Adjustable precise boring cutter

An adjustable and precise technology, applied in the direction of boring heads, accessories of tool holders, tools used in lathes, etc., can solve the problems of shortened service life, reduced adjustment accuracy of boring tools, and increased accumulated errors, so as to reduce labor The effect of strength, high production efficiency and stable cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

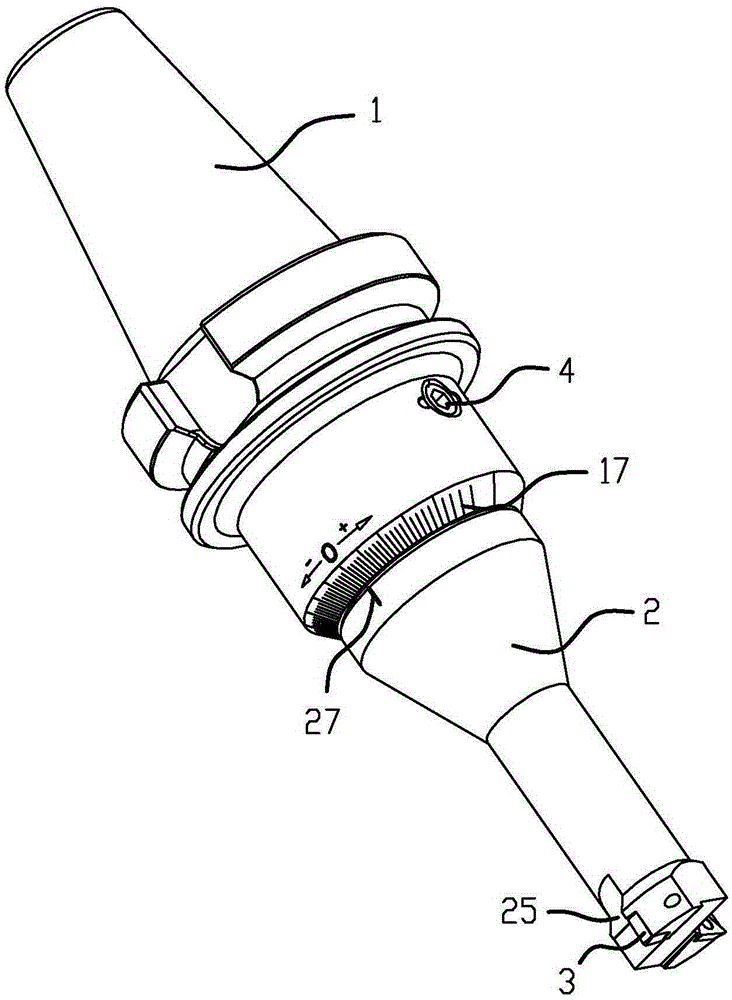

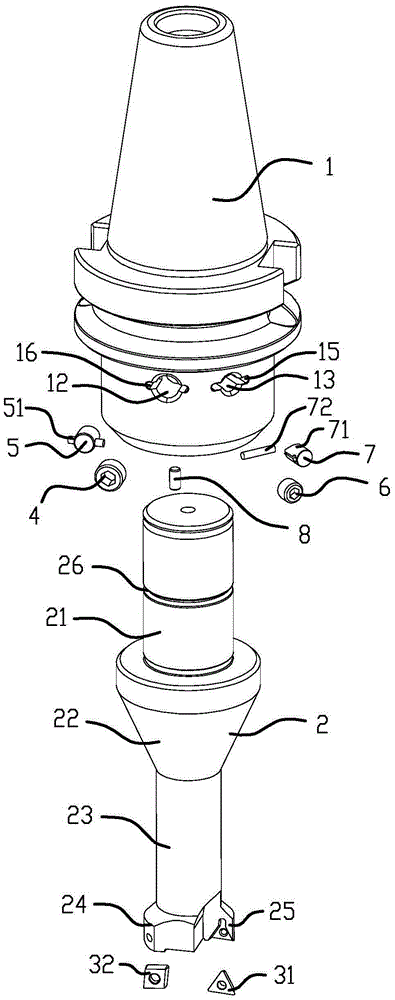

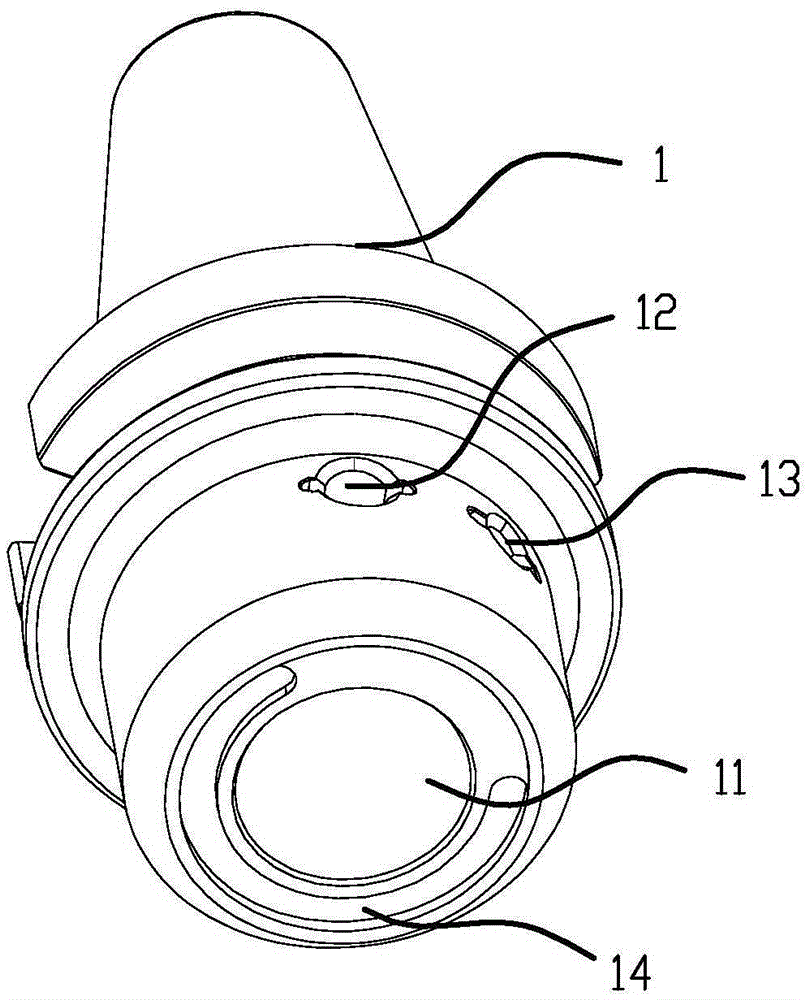

[0029] Such as figure 1 , figure 2 and Figure 5 As shown, the adjustable precision boring tool includes: a tool handle 1, a tool bar 2 and a blade 3, an eccentric hole 11 is provided on the tool handle 1, and the axis of the eccentric hole 11 and the axis of the tool handle 1 are provided with an eccentric distance and The axis of the eccentric hole 11 is parallel to the axis of the shank 1, and a fastening hole 12 vertically connected to the eccentric hole 11 is opened on the shank 1, and a locking bolt 4 is installed in the fastening hole 12; the shank 2 is installed on the eccentric On the hole 11, an installation groove 25 is provided at the end of the knife bar 2; the blade 3 is installed in the installation groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com