Impact-resistant and wear-resistant concrete for civil engineering and preparation method thereof

A technology of civil engineering and concrete, which is applied in the field of impact and wear-resistant concrete for civil engineering and its preparation, can solve the problems of poor performance such as erosion resistance, wear resistance and cavitation resistance, etc., to improve interface performance, increase overall strength, The effect of excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

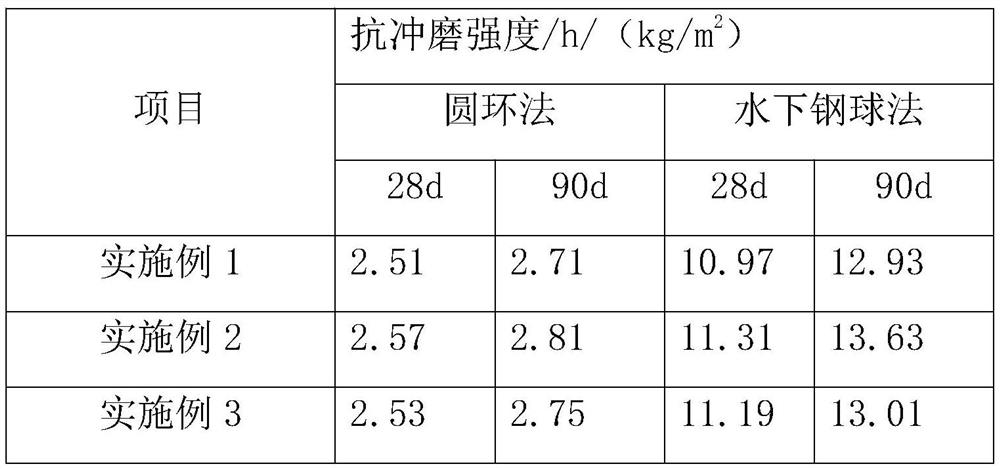

Embodiment 1

[0024] Example 1, a kind of anti-impact and wear-resistant concrete for civil engineering, prepared from the following raw materials in parts by weight:

[0025] 100 parts of Portland cement, 200 parts of river sand, 40 parts of igneous rock fiber, 6 parts of fly ash, 20 parts of large-pore mesoporous silica, 10 parts of silica fume, 3 parts of HF anti-impact and wear-resistant special water reducer, 1 part of 0.05g / L graphene oxide solution, 5 parts of nano-crystalline cellulose, 1 part of nano-corn starch, 5 parts of lithium polysilicate, and 50 parts of water.

[0026] A method for preparing impact-resistant and wear-resistant concrete for civil engineering, comprising the steps of:

[0027] S1. Weigh by weight: 100 parts of Portland cement, 200 parts of river sand, 40 parts of igneous rock fiber, 6 parts of fly ash, 20 parts of large-aperture mesoporous silica, 10 parts of silica fume, HF impact resistance 3 parts of special water reducer for grinding, 1 part of 0.05g / L g...

Embodiment 2

[0033] Embodiment 2, a kind of impact-resistant and wear-resistant concrete for civil engineering, prepared from the following raw materials in parts by weight:

[0034] 120 parts of Portland cement, 300 parts of river sand, 50 parts of igneous rock fiber, 10 parts of fly ash, 30 parts of large-pore mesoporous silica, 12 parts of silica fume, 5 parts of HF anti-impact and wear-resistant special water reducer, 2 parts of 0.05g / L graphene oxide solution, 8 parts of nano-crystalline cellulose, 3 parts of nano-corn starch, 10 parts of lithium polysilicate, and 80 parts of water.

[0035] A method for preparing impact-resistant and wear-resistant concrete for civil engineering, comprising the steps of:

[0036] S1. Weigh by weight: 120 parts of Portland cement, 300 parts of river sand, 50 parts of igneous rock fiber, 10 parts of fly ash, 30 parts of large-pore mesoporous silica, 12 parts of silica fume, HF impact resistance 5 parts of special water reducer for grinding, 2 parts of...

Embodiment 3

[0042] Embodiment 3, a kind of impact-resistant and wear-resistant concrete for civil engineering, prepared from the following raw materials in parts by weight:

[0043] 110 parts of Portland cement, 250 parts of river sand, 45 parts of igneous rock fiber, 8 parts of fly ash, 25 parts of large-pore mesoporous silica, 11 parts of silica fume, 4 parts of HF special water reducer for impact and wear resistance, 1.5 parts of 0.05g / L graphene oxide solution, 6.5 parts of nano-crystalline cellulose, 2 parts of nano-corn starch, 7.5 parts of lithium polysilicate, and 65 parts of water.

[0044] A method for preparing impact-resistant and wear-resistant concrete for civil engineering, comprising the steps of:

[0045] S1. Weigh by weight: 110 parts of Portland cement, 250 parts of river sand, 45 parts of igneous rock fiber, 8 parts of fly ash, 25 parts of large-aperture mesoporous silica, 11 parts of silica fume, HF impact resistance 4 parts of special water reducer for grinding, 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com