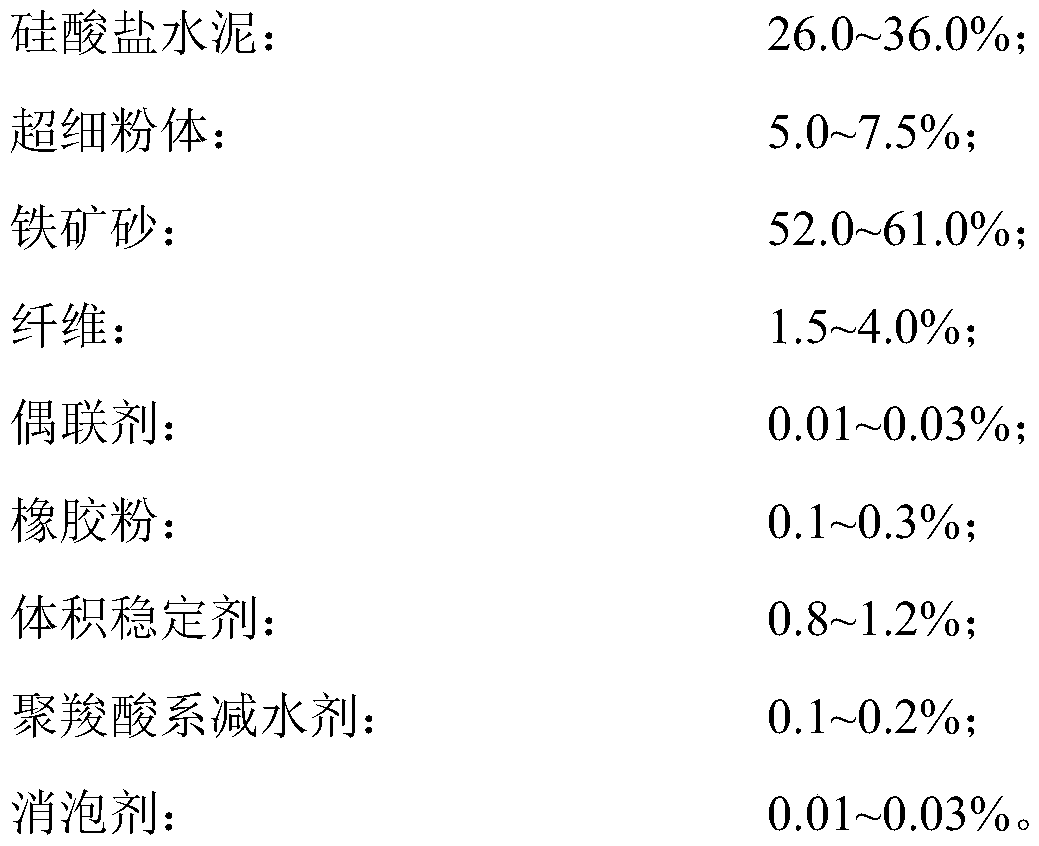

Method used

Image

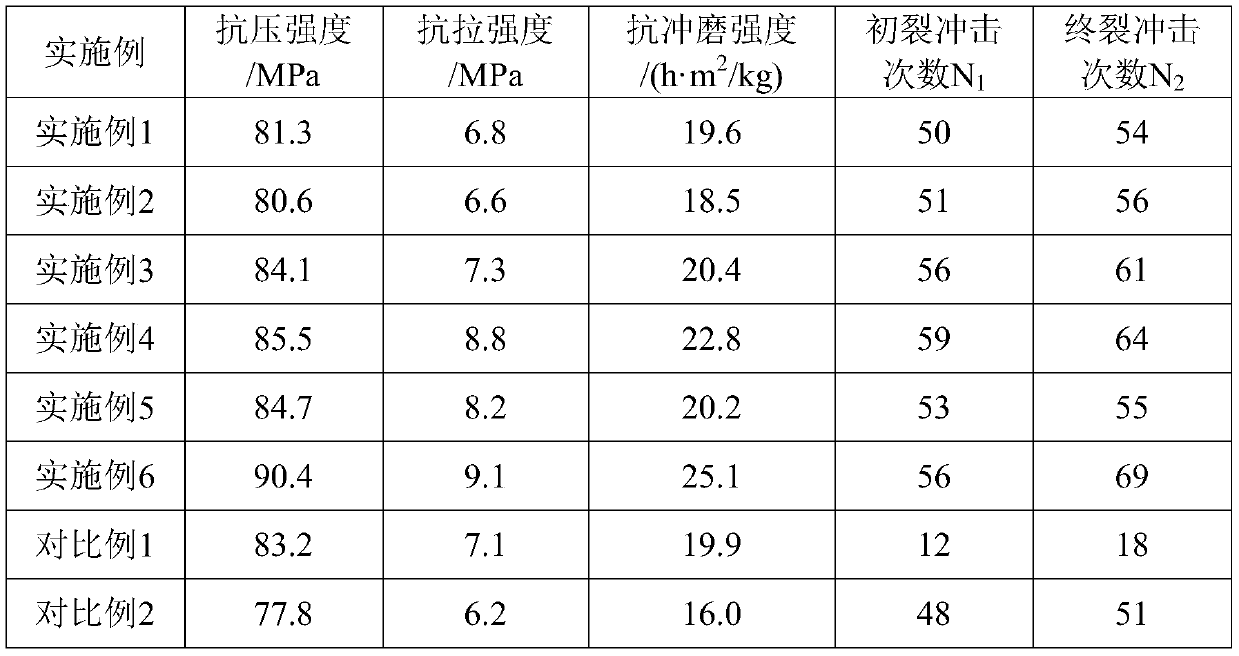

Examples

Embodiment 1

[0025] A high-toughness anti-impact and wear-resistant repair material, comprising the following raw materials by mass: 310 parts of P·Ⅱ 52.5 cement, 8.0 parts of silicon powder, 53.0 parts of finely ground slag, 4.0 parts of nano-graphene, 587 parts of iron ore, 19.0 parts of steel fiber, 4.3 parts of plastic steel fiber, 1.1 part of basalt fiber, 0.1 part of KH560 silane coupling agent, 1.6 parts of rubber powder (fineness 24 mesh), 0.8 parts of plastic expansion agent, 6.0 parts of UEA expansion agent, magnesium oxide expansion agent 3.2 parts, 1.7 parts of polycarboxylate water reducer, 0.2 parts of polyether type defoamer.

Embodiment 2

[0027] A high-toughness anti-impact and wear-resistant repair material, comprising the following raw materials by mass: 320 parts of P·Ⅱ 52.5 cement, 8.0 parts of silicon powder, 54.3 parts of ground slag, 3.3 parts of nano-graphene, 573 parts of iron ore, 20.4 parts of steel fiber, 4.6 parts of plastic steel fiber, 1.3 parts of basalt fiber, 0.1 part of KH550 silane coupling agent, 1.8 parts of rubber powder (fineness 24 mesh), 0.9 parts of plastic expansion agent, 7.2 parts of UEA expansion agent, magnesium oxide expansion agent 3.0 parts, 1.8 parts of polycarboxylate water reducer, 0.3 parts of silicone defoamer.

Embodiment 3

[0029] A high-toughness anti-impact and wear-resistant repair material, comprising the following raw materials by mass: 335 parts of P.O4 2.5 cement, 7.2 parts of silicon powder, 49.0 parts of finely ground slag, 2.8 parts of nano-graphene, 557 parts of iron ore, 26.5 parts of steel fiber, 5.4 parts of plastic steel fiber, 1.5 parts of basalt fiber, 0.2 part of KH560 silane coupling agent, 2.5 parts of rubber powder (fineness 40 mesh), 0.7 part of plastic expansion agent, 7.0 parts of UEA expansion agent, magnesium oxide expansion agent 3.1 parts, 1.9 parts of polycarboxylate water reducer, 0.2 parts of polyether type defoamer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com