Clutch assembly

A clutch and assembly technology, applied in the direction of clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problem of high manufacturing cost of synchronous rings, and achieve the effects of low cost, reduced installation space, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

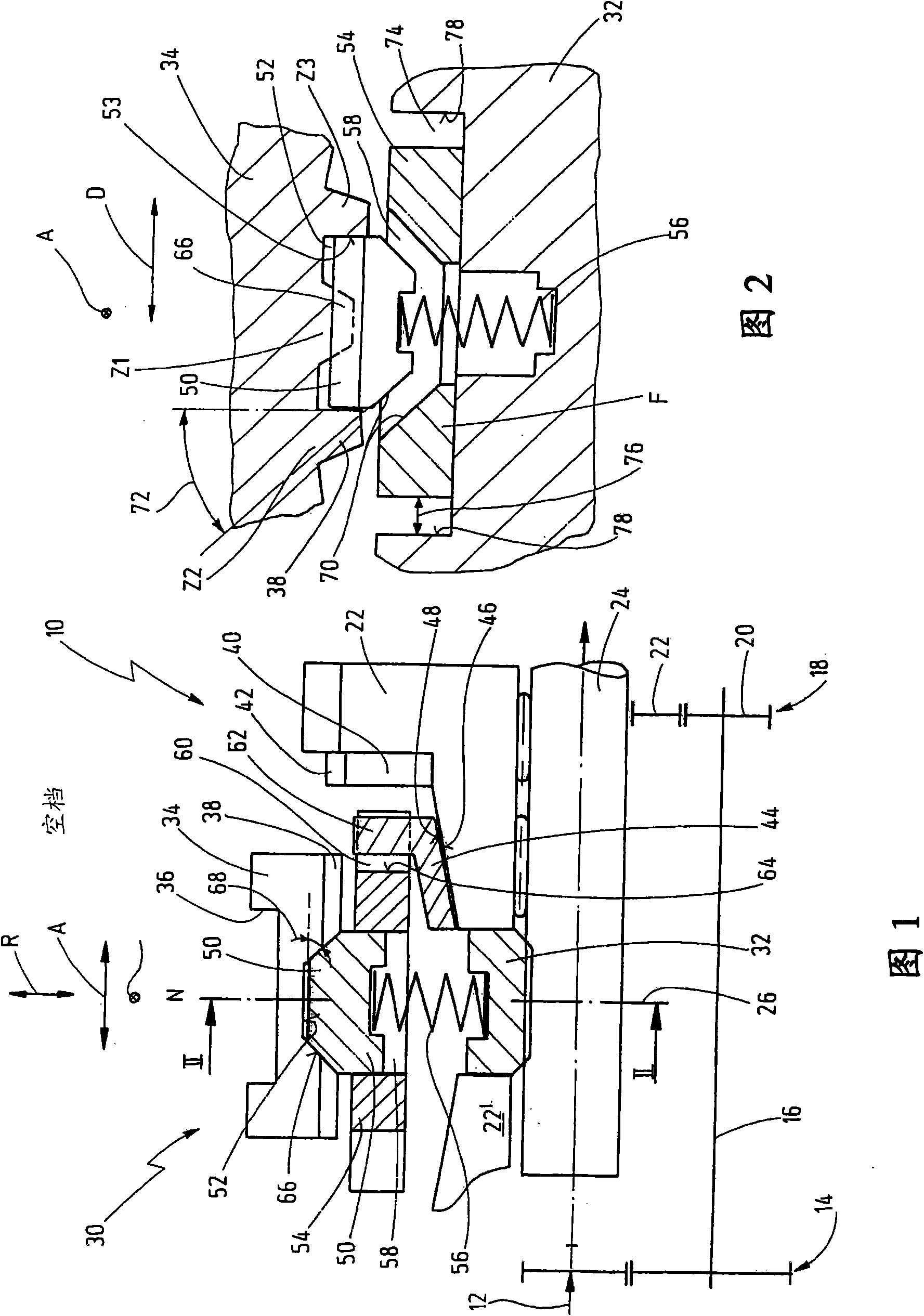

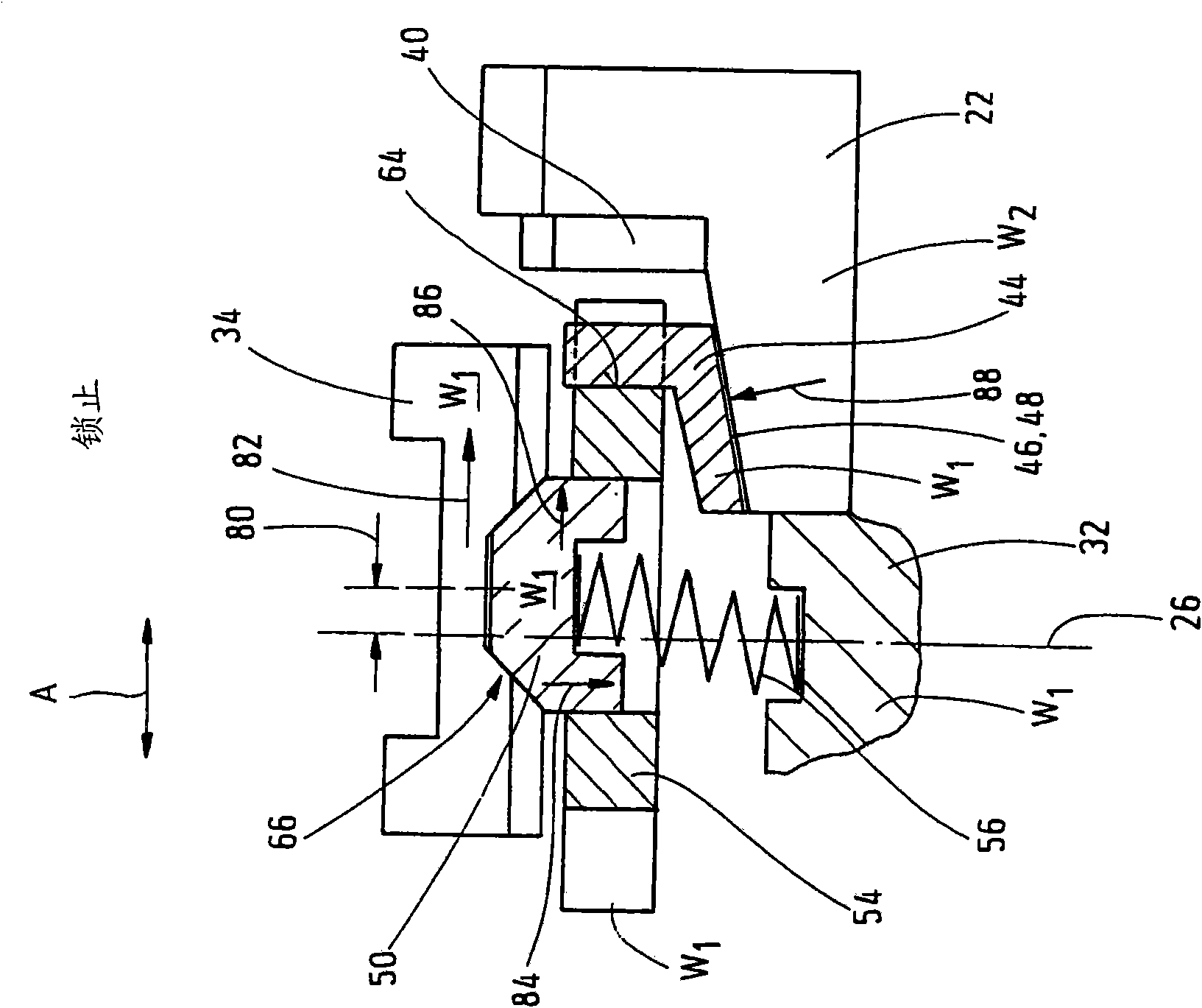

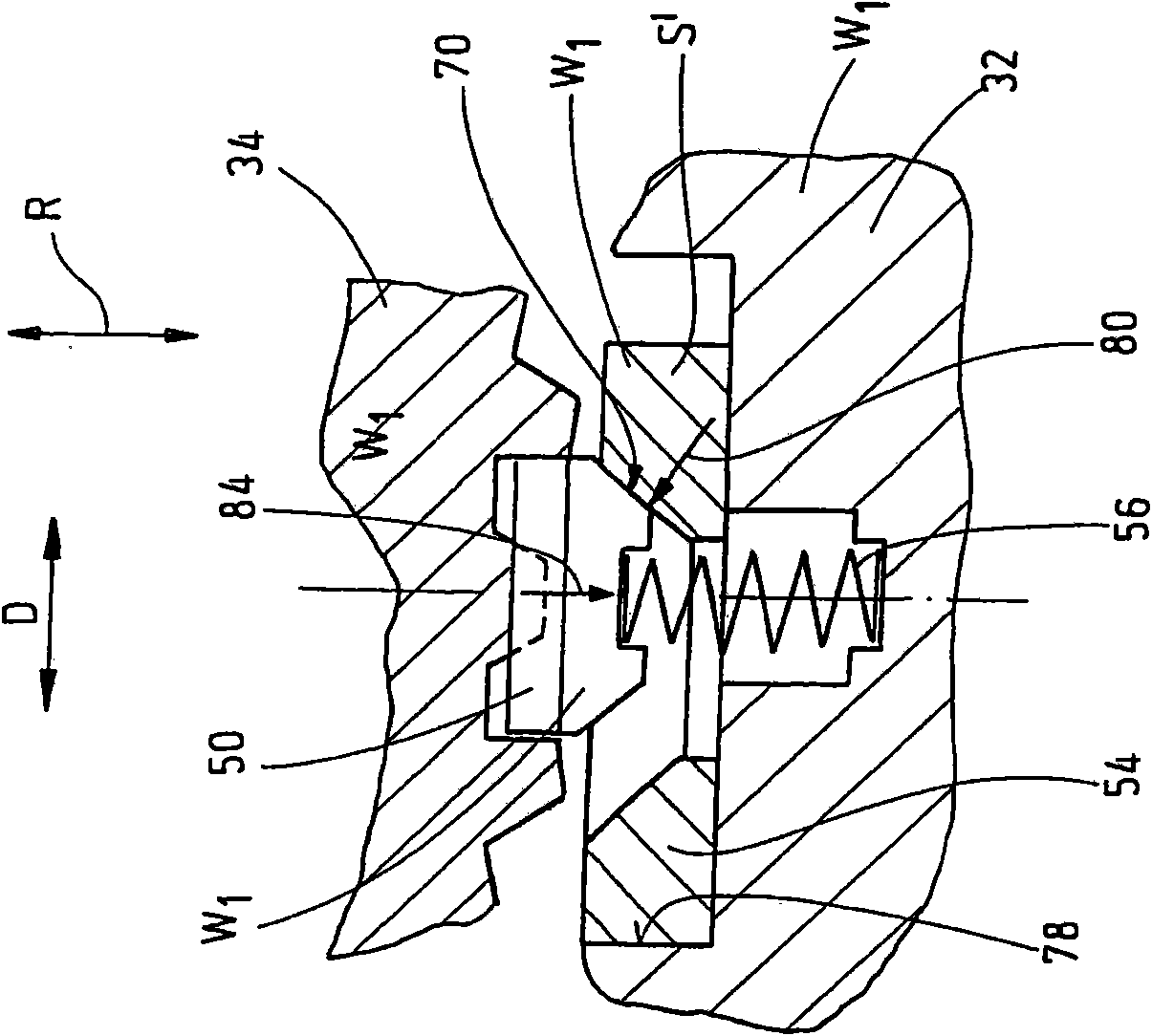

[0092] exist figure 1 and 2 A transmission for a motor vehicle is indicated generally at 10 in .

[0093] The transmission 10 has an input shaft 12 , which is connected via a constant gear set 14 to an intermediate shaft 16 , which is parallel to the input shaft.

[0094] The output shaft 24 is arranged coaxially with the input shaft 12 . A plurality of ratchet sets 18 are disposed on an intermediate or output shaft 24 . exist figure 1 For reasons of clarity, only one ratchet set 18 is shown, which has a fixed gear 20 which is connected to the intermediate shaft 16 . The ratchet set 18 also has an idler gear 22 , which is rotatably mounted on an output shaft 24 .

[0095] exist figure 1 The other idler gear 22' is only schematically shown in FIG.

[0096] Of course, the shown transmission device, which is designed for longitudinal installation in a vehicle, represents only one example. The invention can likewise be applied to transmissions with other layouts (eg for fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com