Debris-flow drainage canal with energy dissipation and drainage functions and application thereof

A technology for draining troughs and debris flows, which is applied in water conservancy projects, artificial waterways, buildings, etc. It can solve problems such as insufficient energy dissipation of V-shaped grooves, failure of the function of the drainage trough, failure of the bottom of the trough, etc., and achieve a good drainage effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

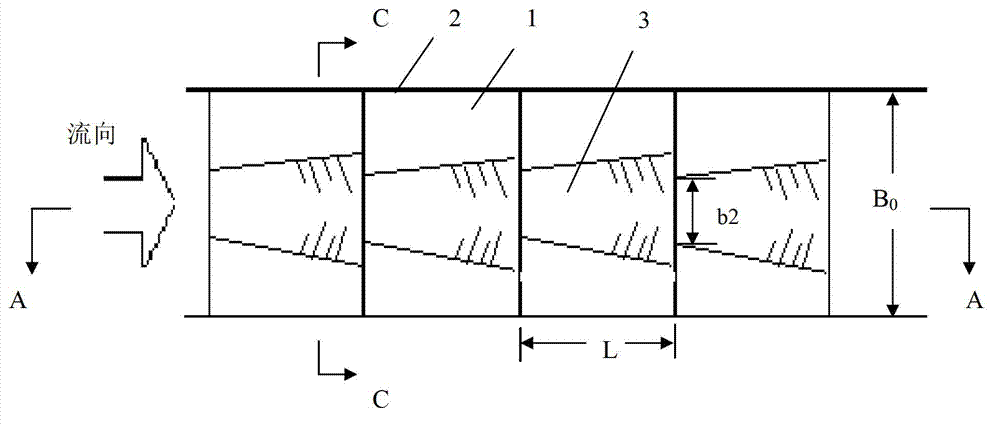

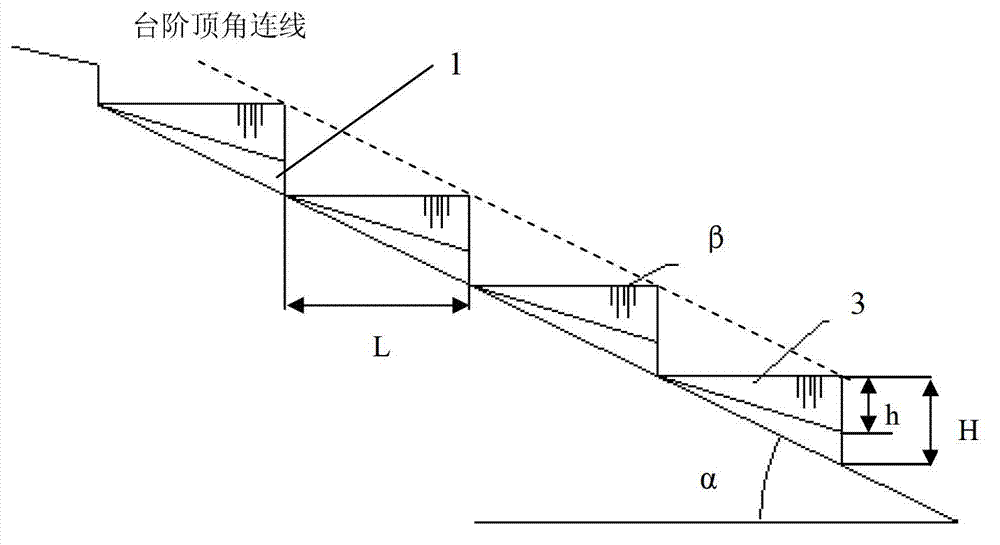

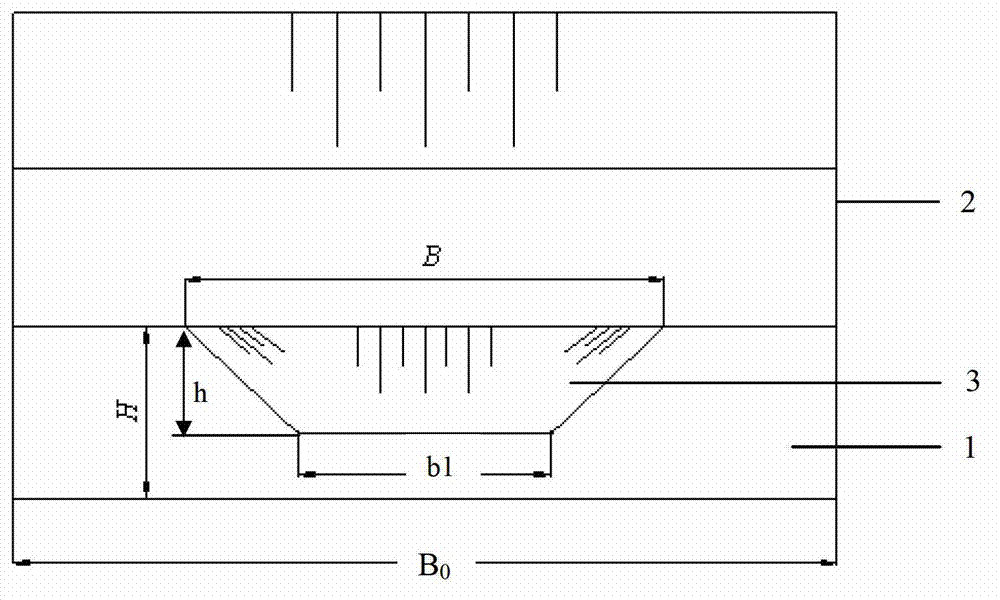

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 shown. For the basin area of 0.5km 2 , bulk density is 1700kg / m 3 , dilute debris flow with ditch-bed gradient of 25% (that is, slope α at the bottom of the ditch is equal to 25%), at P 2% Under the design standard, the flow rate of debris flow is 20m 3 / s, it is proposed to build a debris flow drainage channel along the debris flow channel with consideration of energy dissipation and drainage. The vertical height difference between the start and end of the guide trough is 48.0m, and the total length of the guide trough is 198.0m. Its structure includes a fully lined row guide trough bottom plate and the row guide trough side walls 2 on both sides. The row guide trough bottom plate is a ladder shape formed by continuous connection of 40 steps. The surface of the ditch bed is parallel; each step 1 is provided with a groove 3, which is symmetrical along the center line of the guide groove, and the width of the g...

Embodiment 2

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 shown. The same place as Embodiment 1 will not be repeated, and the difference is that the bulk density of debris flow is 1300kg / m 3 , in order to enhance the turbulence of the debris fluid and further improve the energy dissipation rate of the drainage channel, the height and length of the steps 1 in Embodiment 1 are reduced, and the number of steps 1 is increased. . The height H of the step 1 is 0.8m, the height h of the groove 3 on the vertical surface of the step 1 is 0.4m; the length L of the step 1 is 3.2m, and the length of the groove 3 on the top surface of the step 1 is 3.2m; The slope β of the top surface is 0.

Embodiment 3

[0037] Such as Figure 5 , Figure 6 , Figure 7 , Figure 8 shown. For a watershed area of 3.5km 2 , bulk density is 2200kg / m 3 , the viscous debris flow with a ditch-bed gradient of 8% (that is, the slope at the bottom of the ditch α is equal to 8%), at P 2% Under the design standard, the flow of debris flow is 60m 3 / s, it is proposed to build a debris flow drainage channel along the debris flow channel with consideration of energy dissipation and drainage. The vertical height difference between the start and end of the guide trough is 48.0m, and the total length of the guide trough is 602.0m. Its structure includes a fully-lined row guide trough bottom plate and the row guide trough side walls 2 on both sides. The row guide trough bottom plate is a ladder shape formed by continuous connection of 24 steps 1, and the connection line between the top corners of steps 1 at each level The surface of the ditch bed is parallel; each step 1 is provided with a groove 3, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com