Three-plate type high-energy-consumption viscous damping wall

A viscous damping wall and high energy consumption technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problem that the viscous damping wall's shock absorption and energy consumption effect cannot reach the expected value, and it cannot be well adapted to site requirements. The energy dissipation capacity of the damping wall is reduced, and the effective contact area is increased, the energy dissipation capacity is strong, and the energy dissipation capacity is enhanced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

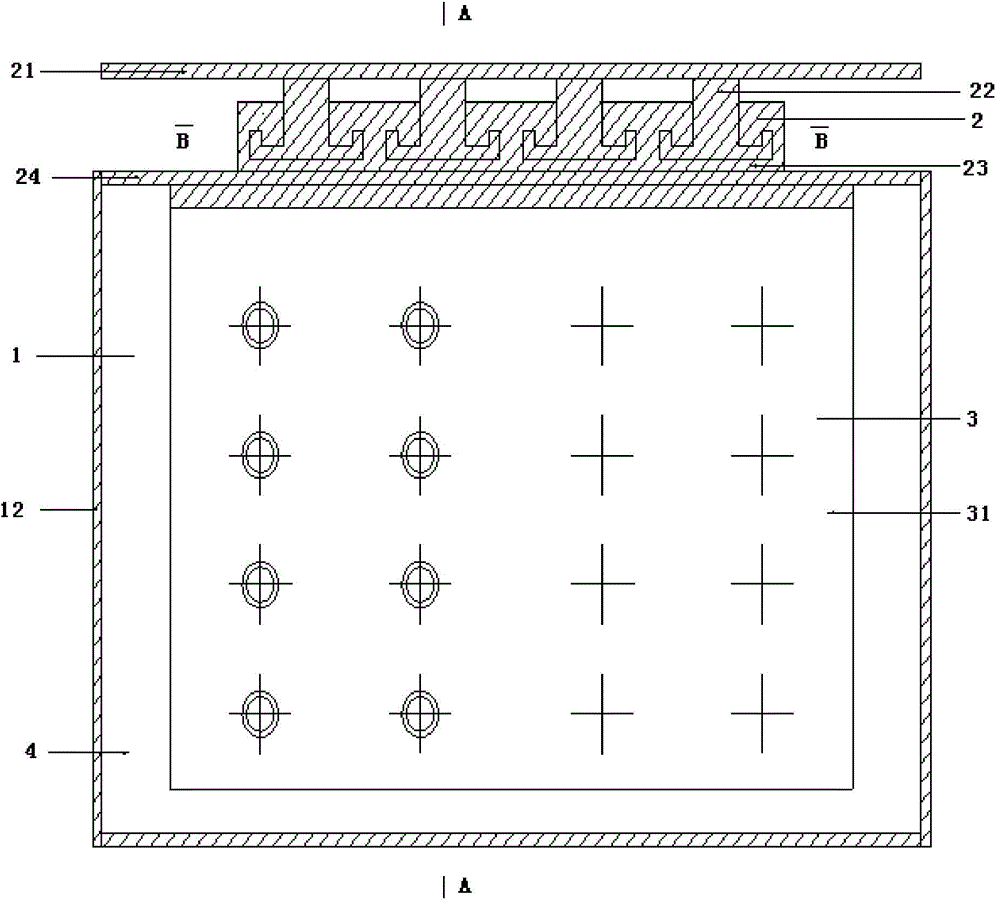

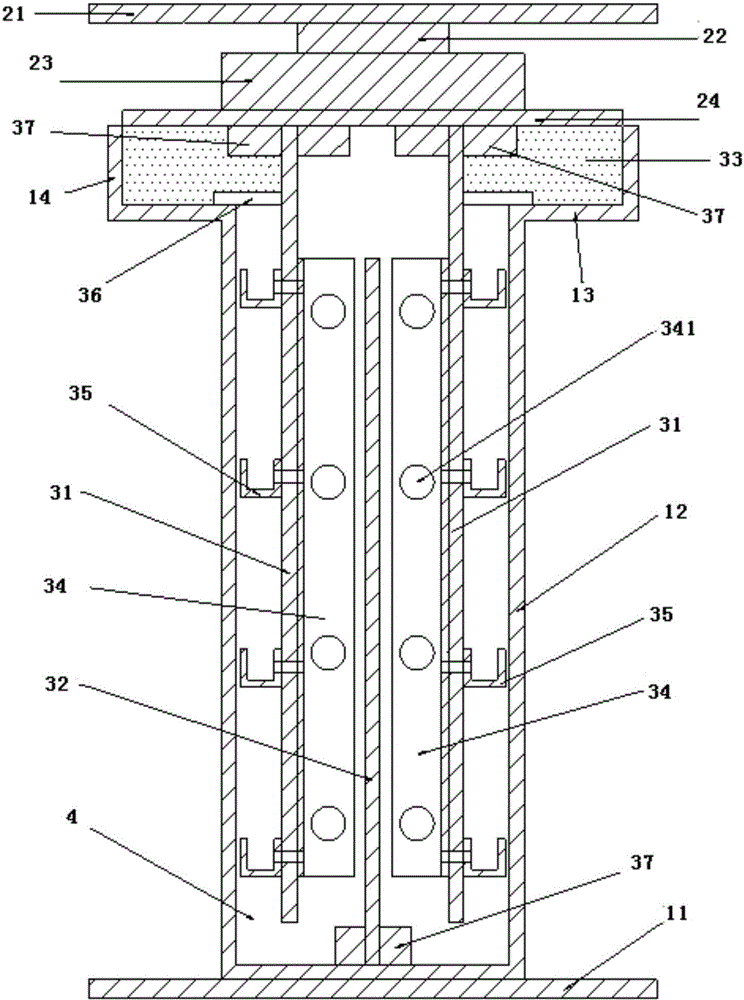

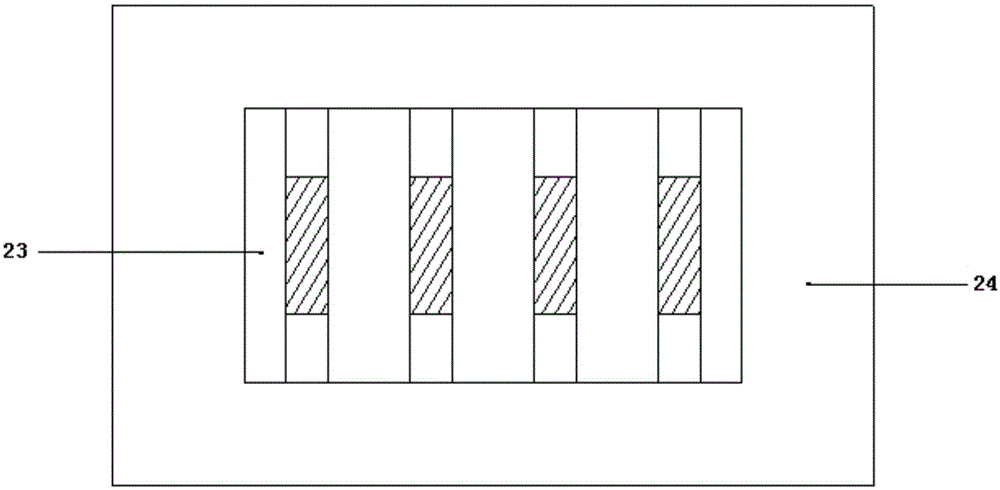

[0032] Such as figure 1 and figure 2 As shown, a three-plate viscous damping wall with high energy consumption is set between the upper and lower floor beams for shock absorption and energy dissipation of the building structure, including the wall 1 and the top seal 2, the upper floor beams, The top seal 2, the wall 1 and the lower floor beams are connected in sequence, the wall 1 and the top seal 2 are connected to form a wall sealing space, and the energy dissipation damping structure 3 is arranged in the wall sealing space, and the energy dissipation damping structure 3 includes The upper inner steel plate 31 and the lower inner steel plate 32, the upper inner steel plate 31 is provided with two pieces, which are rigidly connected with the top seal 2 respectively, and the lower inner steel plate 32 is arranged between the two upper inner steel plates 31, and is rigidly connected to the bottom of the wall body 1 catch.

[0033] The energy dissipation damping structure 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com