A crack-resistant high-impact and wear-resistant repair material

A repair material and high impact resistance technology, which is applied in the field of cement-based repair materials, can solve the problems of high technical requirements for operation, easy cracking of the repair layer, and high product price, so as to improve crack resistance, eliminate harmful bubble defects, and improve compactness and the effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

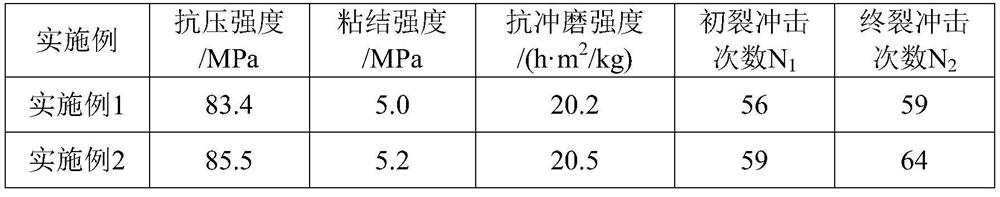

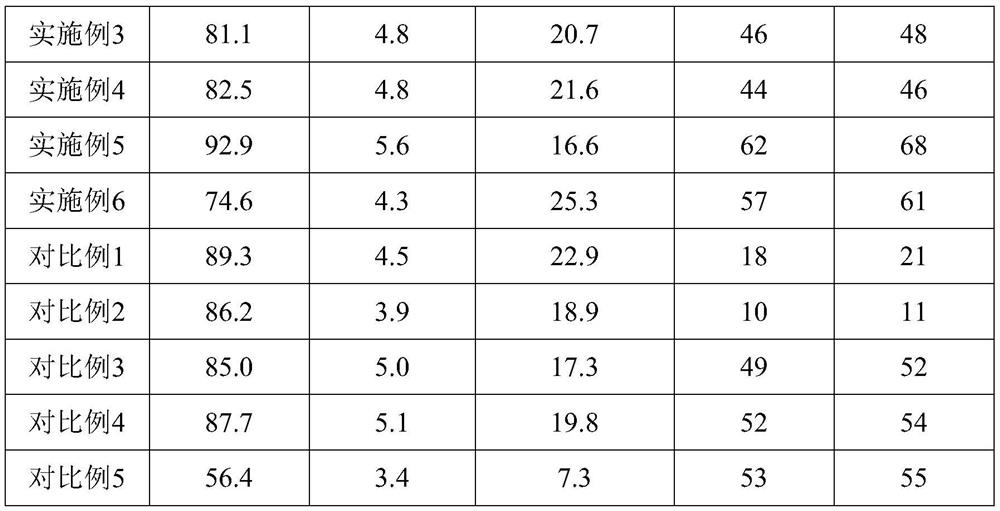

Embodiment 1

[0025] A crack-resistant high-impact and wear-resistant repair material, comprising the following raw materials by mass: 340 parts of P·Ⅱ 52.5 cement, 8.0 parts of silicon powder, 53.2 parts of finely ground slag, 1.2 parts of carbon nanotubes, and 576 parts of iron ore 8.0 parts of pure acrylic redispersible rubber powder, 0.6 parts of water-absorbing resin, 0.8 parts of plastic expansion agent, 7.0 parts of UEA expansion agent, 3.2 parts of magnesium oxide expansion agent, 1.8 parts of polycarboxylate water reducer, polyether type dispersant Foam agent 0.2 part.

Embodiment 2

[0027] A crack-resistant high-impact and wear-resistant repair material, comprising the following raw materials by mass: 355 parts of P·O4 2.5 cement, 8.0 parts of silicon powder, 54.2 parts of finely ground slag, 2.0 parts of carbon nanotubes, and 556 parts of iron ore 10.0 parts of pure acrylic redispersible rubber powder, 0.5 parts of water-absorbent resin, 0.9 parts of plastic expansion agent, 8.2 parts of UEA expansion agent, 3.0 parts of magnesium oxide expansion agent, 1.9 parts of polycarboxylate water reducer, polyether type Foam agent 0.3 parts.

Embodiment 3

[0029] A crack-resistant high-impact and wear-resistant repair material, comprising the following raw materials by mass: 315 parts of P·Ⅱ 52.5 cement, 7.2 parts of silicon powder, 60.8 parts of finely ground slag, 1.4 parts of carbon nanotubes, and 591 parts of iron ore 9.0 parts of styrene-acrylic redispersible rubber powder, 0.8 parts of water-absorbing resin, 0.8 parts of plastic expansion agent, 9.0 parts of UEA expansion agent, 3.2 parts of magnesium oxide expansion agent, 1.6 parts of polycarboxylate water reducer, silicone defoaming agent 0.2 parts of the agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com