Plastic composite board and preparation method thereof

A technology for composite boards and manufacturing methods, which is applied in the field of construction boards and decorations, can solve problems such as deformation or distortion of the overall board surface, increased construction difficulty, and falling off, so as to improve product wear resistance, increase product added value, and prolong the life of the board. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

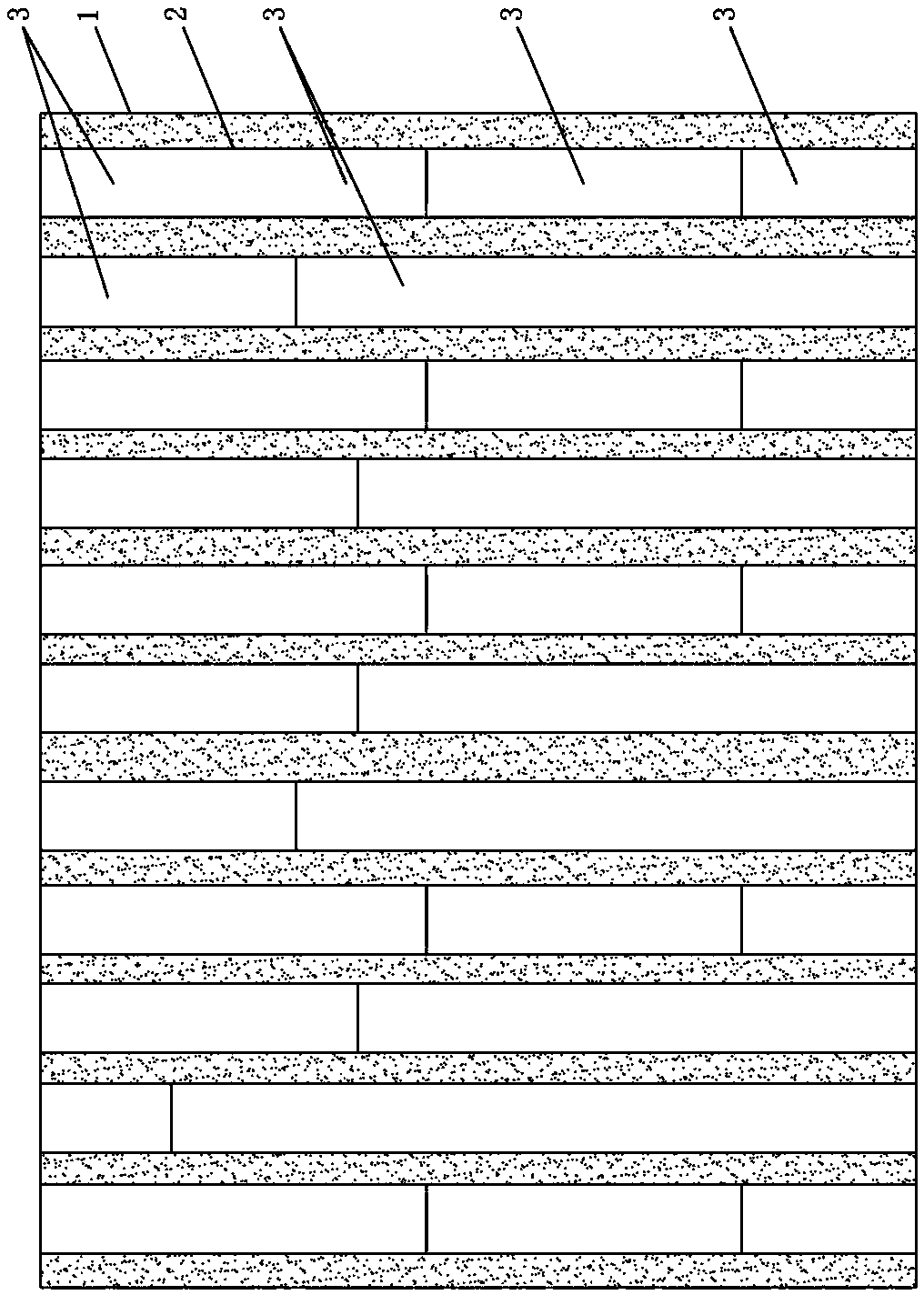

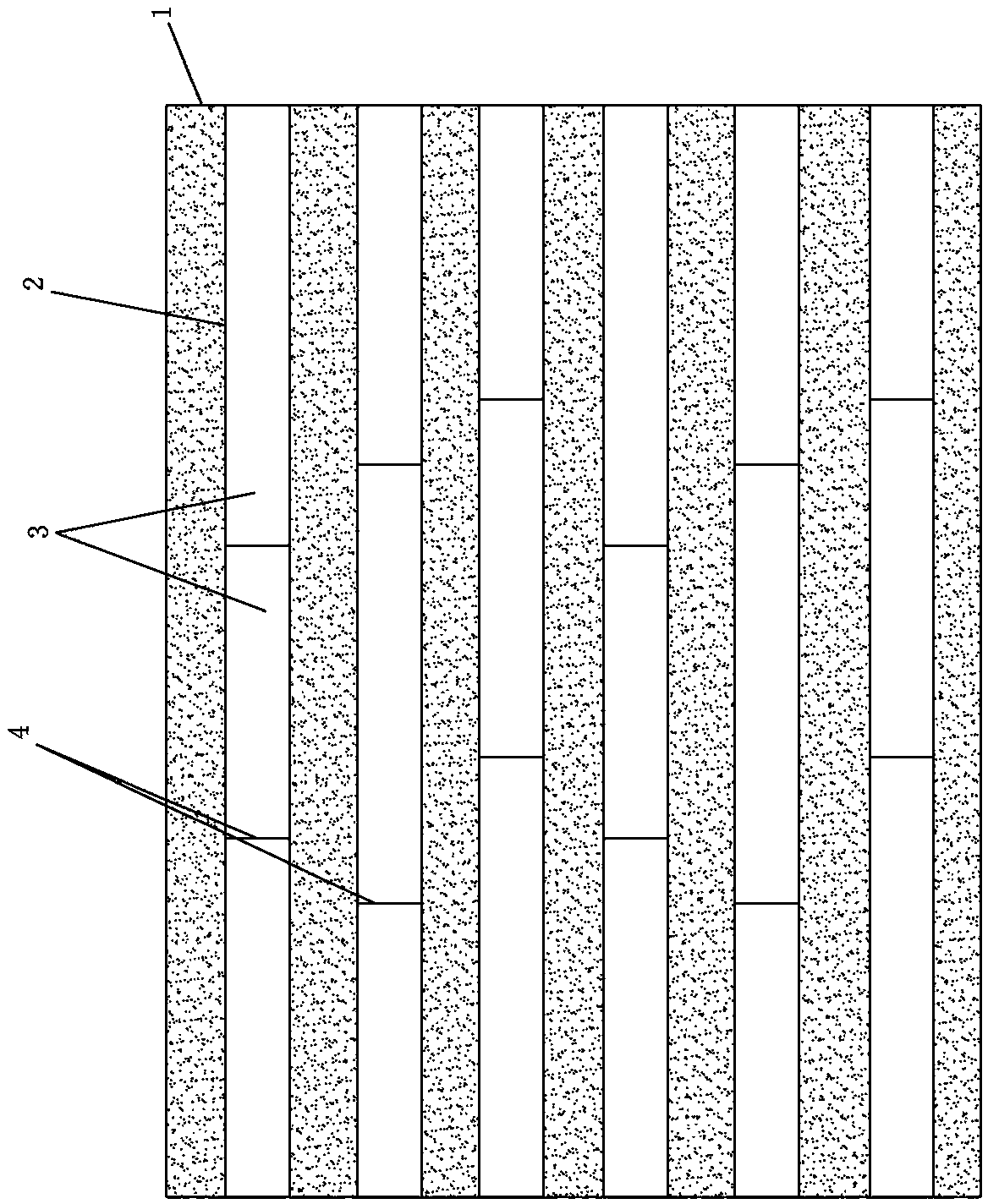

[0041] The plurality of ribbed panels 2 are composed of multiple groups of wooden square boards arranged vertically or horizontally, each group of wooden square boards is composed of at least two wooden square strips 3 that are butted front and back, and two adjacent groups The connection sections 4 of the front and rear two wooden square strips 3 of the wooden square board body are arranged in a dislocation manner.

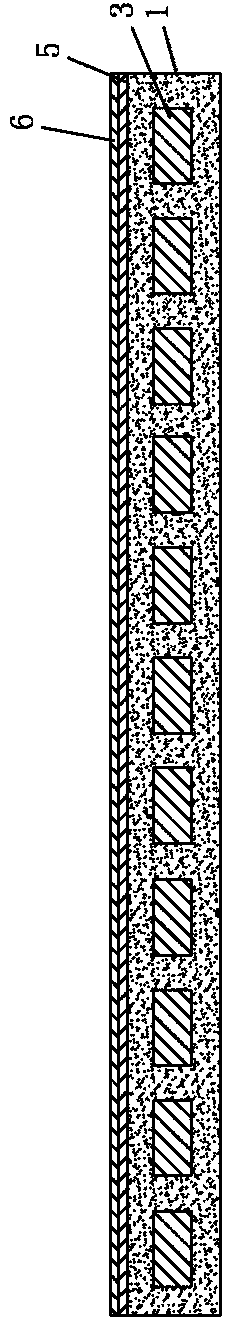

[0042] The surface of the plastic outer layer 1 is rolled with a decorative pattern layer 5; the pattern layer 5 can be various patterns, imitation wood grain texture and the like.

[0043] The surface of the plastic outer layer 1 or the decorative pattern layer 5 is spray-coated to cover the wear-resistant layer 6; it can improve the wear resistance of the product and prolong the service life of the product, which is also a conventional means of traditional boards.

[0044] The rib plate 2 and the plastic outer layer 1 are connected and fused into a whole by hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com