Production die and production process for glass chopsticks

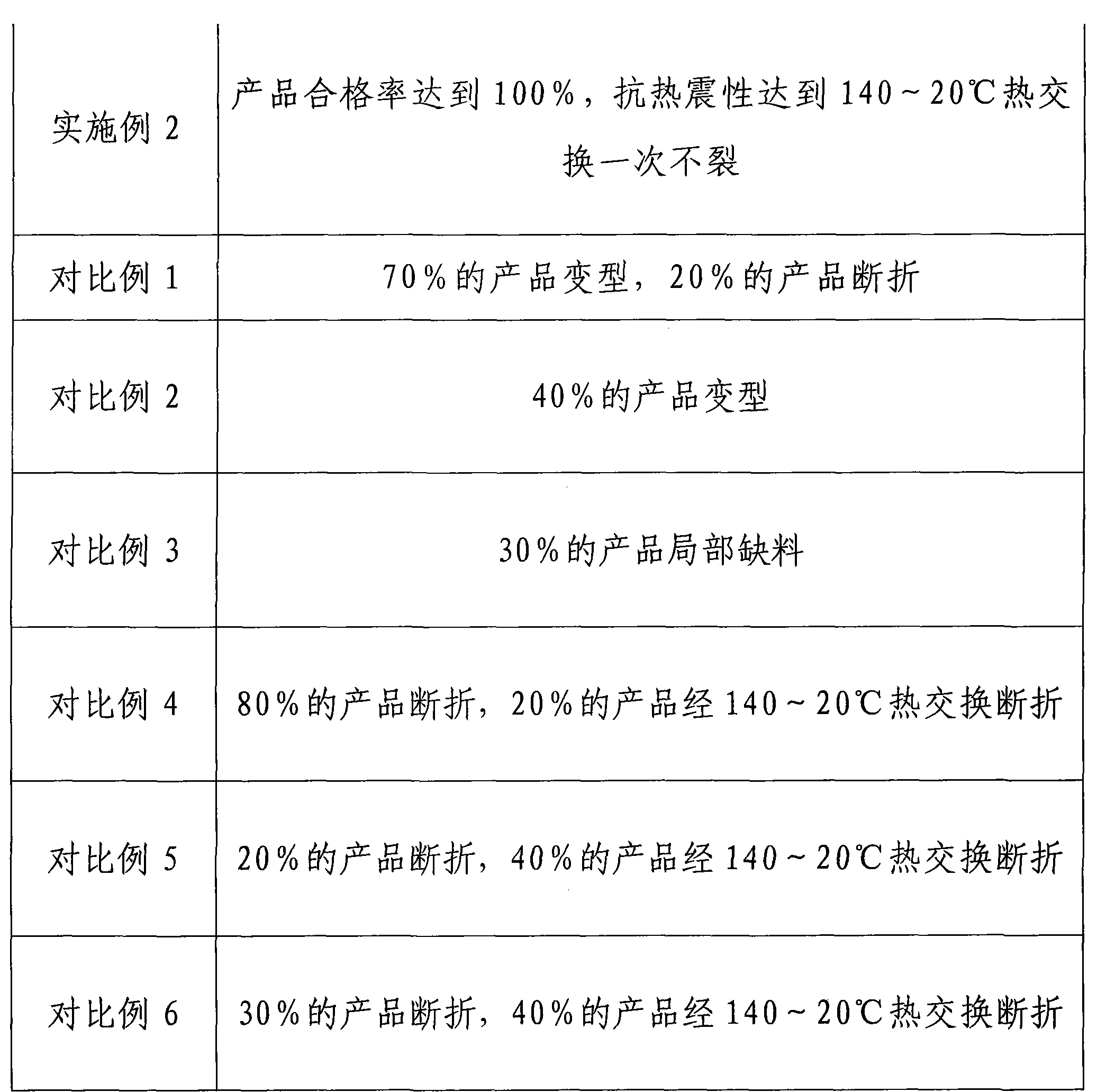

A production process and technology for chopsticks, which are applied to the production mold and production process of glass chopsticks, can solve the problems of easy breaking, easy product deformation, low regularity, etc., and achieve extended mold opening time, low production cost, and high product qualification rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

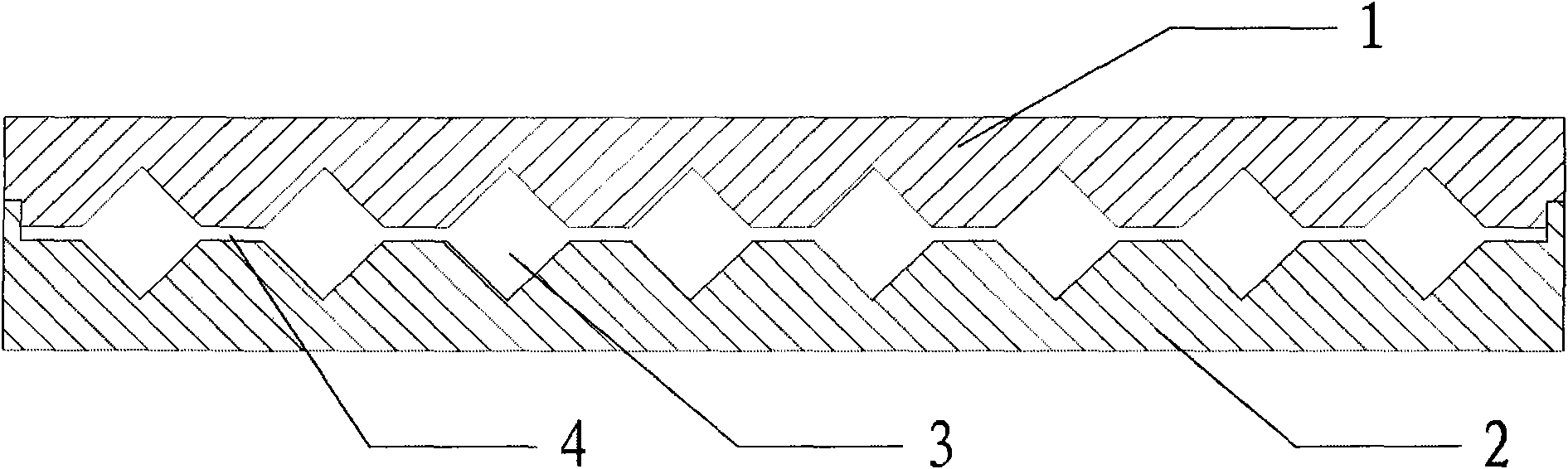

[0020] Embodiment 1: as figure 1 As shown, the production mold of the glass chopsticks of the present invention is composed of an upper mold 1 and a lower mold 2. A plurality of chopstick-shaped mold cavities 3 are arranged in the mold, and there are communication gaps 4 between the mold cavities 3 .

Embodiment 2

[0021] Embodiment 2: the production technology of glass chopsticks of the present invention comprises:

[0022] (1) Glass raw material smelting: the glass raw material is smelted at 1500°C to make glass slurry for later use;

[0023] (2) Press molding of glass chopsticks: put figure 1 The mold is installed on the hydraulic machine tool, and the mold is in the mold opening state of the upper and lower molds;

[0024] The spare glass slurry is metered and injected into the lower mold 2 of the mold. When the temperature of the glass slurry in the mold cavity 3 cools down to 950°C, the upper mold 1 descends and matches with the lower mold 2 to form a mold clamping; due to the pressure of the upper mold 1, the glass slurry squeezes out. Full cavity 3 and flow gap 4 between cavity 3;

[0025] After 2 seconds of mold closing, the mold is opened, the upper mold 1 rises, and the formed glass chopsticks connected in rows are taken out from the mold cavity 3 with a clamp;

[0026] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com