Sheet-type contact component, electric connector and printed board component

A technology of electrical connectors and contacts, which is applied in the direction of contact parts, fixed/insulated contact components, connections, etc., can solve the problems of large volume of high-current connectors, and achieve the effect of simple structure, large volume and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

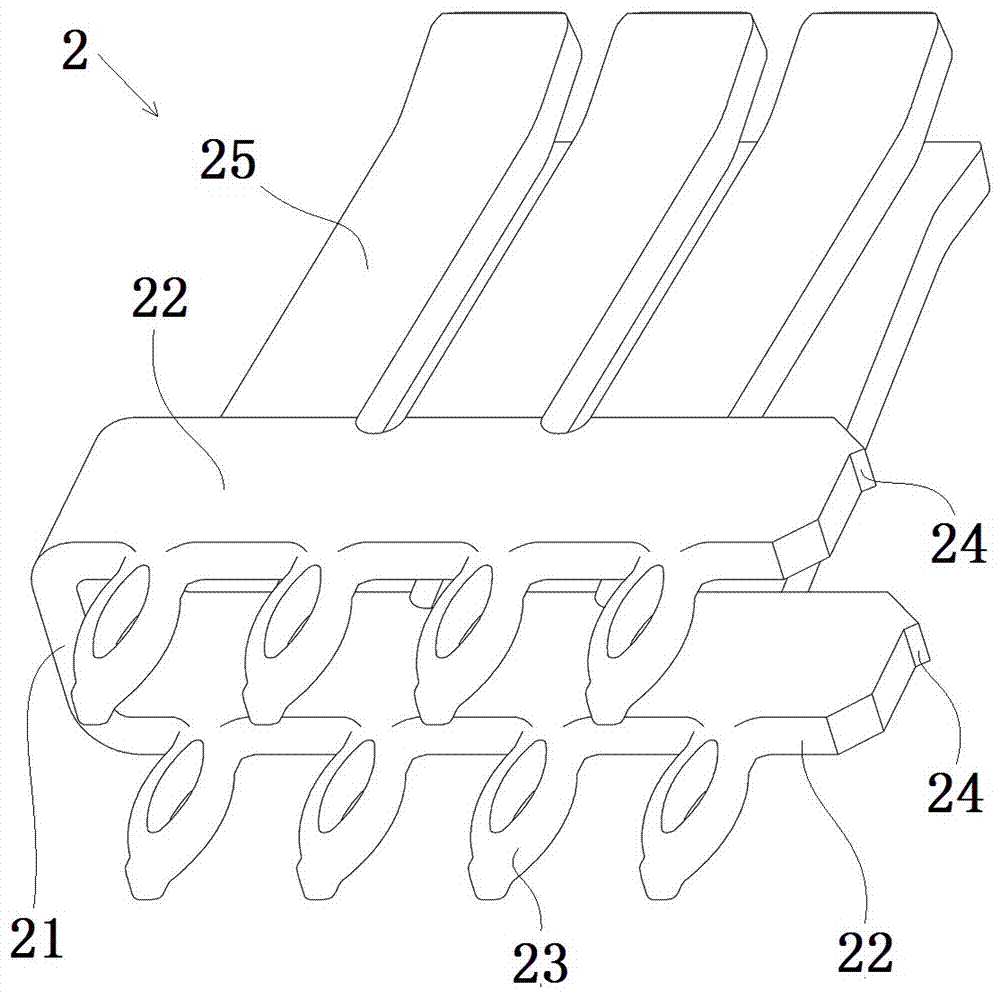

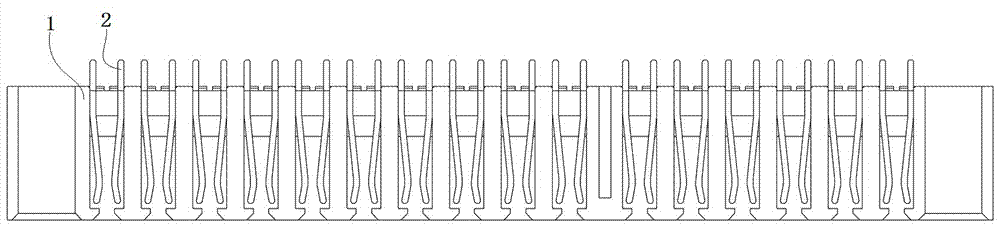

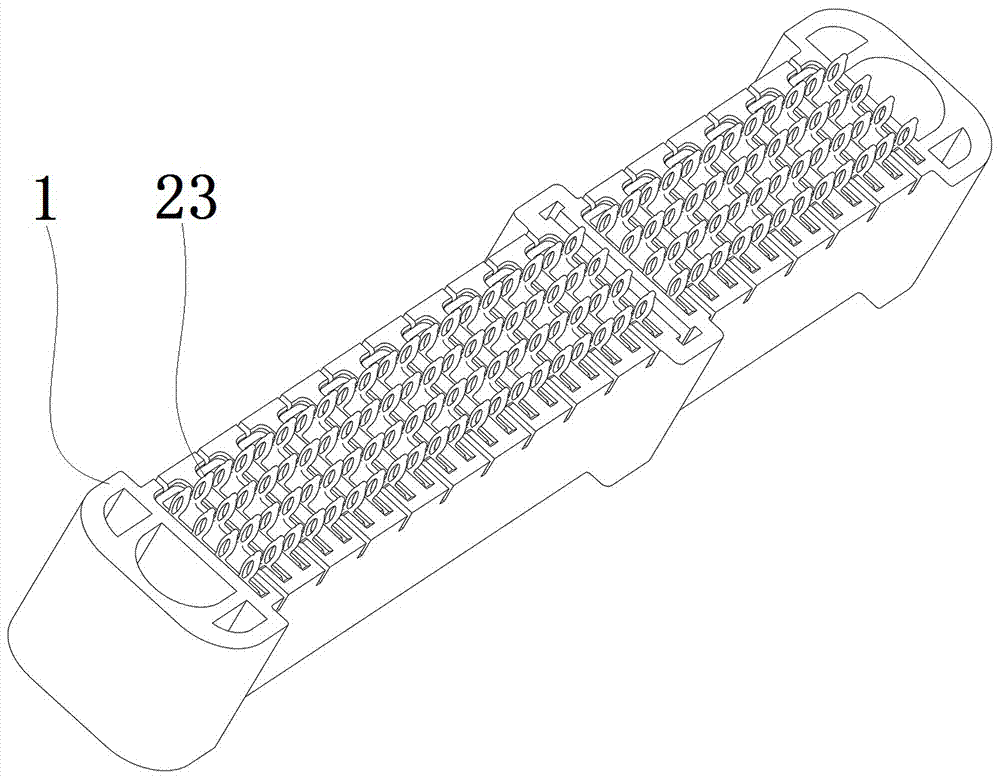

[0037] A specific embodiment of the printed board assembly of the present invention, such as Figure 1 to Figure 4 As shown, the printed board assembly includes a printed board 4 and a socket installed on the printed board 4, and the socket is an electrical connector. The electrical connector includes an insulator 1 provided with a slot and a blade contact 2 installed in the slot. The blade contact 2 includes a beam and a conductive piece 25 arranged on the beam. The beam is a U-shaped frame structure surrounded by a vertical plate 21 extending in the vertical direction and two extension plates 22 that are arranged on the front and rear sides of the vertical plate 21 and extend to the right. The slots run through the front and rear sides of the insulator , its cross-sectional shape is U-shaped adapted to the shape of the beam, the upper notch of the slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com