A kind of underwater composite anti-corrosion coating and preparation method thereof

A technology of anti-corrosion coating and surface coating, which is applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of not meeting the dual requirements of anti-corrosion and impact protection, and meet the requirements of anti-corrosion and anti-abrasion, and construction difficulty High and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. Preparation equipment for epoxy nano-titanium primer:

[0057] (1) PM 400 Planetary Ball Mill Verder (Shanghai) Instrument Equipment Co., Ltd.

[0058] (2) Frequency conversion dispersing machine Qinhuangdao Oulu Chemical Machinery Co., Ltd.

[0059] (3) Rod Pin Sand Mill Qinhuangdao Oulu Chemical Machinery Co., Ltd.

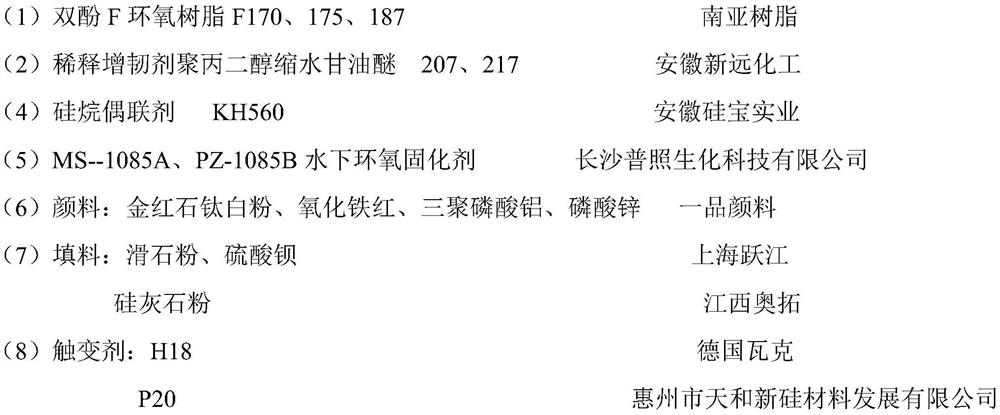

[0060] 2. Reagents for the preparation of epoxy nano-titanium primer:

[0061]

[0062] 3. Preparation method of epoxy nano-titanium primer:

[0063] (1) According to parts by weight, 80 parts of bisphenol F170 epoxy resin, 20 parts of polymalonate diglycidyl ether 207 prepare ball milling medium solution;

[0064] (2) According to the ratio of ball milling medium solution to titanium powder mass ratio of 10:1, pour the micron titanium powder (400 mesh) into the ball milling medium solution and disperse and stir in the frequency conversion shearing disperser, the stirring speed is 800r / mim, and the stirring time is 15min Finally, put it into the...

Embodiment example 2

[0075] (1) according to 80 parts of bisphenol F187 epoxy resins, the ratio of polymalonate diglycidyl ether 217 20 parts is mixed with ball milling medium solution;

[0076] (2) Mix the 400-mesh micron titanium powder with the ball milling medium solution, perform high-energy ball milling, the ball milling tank speed is 400r / min, and the ball milling time is 4h to obtain 80nm titanium nano-modified polymer slurry;

[0077] (3) According to bisphenol F170 epoxy resin 40%, 217 polypropylene glycol diglycidyl ether diluent 8%, silane coupling agent 1.5%, defoamer 0.1%, wetting agent disperser BYK-P105 0.5%, pigment : iron oxide red 5%, aluminum tripolyphosphate 10%, zinc phosphate 14%, filler: barium sulfate 13%, mix by above raw material ratio, mixing process is with embodiment 1;

[0078] (4) Pour a certain proportion of titanium nano-modified polymer slurry into the epoxy anti-corrosion coating base liquid, mix according to the mass ratio of 20:80, the mixing process is the sa...

Embodiment 3

[0088] (1) According to 83 parts of bisphenol F170 epoxy resin, polymalonate diglycidyl ether 207, 15 parts of silane coupling agent KH560 2 parts, the ratio is mixed into ball milling medium solution;

[0089] (2) Mix the titanium powder with the ball milling medium solution, carry out high-energy ball milling, the ball milling tank speed is 400r / min, and the ball milling time is 3.5h, to obtain 85nm titanium nano-modified polymer slurry;

[0090] (3) Bisphenol F170 epoxy resin 40%, 207 polypropylene glycol diglycidyl ether diluent 8%, silane coupling agent 1.5%, defoamer 0.1%, wetting agent disperser BYK-P105 0.5%, pigment 8% of rutile titanium dioxide, filler: 21% of barium sulfate, 5% of talcum powder, 10% of wollastonite powder, mixed according to the above ratio, and the mixing process is the same as that of Example 1;

[0091] (4) Pour the titanium nano-modified polymer slurry into the epoxy anti-corrosion coating base liquid, mix according to the mass ratio of 15:100, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com