High-strength concrete cementitious composition and high-strength concrete thereof

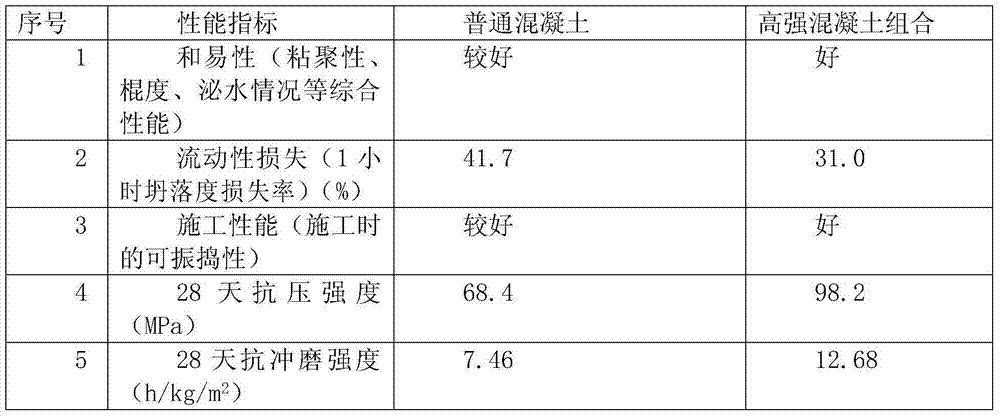

A technology of high-strength concrete and composition, applied in the field of building materials, can solve the problems of thick concrete, poor comprehensive quality, and large amount of glue material, and achieve good impact and wear resistance, good construction performance, and small loss of fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Using 155 parts of water, 521 parts of ordinary Portland cement, 50 parts of fly ash, 50 parts of silica fume, 567 parts of artificial sand, 1008 parts of small stone, 9.92 parts of superplasticizing enhancer, 1.24 parts of retarder as raw materials, water Concrete prepared with a rubber ratio of 0.25 has a 28-day compressive strength of 98.7MPa and a 28-day impact and abrasion resistance of 13.2h / (kg / m 2 ).

Embodiment 2

[0026] Using 155 parts of water, 496 parts of ordinary Portland cement 52.5, 74 parts of fly ash, 50 parts of silica fume, 567 parts of artificial sand, 1008 parts of small stone, 9.92 parts of superplasticizing enhancer, 1.24 parts of retarder as raw materials, water Concrete prepared with a rubber ratio of 0.25 has a 28-day compressive strength of 97.5MPa and a 28-day impact and wear resistance of 13.2h / (kg / m 2 ).

Embodiment 3

[0028] Using 155 parts of water, 446 parts of ordinary Portland cement 52.5, 124 parts of fly ash, 50 parts of silica fume, 567 parts of artificial sand, 1008 parts of small stone, 9.92 parts of superplasticizing enhancer, 1.24 parts of retarder as raw materials, water Concrete prepared with a rubber ratio of 0.25 has a 28-day compressive strength of 94.2MPa and a 28-day impact and wear resistance of 12.3h / (kg / m 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com