Smart card conveyer belt and smart card conveying mechanism

A conveying mechanism and conveying belt technology, applied in the field of smart card production equipment, can solve problems such as deformation, text cannot be typed, affecting production efficiency, etc., and achieve the effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

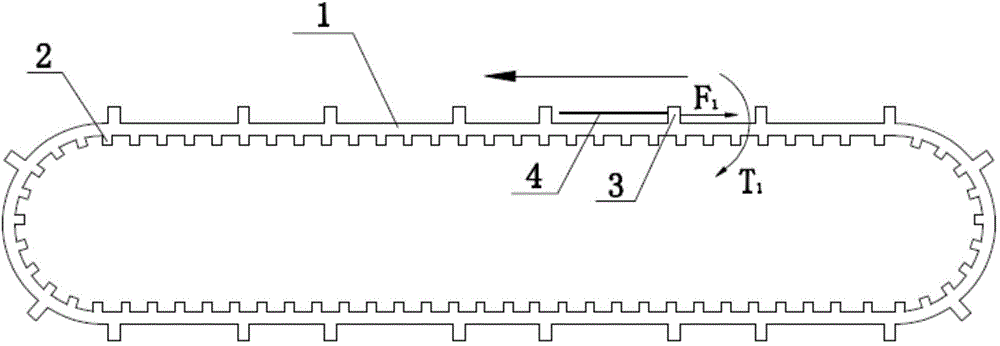

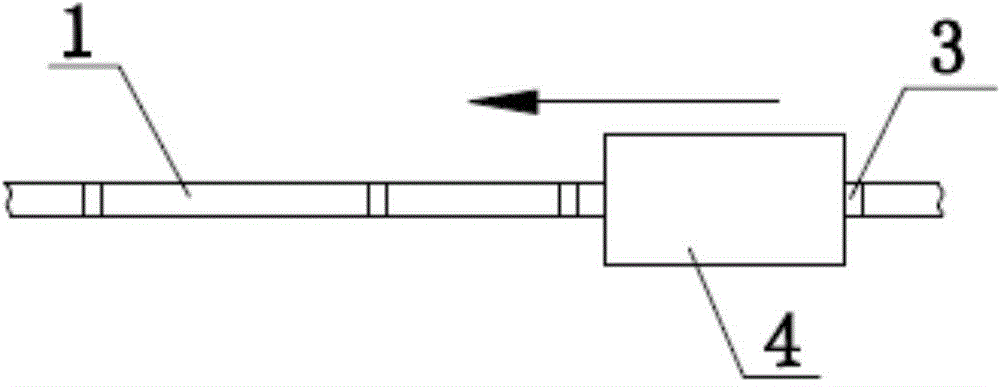

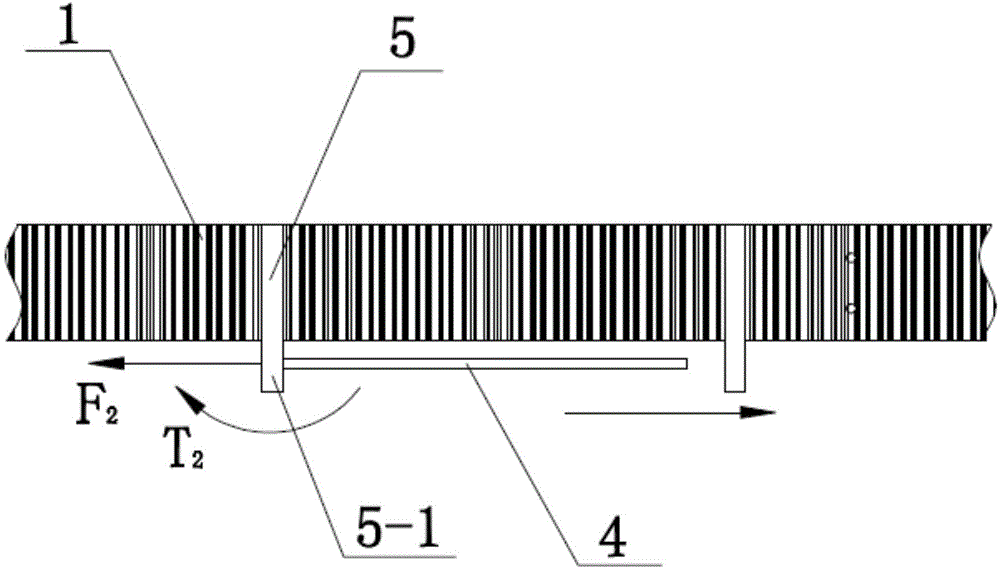

[0038] see Figure 3 to Figure 5 , the smart card conveyor belt of the present invention includes a synchronous belt body 1, which is provided with several rigid shifting teeth 5, and the shifting teeth 5 extend along the height direction of the synchronous belt body 1 and extend out of the synchronous belt The lower edge of the belt body 1 , the protruding part constitutes the card pushing part 5 - 1 for pushing the card 4 .

[0039] see Figure 3 to Figure 5 , the shifting tooth 5 is arranged on the outer belt surface of the synchronous belt body 1, and the shifting tooth 5 and the synchronous belt body 1 are integrally formed. In this way, when the synchronous belt body 1 is formed, the shifting teeth 5 are formed, and the subsequent installation of the shifting teeth 5 can be omitted. The disadvantage is that once the position of the shifting teeth 5 is formed, it cannot be changed.

[0040] see Figure 3 to Figure 5 , the inner belt surface and the outer belt surface o...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is:

[0047] see Figure 9 to Figure 12 , In the conveyor belt of this embodiment, the timing belt body 1 is provided with timing teeth 2 only on the inner belt surface. The shifting tooth 5 is an independent member made of metal connected to the synchronous belt body 1. The shifting tooth 5 includes a main rod 5-4 and clamping parts arranged on the back side of the upper and lower ends of the main rod 5-4. A piece 5-2, a clamping space 5-3 for clamping the upper and lower edges of the synchronous belt body 1 is provided between the clamping piece 5-2 and the main rod 5-4, and the clamping Part 5-2, the synchronous belt body 1 and the main rod 5-4 are fixedly connected together by screw connection, wherein the main rod 5-4 is located on the outer surface of the synchronous belt body 1, and the clamping part 5- 2 is located on the inner belt surface of the belt body 1 of the synchronous belt. The joint surface of...

Embodiment 3

[0051] see Figure 14 to Figure 17 The difference between this embodiment and embodiment 2 is that, in this embodiment, the inner belt surface and the outer belt surface of the synchronous belt body 1 are provided with synchronous teeth 2, and the main rod 5- 4 is matched to the tooth groove on the outer belt surface of the synchronous belt body 1, and the clamping part 5-2 is matched to the tooth groove on the inner belt surface of the synchronous belt body 1. Since both sides of the synchronous belt body 1 are provided with synchronous teeth 2, the main rod 5-4 and the clamping part 5-2 can be matched in the tooth groove, which not only facilitates the main rod 5-4 and the clamping part 5 -2 is fixed, and the force-bearing area between the shifting tooth 5 and the synchronous belt body 1 is improved, especially the cooperation between the side of the main rod 5-4 and the clamping part 5-2 and the side of the tooth groove, which can make the affected The force is uniform and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com