Integrated regenerative fuel cell membrane electrode assembly and preparation method thereof

A fuel cell membrane and assembly technology, which is applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of poor reliability and stability of membrane electrodes, unsuitability for URFC fuel cells, and difficulty in ensuring the quality of MEA, etc., to achieve repeatability Strong, easy to assemble and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Electrode preparation

[0036] 1) 200 milligrams of titanium powder with a particle size of 30-50 nanometers, 2 mL of PTFE emulsion with a solid content of 5% and 50 mL of ethanol are evenly vibrated with ultrasonic waves, and then the above slurry is scraped on the titanium fiber net to prepare a microporous layer with a scraper method. The knife-coated gas diffusion layer was dried at 120 and 250°C for 30 minutes, respectively, and finally fired at 340°C for 60 minutes.

[0037] 2) Stir 20 mg of platinum black catalyst, 20 mg of iridium black, 2 mL of PTFE emulsion with a solid content of 5% and 50 mL of isopropanol with ultrasonic waves, and then apply the slurry evenly on the prepared On the gas diffusion layer, it was dried at 120°C and 250°C for 30 minutes under nitrogen protection, and finally fired at 340°C for 60 minutes.

[0038] 3) Carry out three-dimensionalization of the electrode, according to the electrode area, weigh 6mL of Nafion resin (trade name Nafi...

Embodiment 2

[0040] MEA preparation

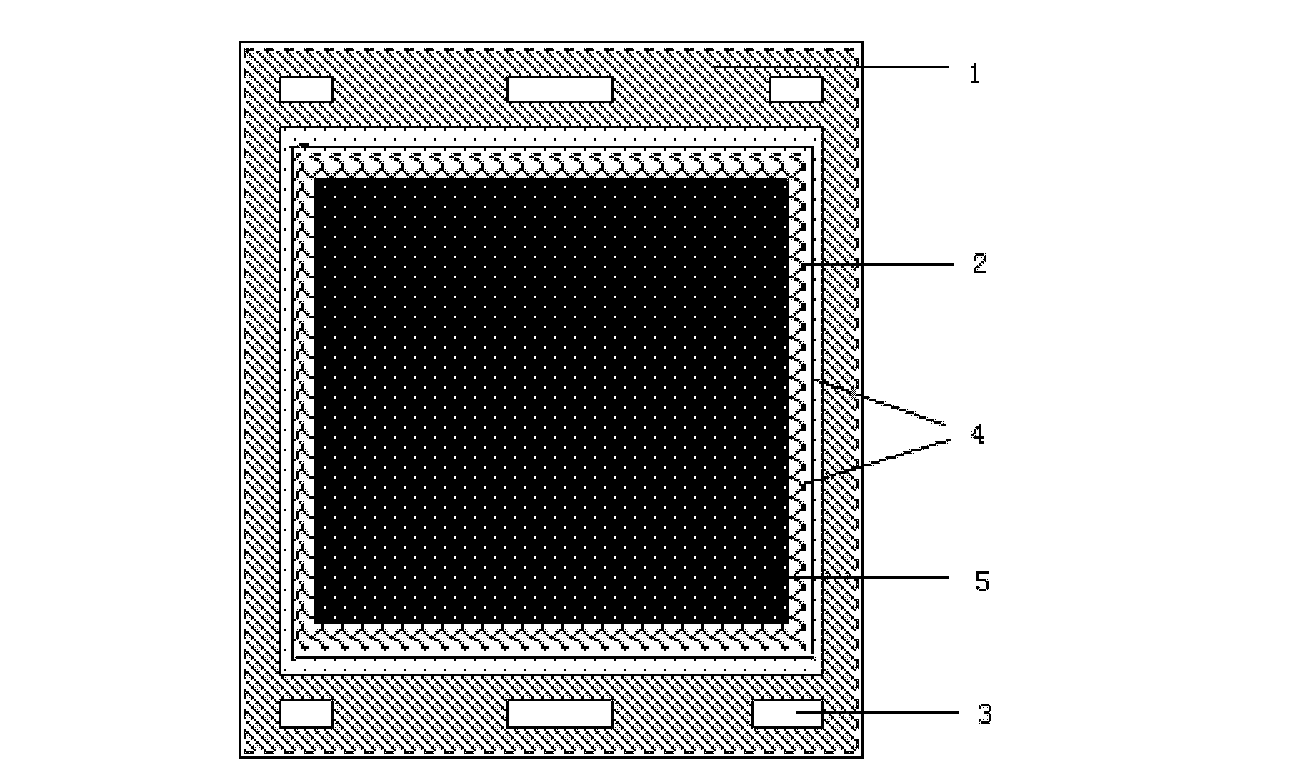

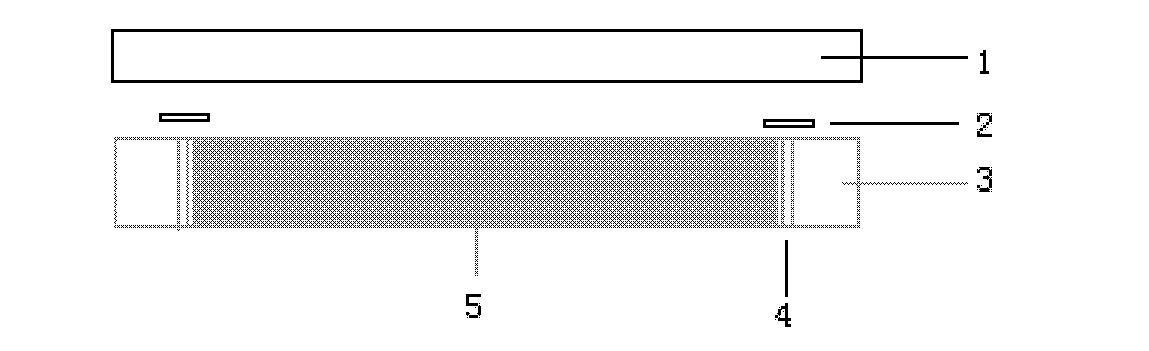

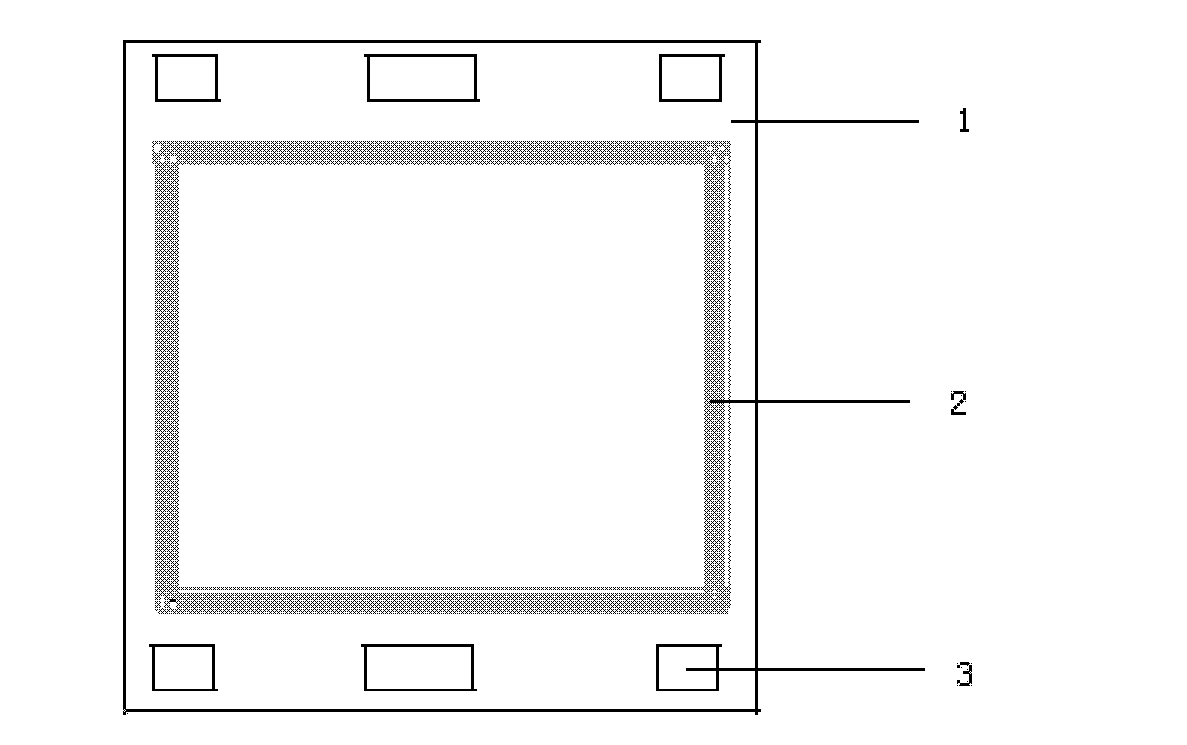

[0041] see attached Figure 1-Figure 3 The assembly position of the middle electrode, the proton exchange membrane, the protective frame and the protective gasket in the transition zone is used to prepare the membrane-electrode assembly.

[0042] Concrete preparation method comprises the following steps:

[0043] 1) Treat the membrane electrode assembly composed of the proton exchange membrane and the anode and cathode on both sides of the proton exchange membrane, and use a cutting knife or mold to cut the periphery of the anode and cathode, so that the proton exchange membrane in the middle The perimeter is protruding, and the width of the protruding is 0.5mm-100mm;

[0044] 2), make protective frame, the inside hole shape of protective frame is identical with the profile of described anode, negative electrode, the peripheral width of protective frame is consistent with the width protruding from proton exchange membrane periphery used, one side of ...

Embodiment 3

[0049] battery pack assembly

[0050] The specific method is as follows: First, put the sealing ring on the proton exchange membrane on both sides of the membrane electrode (MEA), and then place the cathode flow field plate and the anode flow field plate on both sides of the membrane electrode respectively, and press the three parts together to form a single battery. Multiple identical single cells are connected in series, that is, assembled into a battery stack. Put two pieces of copper (for current collection) on both sides of the first and last batteries respectively, and finally fix the battery stack with fixing plates and screws, thus assembling a battery stack. After checking that the airtightness of the battery stack is qualified, the performance test of the battery pack can be carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com