Patents

Literature

128results about How to "Will not bend" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

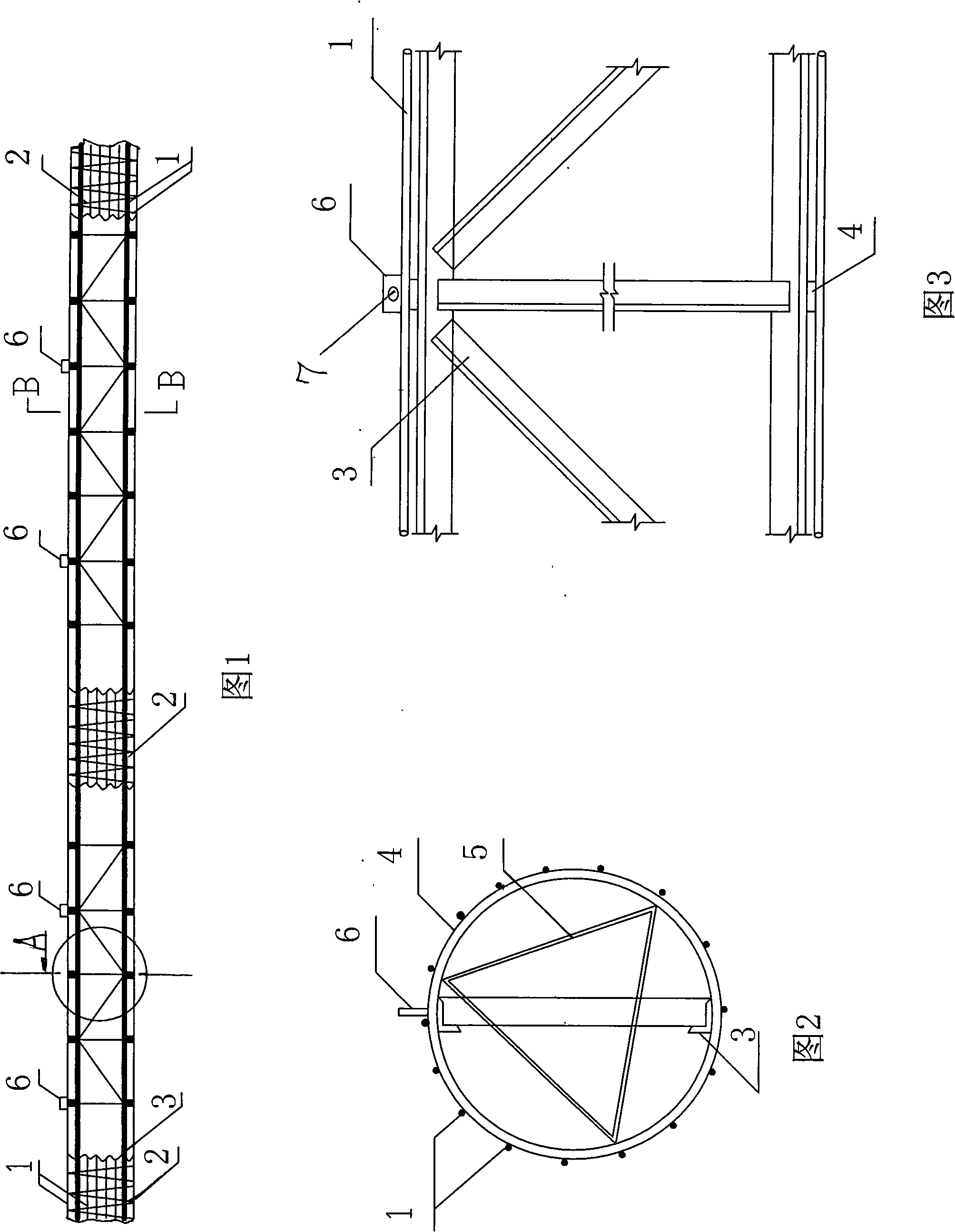

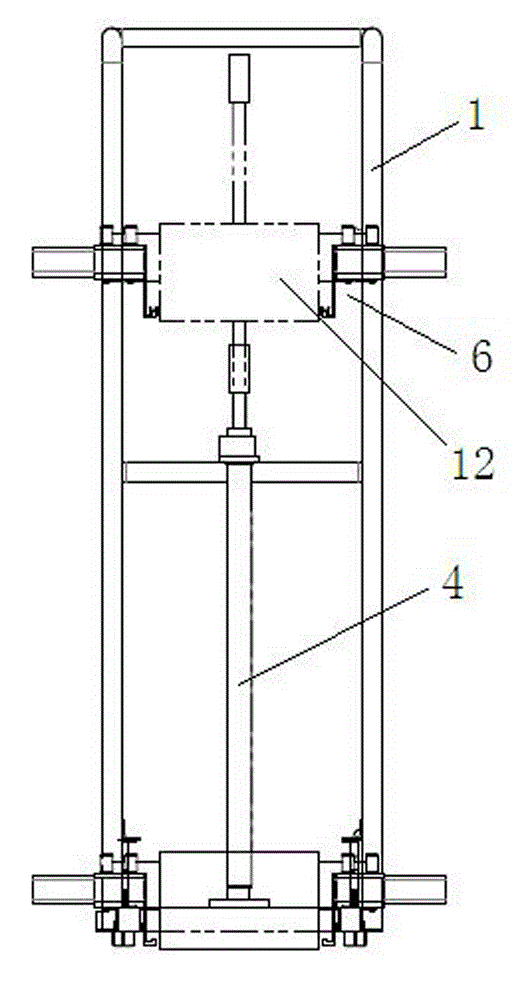

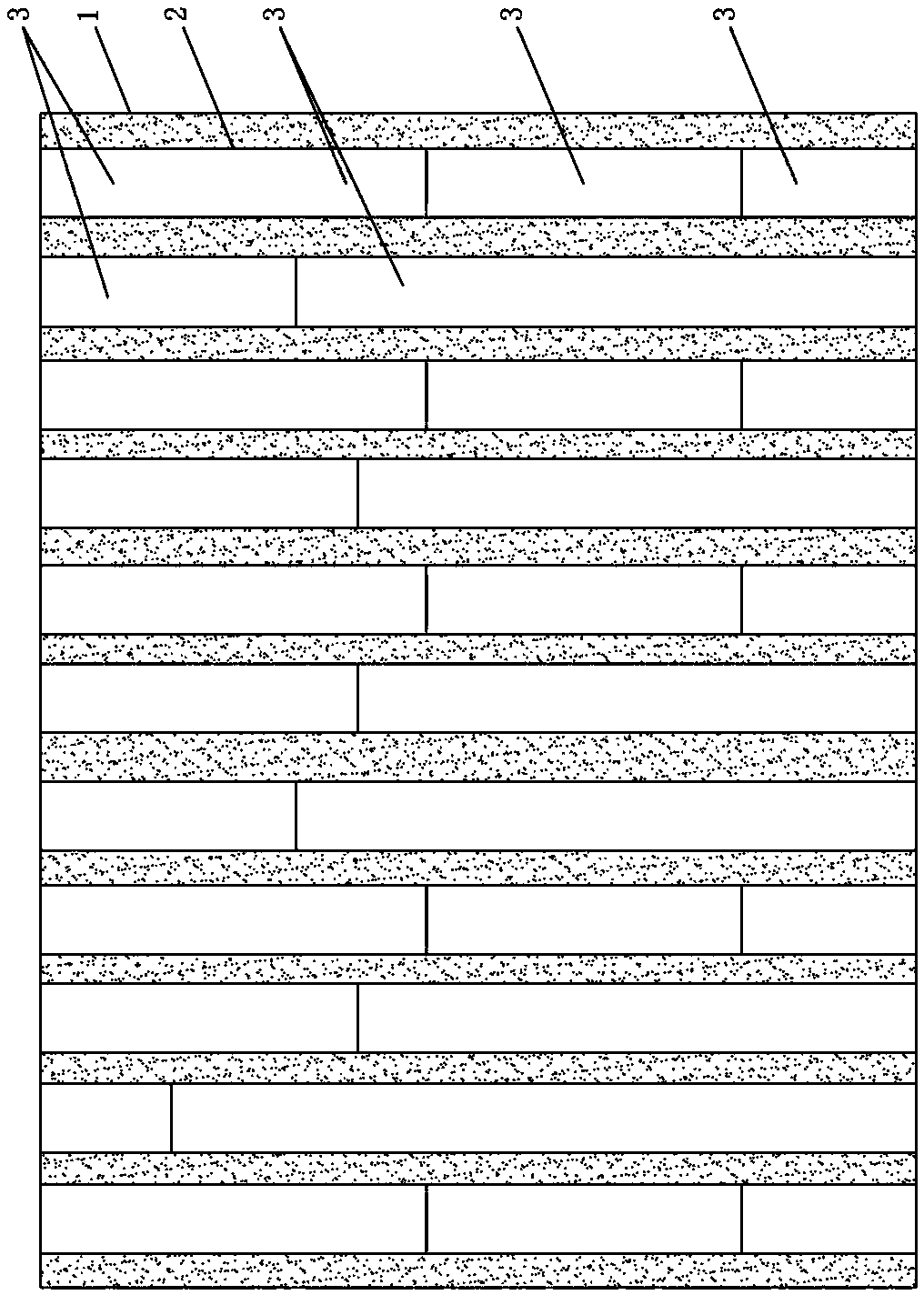

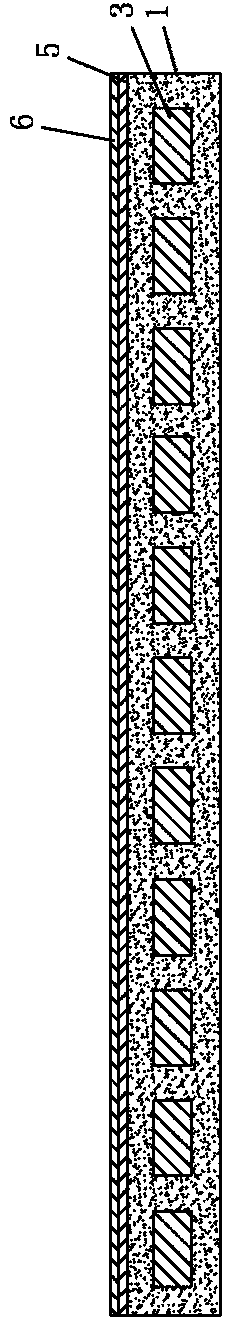

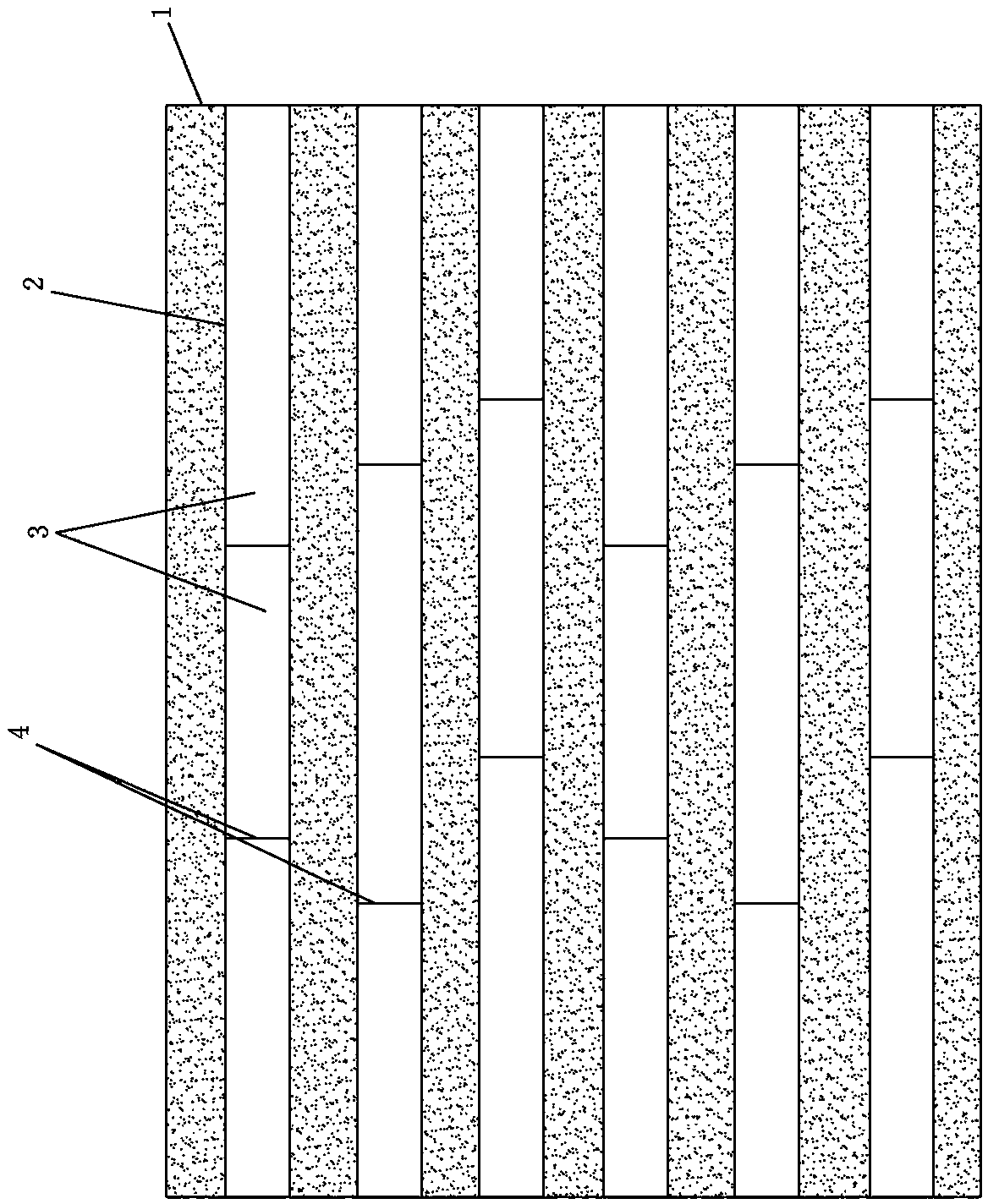

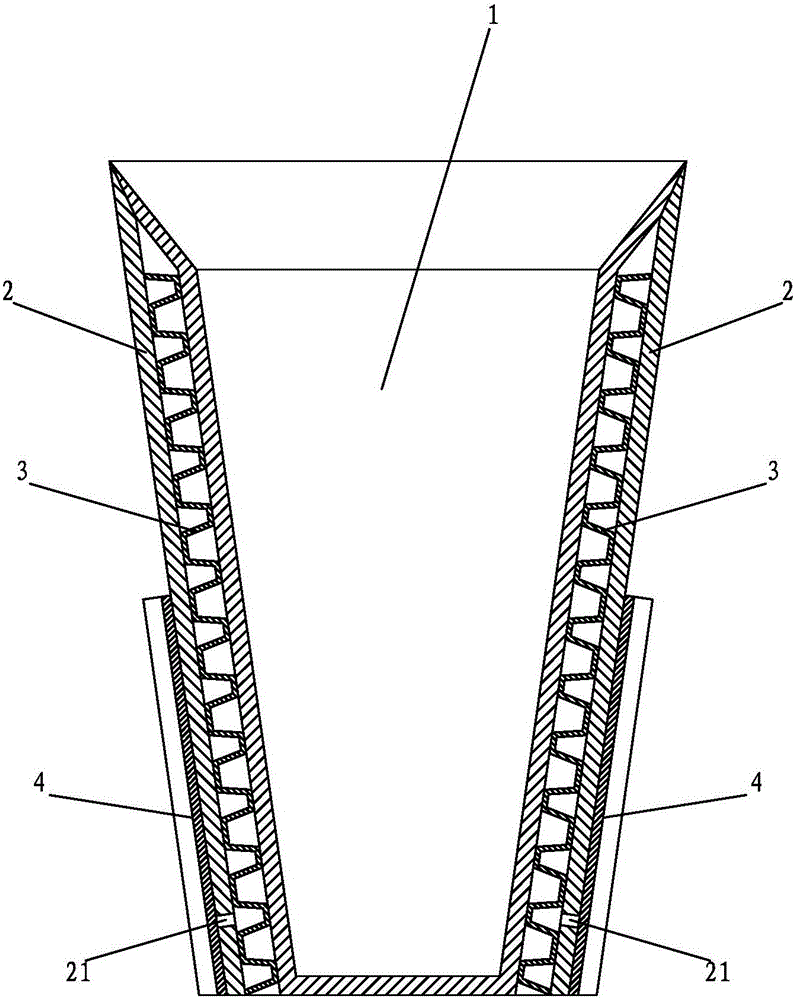

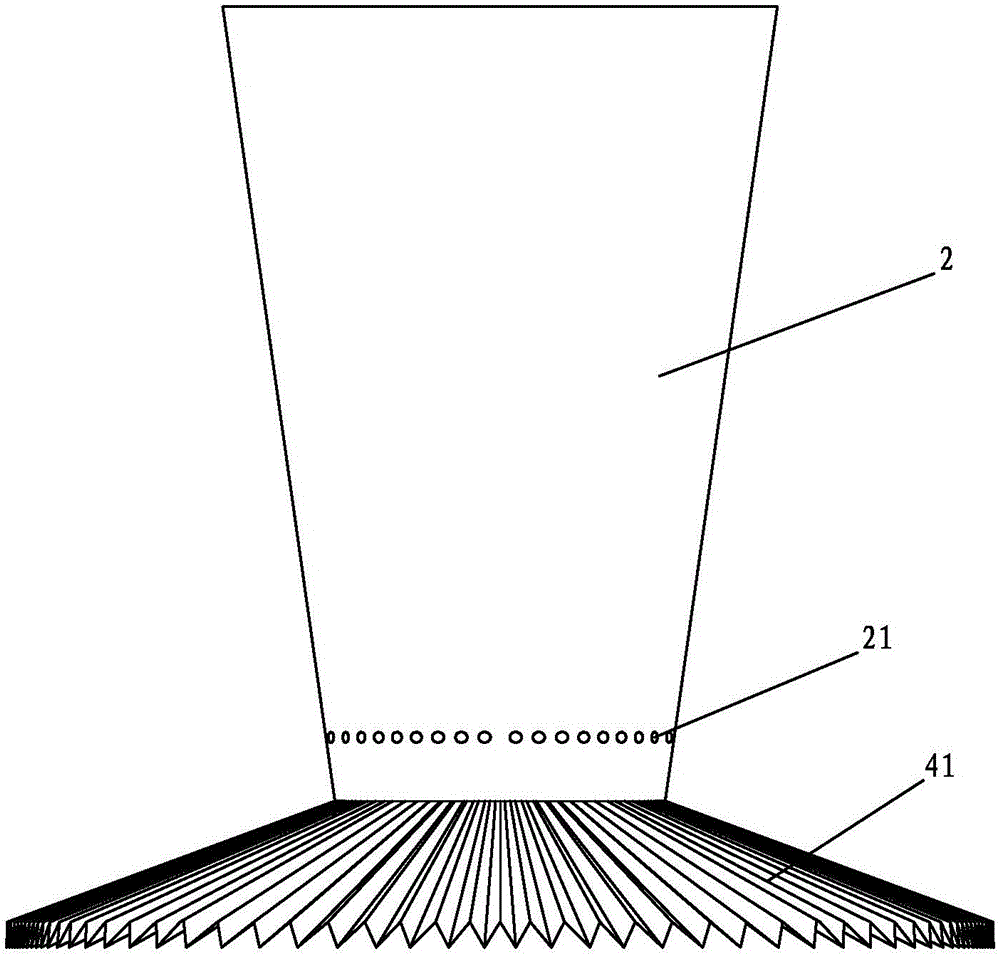

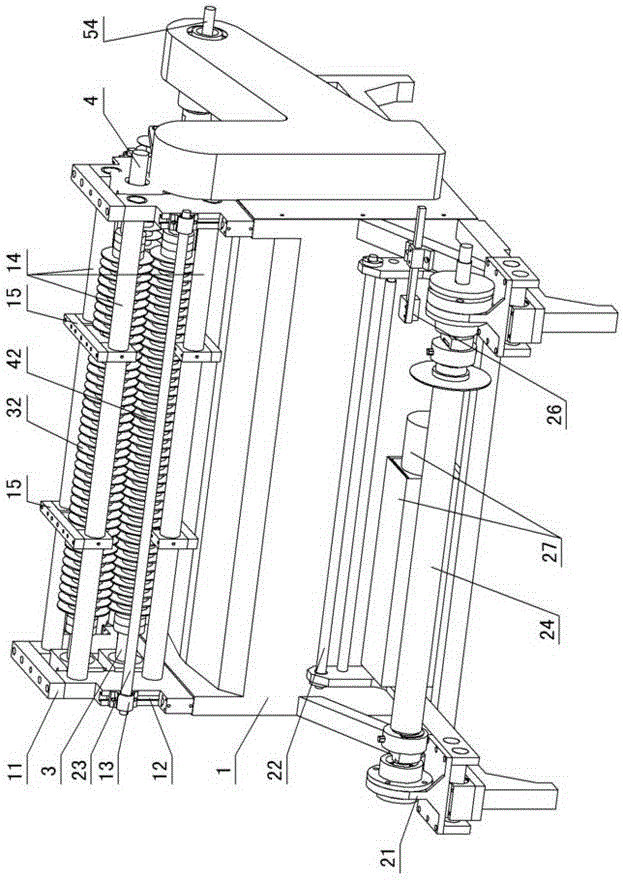

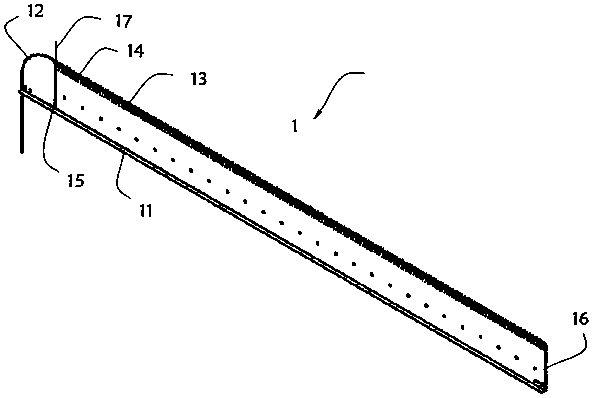

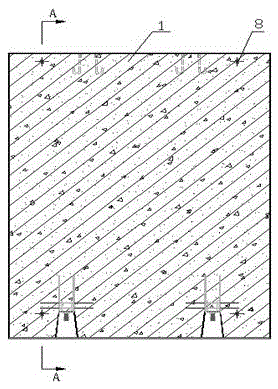

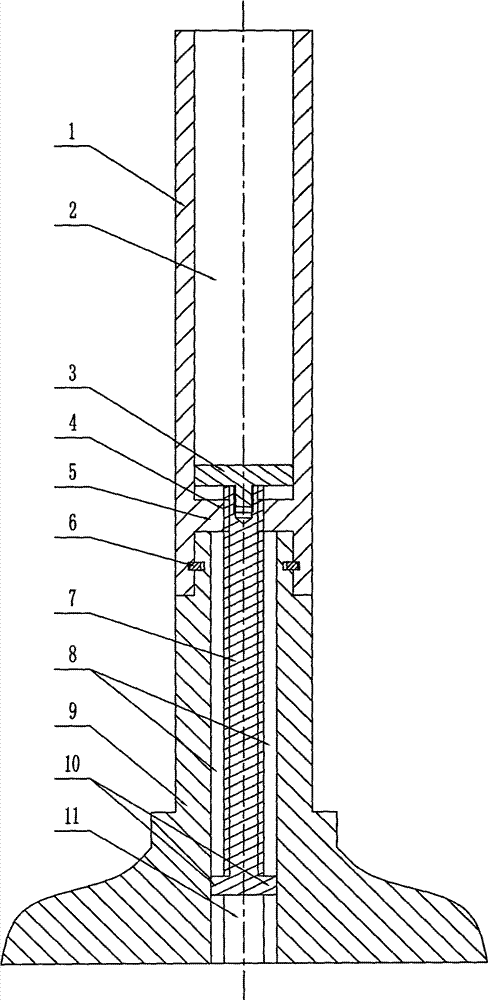

Ultralong overweight concrete filling pile reinforcement type reinforcing steel bar caging

InactiveCN101302760AIncrease stiffnessWill not bendBuilding reinforcementsBulkheads/pilesRebarBuilding construction

The invention relates to a strengthening steel reinforcement cage of an ultra-long and heavy concrete cast-in-place pile. The strengthening steel reinforcement cage of the invention comprises a steel reinforcement cage which consists of a main vertical reinforcement and a spiral construction hoop surrounding the main reinforcement. The strengthening steel reinforcement cage is characterized in that rigid reinforcing devices are vertically distributed in the steel reinforcement cage section by section, and fixed with the steel reinforcement cage as a whole. The steel reinforcement cage of the invention has the advantages that the reinforcing devices are additionally arranged in the steel reinforcement cage of the ultra-long and heavy concrete cast-in-place pile with a large diameter, which can greatly improve the integral rigidity of the steel reinforcement cage and ensure that the steel reinforcement cage does not bend or deform when being lifted, and the solder joint of the steel reinforcement cage does not crack and loose, as well as guarantee that the steel reinforcement cage can be smoothly hoisted and installed in the hole.

Owner:TIANJIN SANJIAN CONSTR ENG

Split type air foot

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

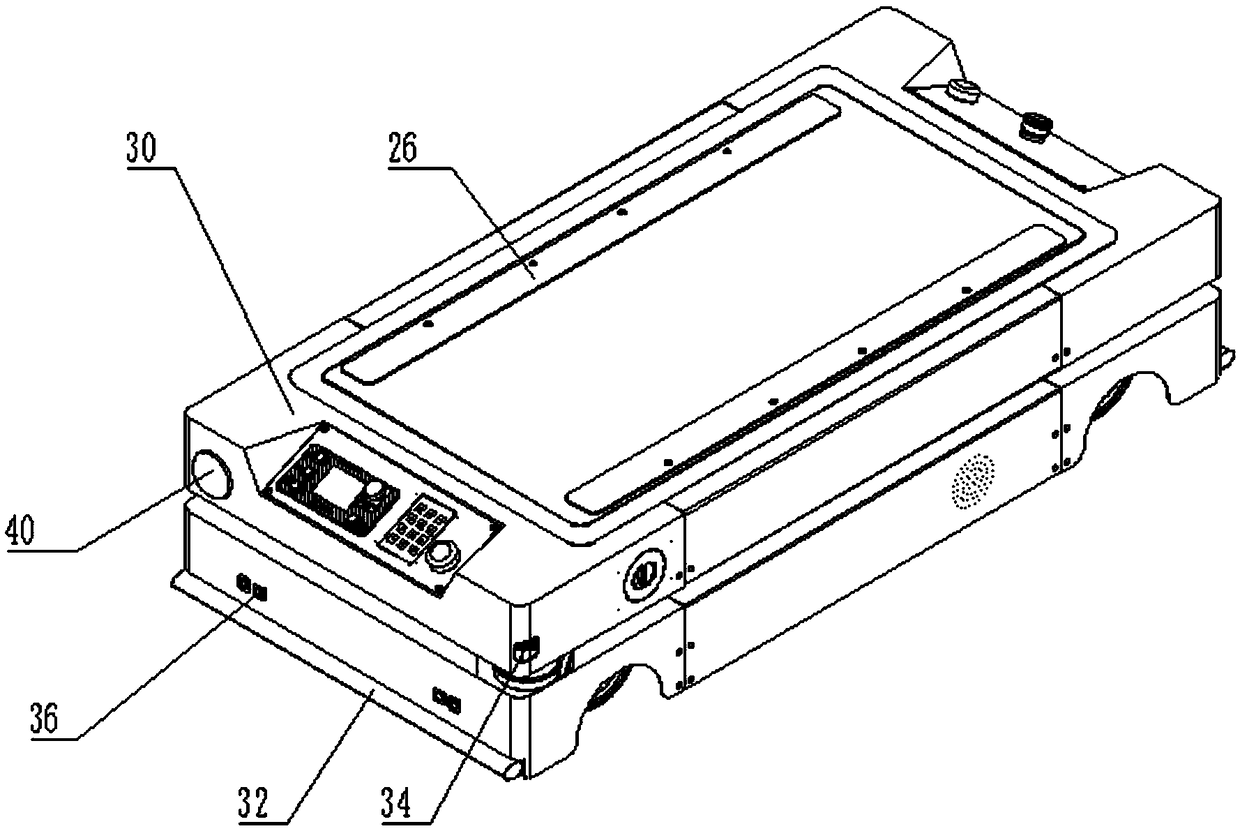

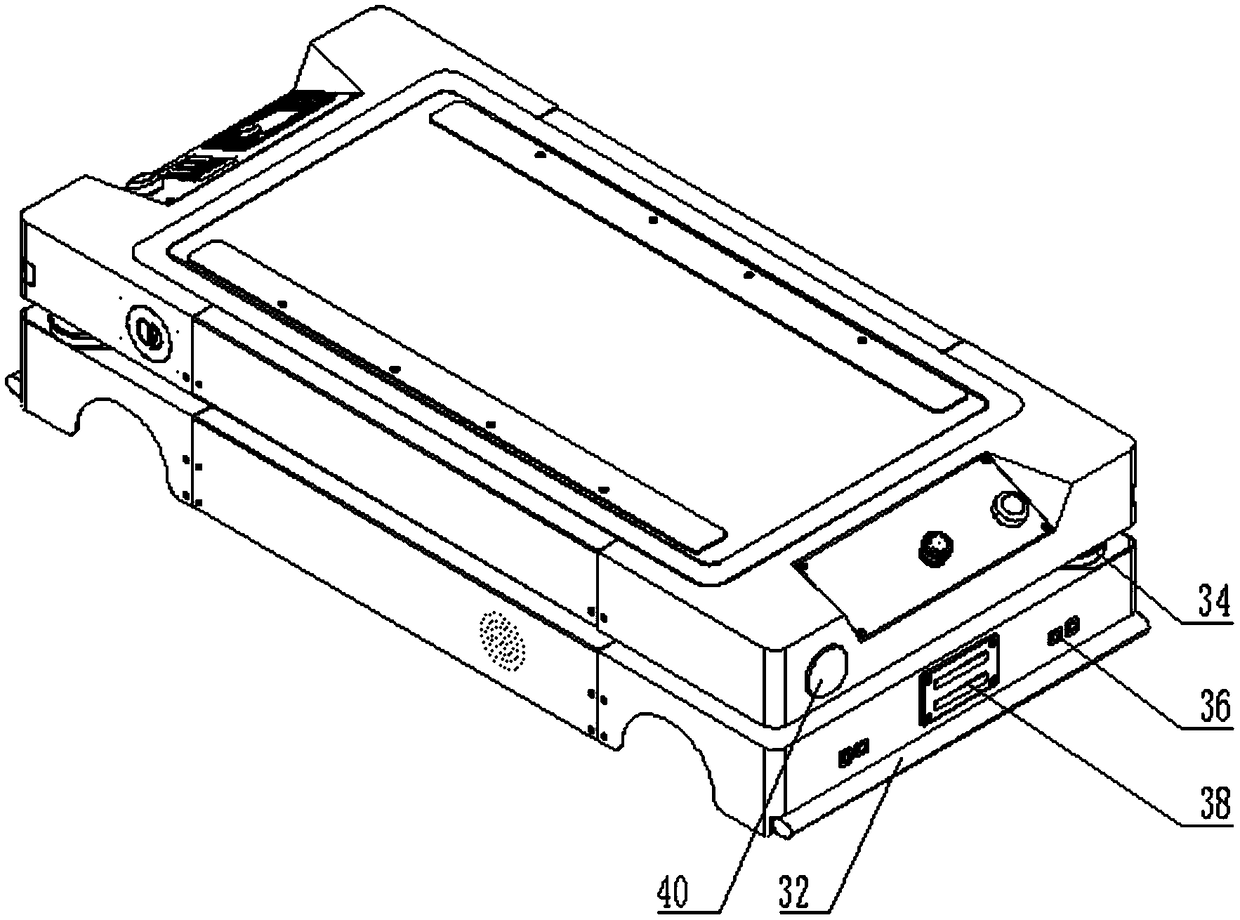

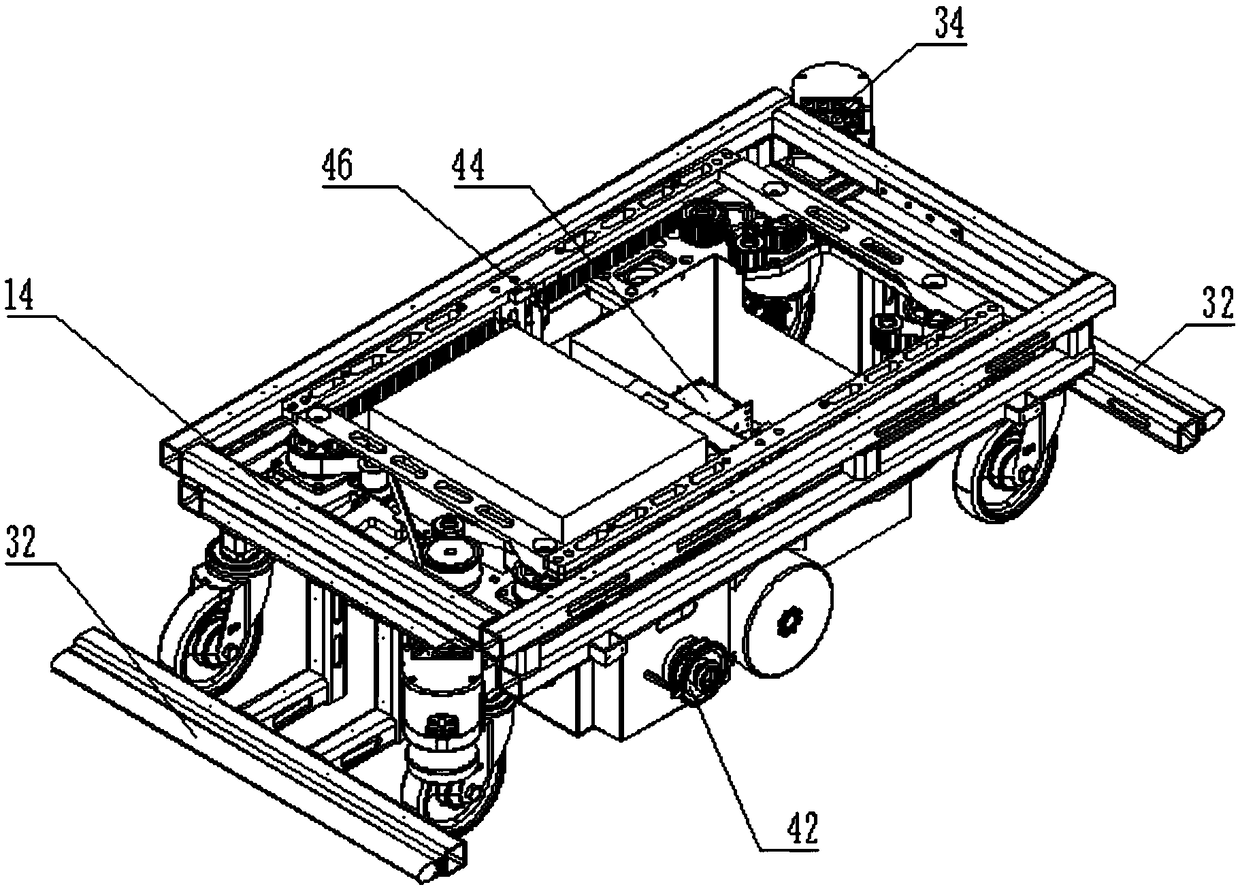

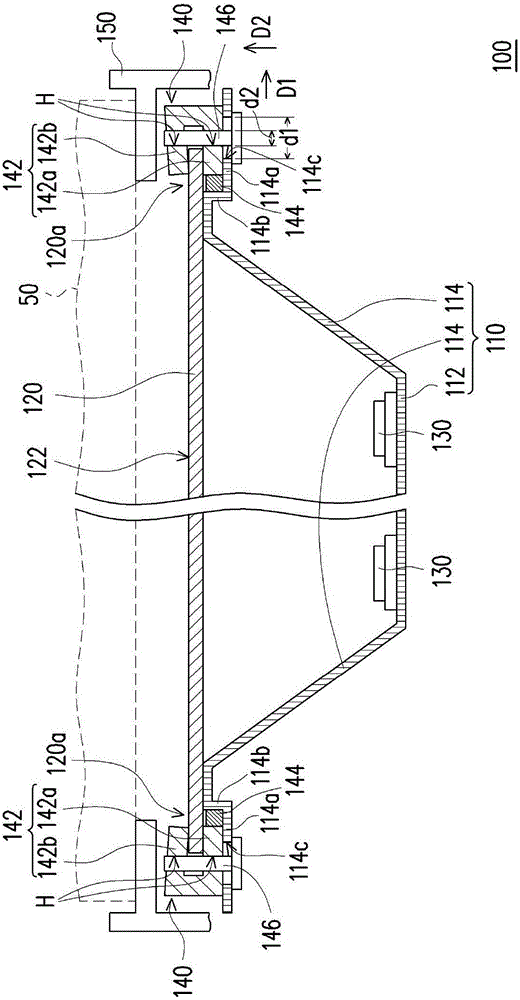

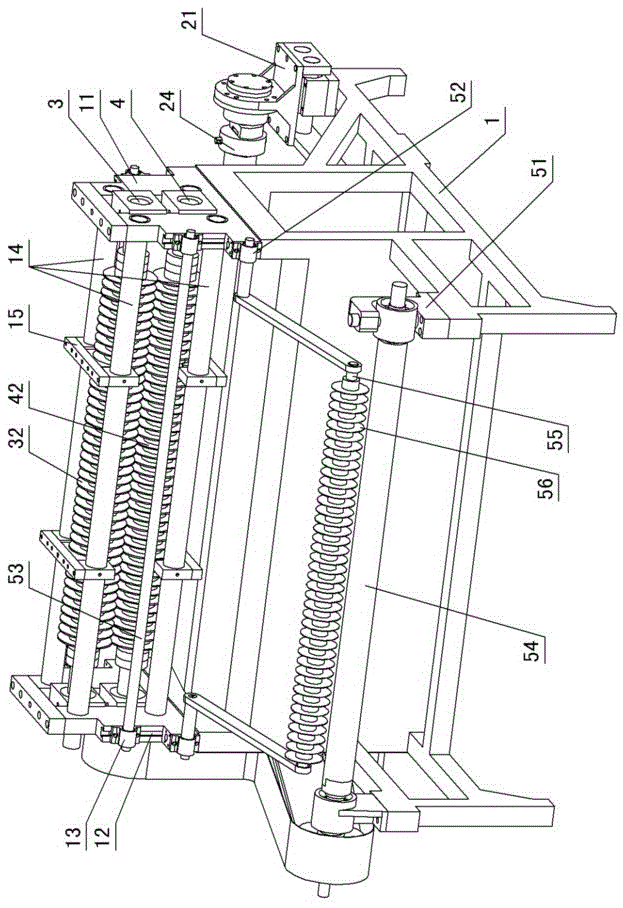

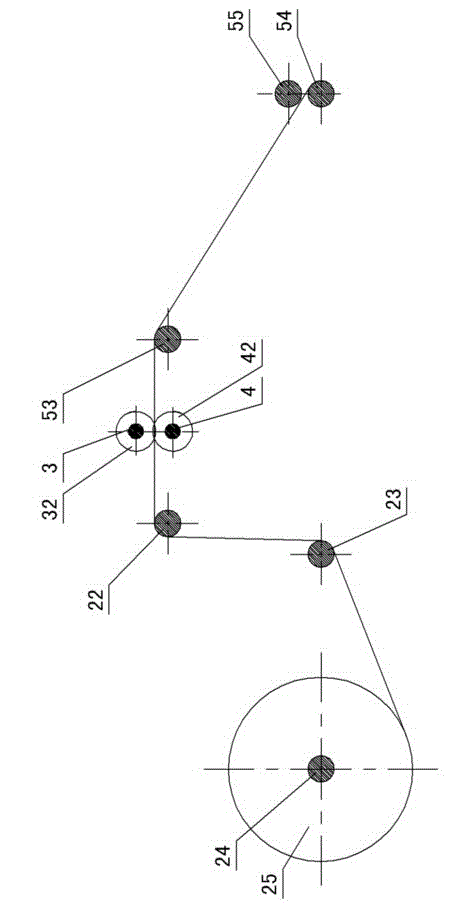

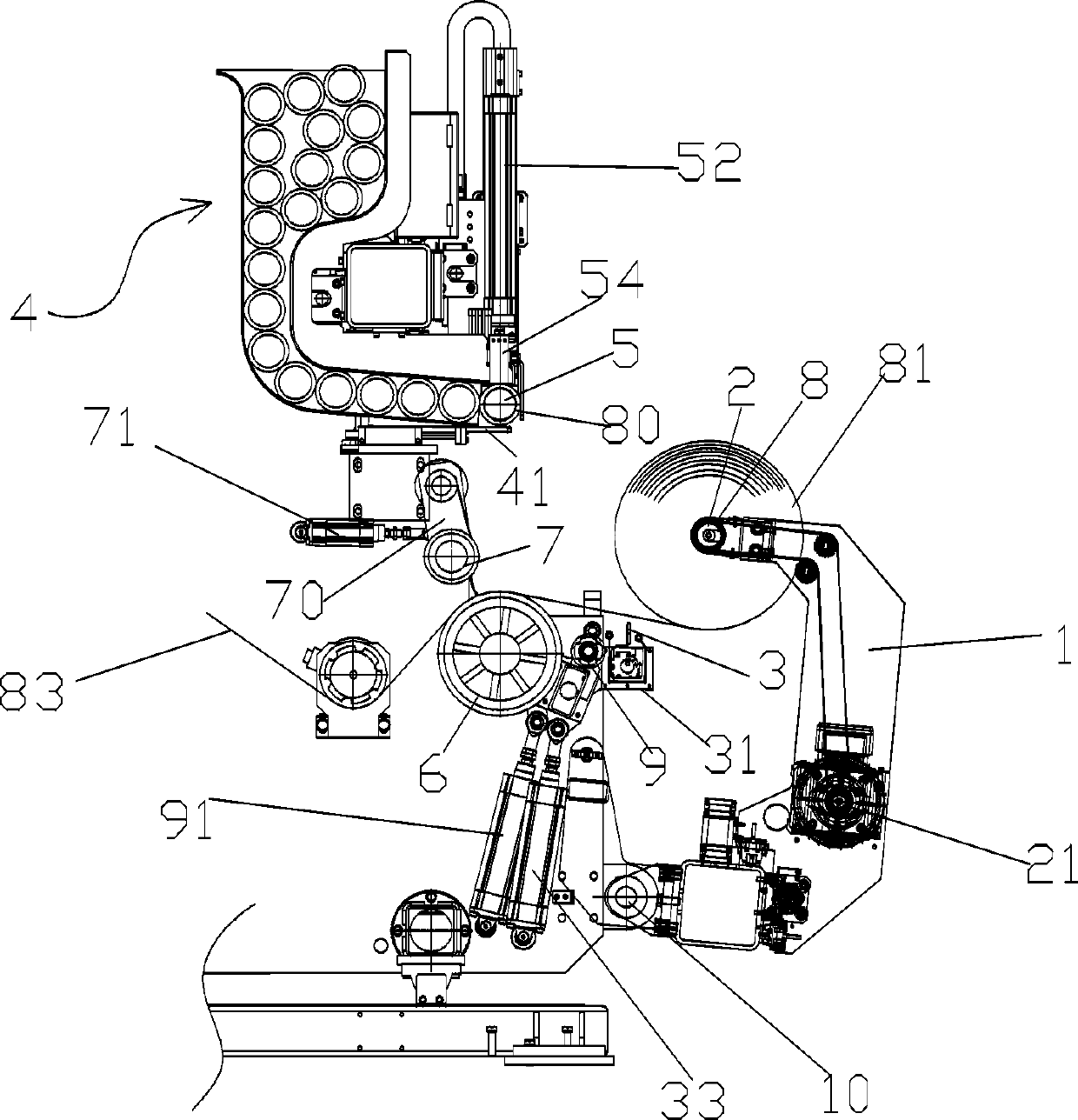

Suspension system and whole backpack-type mobile robot

InactiveCN108839725AEven by forceWill not bendMobile jacksResilient suspensionsDrive wheelVehicle frame

The invention discloses a suspension system and a whole backpack-type mobile robot. The robot includes a vehicle frame, the suspension system arranged at the bottom of the vehicle frame and a jackingmechanism arranged on the vehicle frame; the suspension system includes two suspension mechanisms on the left and right sides, each suspension mechanism includes a supporting girder, a driving wheel,a connector and a first driven wheel, each first driven wheel and the corresponding driving wheel are used for supporting the front and rear ends of the corresponding supporting girder respectively, and each connector is connected to the corresponding supporting girder and positioned between the corresponding driving wheel and the corresponding first driven wheel; the jacking mechanism includes multiple jacking assembles, a first driving system used for driving the jacking assembles and a transmission system used for transmitting a driving force of the first driving system to the jacking assembles; each jacking assembly includes a group of ball screw nut pairs and a mounting base used for installing the ball screw nut pairs, a first fixing base is arranged at the lower end of each first mounting base, and each first mounting base is arranged on a substrate board. Force is uniformly performed on the whole backpack-type robot, and the robot can achieve jacking with a large load.

Owner:SUZHOU YUANMOU INTELLIGENT ROBOT SYST CO LTD

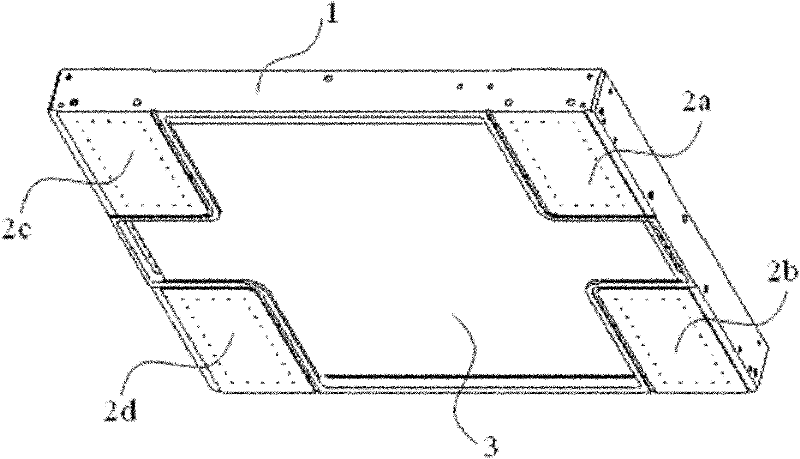

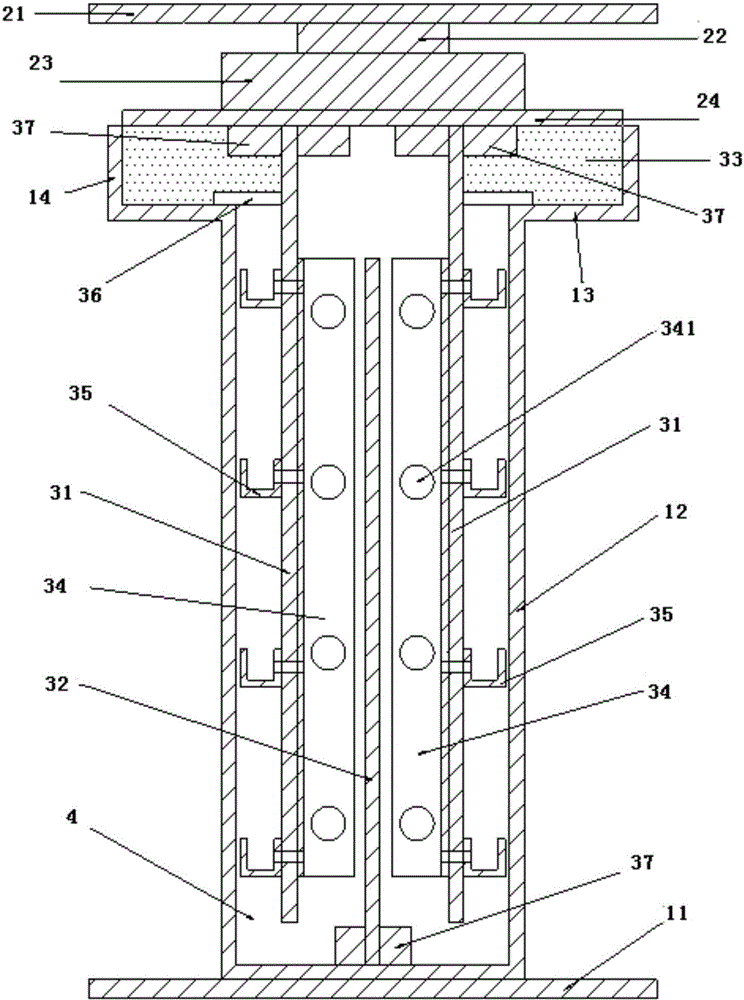

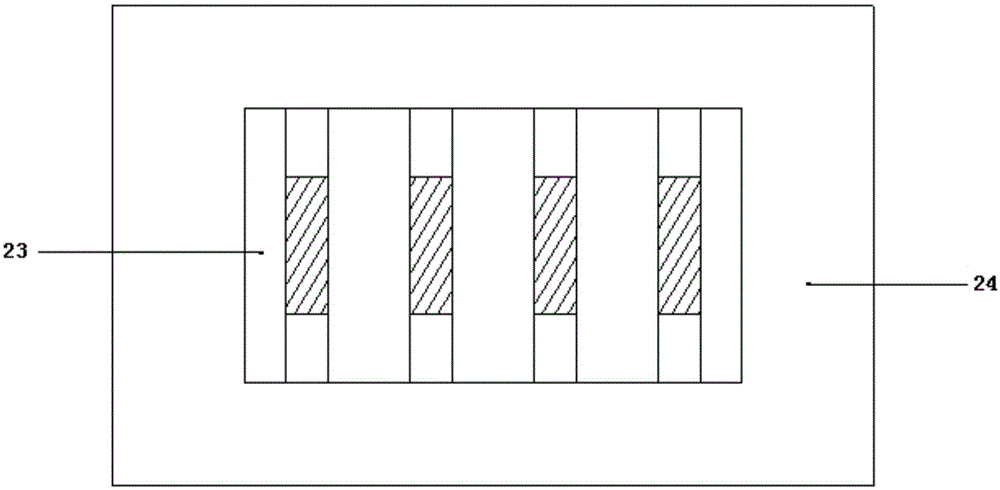

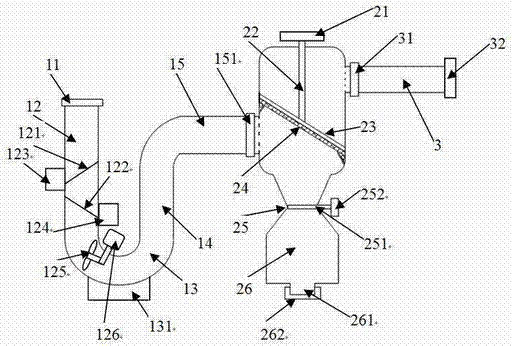

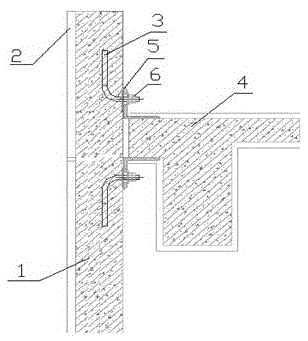

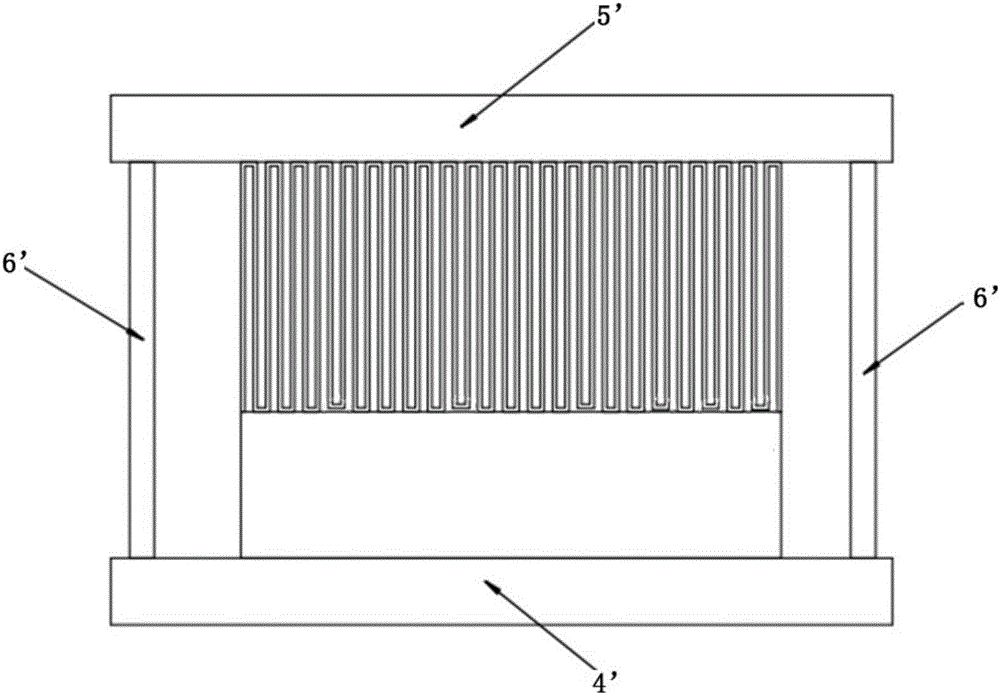

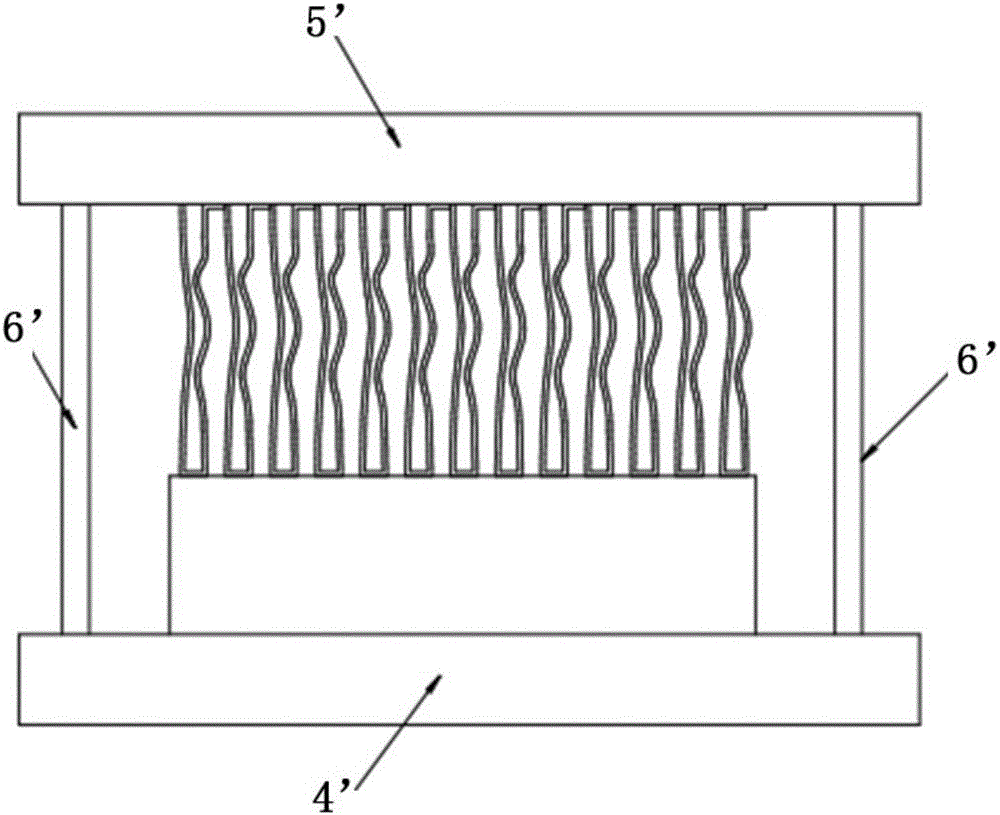

Three-plate type high-energy-consumption viscous damping wall

ActiveCN104405057AImprove energy consumptionIncrease shear areaWallsShock proofingViscous dampingRelative displacement

The invention relates to a three-plate type high-energy-consumption viscous damping wall which is arranged between upper and lower floor surface beams and is used for vibration absorption and energy dissipation of a building structure. The three-plate type high-energy-consumption viscous damping wall comprises a wall body and a top sealing piece; the upper floor surface beam, the top sealing piece, the wall body and the lower floor surface beam are connected in sequence; a wall body sealing space is formed by connecting the wall body with the top sealing piece; an energy consumption damping structure is arranged in the wall body sealing space and the wall body sealing space is filled with viscous damping liquid; when a building floor has relative displacement, the energy consumption damping structure can slide in a viscous damping material of the wall body along the vertical direction of the wall body to generate a damping force, so that the energy of earthquakes or a wind load input structure is dissipated and a power reaction of the structure is reduced. Compared with the prior art, the three-plate type high-energy-consumption viscous damping wall has the advantages of strong energy consumption capability, stable performance, deformation resistance, stable output force, damage resistance and the like.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

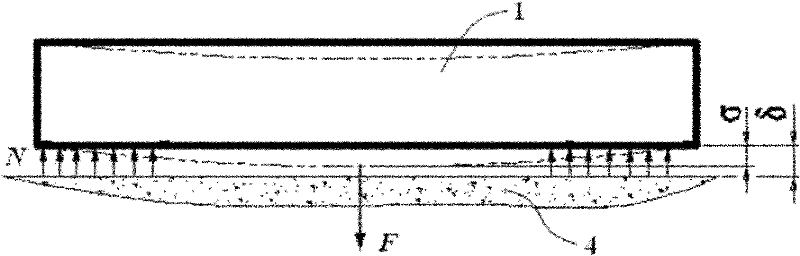

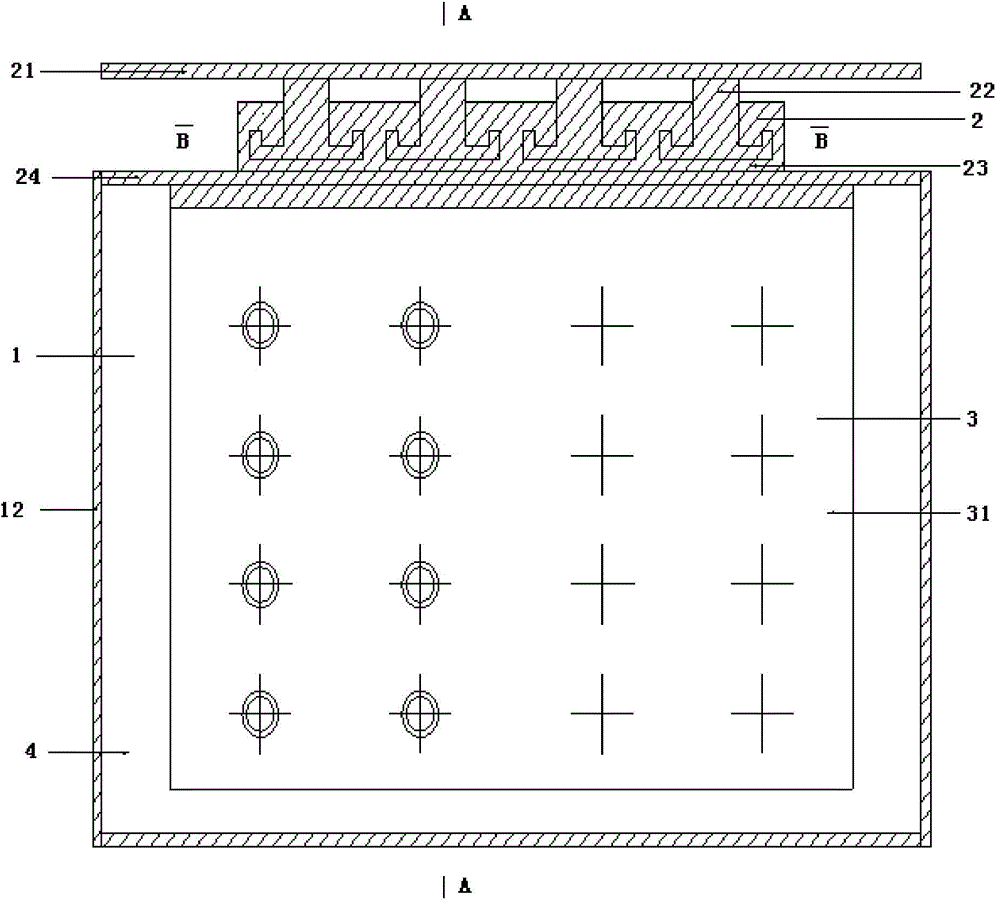

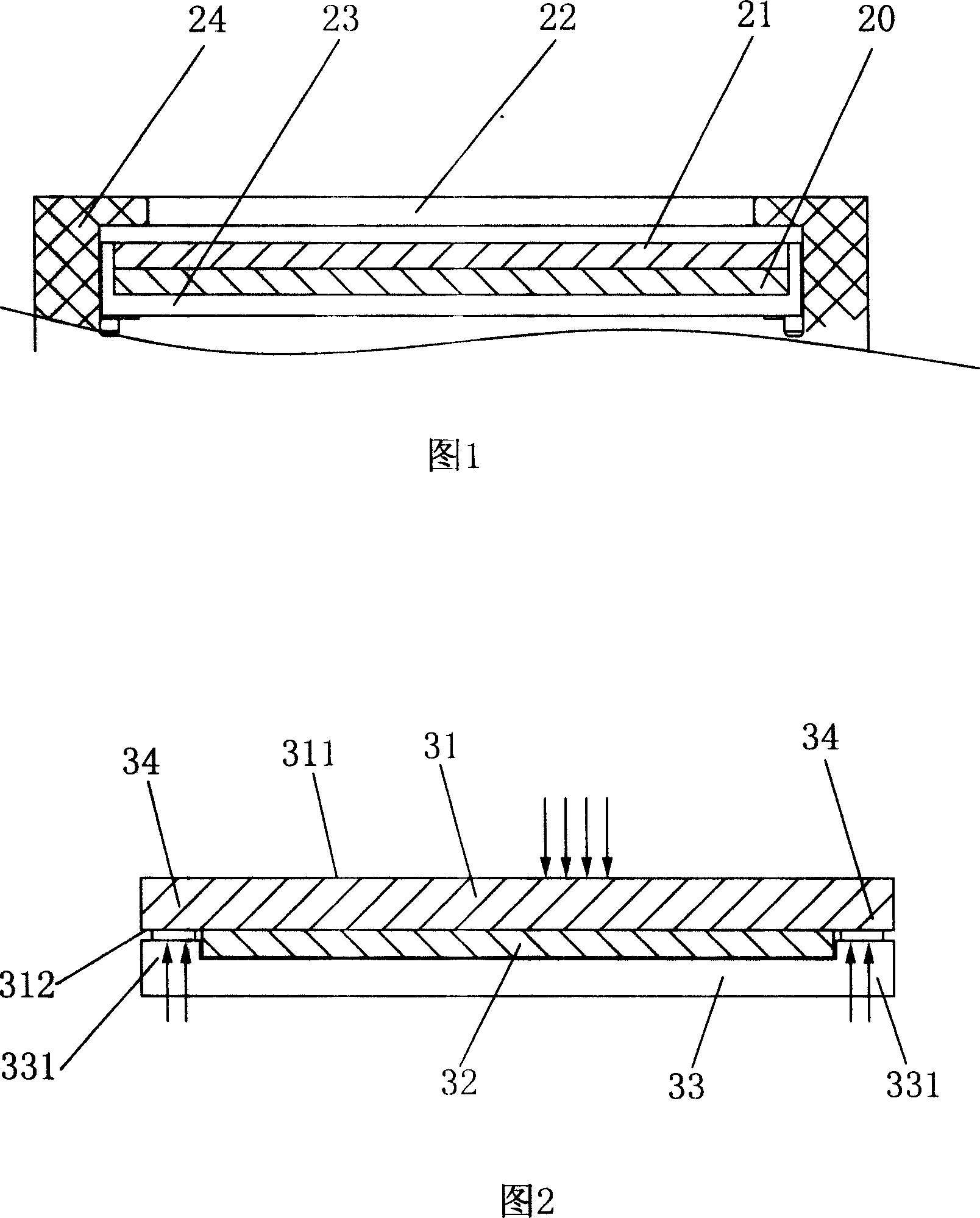

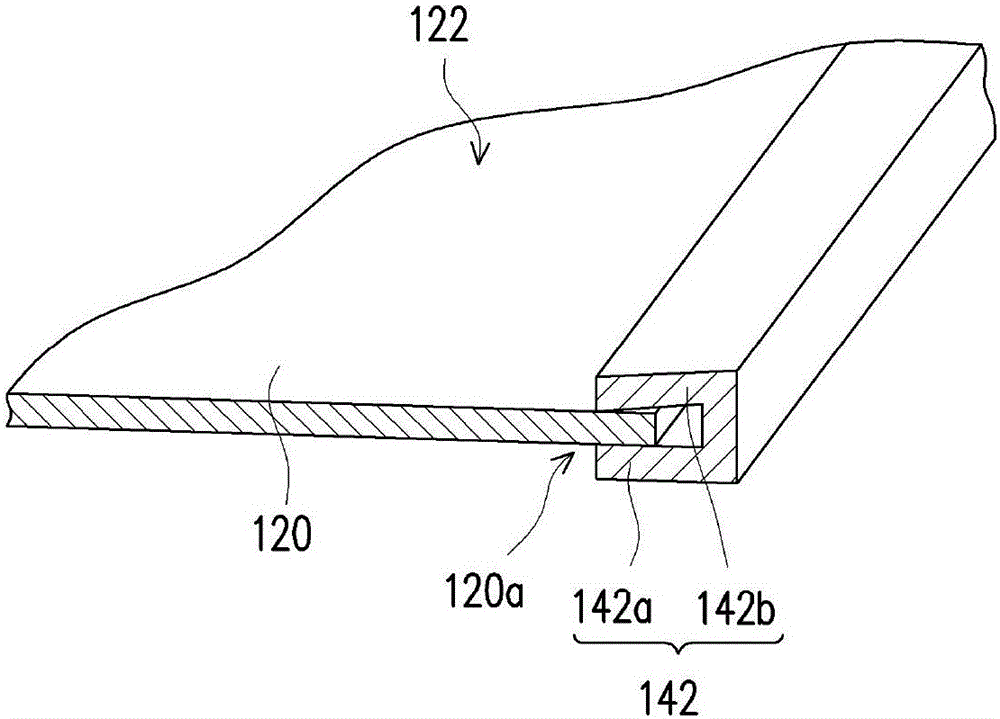

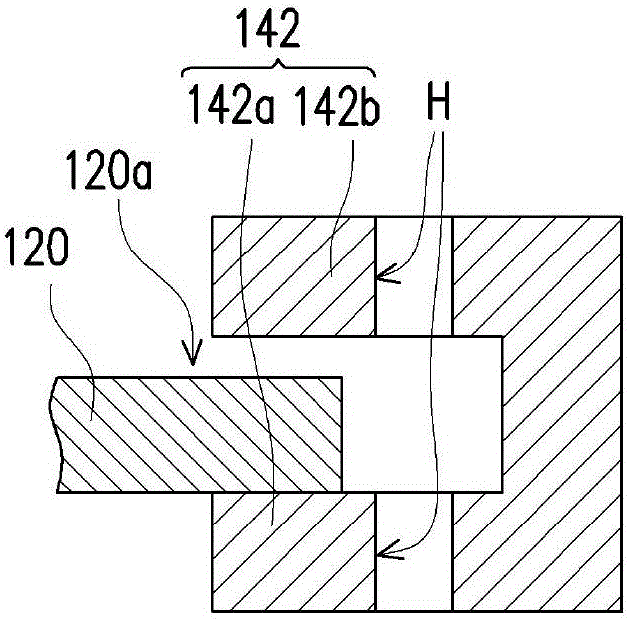

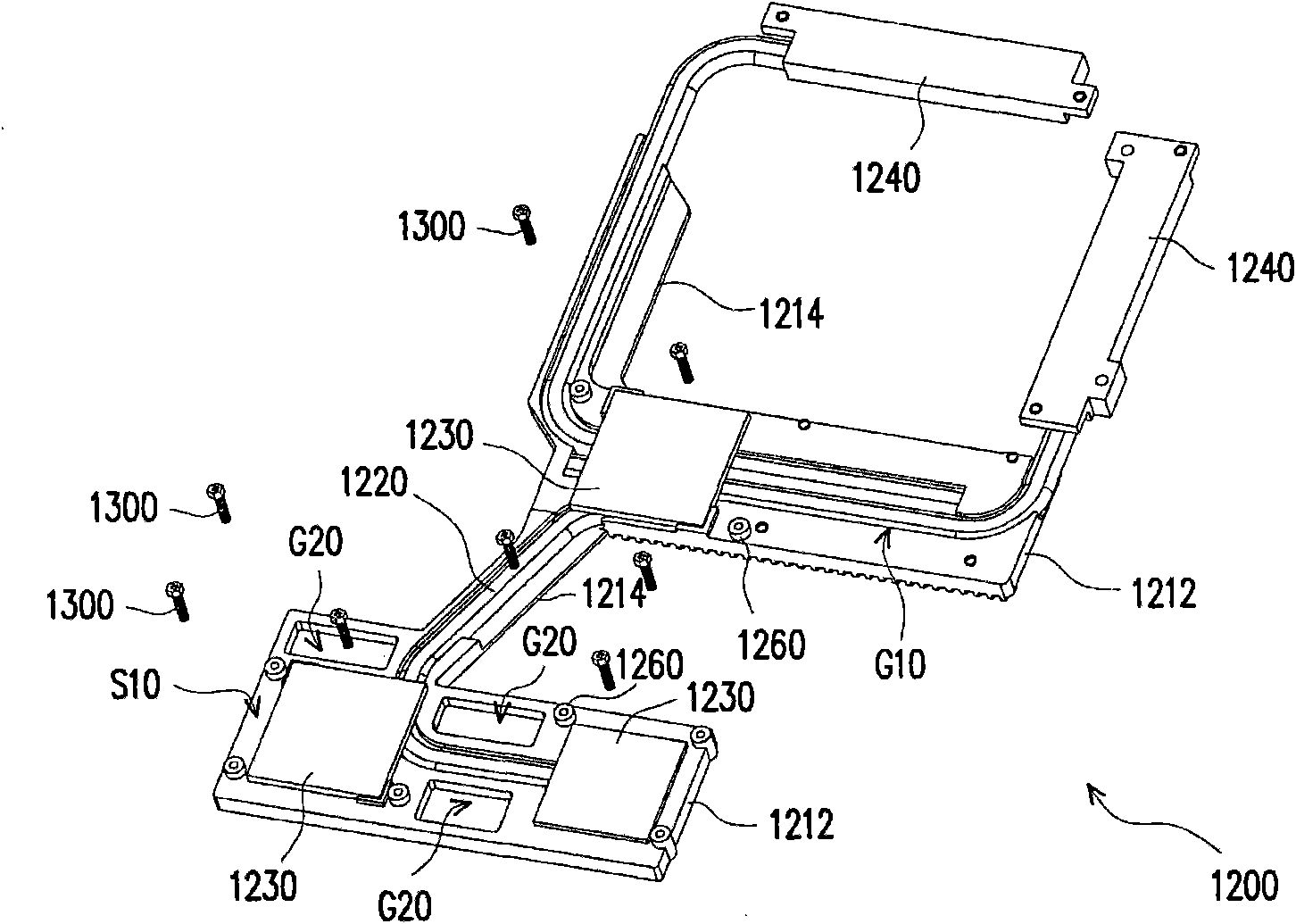

Liquid crystal box and liquid crystal display module group with liquid crystal box

The invention discloses a liquid display module which includes liquid box and negative module, the liquid box includes the first glass base board, the second glass base board and framework glue set between the first and second glass base board, in direction of width, two ends of the first glass base board extend the second glass base board, the glue framework of the negative module possesses supporting part for extending part of the first glass base board, the lower surface of the extended part of the first glass base board is pressed to the supporting part. The liquid box and negative module are packaged together and mounted on shell of electric equipment, when the first glass base board is forced, the force is supported by glue framework of negative module, force supported by the framework can be decreased greatly, and affect of liquid layer thickness can be decreased, at the same time because current protection glass is not needed, so weight and thickness of electric equipment is easy to be reduced.

Owner:深圳市合力泰光电有限公司

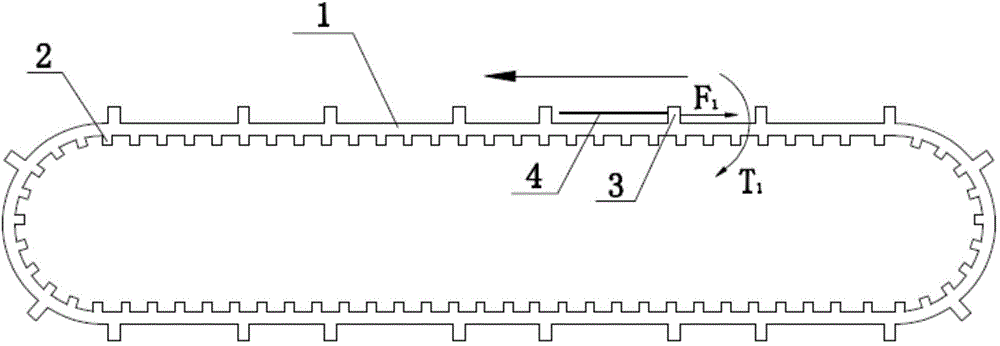

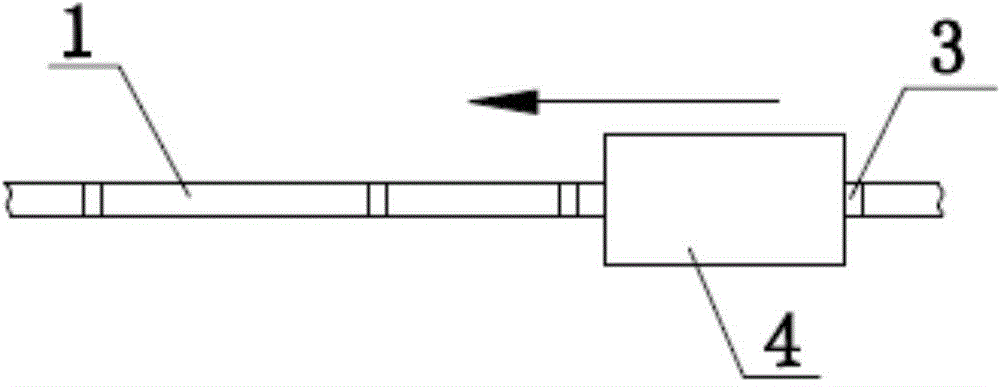

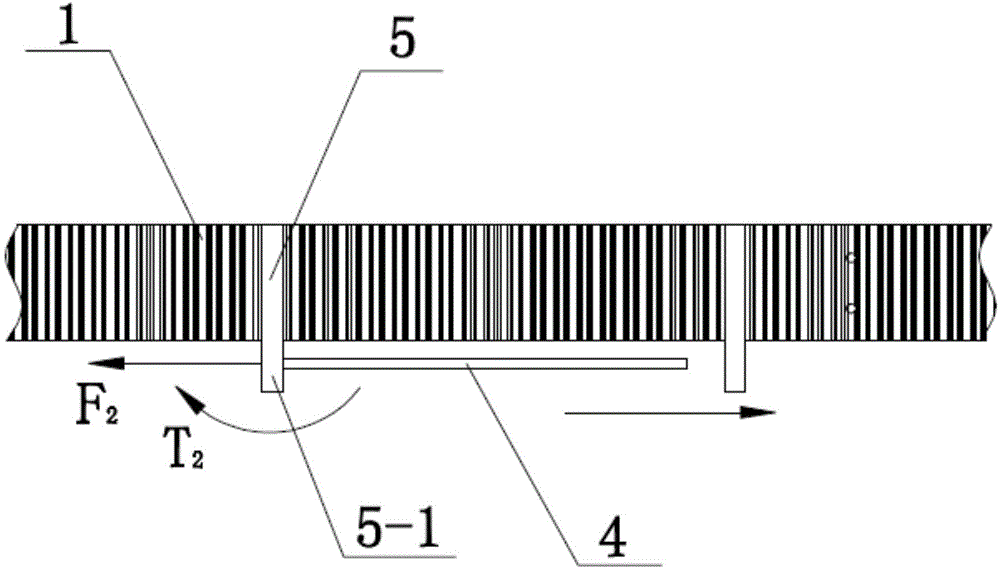

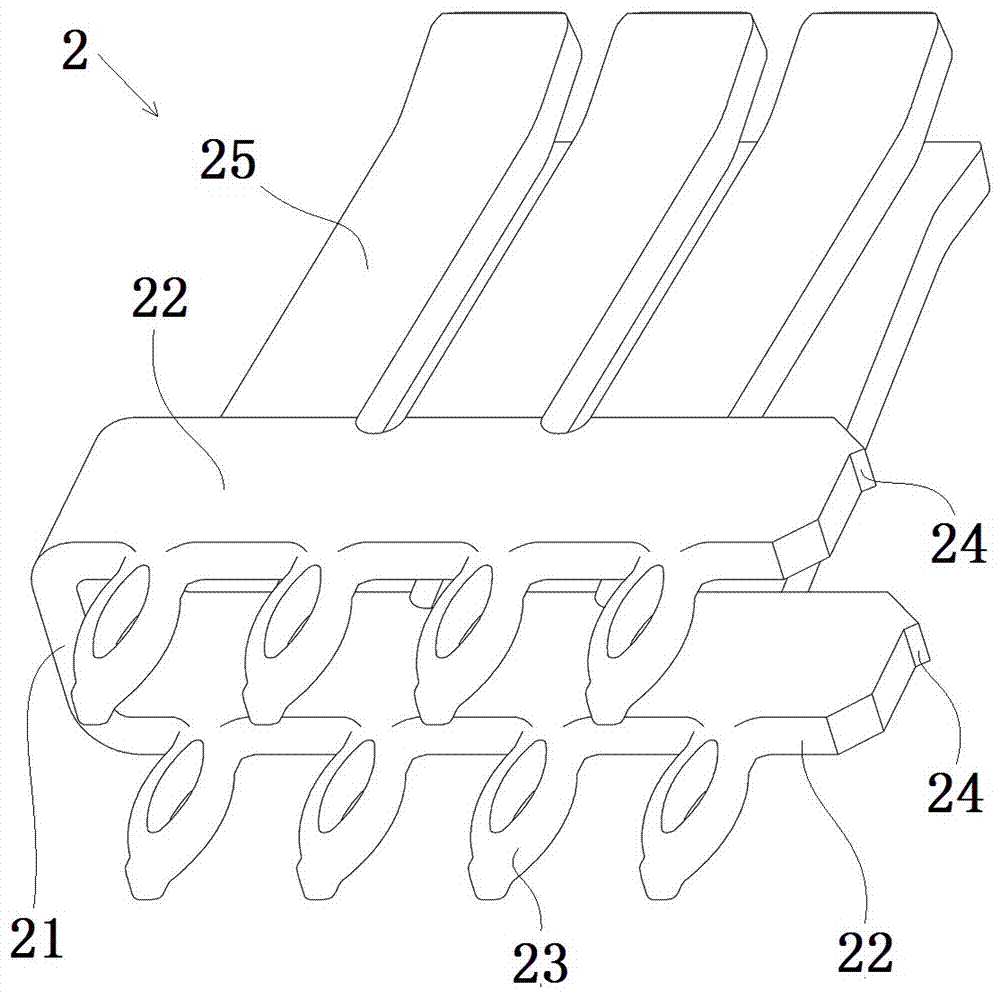

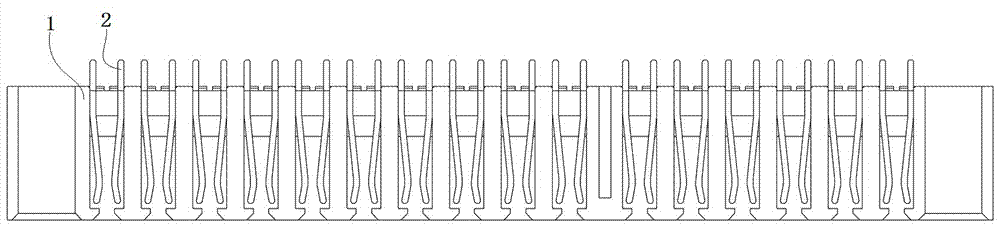

Smart card conveyer belt and smart card conveying mechanism

The invention discloses a smart card conveyer belt and a smart card conveying mechanism. The smart card conveyer belt comprises a conveyer belt body, the conveyer belt body is provided with a plurality of rigid shifting teeth, the shifting teeth extend in the height direction of the conveyer belt body to extend out of the lower edge of the conveyer belt body, and a card pushing part for pushing cards is formed by the extending-out part. The smart card conveying mechanism comprises the conveyer belt and a power mechanism, the power mechanism comprises a motor and at least two synchronization belts, synchronization teeth of the conveyer belt are meshed with tooth grooves in synchronization belt wheels, and one synchronization belt wheel is driven by the motor. By means of the smart card conveyer belt, the shifting teeth cannot be bent and deformed when the cards are pushed to conduct code printing, and it is guaranteed that the positions of printed characters on the cards are accurate.

Owner:GUANGZHOU MINGSEN TECH CO LTD

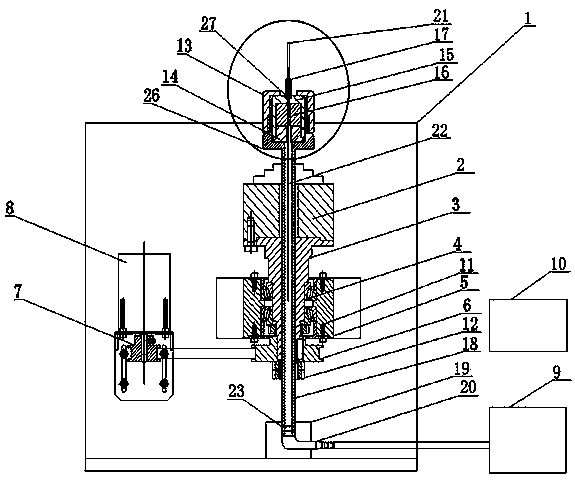

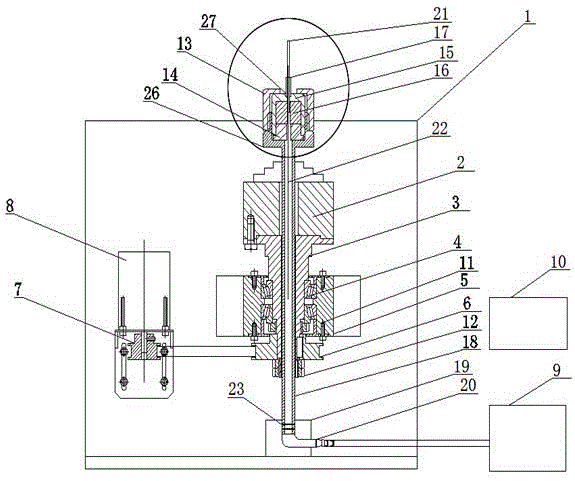

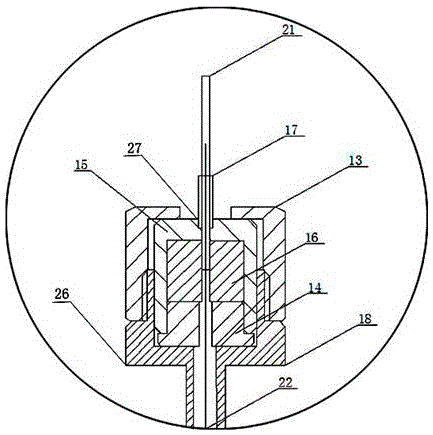

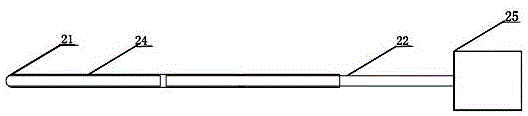

Manufacturing method of optical fiber F-P cavity sensor and manufacturing device thereof

ActiveCN103644925AGuaranteed reliabilityUniform angular stressCoupling light guidesConverting sensor output opticallyFiberWasher

The invention provides a manufacturing device of an optical fiber F-P cavity sensor and a manufacturing method thereof. The manufacturing device comprises a bracket, a stepping motor, large and small synchronous belt wheels, a three-jaw chuck, a tapered roller bearing, a vacuum pump, an oxyhydrogen flame hot melting machine, and a capillary glass tube clamp. One end of a capillary glass tube is welded by oxyhydrogen flame, the other end of the capillary glass tube is inserted into a fiber, and the capillary glass tube is inserted into the capillary glass tube clamp. A tail fiber passes through a tube shaft and is fixed and sealed by a rubber washer and a fixing nut. The rotating speed is in a range of 120r / min to 140r / min. The heating of the capillary glass tube is uniform. The vacuum pump is connected with a tower joint and the capillary glass tube is pumped into vacuum while the clamp is rotated. At the same time, the capillary glass tube is heated and melted by the oxyhydrogen flame hot melting machine, and under the effect of pumping, a capillary glass tube wall is collapsed inward to melt the fiber with the capillary glass tube. According to the melting method, the capillary glass tube and the fiber are firmly melted, the sealing performance is good, the penetration of oil and moisture from a welding point to damage an F-P cavity can be effectively prevented, and a solid foundation is laid for the long-term application of the optical fiber F-P cavity sensor in a harsh environment.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

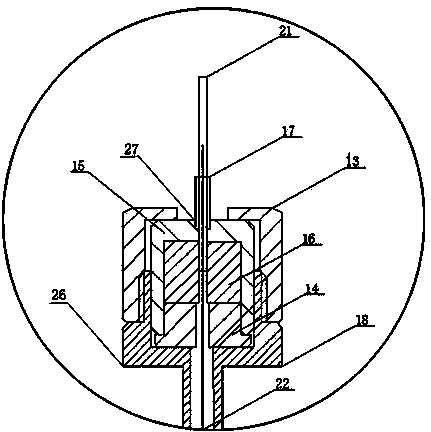

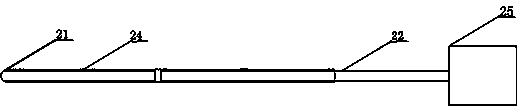

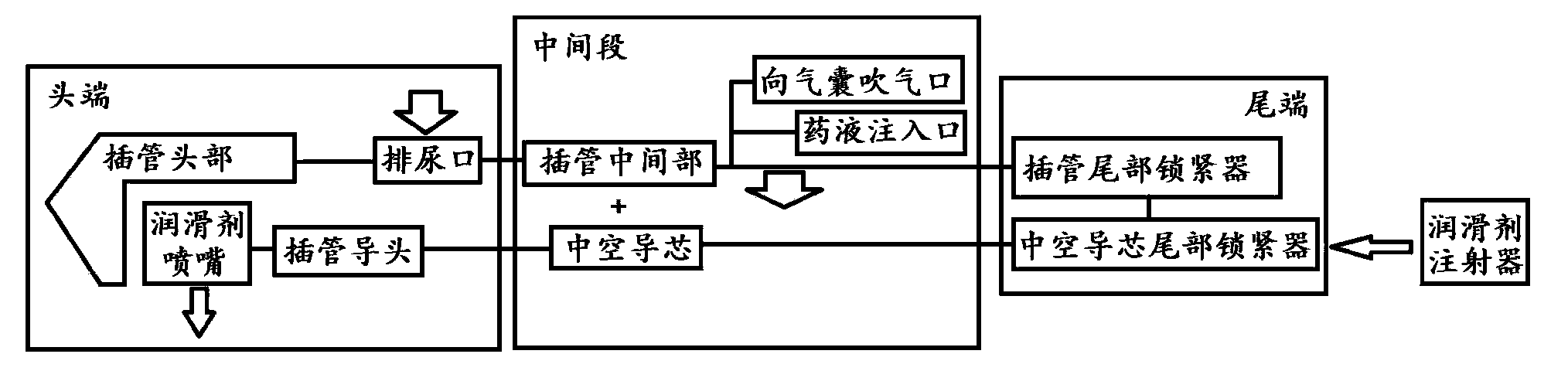

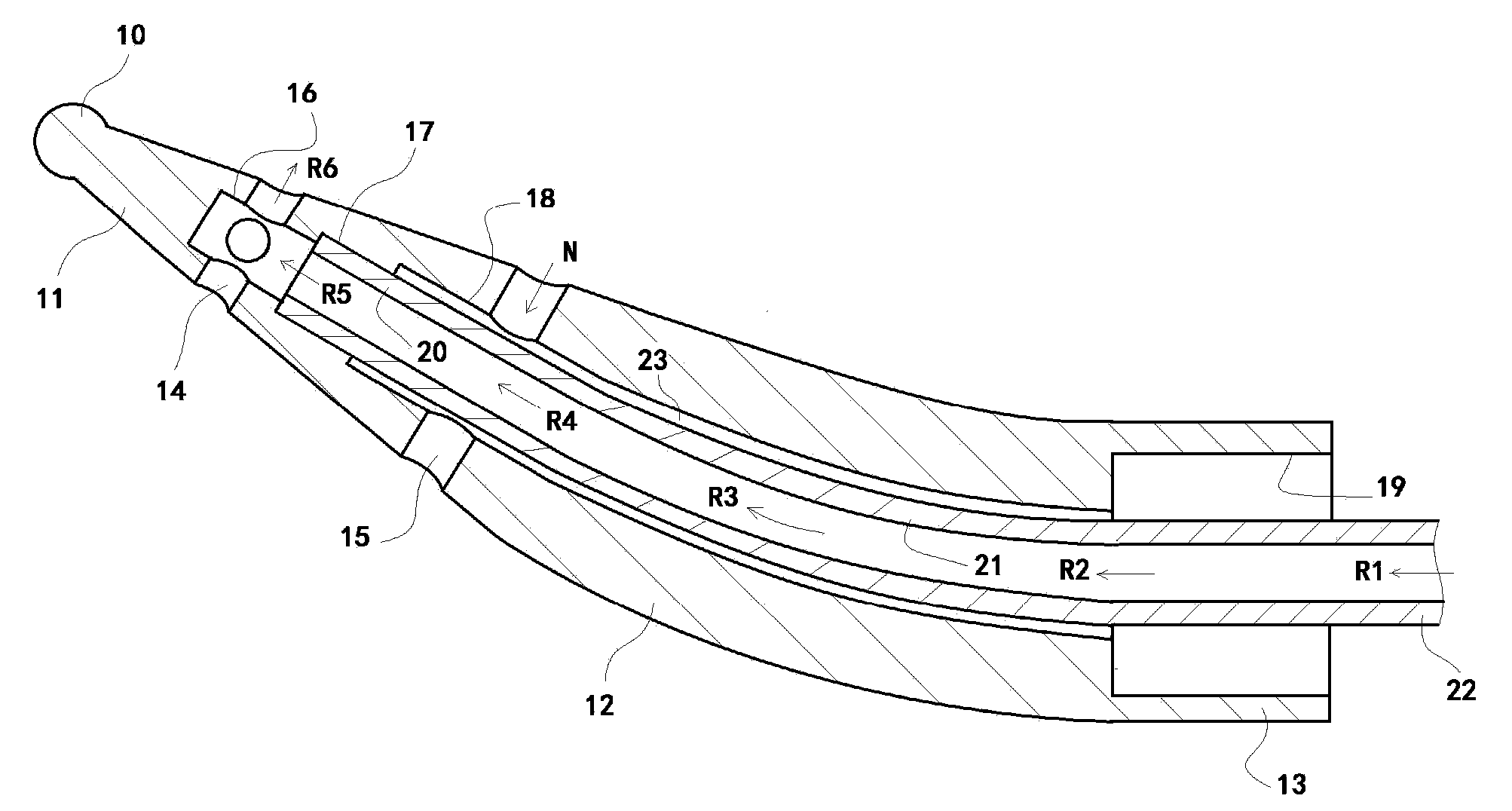

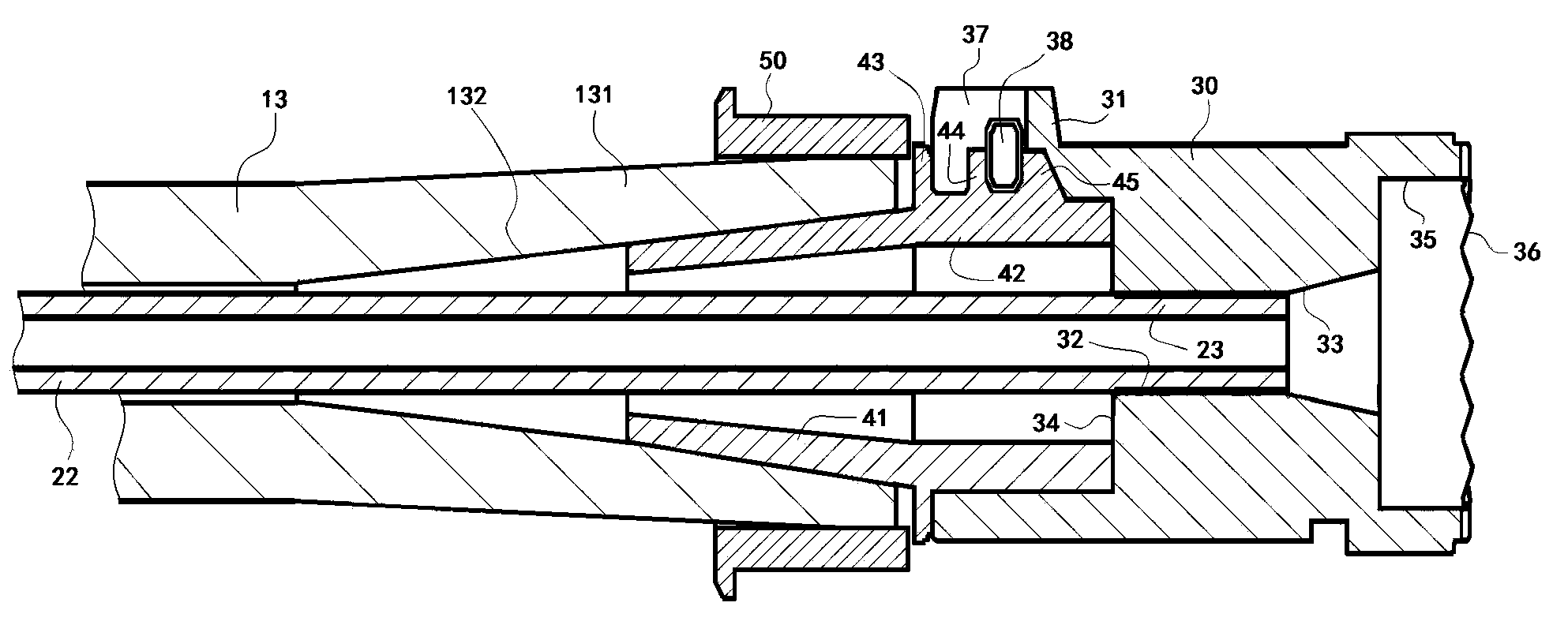

Urine educing device with bent hollow guide head

ActiveCN103861159AReduce resistanceAvoid damageBalloon catheterIntravenous devicesEngineeringGuide tube

The invention provides a urine educing device with a bent hollow guide head. The head end of the urine educing device comprises an insert tube head and an insert tube guide head, wherein the insert tube head comprises a conical section, a transitional section and a joint section; the diameter of the transitional section is gradually increased from the diameter of the bottom end of the conical section to the diameter of the joint section; the diameter of the joint section is outer diameter of the middle section of an insert tube; the conical section is internally provided with a lubricant nozzle inner hole and an insert tube guide head mounting stepped hole; the side wall of the lubricant nozzle inner hole is provided with at least one radial lubricant nozzle; the insert tube guide head mounting stepped hole and the insert tube guide head at the front end of a hollow guide core are tightly, easily and detachably matched; the joint section is provided with an insert tube mounting stepped hole; at the head end, the hollow guide core comprises an insert tube guide head at the front end, an insert tube of the transitional section and an insert tube of a straight section; a lubricant enters into a urine duct by virtue of the lubricant nozzle inner hole and the lubricant nozzle. According to the urine educing device, the thrusts of the insert tubes can be concentrated at the head end of a urine guide tube; the lubricant is capable of lubricating and expanding the urine duct in the whole process, further reducing the resistance of the insert tubes and reducing the inner wall damage of the urine duct.

Owner:WUHAN XUNSHU TECH CO LTD

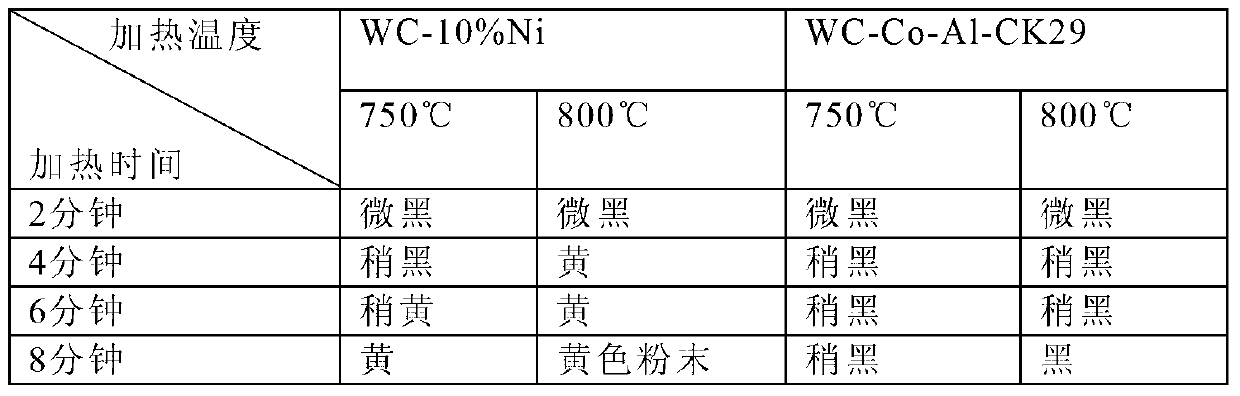

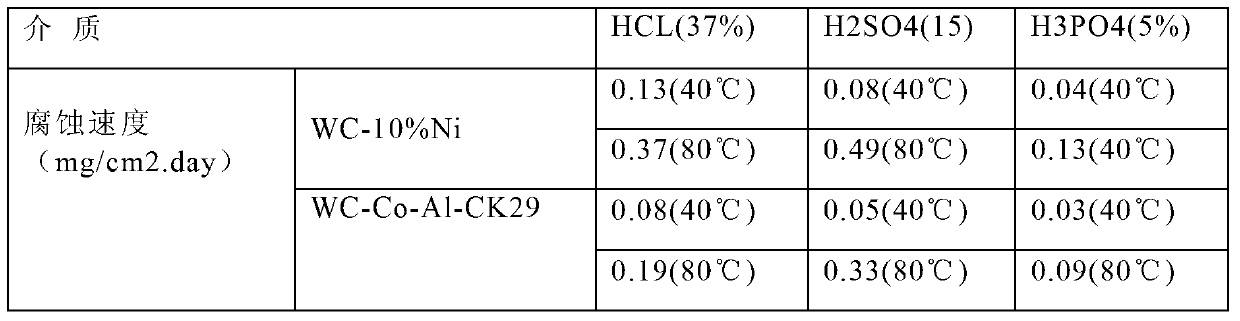

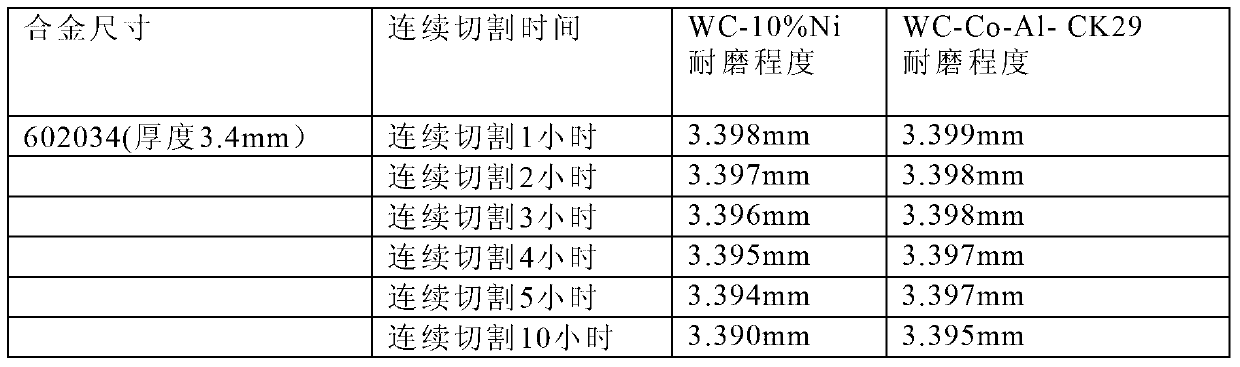

High-performance hard alloy and manufacturing method thereof

The invention discloses high-performance hard alloy and a manufacturing method thereof. The high-performance hard alloy mainly comprises the following components in percentage by weight: 5 to 10 percent of Co powder, 4 to 7 percent of Co-Al powder, 3 to 5 percent of CK29 powder and the balance of WC powder and inevitable impurities. The manufacturing method comprises the following technological steps of: (1) preparing: preparing materials according to the weight percentage; (2) wet grinding: adding the prepared raw materials into a high-energy ball mill and performing wet grinding for 67-77 hours by using alcohol so as to refine the materials until nano-composite degree; (3) drying: drying the ground mixed materials in a drying tower; (4) forming: adding an adhesive, pelleting and pressing into the shape of the product; and (5) sintering: vacuum-sintering the formed product at 1,430-1,460 DEG C and preserving heat for 15-25 minutes to prepare the high-performance hard alloy product. After the hard alloy provided by the invention is adopted, the hot red hardness is enhanced, and the product has the advantages of excellent corrosion resistance, good mechanical property and wear resistance and the like.

Owner:浙江长恒工具有限公司

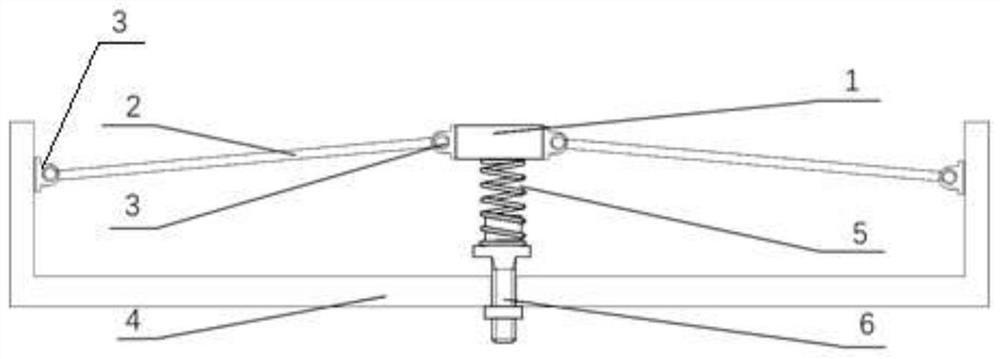

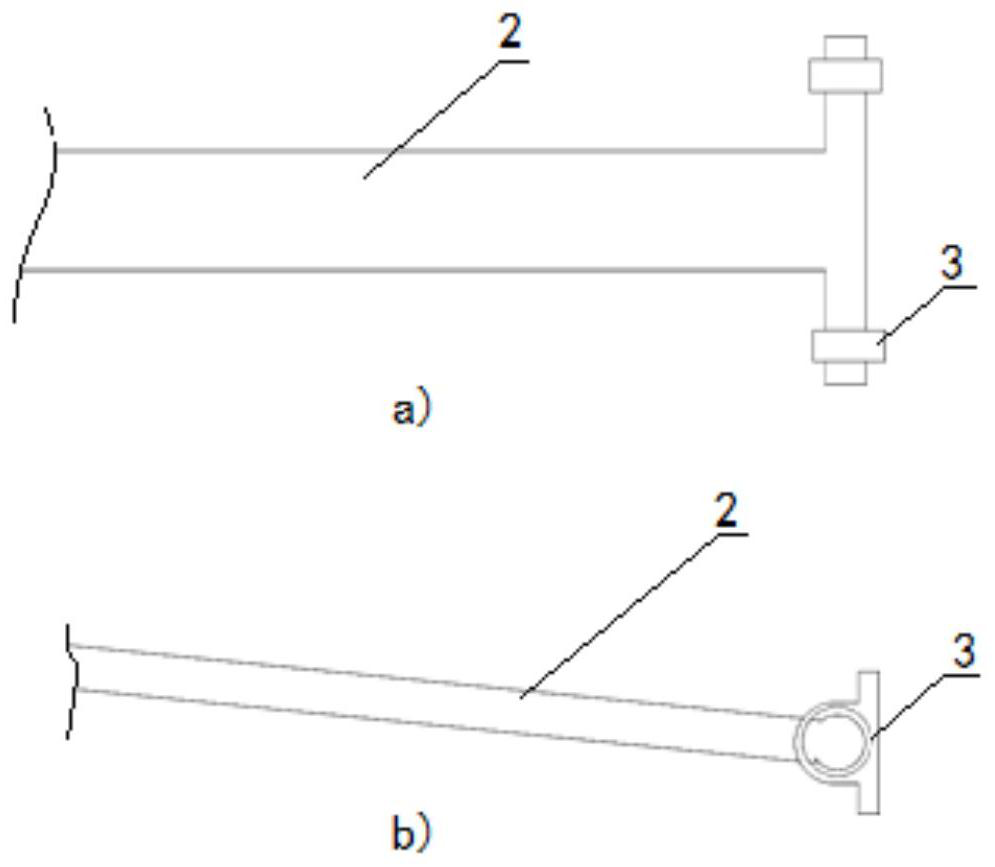

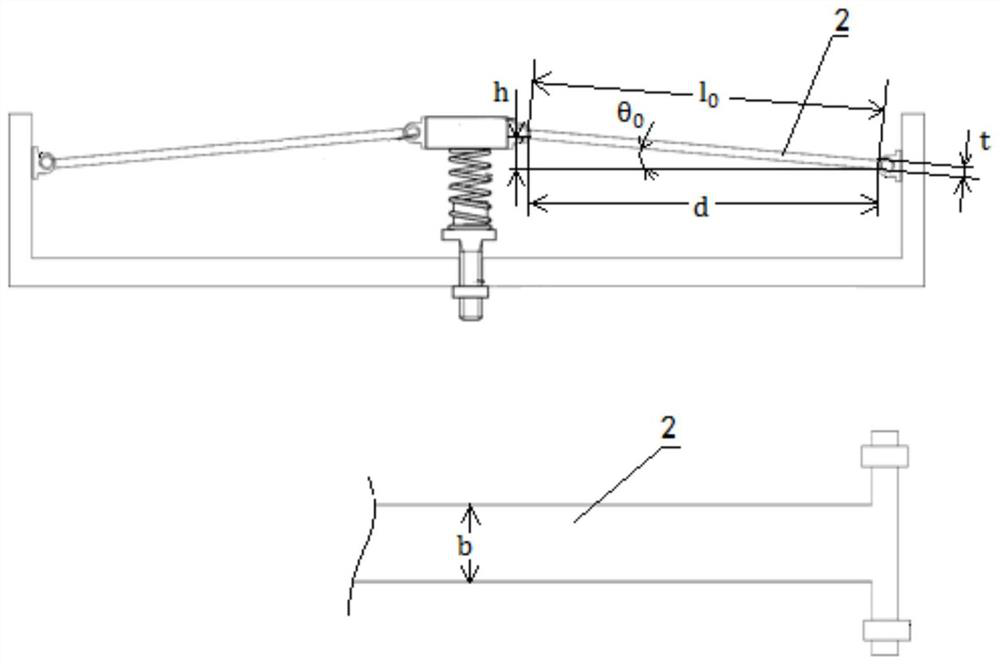

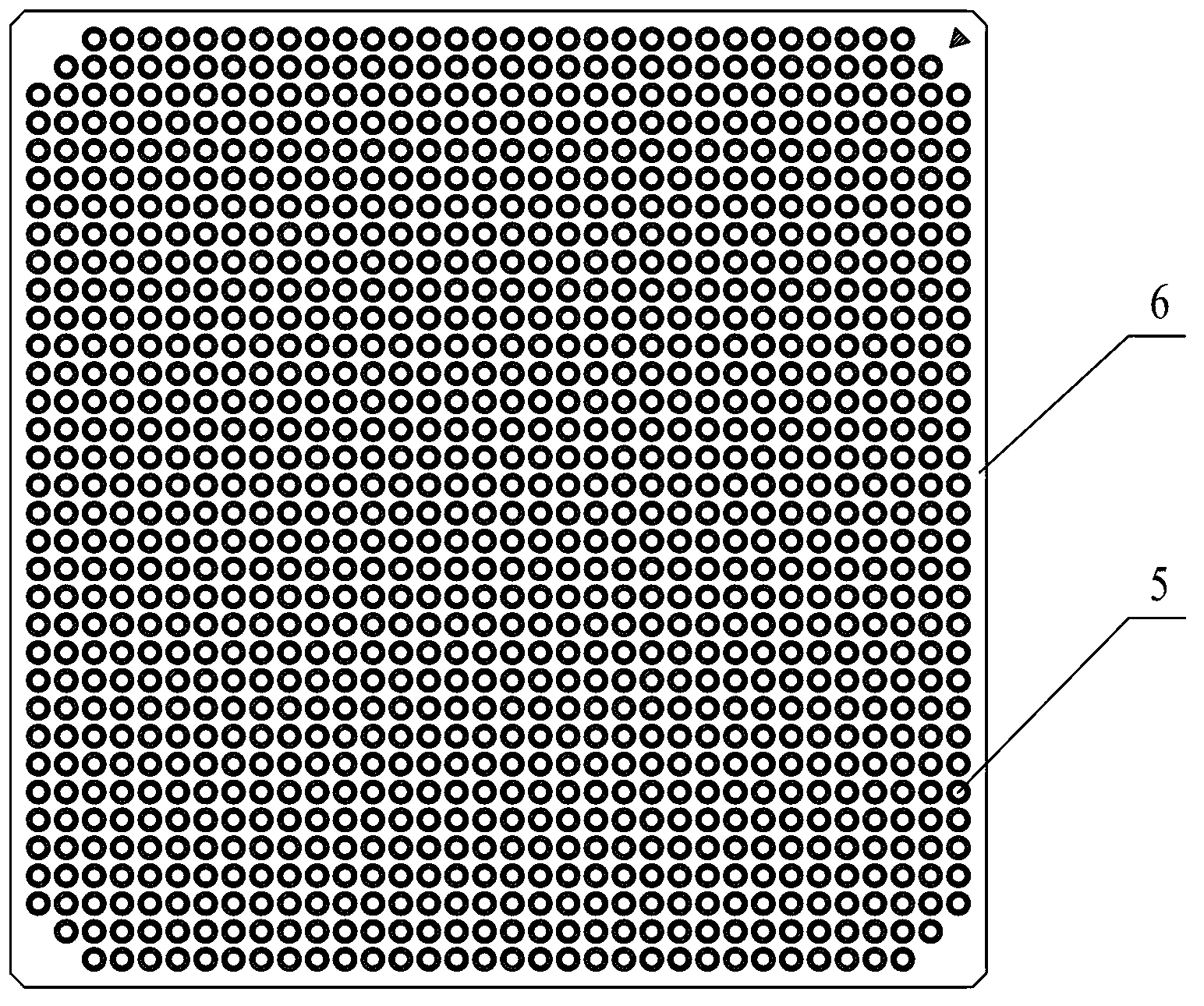

Quasi-zero stiffness vibration isolator of oblique compression rod

ActiveCN112178121AAngle is not zeroWill not bendNon-rotating vibration suppressionClassical mechanicsStructural engineering

The invention discloses a quasi-zero stiffness vibration isolator of an oblique compression rod. The quasi-zero stiffness vibration isolator comprises a shell, a platform, rod bodies and a spring, wherein the platform is located on the upper part of the shell; the rod bodies comprise first ends and second ends, the first ends of the rod bodies are hinged to the platform, and the second ends of therod bodies are hinged to the shell; the widths and the thicknesses of the rod bodies are slightly smaller than the lengths of the rod bodies, and a plurality of rod bodies are symmetrically distributed around the platform; the spring comprises a first end and a second end, and the first end of the spring is connected with the platform; the second end of the spring is connected to the shell; and when no load exists on the platform, the included angle between the rod bodies and a horizontal plane is not zero. In the process of compression deformation of the rod bodies due to the load on the platform, the deformation of the rod bodies is limited to the length direction of the rod bodies, the bending deformation of the rod bodies cannot occur, that is, the deformation direction of a system ofthe quasi-zero stiffness vibration isolator of the oblique compression rod is consistent with the stress direction during bearing, and the stiffness of the system can be analyzed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Assembling method of welding columns used for ceramic column grid array packaging

ActiveCN103258748ASimple structureEasy to installSemiconductor/solid-state device manufacturingSolder pasteEngineering

The invention relates to an assembling method of welding columns used for ceramic column grid array packaging. The method comprises the steps of (1) manufacturing a porcelain body positioning frame, a loading bearing plate and welding column carriers with Kovar materials and etching welding column positioning holes distributed in an array mode in each welding column carrier, (2) installing the load bearing plate on the bottom of the porcelain body positioning frame, installing the plurality of welding column carriers on the load bearing plate and installing the welding columns in the welding column positioning holes, (3) printing welding paste on a welding disc corresponding to a circuit porcelain body, (4) installing the circuit porcelain body with the welding paste printed on in the porcelain body positioning frame and enabling the welding paste to correspond to the welding columns in a one-to-one mode, (5) placing the welding columns, the porcelain body positioning frame and the circuit porcelain body with the welding paste printed on in a reflow furnace and welding the welding columns and the circuit porcelain body at a temperature between 210 DEG C and 230 DEG C, and (6) taking down the welding column carriers from the circuit porcelain body, leaving the circuit porcelain body and obtaining a packaging product. According to the assembling method of the welding columns used for ceramic column grid array packaging, assembly of welding columns used for CCGA circuits with different sizes and pitches can be achieved, and damage on the welding columns in a jig dismantling process is avoided.

Owner:WUXI ZHONGWEI GAOKE ELECTRONICS

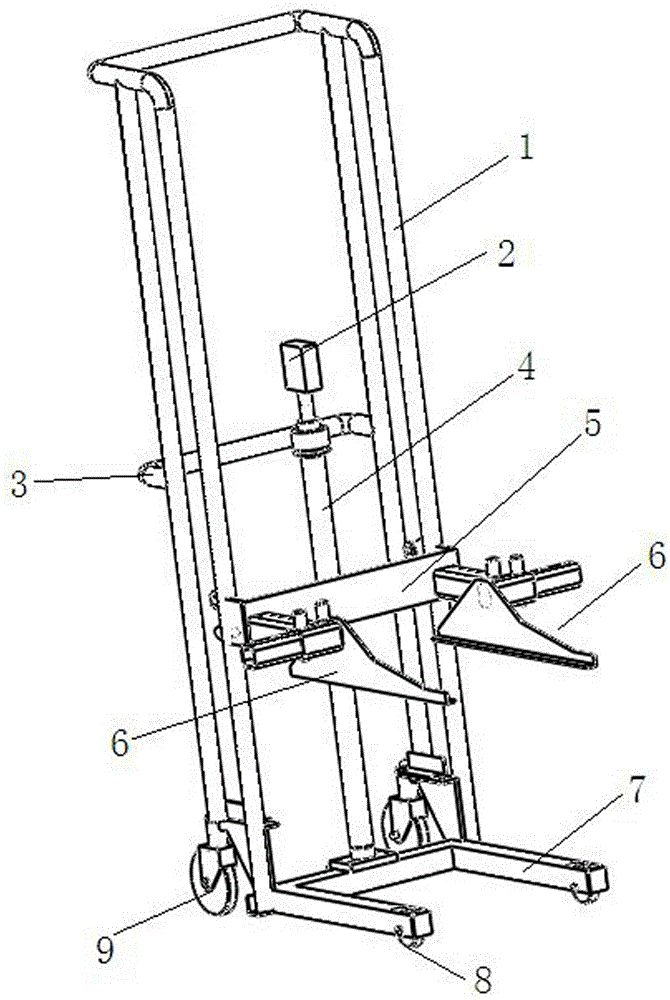

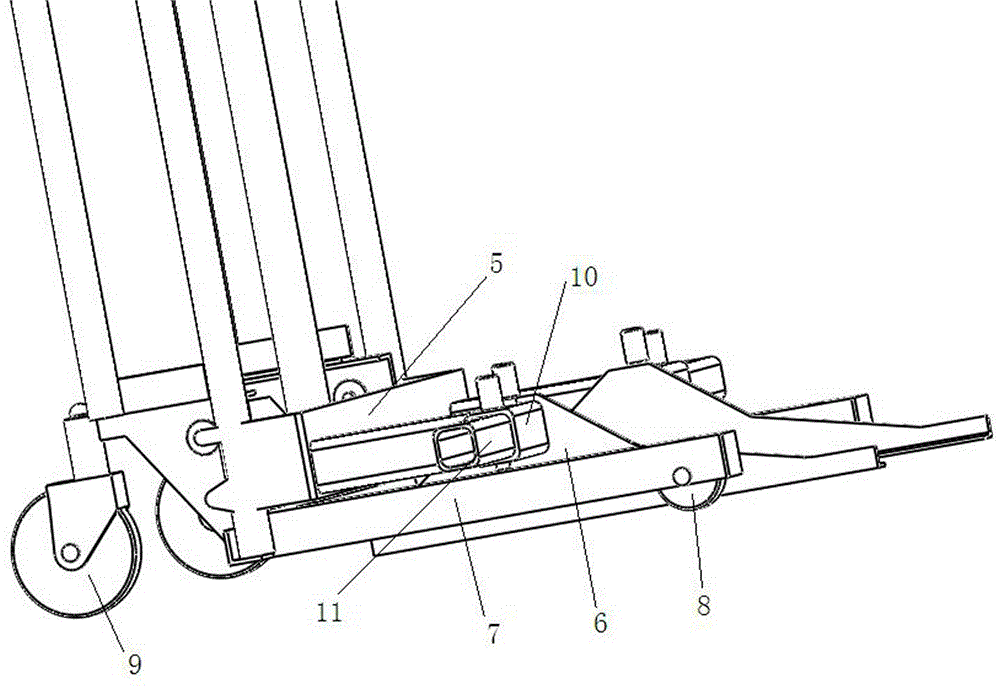

Fork and forklift applying same

The invention relates to a fork and a forklift applying the same. The forklift comprises a floor stand, an erector capable of being guided to move along the vertical direction is assembled on the floor stand, fork bodies are arranged on the erector, each fork body comprises a connecting plate and a fork plate, the thickness of each connecting plate extends in the left and right directions, the connecting plate is connected with the erector, each fork plate horizontally arranged with the length extending in the front-back direction is provided with an upper plate surface matched with bracketing of the to-be-transferred workpiece and is fixedly arranged at the lower end of the corresponding connecting plate, the front end of each connecting plate extends to the front end of the corresponding fork plate, and the rear end of each connecting plate extends to the rear end of each fork plate. By the arrangement, the problem that the height between the bearing surface of a cross arm and the loading surface is larger when the erector is at the lowest position due to the fact that the cross arm is thicker in the prior is solved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

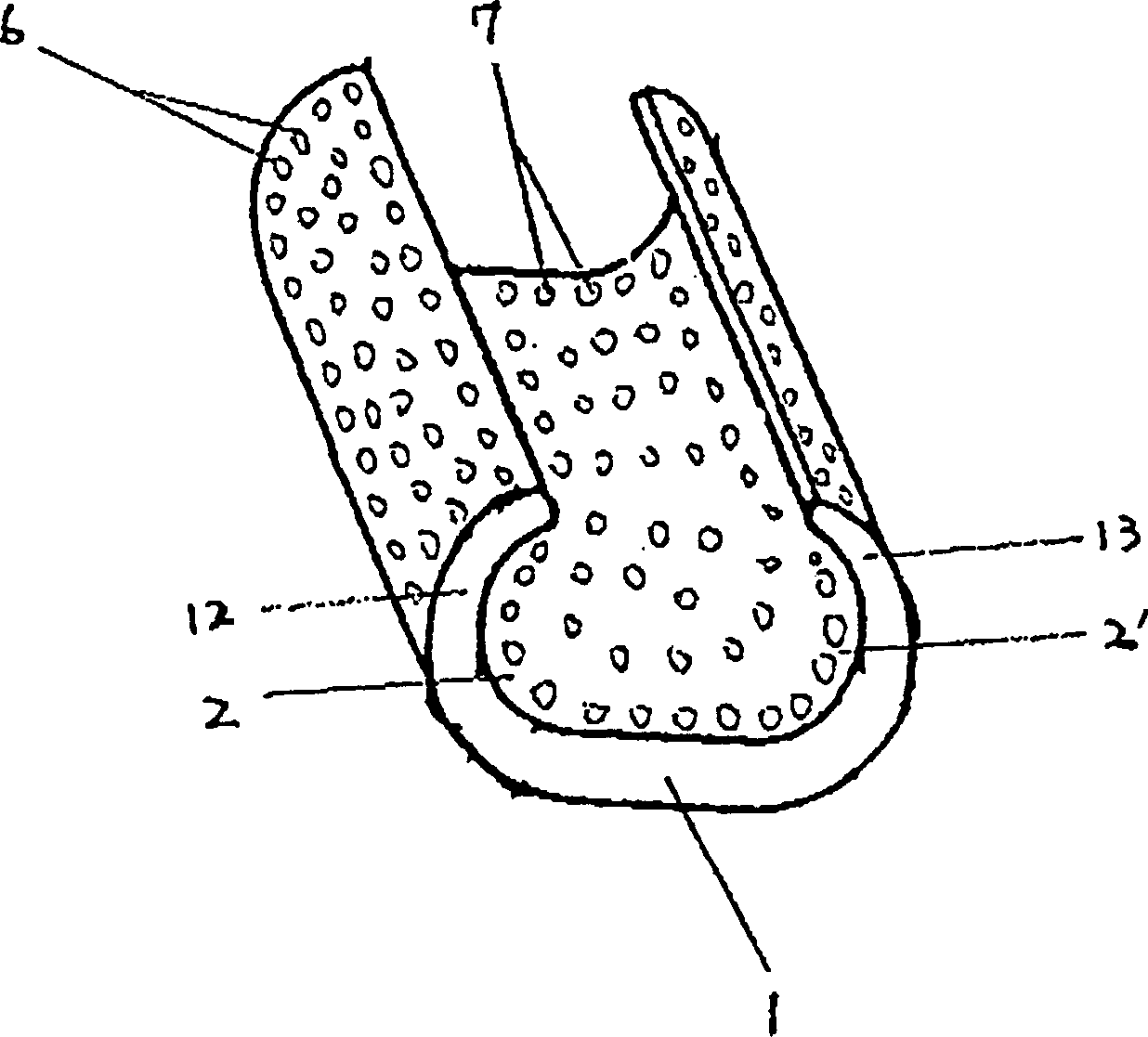

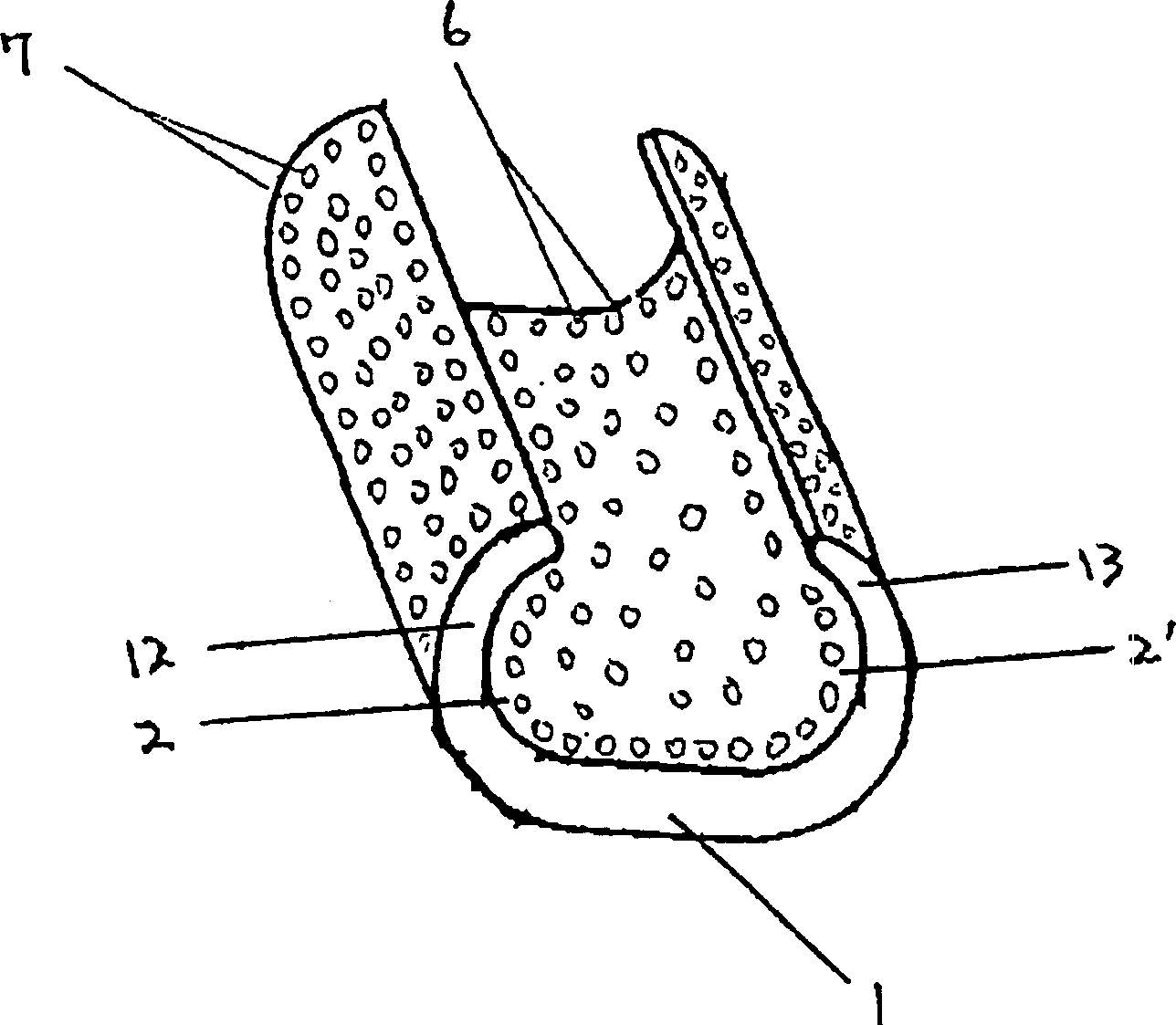

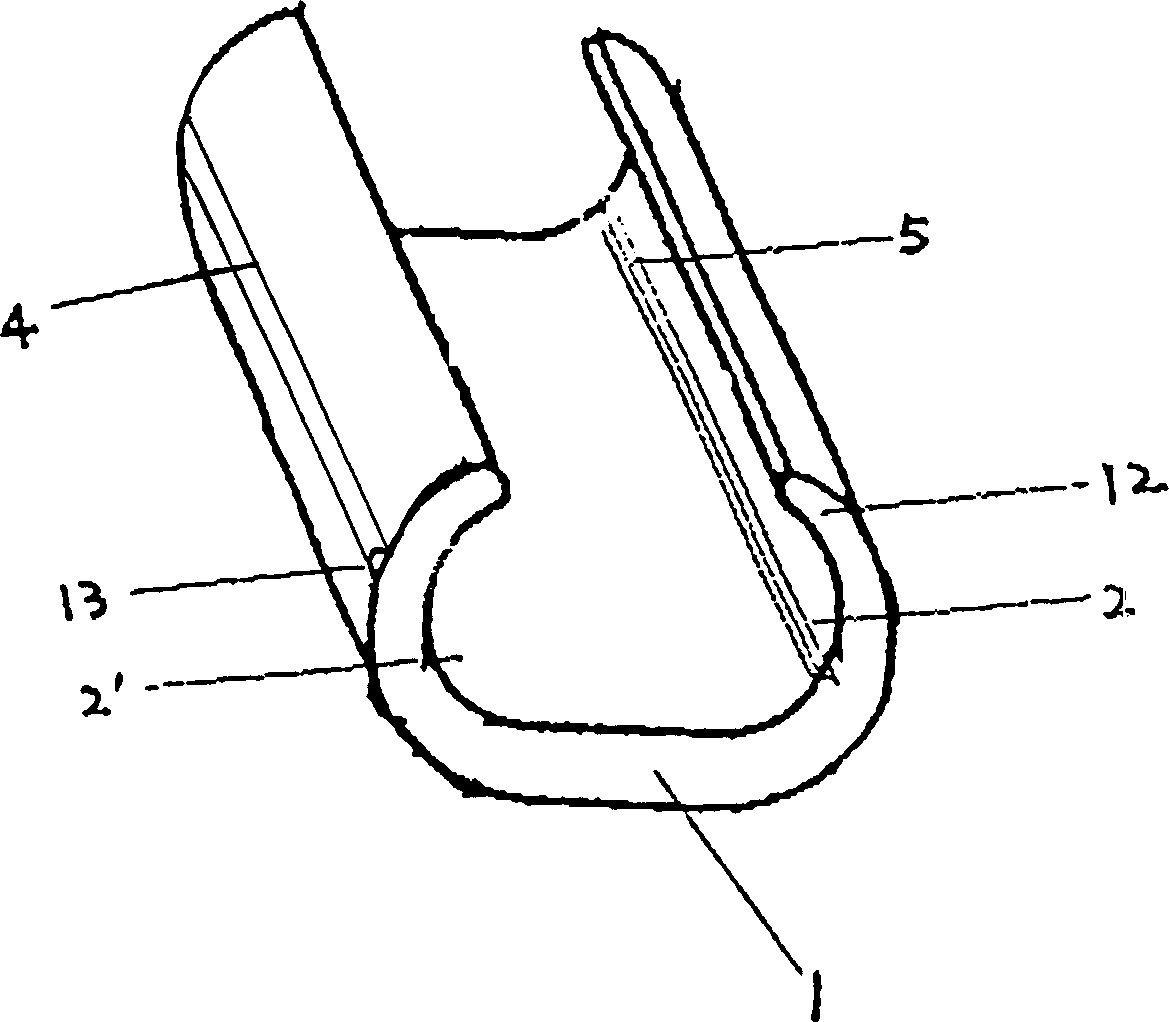

Crimped casing for electric transmission and distribution wire

InactiveCN1409439AReduce tensile stressHigh strengthConnections effected by permanent deformationElectric power transmissionPull force

This invention discloses a crimp connection for casing tube or crimped lock for wire used in power transmission and distribution line composed of a columnary matrix, the section of which exhibits C shape, two lineal furrows are set at both ends point distributed locking reentrants / humps or continuous or discontinuous locking furrows or locking ribs are set up on the surfaces of inner / output surfaces of the matrix and the furrows to stitch the crimped lock with wires due to the above-mentioned crimped lock structure, increasing its pulling force, reducing its connection adapted resistance and temperature rising.

Owner:陈国雄

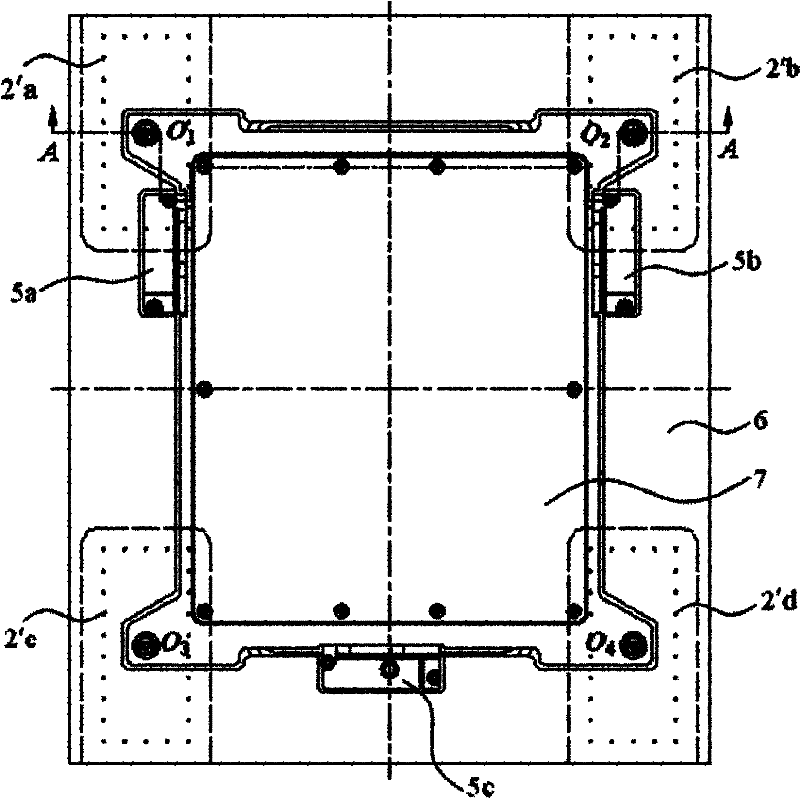

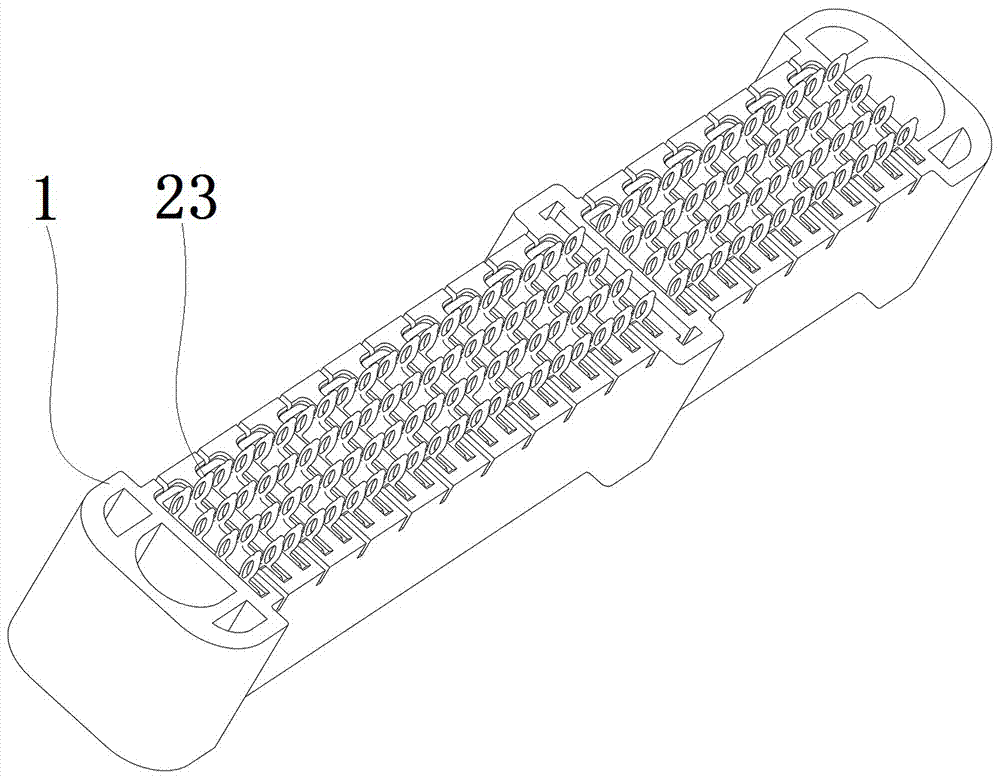

Sheet-type contact component, electric connector and printed board component

ActiveCN107104305ASolve the large volumeWill not bendSecuring/insulating coupling contact membersCoupling contact membersPull forceEngineering

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

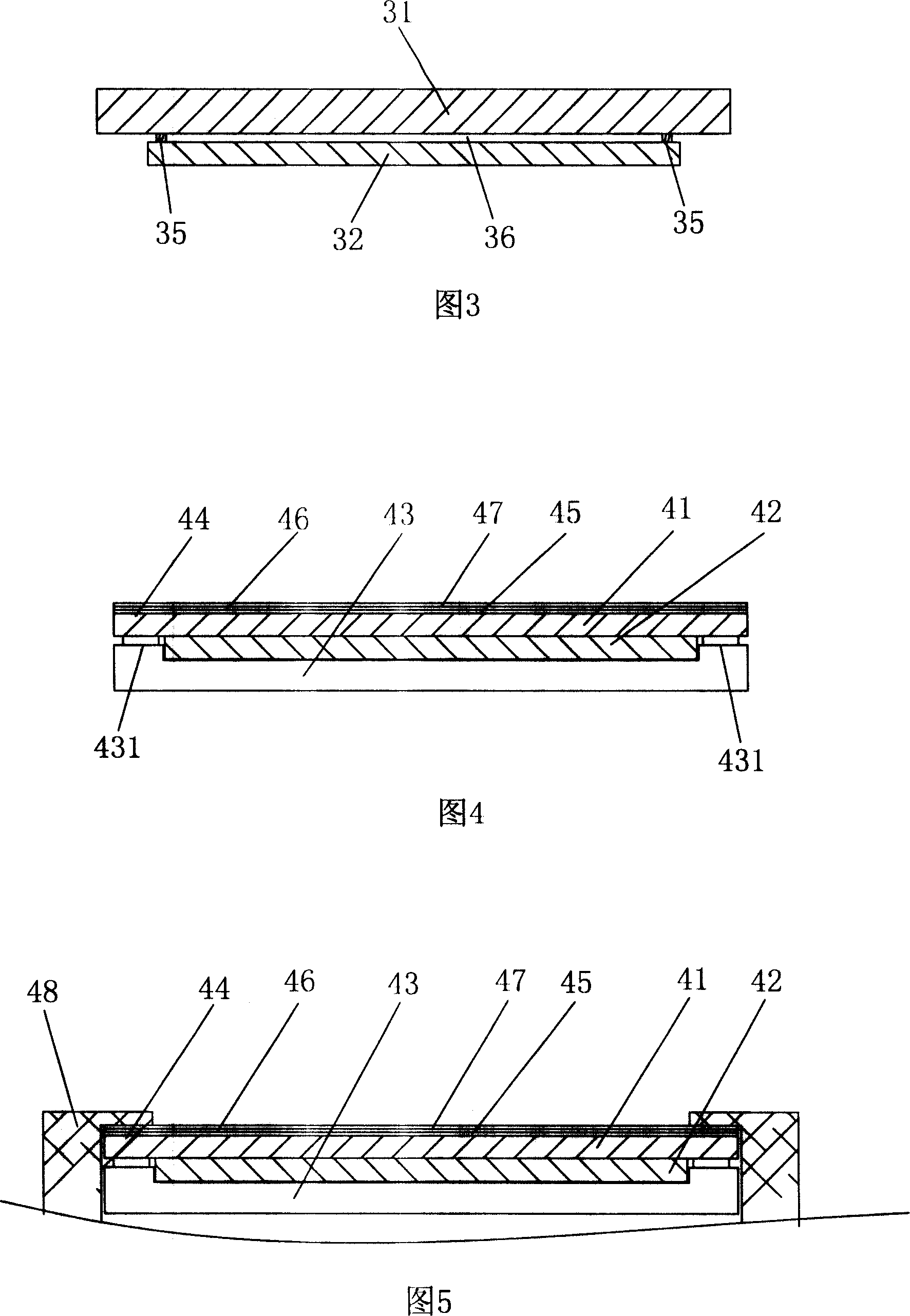

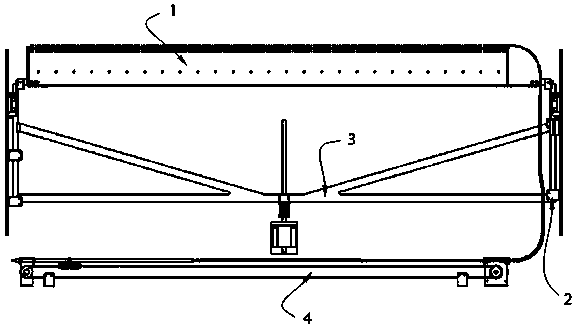

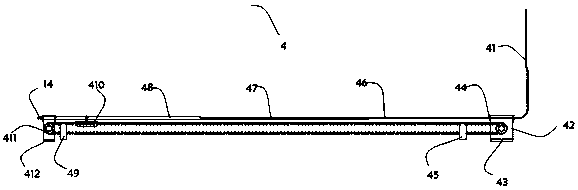

Backlight module

ActiveCN106468411AWill not bendLight fasteningsSemiconductor devices for light sourcesPull forceEngineering

The invention discloses a backlight module. The backlight module comprises a backboard, an optical diaphragm, at least one light source and at least one clamping assembly. The optical diaphragm is configured on the backboard. The light source is configured between the backboard and the optical diaphragm. The clamping assembly comprises a clamping structure and an elastic part. The clamping structure is configured on the backboard. One end part of the optical diaphragm is clamped in the clamping structure. The elastic part is configured between the clamping structure and the backboard. The clamping structure applies pulling force on the optical diaphragm through elastic force provided by the elastic part. The backlight module has following beneficial effects: without additional configuration of a dispersion board, the optical diaphragm is supported, thereby saving manufacture cost and assembly procedures of the backlight module.

Owner:CORETRONIC OPTOTECHSUZHOU CO LTD

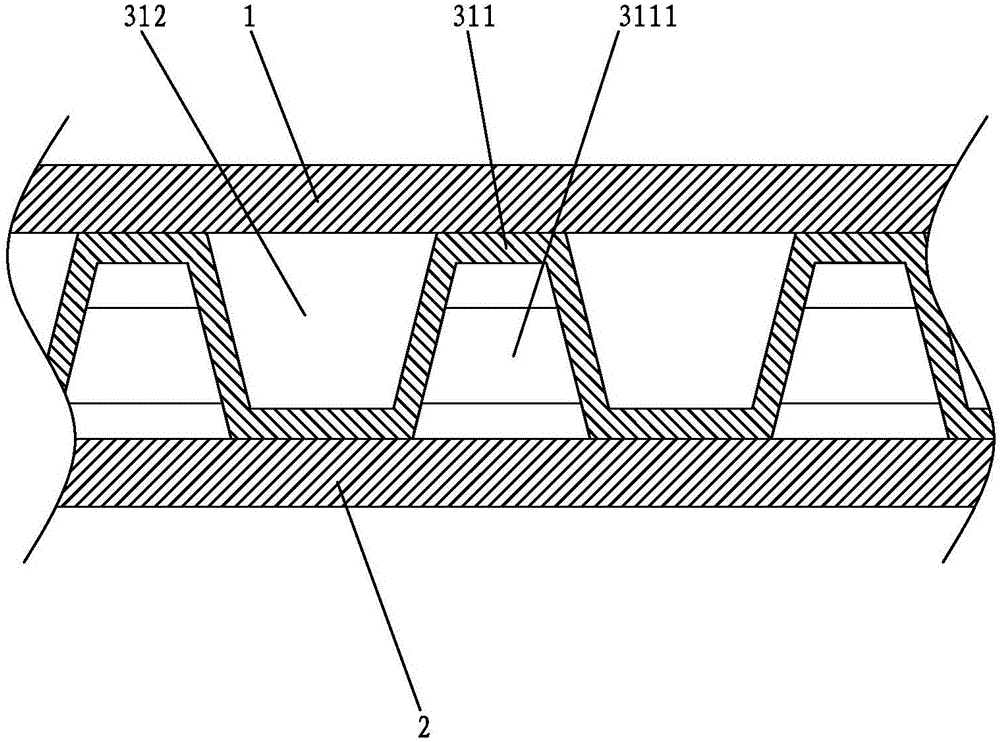

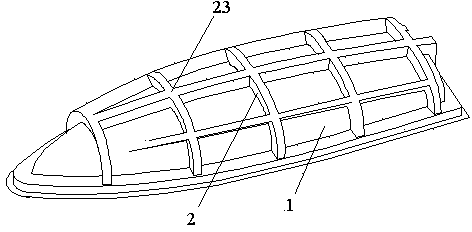

Corrugated paper cup

ActiveCN105775300AAvoid bending deformationWill not bendVenting meansRigid containersAir cyclePaper based

The invention discloses a corrugated paper cup. An isolation cavity is formed by a corrugated paper layer, so that the fact that the hand of a user is scalded by a hot beverage in a paper cup main body; longitudinal corrugated structures are laterally supported and restrained by horizontal corrugated structures; the horizontal corrugated structures are laterally supported and restrained by the longitudinal corrugated structures; and the sidewalls of the longitudinal corrugated structures and the sidewalls of the horizontal corrugated structures do not easily curve laterally. The longitudinal corrugated structures and the horizontal corrugated structures can perform bending resistance supporting, so that the defect of a traditional corrugated paper cup that a crease is formed along a corrugated structure extension direction, so that bending deformation is formed in the direction vertical to corrugated structures is overcome. The upper surfaces and the lower surfaces of the longitudinal corrugated structures and the horizontal corrugated structures all form planar surfaces, so that the contact area of the paper cup main body and an outer paper layer is enlarged, and the longitudinal corrugated structures and the horizontal corrugated structures are favorably glued onto the paper cup main body and the outer paper layer. A communication ventilation web is formed by the whole corrugated paper layer, and the corrugated paper layer communicates with the outside to perform cold and hot air circulation; and the hot beverage in the paper cup main body is subjected to rapid and natural heat dissipation and cooling. An annular corrugated paper base can be overturned up and down to perform stable and stretched support or to be folded.

Owner:FUJIAN WENSONG COLOR PRINTING

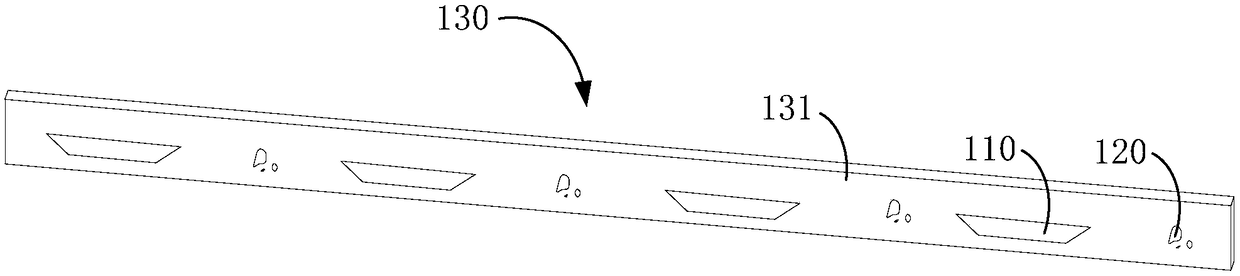

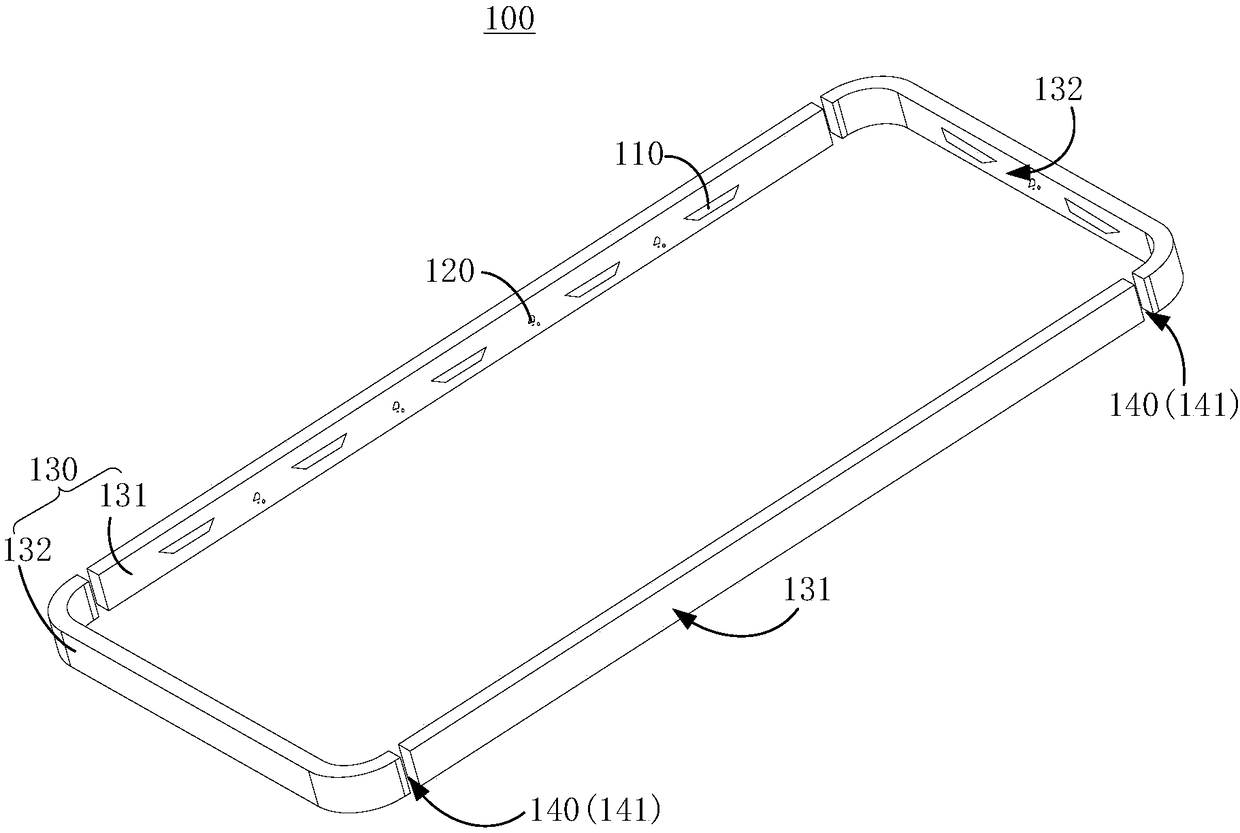

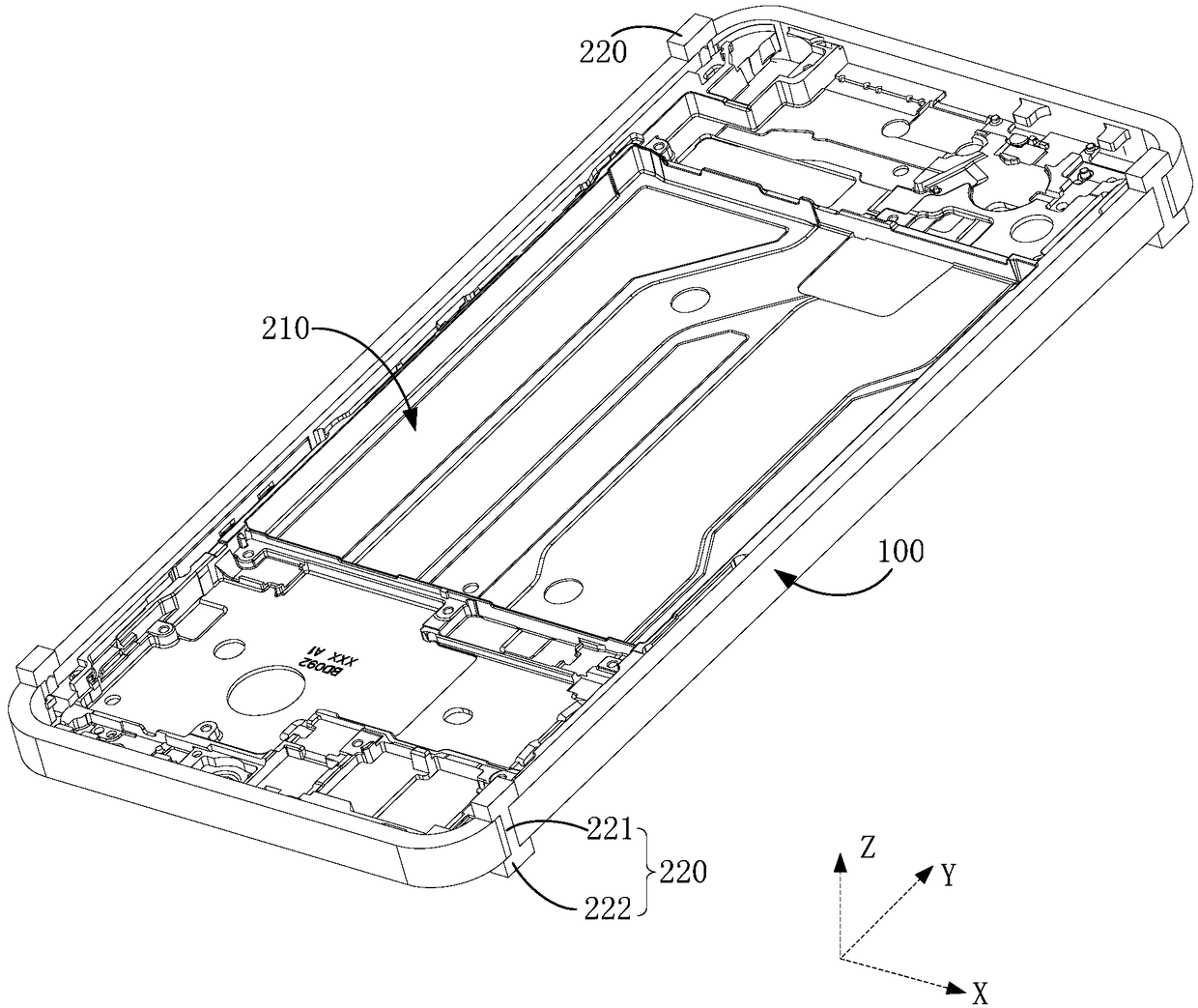

Machining method of metal middle frame, metal middle frame and mobile terminal

ActiveCN108655368AGood bending resistanceImprove production and processing efficiencyTelephone set constructionsForming processesMetal

The invention relates to a machining method of a metal middle frame, a metal middle frame and a mobile terminal. The machining method of the metal middle frame comprises the following steps that a plurality of connecting sections is provided; the connecting sections is arranged in a die-casting die at intervals, and the plurality of connecting sections define an annular frame with a gap; molten aluminum liquid is injected into the cavity of the die-casting die and fills the cavity of the die-casting die through a die-casting treatment technology, wherein part of the molten aluminum liquid is solidified to form a middle plate which is integrally formed with the connecting sections, and the rest of the molten aluminum liquid fills the gap and is solidified to form a filled aluminum material;and surface treatment is carried out on the frame and the filled aluminum material. Due to the fact that the connecting sections are placed in the cavity of the die-casting die at intervals, the tensile stress generated by the filled aluminum material located in different gaps in the cooling and forming process is counteracted mutually; and defects of bending deformation and the like caused by unbalanced stress of the frame formed after the connecting sections are connected through the filled aluminum material are avoided, so that the forming quality of the whole metal middle frame is ensured.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Full-automatic shearing type abrasive cloth ripping machine

InactiveCN102744740AAccurate locationWill not bendMetal-working feeding devicesShearing machinesMechanical engineeringPower transmission

The invention relates to a full-automatic shearing type abrasive cloth ripping machine, which comprises a feeding device, a shearing device, a receiving device and a power transmission device that are arranged on a rack. The feeding device comprises a feeding roller swinging device, an upper guide shaft and a lower guide shaft which are arranged on the rack, and the feeding roller swinging device is provided with a feeding roller. The shearing device comprises two side fixed plates which are arranged on the rack, and upper and lower cutter shafts are arranged between the two side fixed plates, and upper and lower separation sleeves and upper and lower blades are arranged outside the upper and lower cutter shafts. Edges of the upper and lower blades abut against each other to form a shearing opening. The receiving device comprises a receiving roller swinging device, a rotary frame and a rear guide shaft which are arranged on the rack. The receiving roller swinging device is provided with a receiving roller. The rotary frame is provided with a separation shaft which is provided with a separation sheet contacted with the receiving roller.

Owner:台州市黄岩豪林抛光磨具有限公司

Method for preparing roller brush fabric from thermoplastic fiber

InactiveCN109868542AHas the effect of hot melt adhesionNot fusion strongBristlePile-fabric loomsFiberEnvironmental resistance

The invention provides a method for preparing a roller brush fabric from thermoplastic fiber. A certain proportion of thermoplastic fiber serves as main fiber materials of upper-layer base cloth and lower-layer base layer, conventional fiber is used for connection of the upper-layer base cloth and the lower-layer base cloth, blank cloth is prepared through a machine knitting method, the upper-layer base cloth and the lower-layer base cloth have hot melting adhesion effects through pile cutting, heating and solidification, and the solidification and non-nap-off effects are achieved without gluing. The fabric can be used for a roller brush and a scrubbing brush, the environmental protection purpose is achieved by omitting the coating process, compared with the similar products, the fabric has fuller suede, a thick and solid hand feeling and non-silk-off and non-nap-off effects, and the solidification effect and the bottom stiffness are good.

Owner:沂水恒泰纺园有限公司

Filter pipeline for water conservancy project

ActiveCN107224779AAvoid collisionAvoid damageFiltration circuitsWater qualityEnvironmental engineering

Owner:嘉善冠通塑业有限公司

Bottom lifting plate steel wire transmission mechanism of telescopic structure

PendingCN110106617AWill not bendAvoid the problem of not being able to penetrate smoothlyWeft knittingTextile manufacturingArchitectural engineering

The invention relates to the technical field of textile manufacturing, in particular to a bottom lifting plate steel wire transmission mechanism of a telescopic structure. The mechanism comprises a bottom lifting needle plate, a first lifting device, a second lifting device and a steel wire drawing device. In the bottom lifting plate steel wire transmission mechanism of the telescopic structure, asteel wire is arranged in a first-stage telescopic sleeve, a second-stage telescopic sleeve and a third-stage telescopic sleeve, so that it is guaranteed that the steel wire cannot be bent or deformed by protecting the steel wire through the first-stage telescopic sleeve, the second-stage telescopic sleeve and the third-stage telescopic sleeve in a normal state, and the problem that smooth penetrating cannot achieved when the locking wire penetrates. The first-stage telescopic sleeve, the second-stage telescopic sleeve and the third-stage telescopic sleeve which are guided by the steel wire are each of the telescopic structure and adopt a telescopic sleeve structure, the friction resistance of the steel wire is reduced, and the problems that the locking wire cannot be pulled out and the locking wire is broken are avoided.

Owner:ZHONGSHAN LONGZU AUTOMATION TECH CO LTD

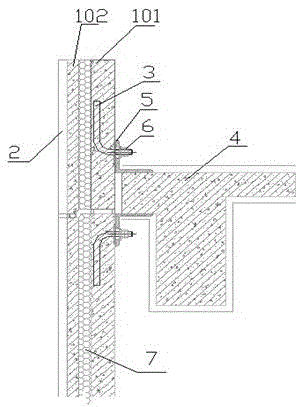

Exterior wall cladding connecting device and construction method

The invention relates to the technical field of mounting construction of exterior wall cladding, in particular to an exterior wall cladding connecting device and a construction method. The exterior wall cladding connecting device comprises sleeves embedded in an exterior wall cladding concrete layer and bolts matched with the sleeves, wherein mounting holes matched with the sleeves are formed in connecting pieces on a structural beam plate, and after the connecting pieces and exterior wall cladding are connected through the bolts, the perpendicularity of the exterior wall cladding meets the standard requirement. The sleeves are embedded in the exterior wall cladding, the high-strength bolts penetrate through the holes in the embedded connecting pieces and the sleeves and are fixed, so that the problems that mounting is difficult and the perpendicularity is more difficult to adjust due to the fact that hanging bars of original exterior wall cladding hanging bar connecting devices are subjected to deformation bending easily due to collision, the construction progress is promoted, the construction quality is improved, the risk that the exterior wall cladding falls and hurts people is completely eradicated, and the problem that a mounted exterior wall cladding surface layer is damaged by hitting is solved.

Owner:CHENGDU SIXTH CONSTR ENG

Production method of optical fiber F-P cavity sensor

ActiveCN105043424AGuaranteed reliabilityUniform angular stressCoupling light guidesConverting sensor output opticallyFiberOil water

The invention provides a manufacturing device of an optical fiber F-P cavity sensor and a manufacturing method thereof. The manufacturing device comprises a bracket, a stepping motor, large and small synchronous belt wheels, a three-jaw chuck, a tapered roller bearing, a vacuum pump, an oxyhydrogen flame hot melting machine, and a capillary glass tube clamp. One end of a capillary glass tube is welded by oxyhydrogen flame, the other end of the capillary glass tube is inserted into a fiber, and the capillary glass tube is inserted into the capillary glass tube clamp. A tail fiber passes through a tube shaft and is fixed and sealed by a rubber washer and a fixing nut. The rotating speed is in a range of 120r / min to 140r / min. The heating of the capillary glass tube is uniform. The vacuum pump is connected with a tower joint and the capillary glass tube is pumped into vacuum while the clamp is rotated. At the same time, the capillary glass tube is heated and melted by the oxyhydrogen flame hot melting machine, and under the effect of pumping, a capillary glass tube wall is collapsed inward to melt the fiber with the capillary glass tube. According to the melting method, the capillary glass tube and the fiber are firmly melted, the sealing performance is good, the penetration of oil and moisture from a welding point to damage an F-P cavity can be effectively prevented, and a solid foundation is laid for the long-term application of the optical fiber F-P cavity sensor in a harsh environment.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

Lifting type candleholder

The invention discloses a lifting type candleholder which comprises a base and further comprises a sleeve, a screw rod and a tray. The lower end of the sleeve is arranged at the upper end of the base in a rotating and sleeved mode, and a clamping spring is arranged between the sleeve and the base. An axial through hole is formed in the base, and symmetrical guiding grooves are formed in two sides of the axial through hole and in the base. The lower end of an inner cavity of the sleeve is provided with a partition board, and a threaded through hole is formed in the partition board. The screw rod is located in the axial through hole, the upper portion of the screw rod is arranged in the threaded through hole in a screwed mode, and the two sides of the lower end of the screw rod are provided with symmetrical sliding blocks which are arranged in the guiding grooves. The tray is arranged in the inner cavity and connected to the upper end of the screw rod. The lifting type candleholder has the advantage that placed candles will not bend and deform.

Owner:NINGBO KWUNGS HOME INTERIOR & GIFT

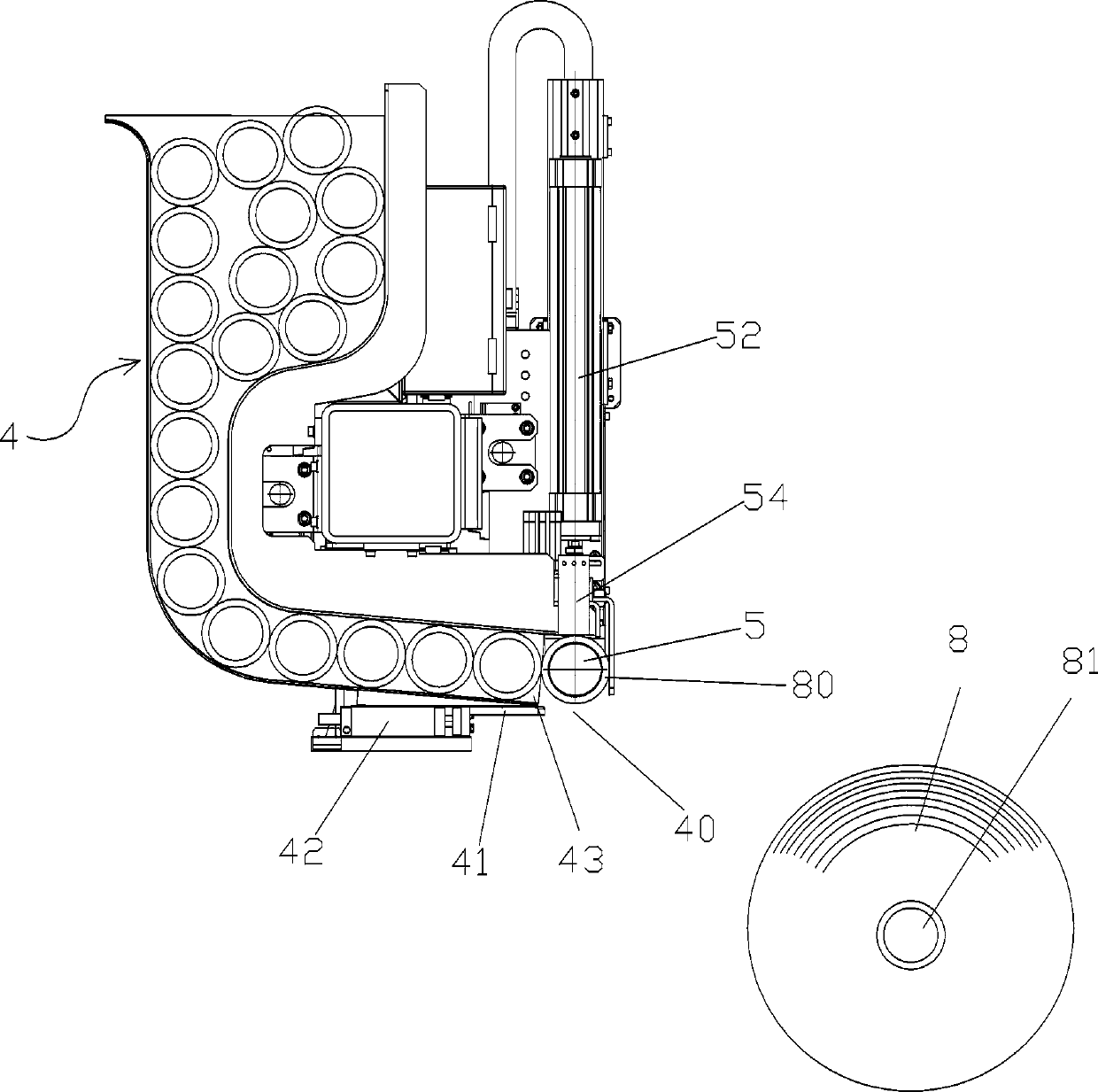

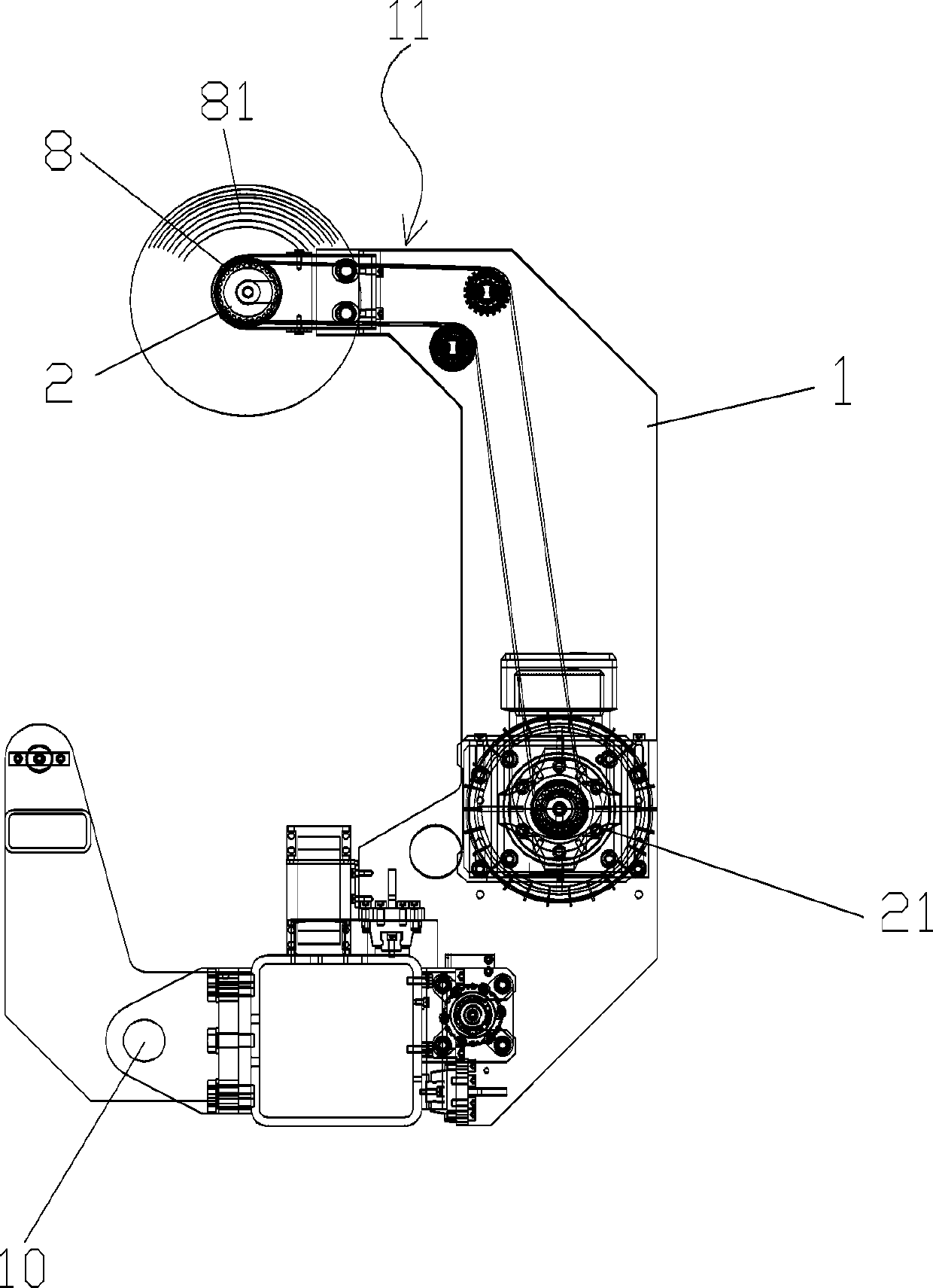

Wide plastic film winding and roll changing equipment and method for mandrel-free center winding mode

The invention discloses wide plastic film winding and roll changing equipment for a mandrel-free center winding mode. The equipment comprises a rack, wherein a front swing arm and a rear swing arm which are capable of synchronously swinging are arranged on the rack, and main winding chucks are respectively arranged on the upper ends of the two swing arms; a cutter bracket is also arranged on the rack, and a cutter for cutting off a plastic film is arranged on the cutter bracket; a core storage cavity used for storing a paper core tube is arranged on the rack, preliminary winding supports are respectively arranged on the front side and the rear side of the core storage cavity, and preliminary winding chucks are arranged on the preliminary winding supports; and a longitudinally extended friction roller is arranged below an outlet of the core storage cavity, a left side roller is further arranged on the upper left of the friction roller, and a right side carrier roller is further arrangedon the right side of the friction roller. According to the equipment, the non-stop roll changing can be automatically realized, and the paper core tube and a film roll cannot be bent and deformed ina winding process. The invention also provides a wide plastic film winding and roll changing method for the mandrel-free center winding mode.

Owner:GUANGDONG JINMING MACHINERY

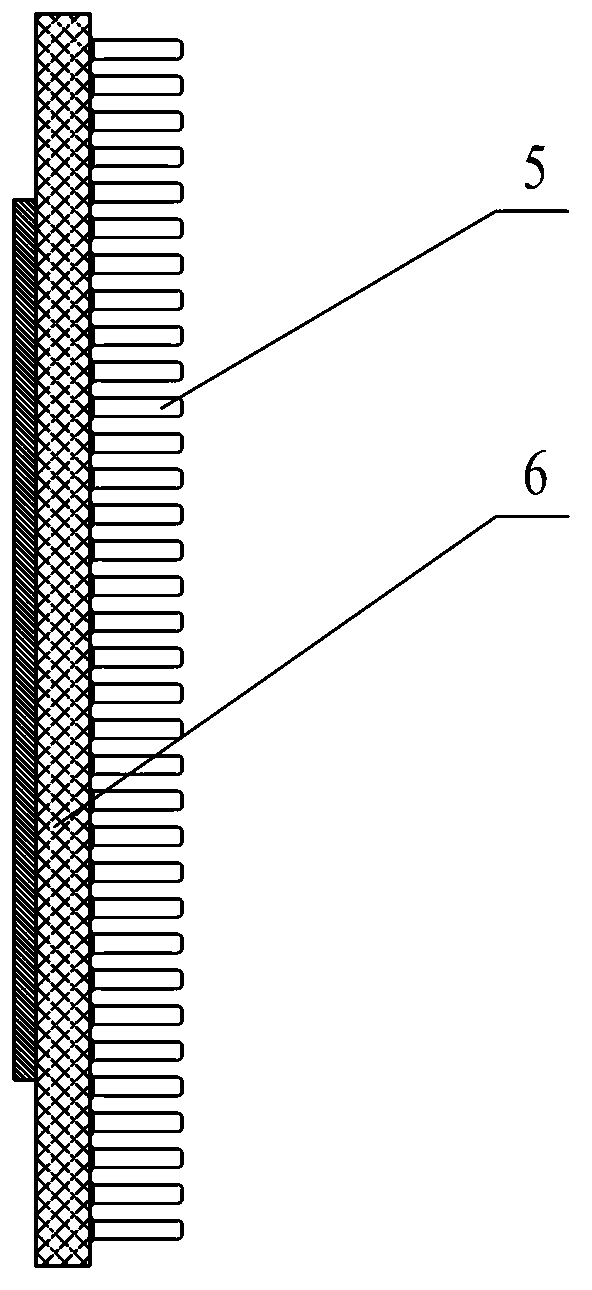

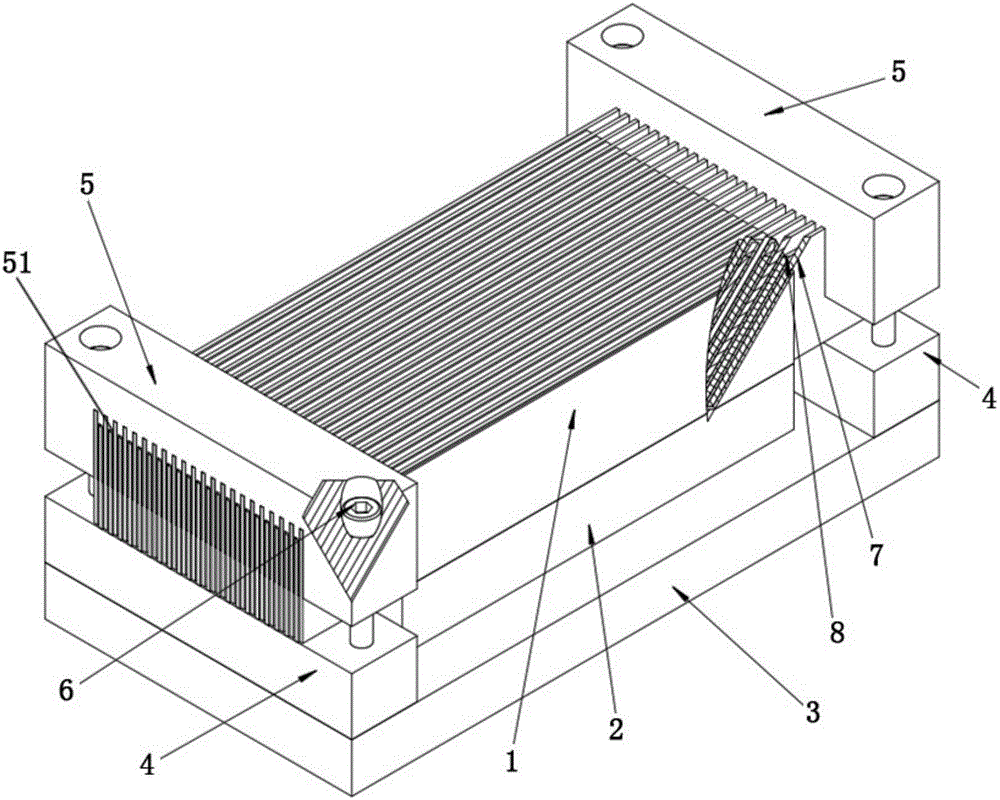

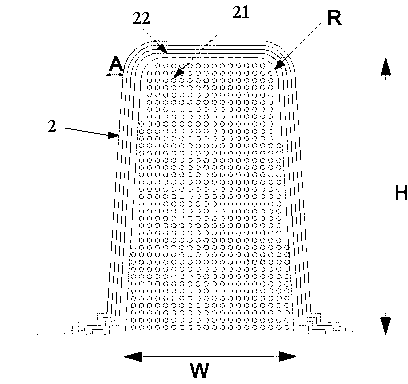

Welding jig for vacuum brazing between metal plate and folded metal sheet

The invention discloses a welding jig for vacuum brazing between a metal plate and a folded metal sheet. The welding jig comprises a base plate, pressing plate limiting blocks, pressing plate positioning blocks and pressing plates, wherein the two pressing plate limiting blocks are arranged on the two sides of the upper surface of the base plate respectively, a space used for containing the metal plate is formed between the two pressing plate limiting blocks, and the folded metal sheet is placed on the upper surface of the metal plate; each pressing plate is arranged between every two adjacent fins of the folded metal sheet in an inserted manner, the bottom surface of each pressing plate abuts against the upper surface of the connected parts of the bottoms of the two corresponding fins in a pressing manner, the length of each pressing plate is larger than that of the folded metal sheet, the two ends of each pressing plate both protrude out of the two sides of the folded metal plate, and the bottom surface of each pressing plate abuts against the upper surfaces of the pressing plate limiting blocks; and the two pressing plate positioning blocks are arranged above the two pressing plate limiting blocks respectively, and are connected with the two pressing plate limiting blocks through locking bolts respectively, so that the two ends of each pressing plate are tightly pressed between the pressing plate positioning blocks and the pressing plate limiting blocks. With the welding jig for vacuum brazing between the metal plate and the folded metal sheet, the welding quality of vacuum brazing between the folded metal sheet and the metal plate can be improved, and the folded metal sheet is prevented from deforming.

Owner:深圳市晟达真空钎焊技术有限公司

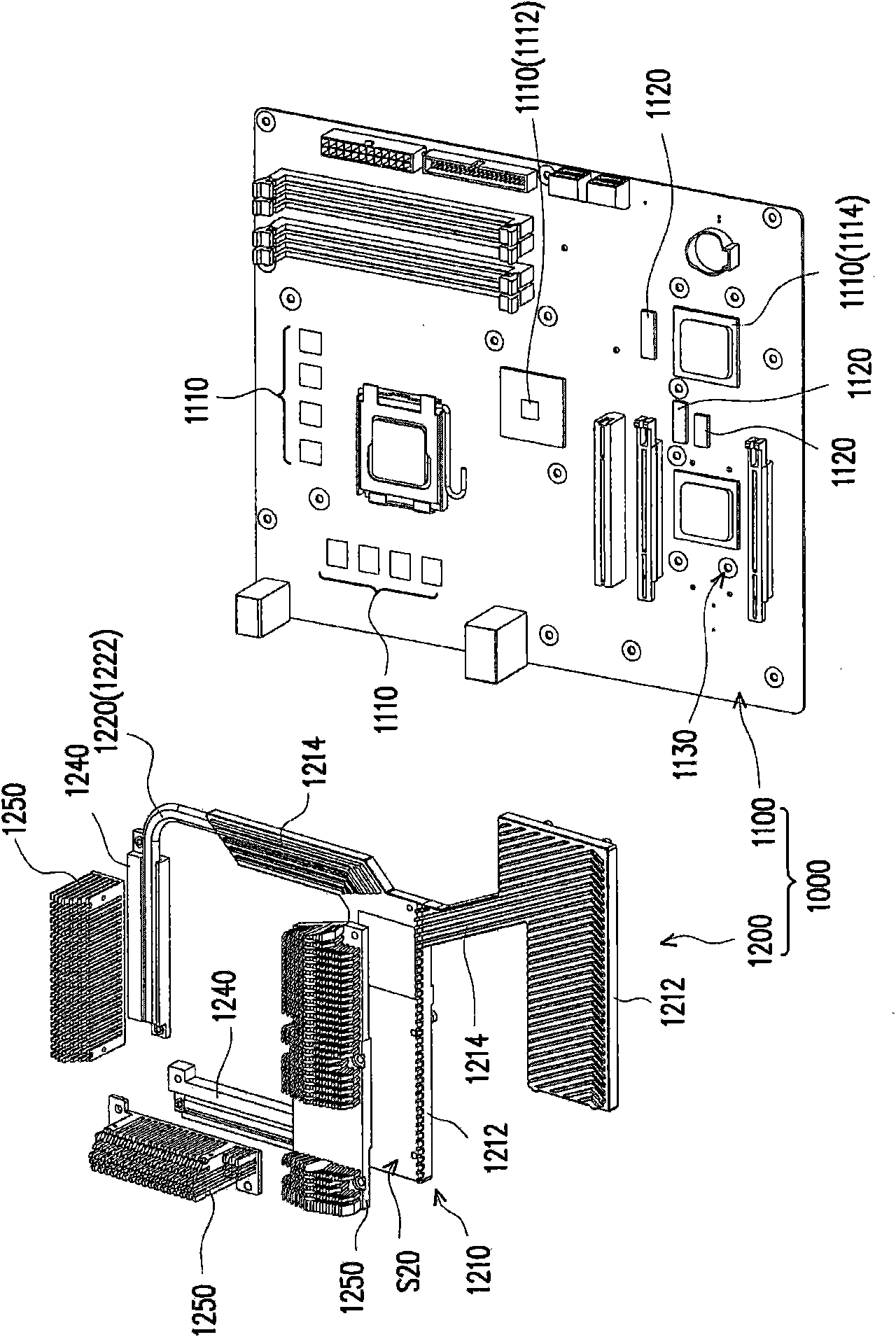

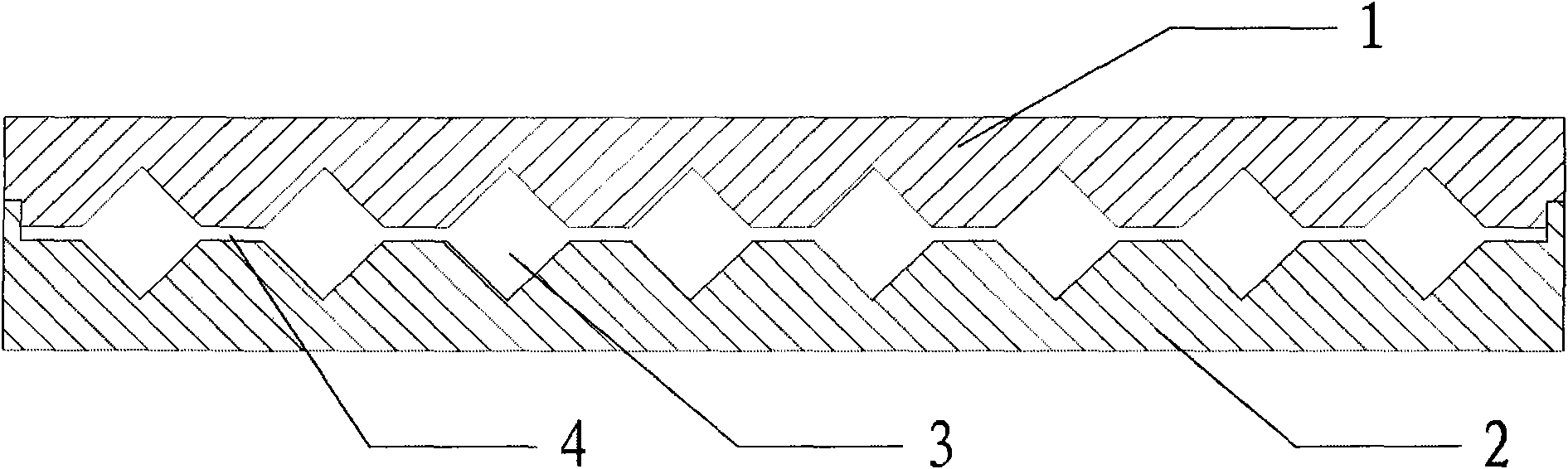

Radiating module and electronic device provided with same

ActiveCN101571741AImprove cooling efficiencyImprove reliabilityDigital data processing detailsCooling/ventilation/heating modificationsComputer moduleEngineering

The invention relates to a radiating module and an electronic device provided with same. The electronic device comprises a circuit board and a radiating module, wherein the circuit board is provided with a plurality of heating elements, and the radiating module comprises a radiating board and a heat pipe group. The radiating board is arranged on the circuit board, is divided into a plurality of contact parts and at least one heat pipe protecting part connected with the contact parts, and has a first surface and a second surface; the contact parts are used for receiving heat from the heating elements; a heat pipe containing groove which passes through the heat pipe protecting part is arranged on the first surface; and the heat pipe group is arranged in the heat pipe containing groove of theradiating plate.

Owner:ASUSTEK COMPUTER INC

Composite material mould with reinforcing structure and preparation method thereof

The invention discloses a composite material mould with a reinforcing structure and a preparation method thereof. The composite material mould with the reinforcing structure comprises a mould casing, wherein a criss-cross #-shaped reinforcing structure is arranged on the mould casing, and is provided with a foam core material; a plurality layers of glass fiber reinforced plastics formed by uniaxial glass fiber cloth are laid on the surface of the foam core material; as the criss-cross #-shaped reinforcing structure is additionally attached onto the mould casing, the composite material mould has the benefits that the mould casing is not subjected to bending deformation, and the stability performance of the mould casing is improved; in addition, the criss-cross #-shaped reinforcing structure is adopted to enable various vertical and horizontal components to be mutually controlled and supported, so that the performance of the mould is enabled to be reasonably controlled; the foam core material has no strength, and plays a role in supporting the reinforcing structure; a plurality layers of glass fiber reinforced plastics formed by uniaxial glass fiber cloth are laid on the surface of the foam core material.

Owner:南京甬博数控科技有限公司

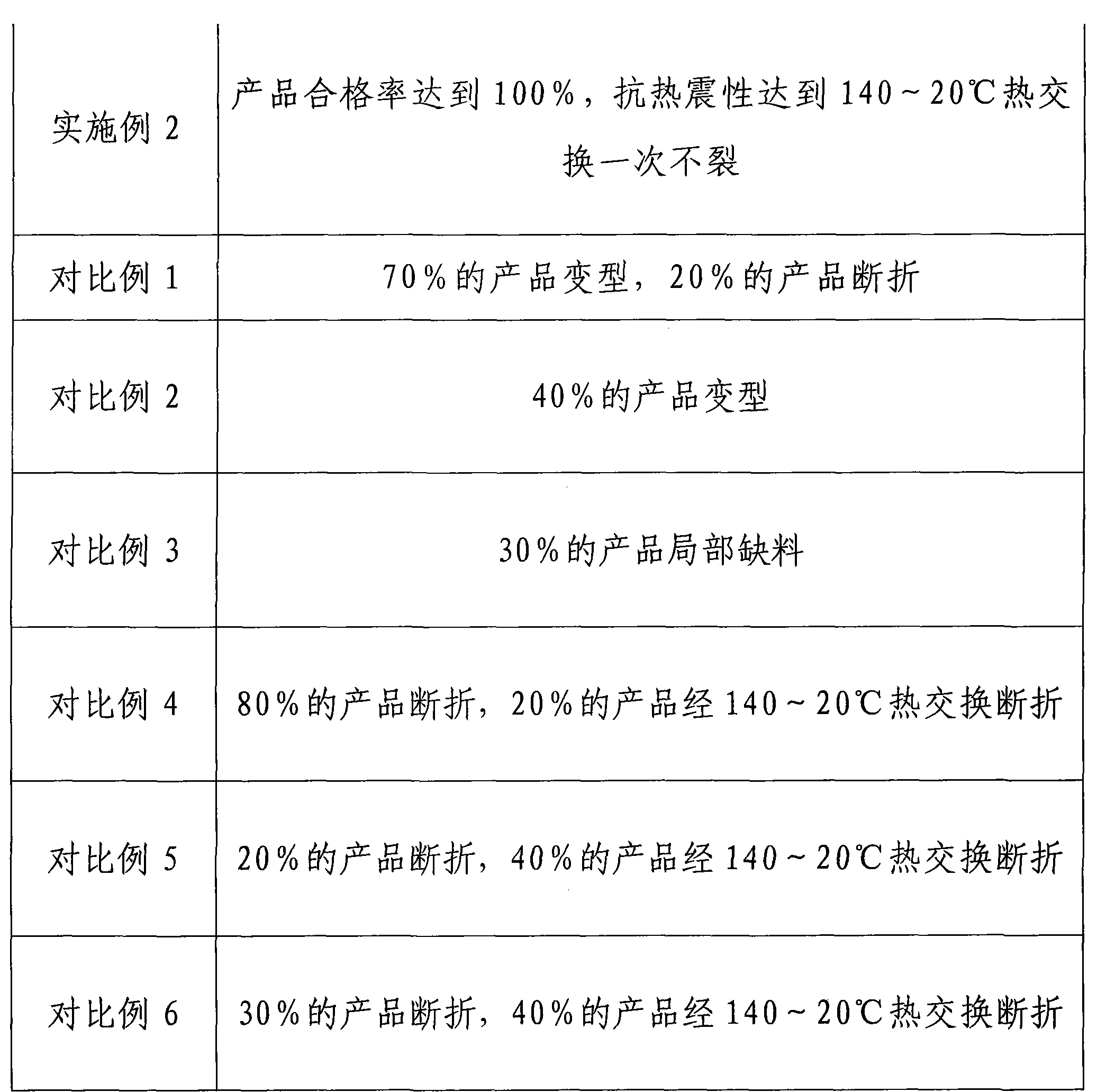

Production die and production process for glass chopsticks

ActiveCN102167494AWill not bendWon't breakGlass pressing apparatusTablewaresGlass meltingThermal shock

The invention discloses a production die and production process for glass chopsticks. The production die for glass chopsticks consists of an upper die and a lower die and is internally provided with a plurality of chopstick type die cavities, and communication clearances are formed among the die cavities; and the production process for glass chopsticks comprises glass melting, glass chopstick pressing and forming, crystallization and annealing treatment, cutting treatment and other steps. For the glass chopsticks made by adopting the die and the process, the product percent of pass is high, the production efficiency is high, and the production cost is low; and the thermal shock resistance of the chopsticks can meet the standard that the chopsticks can be once subjected to heat exchange at 140-20 DEG C without cracking, and the technical indexes of physics, sanitation and the like of the product can all conform to the requirements of the current domestic and overseas glass dinnerware standards.

Owner:GUANGDONG SANYUAN MICROCRYSTAL GLASS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com