Production method of optical fiber F-P cavity sensor

A manufacturing method and sensor technology, which are applied in the direction of using optical devices to transmit sensing components, coupling of optical waveguides, etc., can solve problems such as poor sealing performance, inability to withstand high temperature strength, and inability to apply, and achieve uniform angular stress and sealing performance. Good and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

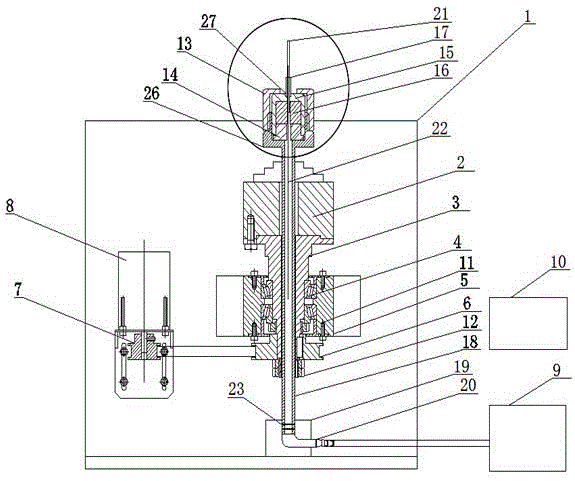

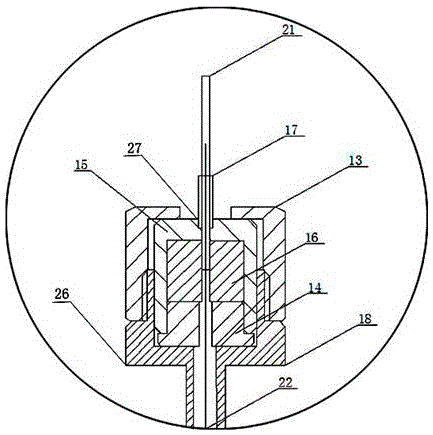

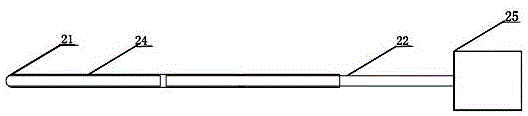

[0032] like Figure 1-2 As shown, a manufacturing device of an optical fiber F-P cavity sensor, it includes a device bracket 1 provided with a fixing seat 5, in which a tapered roller bearing 4 is fixed; the top of the hollow fixed shaft 3 and the hollow three-claw clamp The disk 2 is fixedly connected; the middle part of the fixed shaft 3 passes through the tapered roller bearing 4 and is supported and fixed on the device bracket 1 and pivots around the axis of the fixed shaft 3 relative to the device bracket 1. The bottom of the fixed shaft 3 is fixedly connected with the large synchronous pulley 6 ;; The small synchronous pulley 7 driven by the large synchronous pulley 6 and the stepper motor 8 is driven by a belt; the hollow tube shaft 18 passes through the center of the three-jaw chuck 2 and the fixed shaft 3, and the upper part of the tube shaft 18 is clamped by the three-jaw The disc 2 is clamped and rotated with the three-jaw chuck 2. The lower end of the tube shaft 18...

Embodiment 2

[0034] Embodiment 2: The similarities between this embodiment and Embodiment 1 will not be repeated, the difference is that it is a method for manufacturing an optical fiber F-P cavity sensor, which uses the manufacturing device for an optical fiber F-P cavity sensor described in Embodiment 1 , which includes the following steps: (1) Build the welding system device, fix the tapered roller bearing 4 in the fixed seat 5, extend the fixed shaft 3 into the three-jaw chuck 2 and the tapered roller bearing 4 and fix it, and use a tight The fixed nut 12 fixes the position of the large synchronous pulley 6, and connects the small synchronous pulley 7 and the stepper motor 8, and extends the tube shaft 18 into the gap between the three-jaw chuck 2, the fixed shaft 3 and the tapered roller bearing 4 , and inserted into the tube shaft base 19, the tube shaft 18 and the tube shaft base 19 realize dynamic sealing through the seal ring 23, the tube shaft base 19 is fixed on the device bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com