Quasi-zero stiffness vibration isolator of oblique compression rod

A quasi-zero stiffness, compression rod technology, applied in the direction of spring/shock absorber, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve large static deformation, large additional mass and damping, and cannot meet the requirements of the free boundary of spacecraft, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

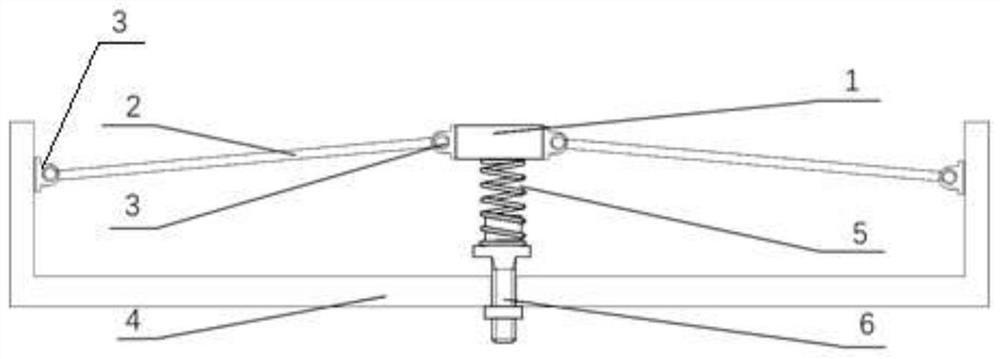

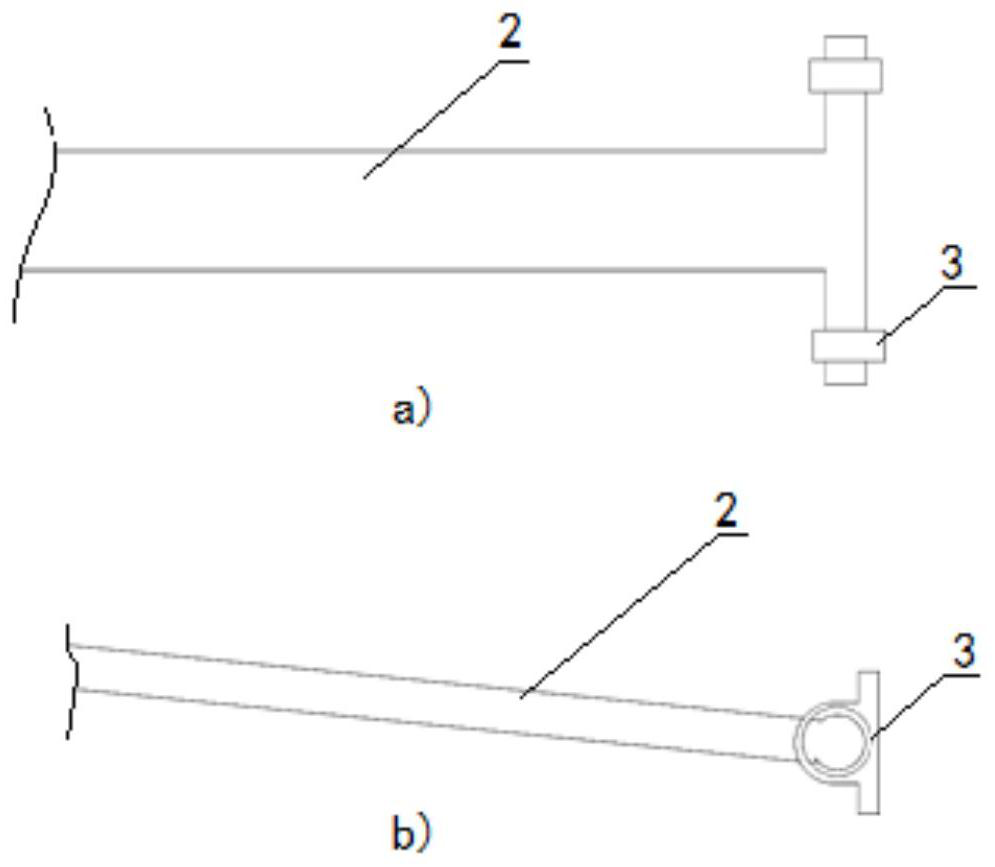

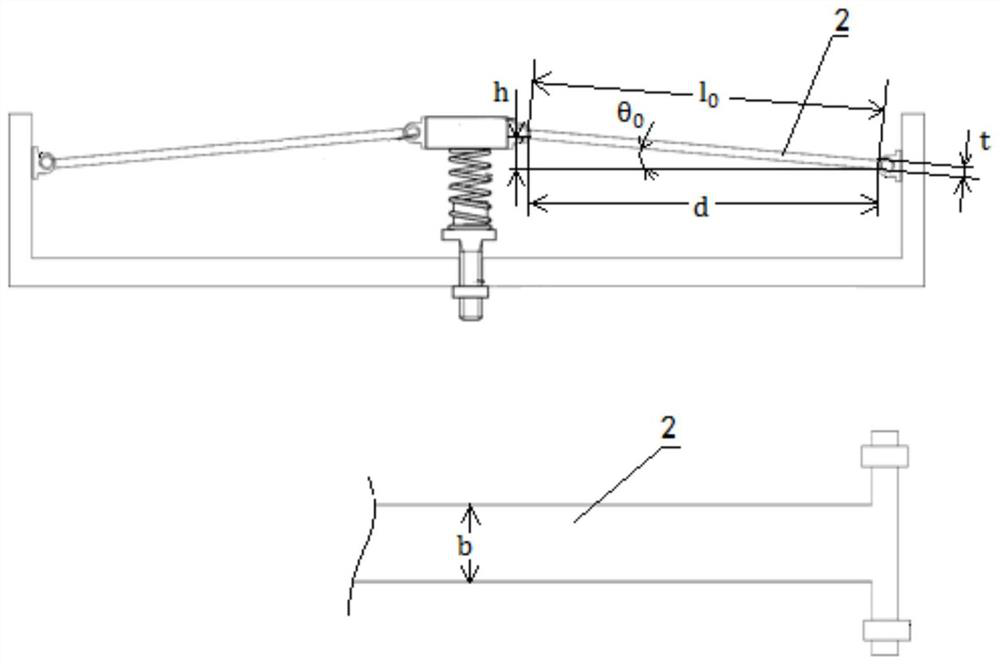

[0059] The invention provides a quasi-zero-stiffness vibration isolator for inclined compression rods, such as figure 1 , 2 As shown in a), 2b) and 5, the quasi-zero stiffness vibration isolator of the inclined compression rod includes:

[0060] shell4;

[0061] Platform 1, the platform 1 is located on the upper part of the shell 4;

[0062] The rod body 2, the rod body 2 includes a first end and a second end, the first end of the rod body 2 is hinged with the platform 1, and the second end of the rod body 2 is hinged with the shell 4; the cross section of the rod body 2 is rectangular, and the rod body 2 Both the width dimension d and the thickness dimension h are slightly smaller than the length dimension l 0 , that is, the rod body 2 as a whole presents a wide and thick rod shape, and when the rod body 2 is deformed, the wide and thick rod shape prevents it from bending and becoming unstable. In this embodiment, four rod bodies 2 are symmetrically distributed around the...

Embodiment 2

[0107] The invention provides a quasi-zero-stiffness vibration isolator for inclined compression rods, such as Figure 6 As shown, the oblique compression rod quasi-zero stiffness vibration isolator includes:

[0108] shell4;

[0109] Platform 1, the platform 1 is located on the upper part of the shell 4;

[0110] The rod body 2, the rod body 2 includes a first end and a second end, the first end of the rod body 2 is hinged with the platform 1, and the second end of the rod body 2 is hinged with the shell 4; the cross section of the rod body 2 is rectangular, and the rod body 2 Both the width dimension d and the thickness dimension h are slightly smaller than the length dimension l 0 , that is, the rod body 2 as a whole presents a wide and thick rod shape, and when the rod body 2 is deformed, the wide and thick rod shape prevents it from bending and becoming unstable. In this embodiment, four rod bodies 2 are symmetrically distributed around the center of the platform 1 . ...

Embodiment 3

[0116] The invention provides a quasi-zero-stiffness vibration isolator for inclined compression rods, such as Figure 7 As shown, the oblique compression rod quasi-zero stiffness vibration isolator includes:

[0117] shell4;

[0118] Platform 1, the platform 1 is located on the upper part of the shell 4;

[0119] The rod body 2, the rod body 2 includes a first end and a second end, the first end of the rod body 2 is hinged with the platform 1, and the second end of the rod body 2 is hinged with the shell 4; the cross section of the rod body 2 is rectangular, and the rod body 2 Both the width dimension d and the thickness dimension h are slightly smaller than the length dimension l 0 , that is, the rod body 2 as a whole presents a wide and thick rod shape, and when the rod body 2 is deformed, the wide and thick rod shape prevents it from bending and becoming unstable. In this embodiment, four rod bodies 2 are symmetrically distributed around the center of the platform 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com