High-flame-retardance low-temperature bicomponent filling material for coal mines and preparation method thereof

A filling material and high flame-retardant technology, which is applied in the field of high flame-retardant low-temperature two-component filling materials for coal mines and its preparation, can solve problems such as insufficient storage stability, pungent odor, and high corrosiveness of raw materials, and achieve production And the requirements of the construction personnel are low, the effect of avoiding high corrosion and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

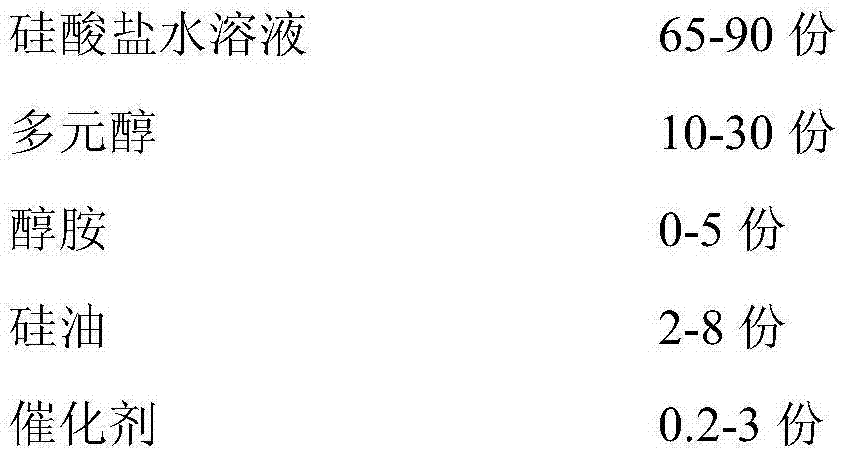

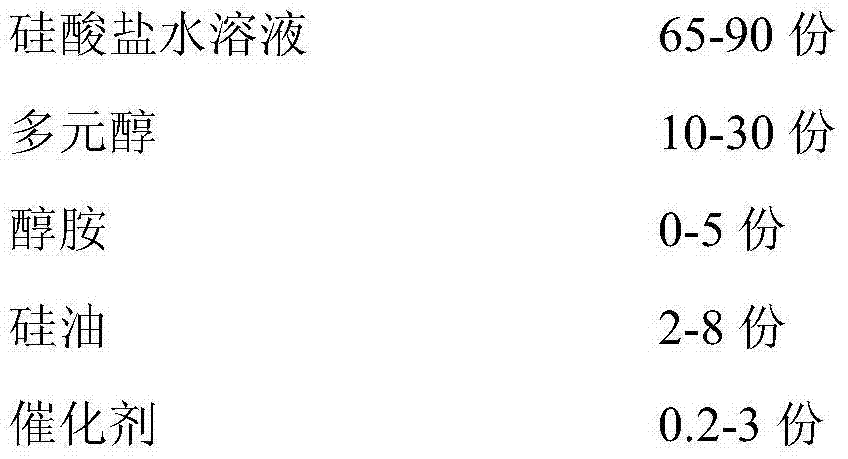

Method used

Image

Examples

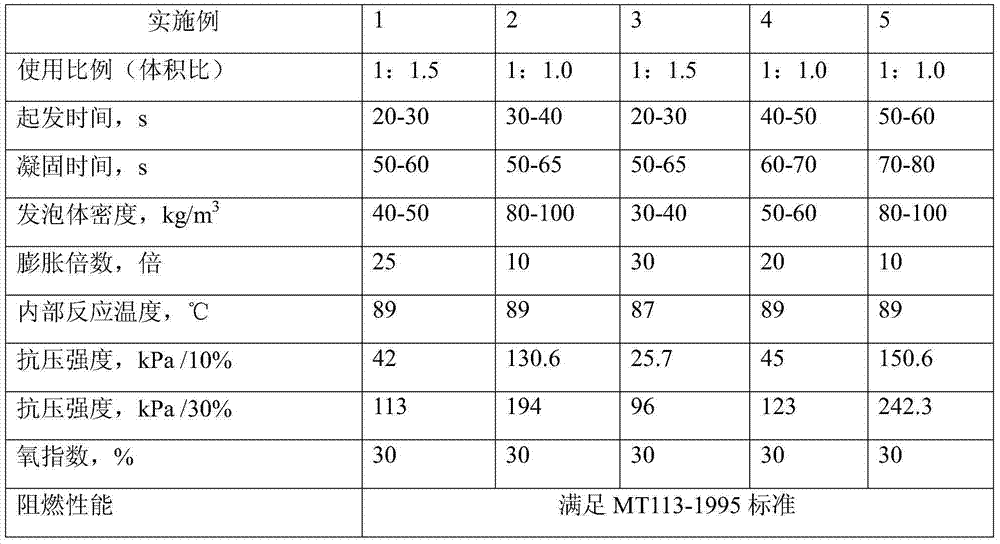

Embodiment 1

[0031] (1) Preparation of component A

[0032] Add 65 parts of accurately measured sodium silicate aqueous solution (water glass modulus 1.5, Baume degree 50), 20 parts polyol (functionality 2, molecular weight 2000), 10 parts ethylene glycol, 5 parts triethanolamine , 3 parts of silicone oil, 1 part of catalyst triethylenediamine, put into the reaction kettle, stir and mix for 1 hour, discharge the material after the sampling test is qualified, and seal the package;

[0033] (2) Preparation of component B

[0034] Put 90 parts of accurately measured polymethylene polyphenyl polyisocyanate 44V20 (Bayer), 5 parts of toughening agent tris(chloroisopropyl) phosphate, and 5 parts of foaming agent HCFC-141b; put them into the reaction kettle in order, and stir Mix for 1 hour, discharge after passing the sampling, and replace with nitrogen and seal the package. The test product indicators are shown in Table 1.

Embodiment 2

[0036] (1) Preparation of component A

[0037] 90 parts of accurately measured sodium silicate aqueous solution (water glass modulus of 2.5, Baume degree of 48), 10 parts of polyol (functionality of 2, molecular weight of 3000), 2 parts of silicone oil, compound catalyst [Sanethylene Base diamine and bis(dimethylaminoethyl)ether compounded at a ratio of 1:1] 2 parts, put into the reaction kettle, stir and mix for 1.5 hours, after the sampling test is qualified, discharge and seal the package;

[0038] (2) Preparation of component B

[0039] Put 70 parts of polymethylene polyphenyl polyisocyanate M20S (BASF) accurately measured, 15 parts of toughening agent citrate, and 15 parts of foaming agent HCFC-141b; put them into the reactor in order, stir and mix for 2 hours, and the sampling is qualified After the material is discharged, the nitrogen is replaced with a sealed package. The test product indicators are shown in Table 1.

Embodiment 3

[0041] (1) Preparation of component A

[0042] 75 parts of sodium silicate aqueous solution (water glass modulus of 2.0, Baume degree of 50), 22 parts of polyol (functionality of 2, molecular weight of 2000), 3 parts of diethanolamine, 3 parts of silicone oil, catalyst 3 parts of triethylenediamine are put into the reaction kettle, stirred and mixed for 2 hours, discharged after the sampling inspection is qualified, and sealed and packed;

[0043] (2) Preparation of component B

[0044] 55 parts of accurately measured polymethylene polyphenyl polyisocyanate PM200 (Yantai Wanhua), 5 parts of modified MDI DG5412 (Shandong Yinuowei Company), 15 parts of toughening agent glycerol triacetate, foaming agent HCFC 25 parts of -141b; put into the reaction kettle in order, stir and mix for 1.5 hours, discharge after passing the sampling, replace with nitrogen and seal the package. The test product indicators are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com