High-temperature axial-flow type tail gas turbine

An exhaust turbine and axial flow technology, which is applied to non-variable-capacity engines, leakage prevention, blade support elements, etc. It can reduce the deformation, reduce the loss of air leakage, and improve the thermal insulation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

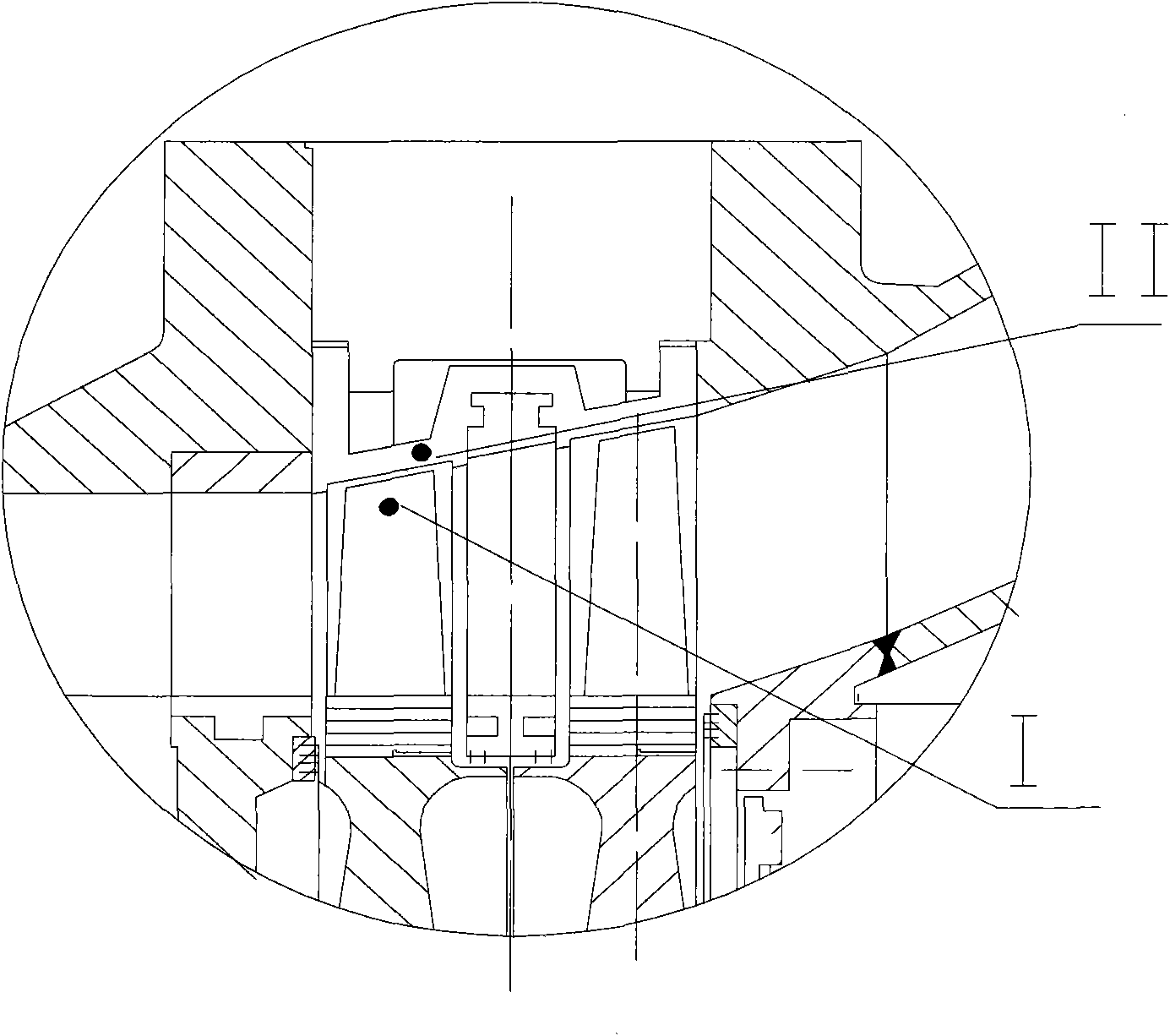

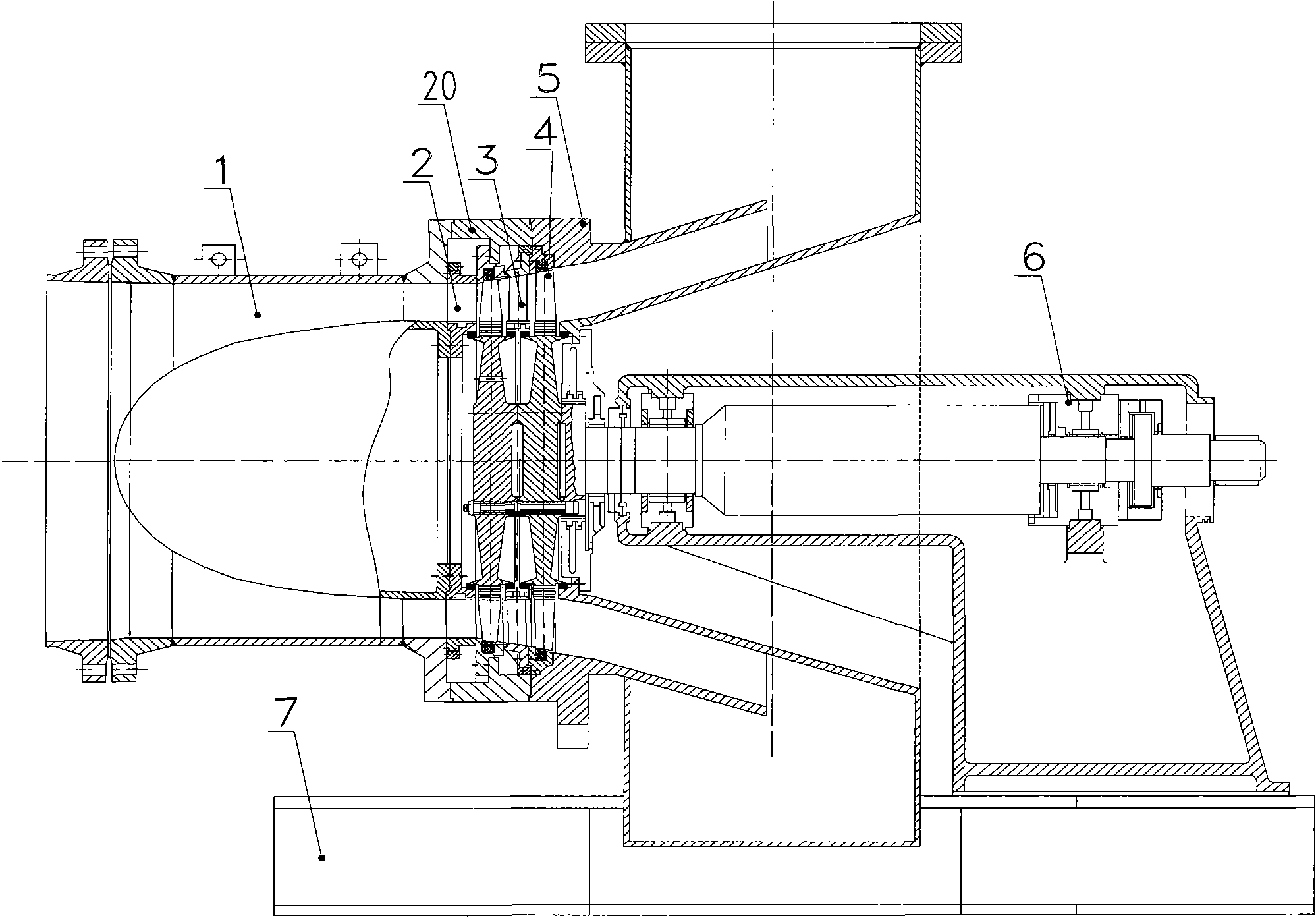

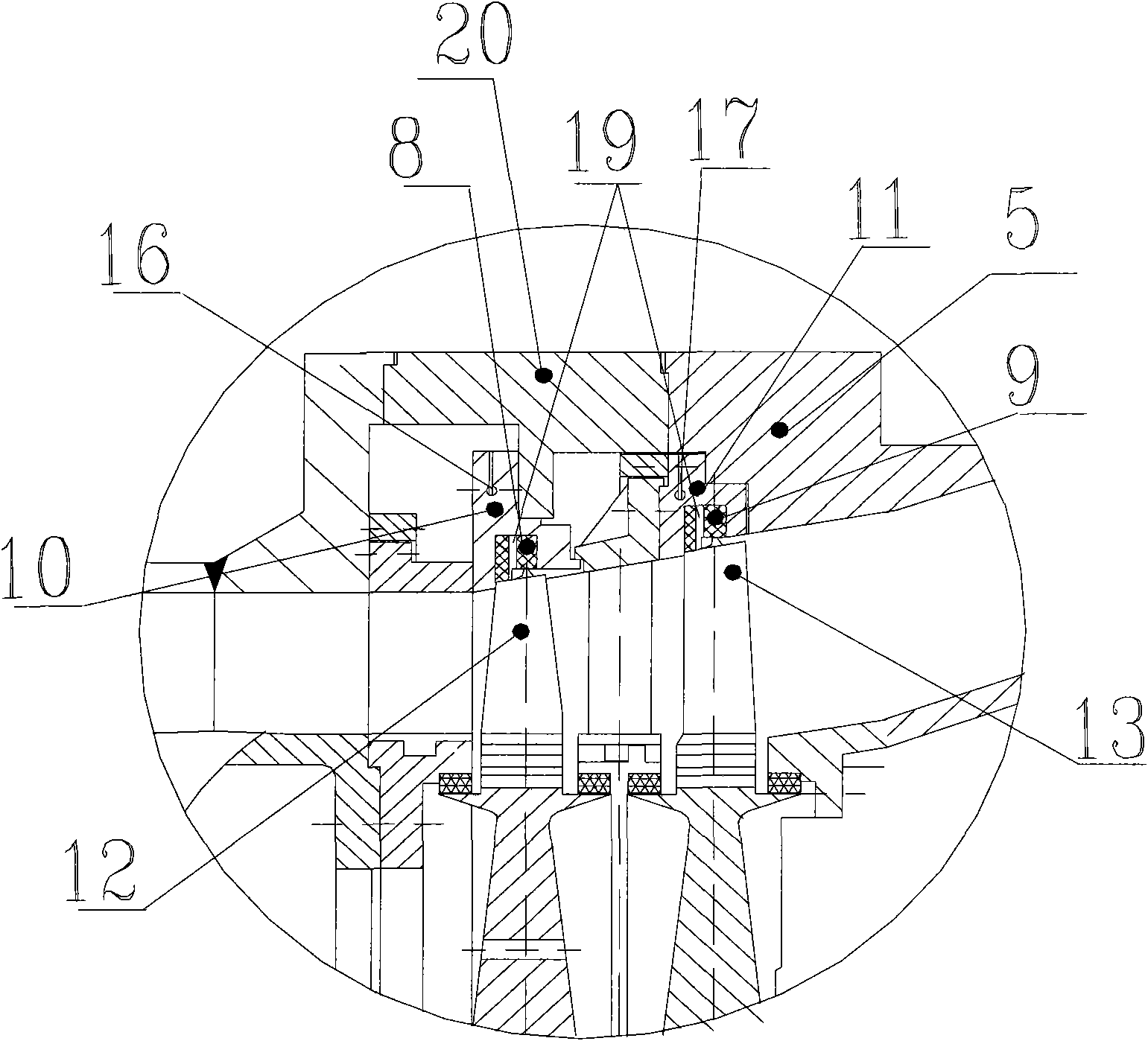

[0026] like figure 2 , image 3 and Figure 4 As shown, a high-temperature axial-flow exhaust gas turbine adopts the structural form of axial intake and radial upward or downward exhaust, including an intake casing 1, a first-stage guide vane 2, a second-stage guide vane 3, Rotor 4, transition housing [20], exhaust casing 5, bearing system 6 and base 7.

[0027] Moving blades are installed on the rotor 4;

[0028] Each blade of the moving blade includes a crown 14, a blade body [18] and a blade root 15; each crown 14 is a V-shaped structure.

[0029] The moving blades include primary moving blades 12 and secondary moving blades 13 .

[0030] The blade tip shroud of the moving blade adopts a honeycomb seal of the whole ring structure, specifically, the first-level moving blade honeycomb seal 8 is on the outside of the first-level moving blade 12, and the second-level moving blade honeycomb seal is on the outside of the second-level moving blade 13. Leaf honeycomb seal9. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com