Concrete with-mold backfill grouting system and grouting method for vault of tunnel

A grouting system and concrete technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of high investment in equipment, long construction period, backfilling and grouting in empty areas, etc. The effect of good connection performance and excellent self-leveling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

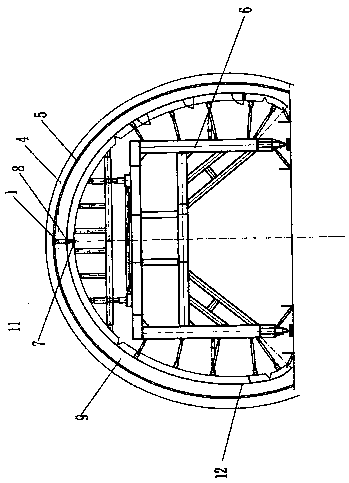

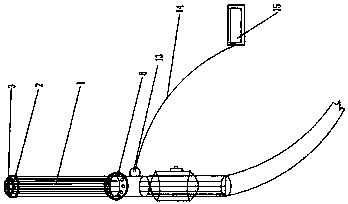

[0019] A tunnel vault concrete belt mold backfill grouting system, comprising a primary lining 4, a waterproof layer 5 is arranged in the primary lining 4, a secondary lining trolley 6 is arranged directly below the primary lining 4, and a secondary lining platform A secondary lining concrete 9 is poured between the vault of the vehicle 6 and the waterproof layer 5, and a cavity 11 is provided between the secondary lining concrete 9 above the vault of the secondary lining trolley 6 and the waterproof layer 5. A backfill grouting port 7 is provided on the vault of the lining trolley 6, and a flange 8 is provided on the backfill grouting port 7, and the end of the backfill grouting pipe 1 is inserted into the backfill grouting port 7 through the flange 8 Among them, the port of the backfilling grouting pipe 1 is attached to the waterproof layer 5 of the primary lining, and a cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com