Composite material mould with reinforcing structure and preparation method thereof

A technology for strengthening structures and composite materials, applied in the field of composite material molds, can solve problems such as low cost rate and unsatisfactory mold service life, and achieve the effect of enhancing stability and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For a more convenient understanding of the content of the present implementation model, the left and right, up and down involved in the following descriptions are consistent with the directions in the drawings.

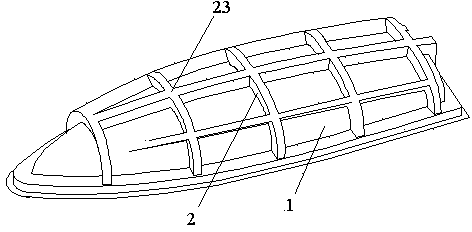

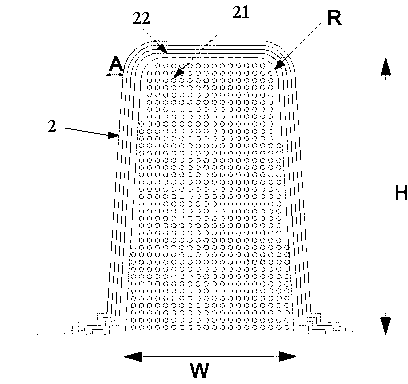

[0026] Such as figure 1 , 2 As shown, the composite material mold with a reinforced structure includes a mold shell 1, and the mold shell 1 is provided with a reinforcement structure 2 that is criss-crossed and hooked into a "well" shape, and the reinforcement structure 2 has a foam core material 21, The surface of the foam core material 21 is laid with several layers of uniaxial glass fiber cloth 22 to form a glass fiber reinforced plastic 23, the thickness of the glass fiber reinforced plastic 23 is at least 1 / 2 of the thickness of the glass fiber reinforced plastic on the mold shell 1, and the reinforcement structure 2 covers The corner part of the mold shell 1 is removed, and the foam core material 21 is made of polyurethane foam.

[0027] The method for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com