Split type air foot

A split-type, air-footed technology, applied to physical instruments, bearings, shafts, etc., can solve problems such as air flotation loss of function, and achieve the effect of high air flotation requirements and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

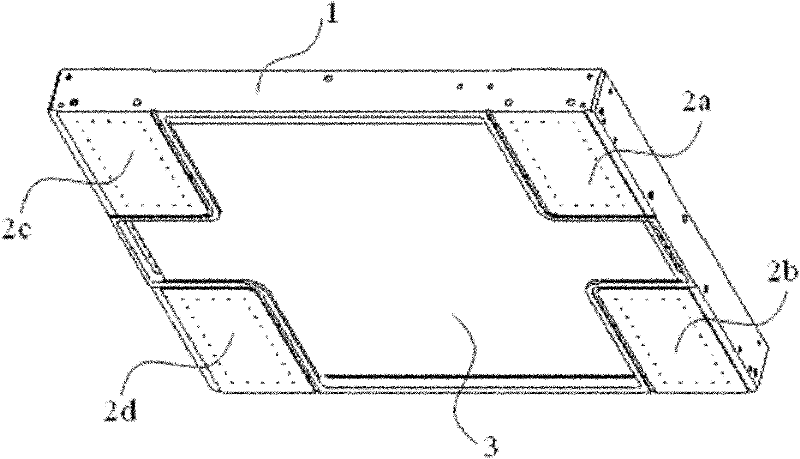

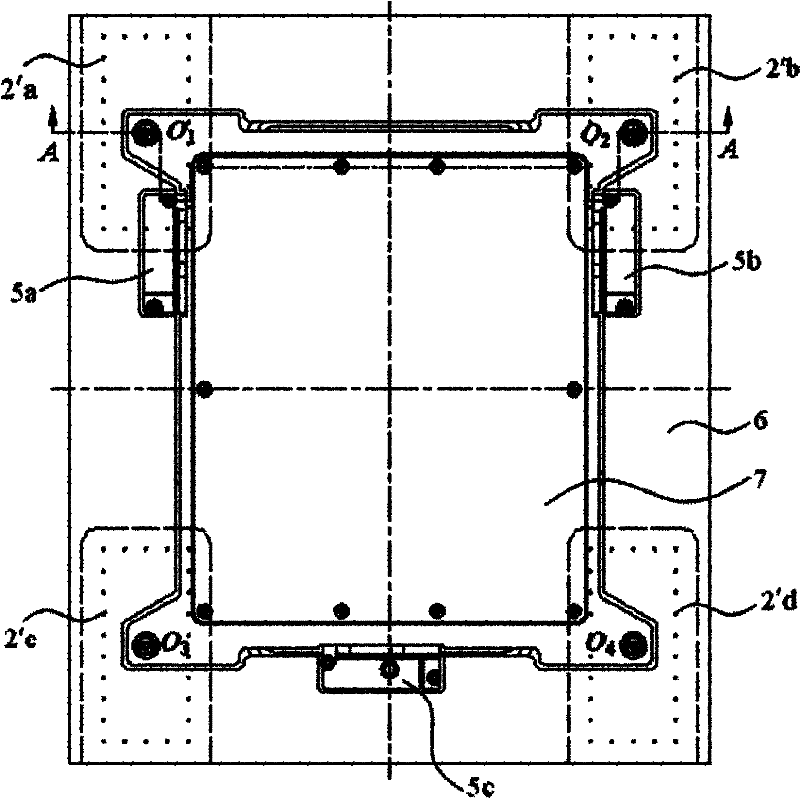

[0028] The following will combine Figure 3 ~ Figure 7 The split type air foot of the present invention is further described in detail.

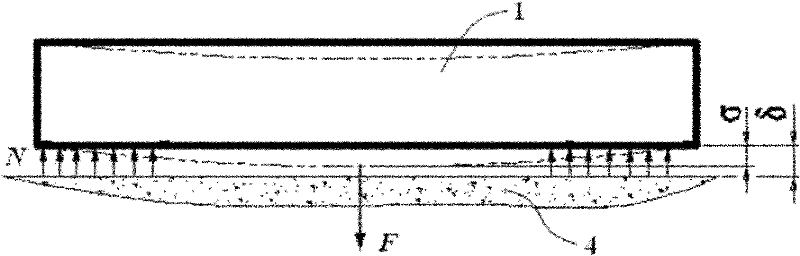

[0029] The split air foot of the present invention includes an air foot plate, an air floating structure arranged at the bottom of the air foot plate, and a vacuum preload structure arranged on the air foot plate, and the vacuum preload structure is connected to the air foot plate The air foot plate is split-connected, and the connection point between the vacuum preload structure and the air foot plate is on the same straight line perpendicular to the platform as the center of the air flotation structure, and the vacuum preload force The position of the bottom surface of the structure is higher than the position of the bottom surface of the air foot plate, and a vacuum cavity is formed between the bottom surface of the vacuum pre-tightening force structure and the bottom surface of the air foot plate.

[0030] The split type air foot of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com