Dump barrow

A trolley, dump truck technology, applied in trolleys, single-axle trolleys, motor vehicles and other directions, can solve the problems of easily damaged frame, unbalanced support surface, tilt damage of feet, etc., to reduce freight and storage costs, and ensure overall stability. properties, and the effect of enhancing the flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

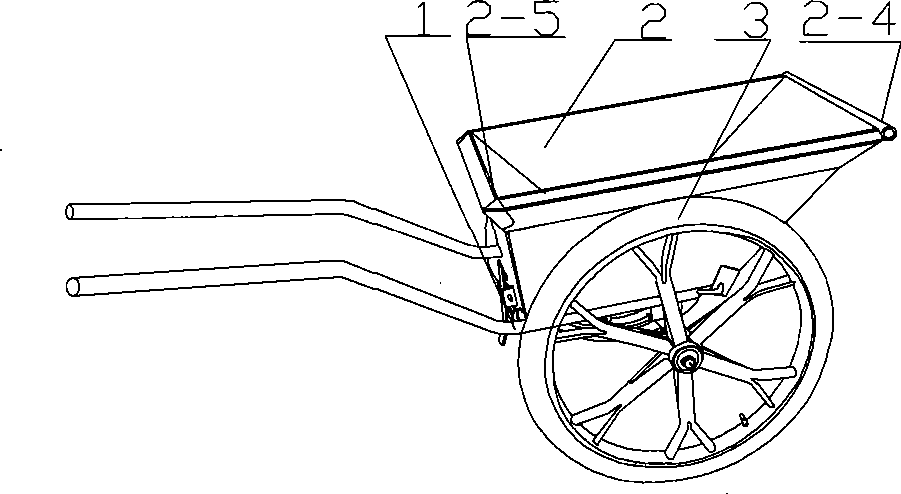

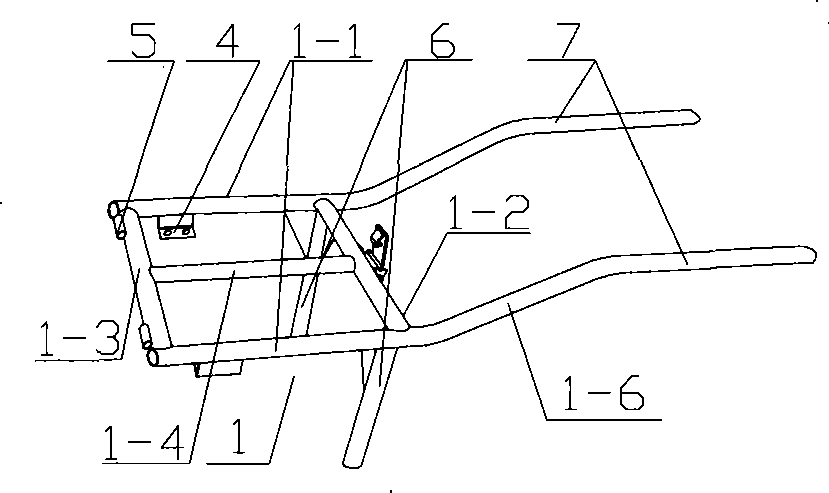

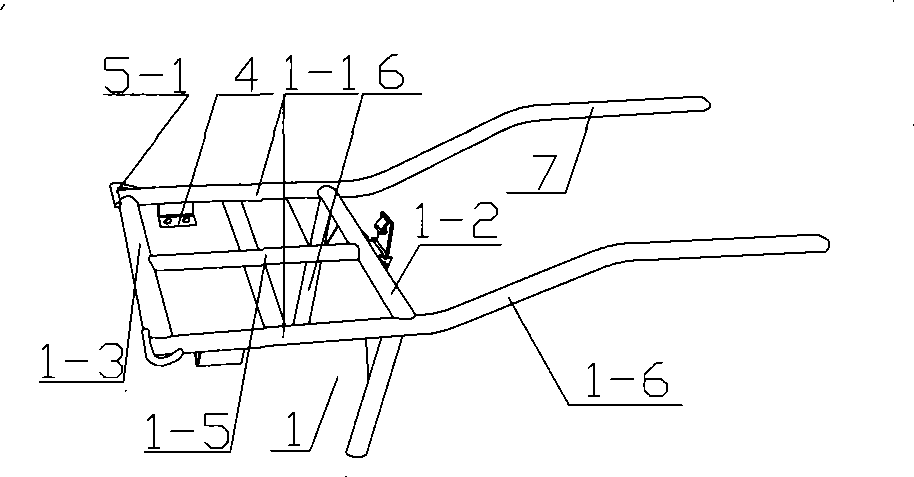

[0014] Embodiment 1: with reference to attached figure 1 , 3 ~7. For the trolley dump truck, the wheels 3 are connected to the chassis of the trolley frame 1, and the bucket 2 is located on the trolley frame 1 and can be turned over. The wheel 3 is purchased from outside and will not be described here. The trolley frame 1 is formed by welding steel pipes. The two steel pipe side beams 1-1 in the trolley frame 1 and the two handlebars 7 of the trolley are respectively bent and formed from the same steel pipe. The boundary buffer rods 1-6 of the steel pipe side beams are in the shape of an upper arc with two bends. The two ends of the front steel pipe crossbeam 1-3 and the rear steel pipe crossbeam 1-2 located between the two steel pipe side beams 1-1 of the trolley frame 1 are respectively welded to the two steel pipe side beams 1-1 and the steel pipe frame core beam 1-1 of the trolley frame The two ends of 4 are welded with front steel pipe crossbeam 1-3 and rear steel pipe...

Embodiment 2

[0015] Embodiment 2: on the basis of embodiment 1, with reference to appended figure 2. The lower part of the front part of the car bucket 2 both sides is connected with the front steel pipe crossbeam 1-3 of the trolley frame 1 by the connecting ear and the front steel pipe beam 1-3, and the car bucket 2 can be turned around the axis, and the trolley bucket 2 is inseparable from the trolley frame 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com