Patents

Literature

64 results about "Thread seal tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thread seal tape (also known as PTFE tape, Teflon tape, or plumber's tape) is a polytetrafluoroethylene (PTFE) film tape commonly used in plumbing for sealing pipe threads. The tape is sold cut to specific widths and wound on a spool, making it easy to wind around pipe threads. Thread seal tape lubricates allowing for a deeper seating of the threads, and it helps prevent the threads from seizing when being unscrewed. The tape also works as a deformable filler and thread lubricant, helping to seal the joint without hardening or making it more difficult to tighten, and instead making it easier to tighten.

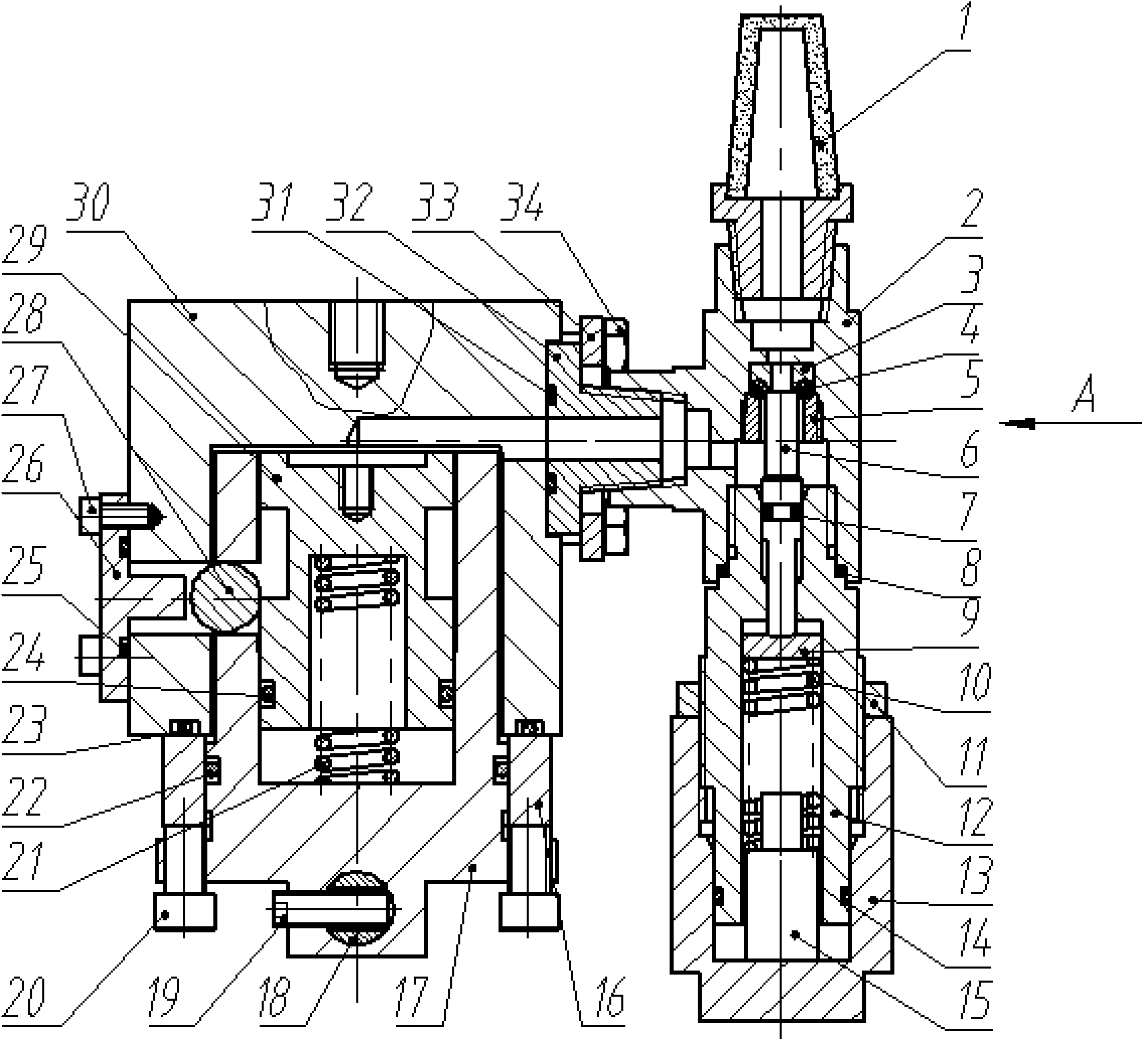

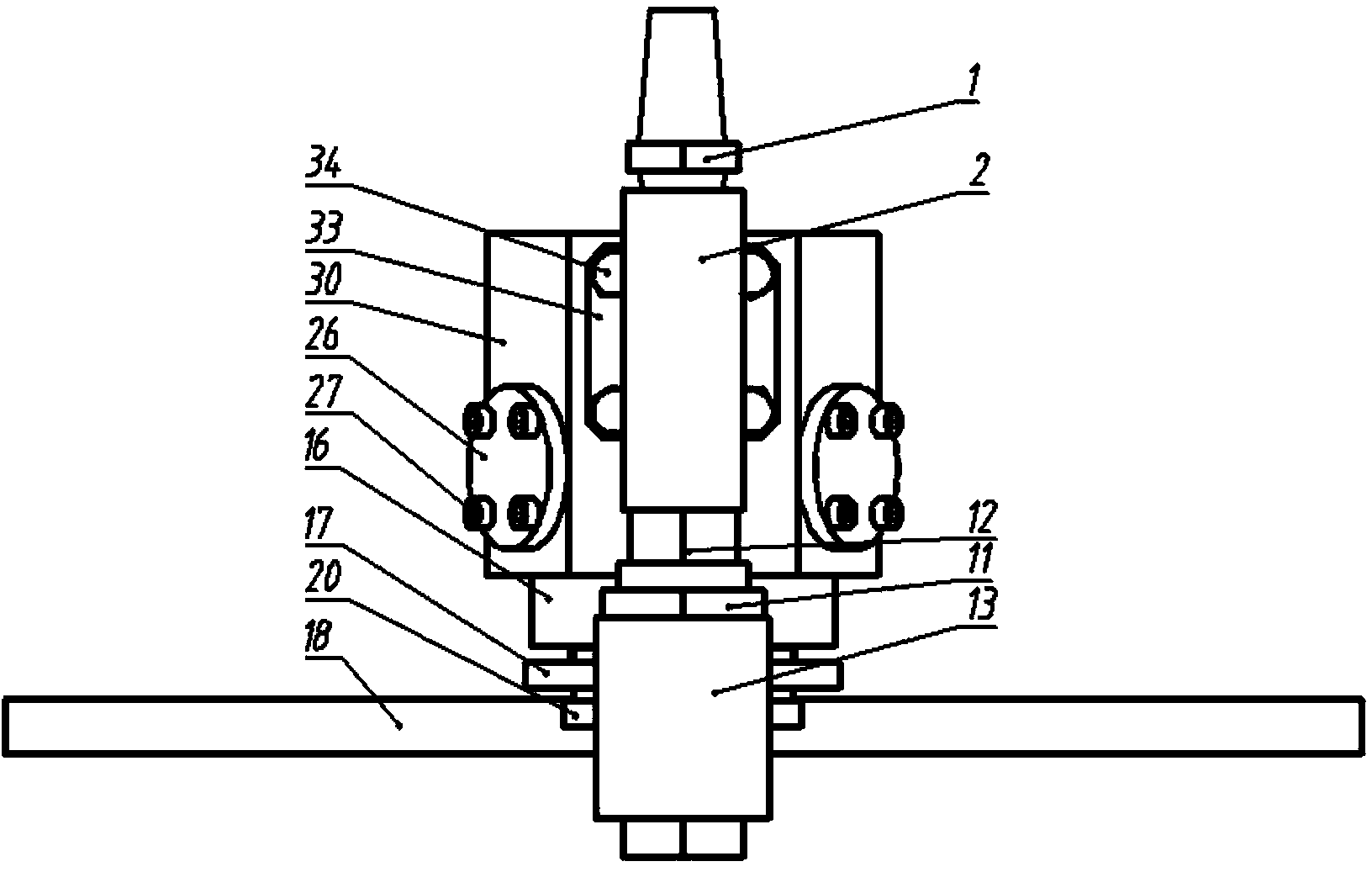

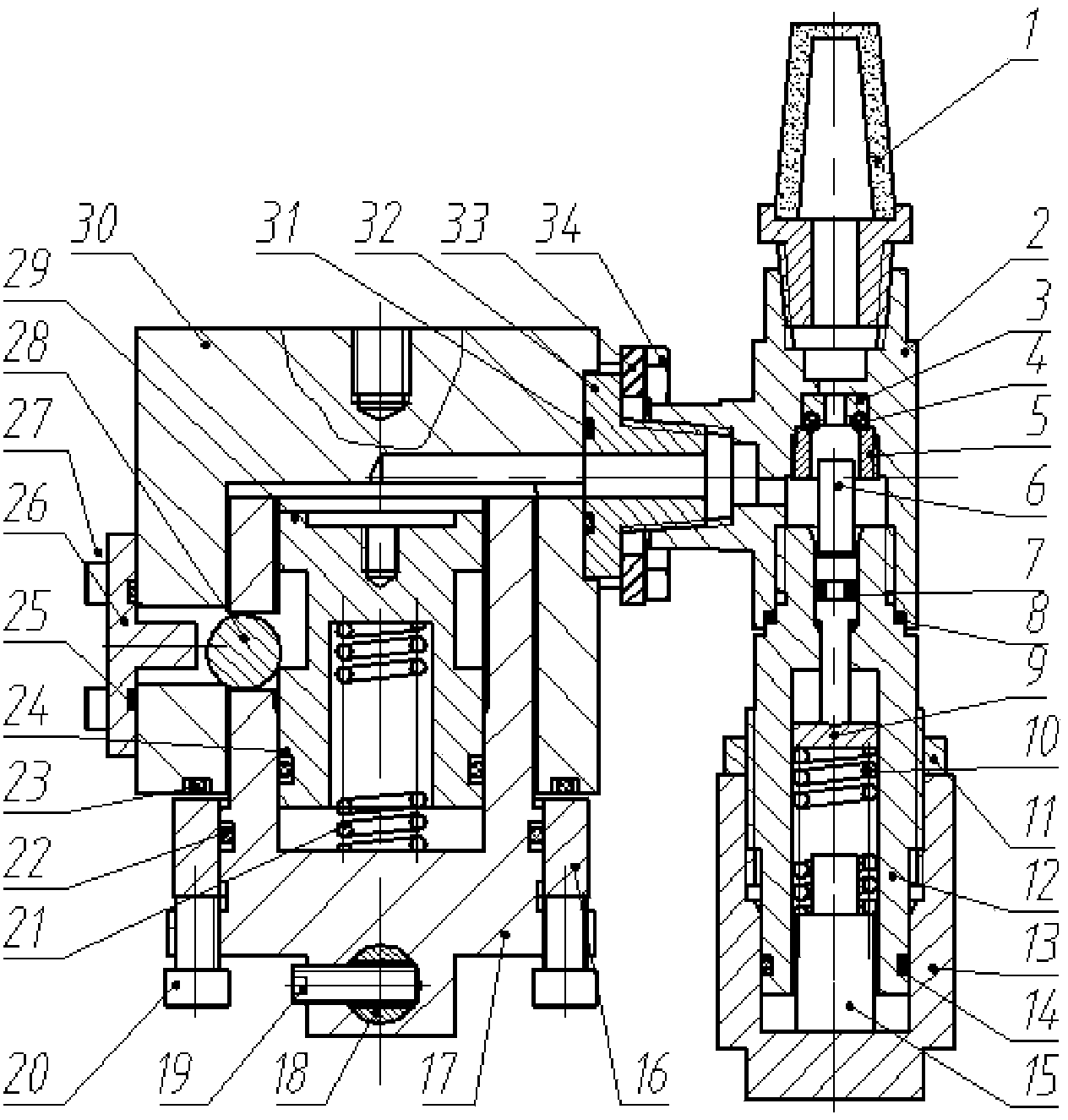

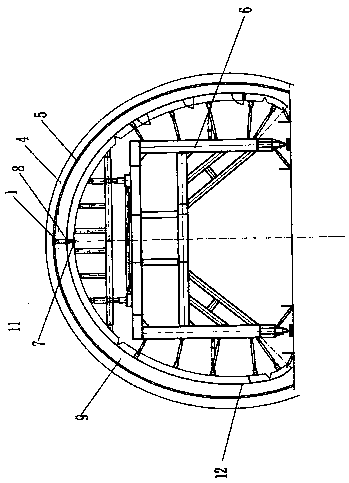

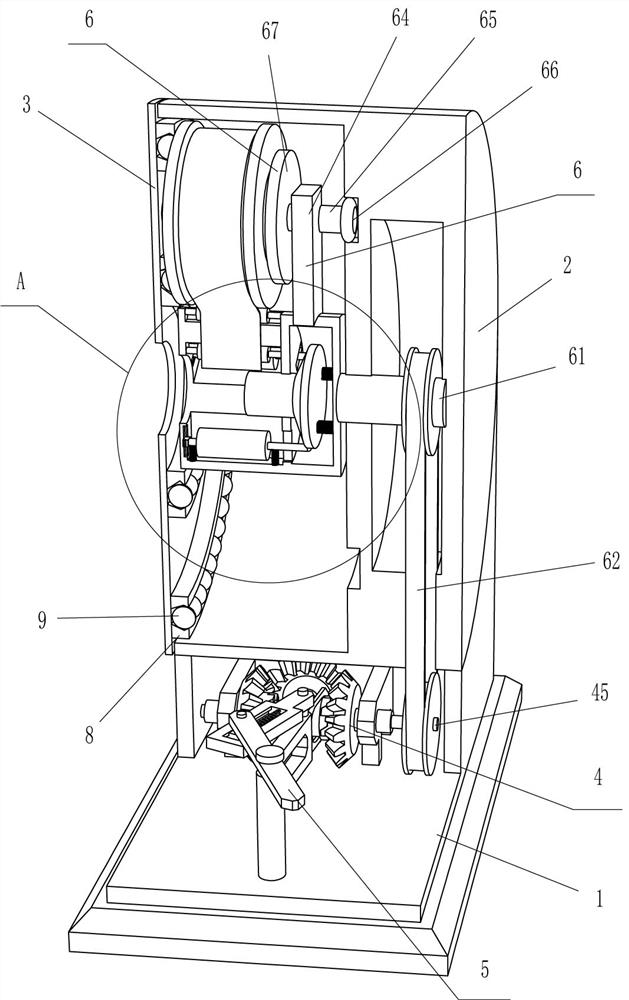

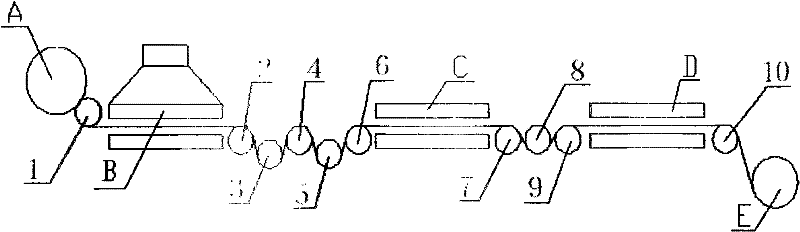

Full-automatic thread seal tape roll separator

ActiveCN103449264AEasy to controlRealize fully automated operationWebs handlingControl systemThread seal tape

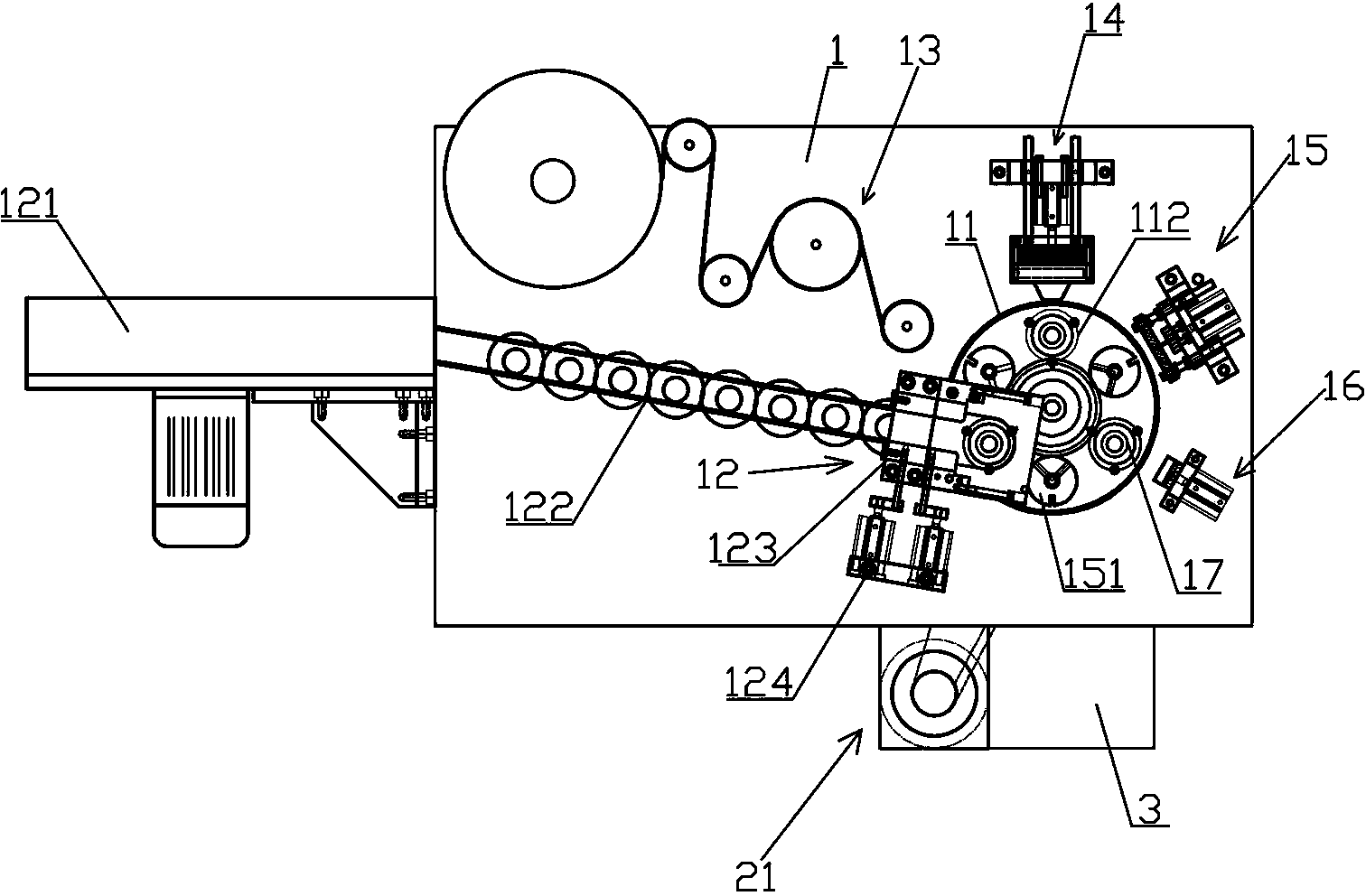

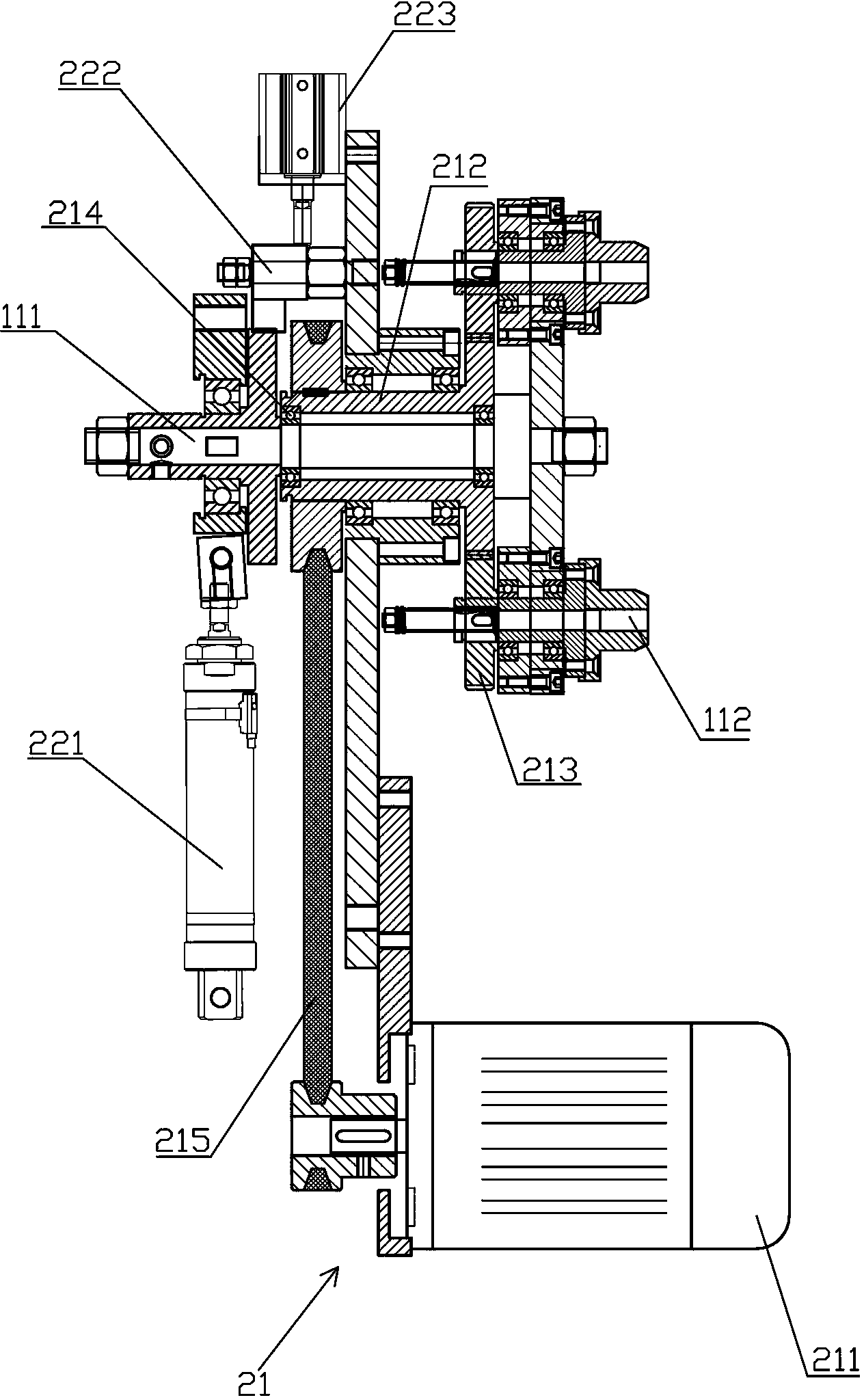

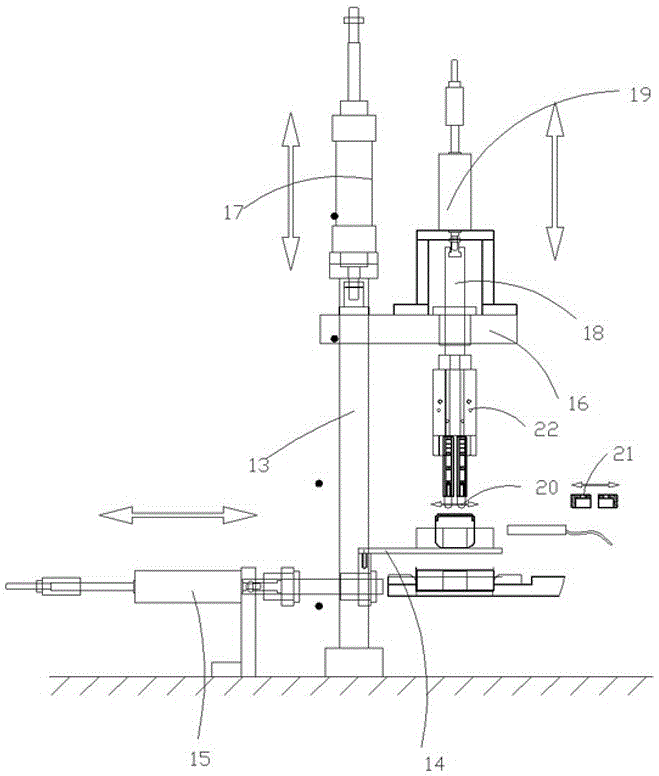

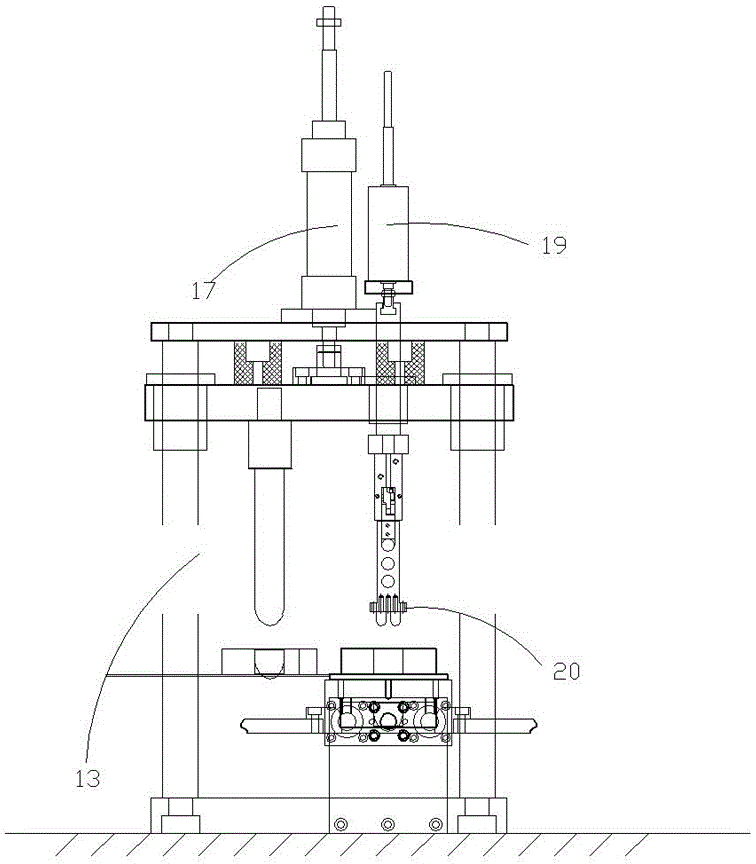

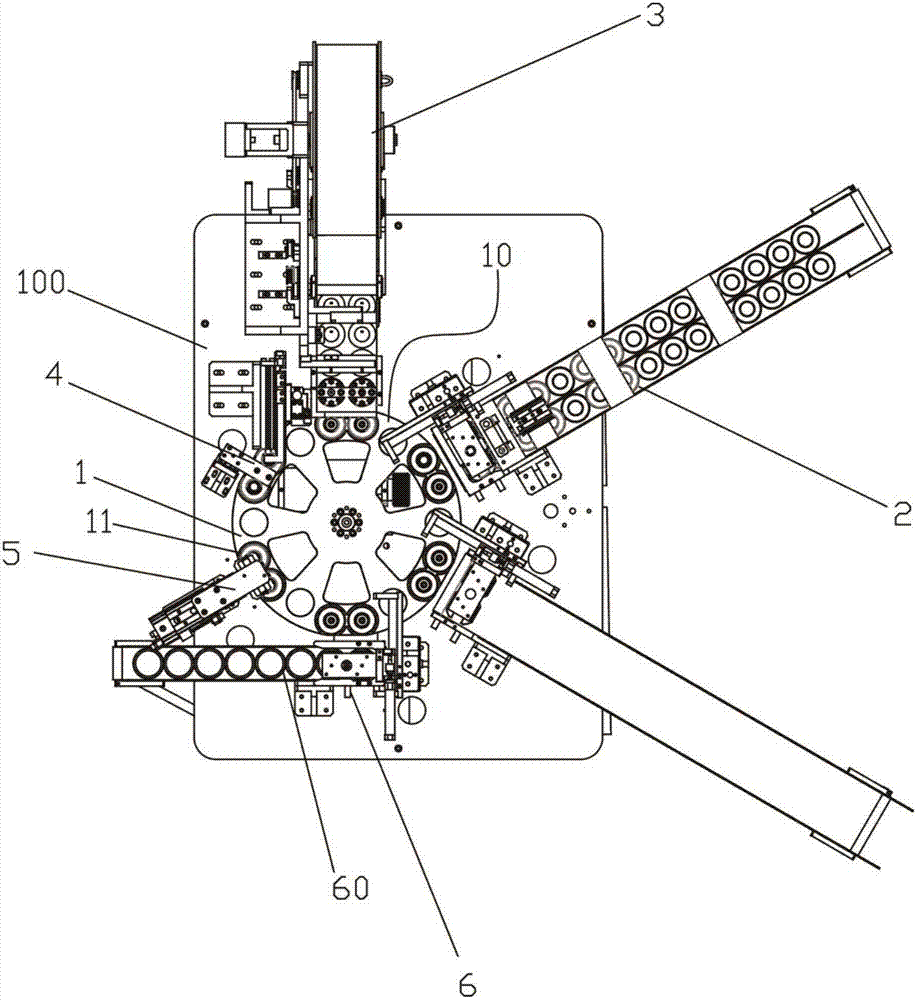

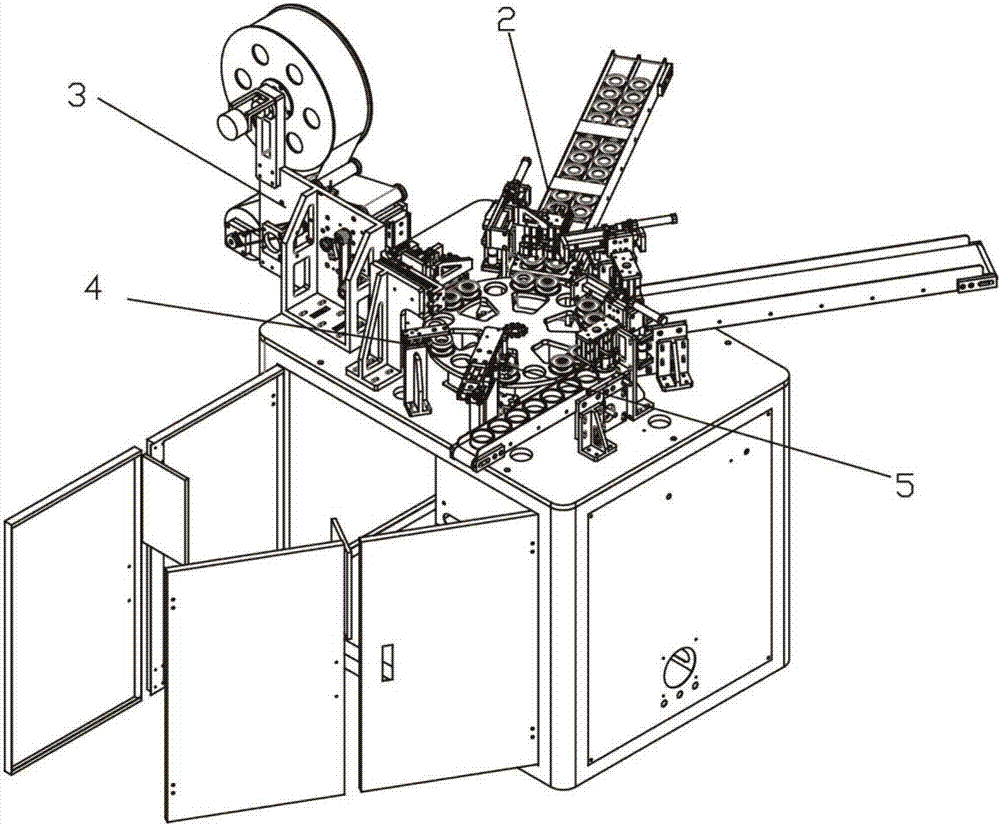

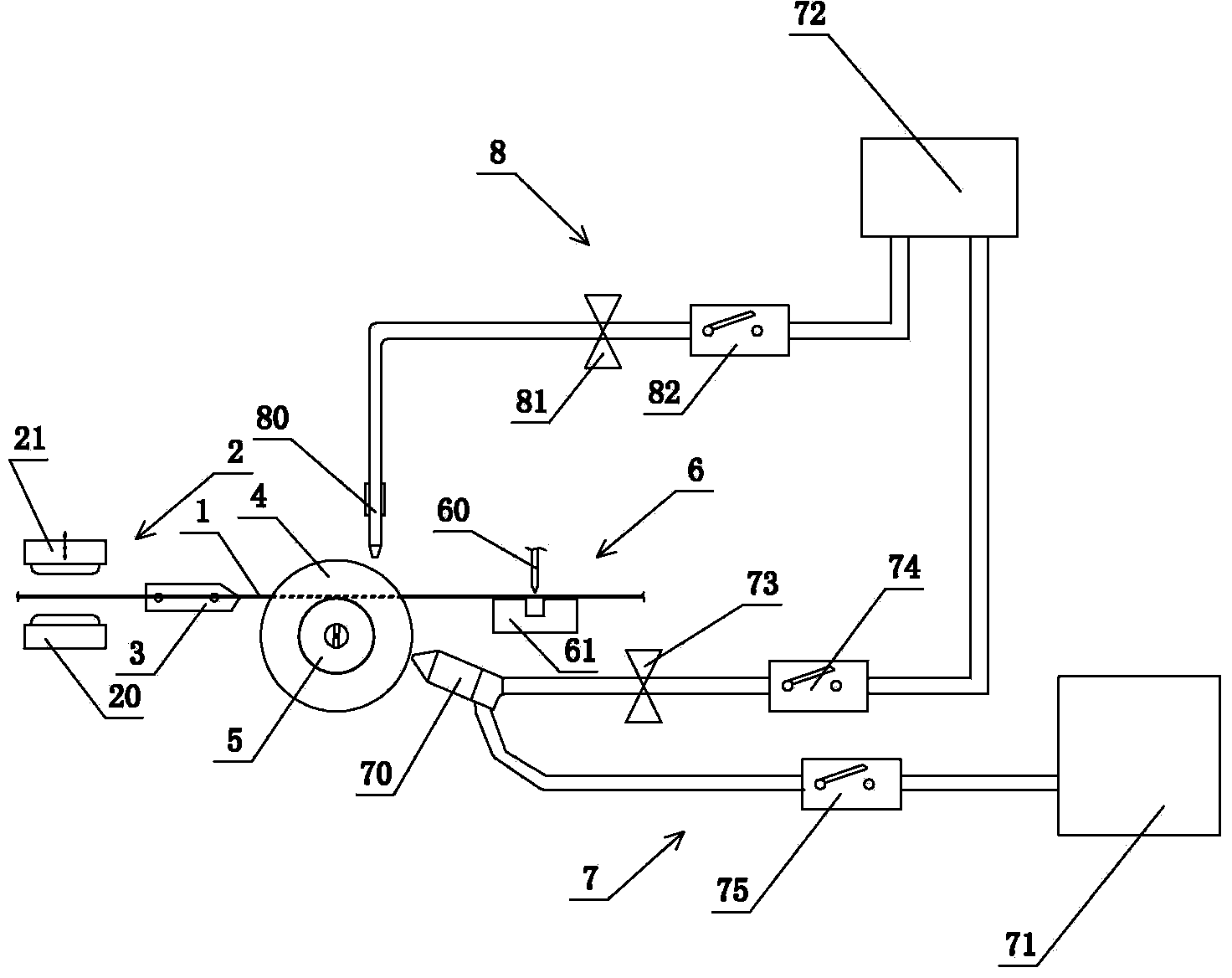

The invention disclose a full-automatic thread seal tape roll separator which comprises a frame body, a power driving mechanism and a control system, wherein a rotatable scale division rotary table is mounted on the frame body; a central rotating shaft and three rotating shafts are arranged on the scale division rotary table; the central rotating shaft is used for driving the scale division rotary table to rotate, and the three rotating shafts are uniformly distributed along the circumference of the scale division rotary table and can rotate independently; a roll core supplying device, a feeding device, a bonding device, a cutting-off device, a tail pressing device and an unloading device of thread seal tapes are sequentially mounted on the frame body on the outer side of the scale division rotary table in the clockwise direction; the roll core supplying device is used for automatically supplying roll cores for the rotating shafts of the scale division rotary table; the feeding device is used for conveying the thread seal tapes to the roll cores on the scale division rotary table and winding; the bonding device is used for bonding the thread seal tapes on the roll cores; the cutting-off device is used for cutting off the thread seal tapes; the tail pressing device is used for pressing the cutting-off thread seal tapes. The full-automatic thread seal tape roll separator has the advantages that the full-automatic operation of thread seal tape roll separation is achieved, the rolled length of the thread seal tapes is controlled accurately, and the production efficiency is improved.

Owner:FUJIAN CHUN FLAG MACHINERY IND & TRADE

Manufacturing method of colored polytetrafluoroethylene (PTFE) thread seal tape for winding and sintering

ActiveCN101597379AImprove performanceHigh voltage resistancePlastic/resin/waxes insulatorsManufacturing technologyMixed materials

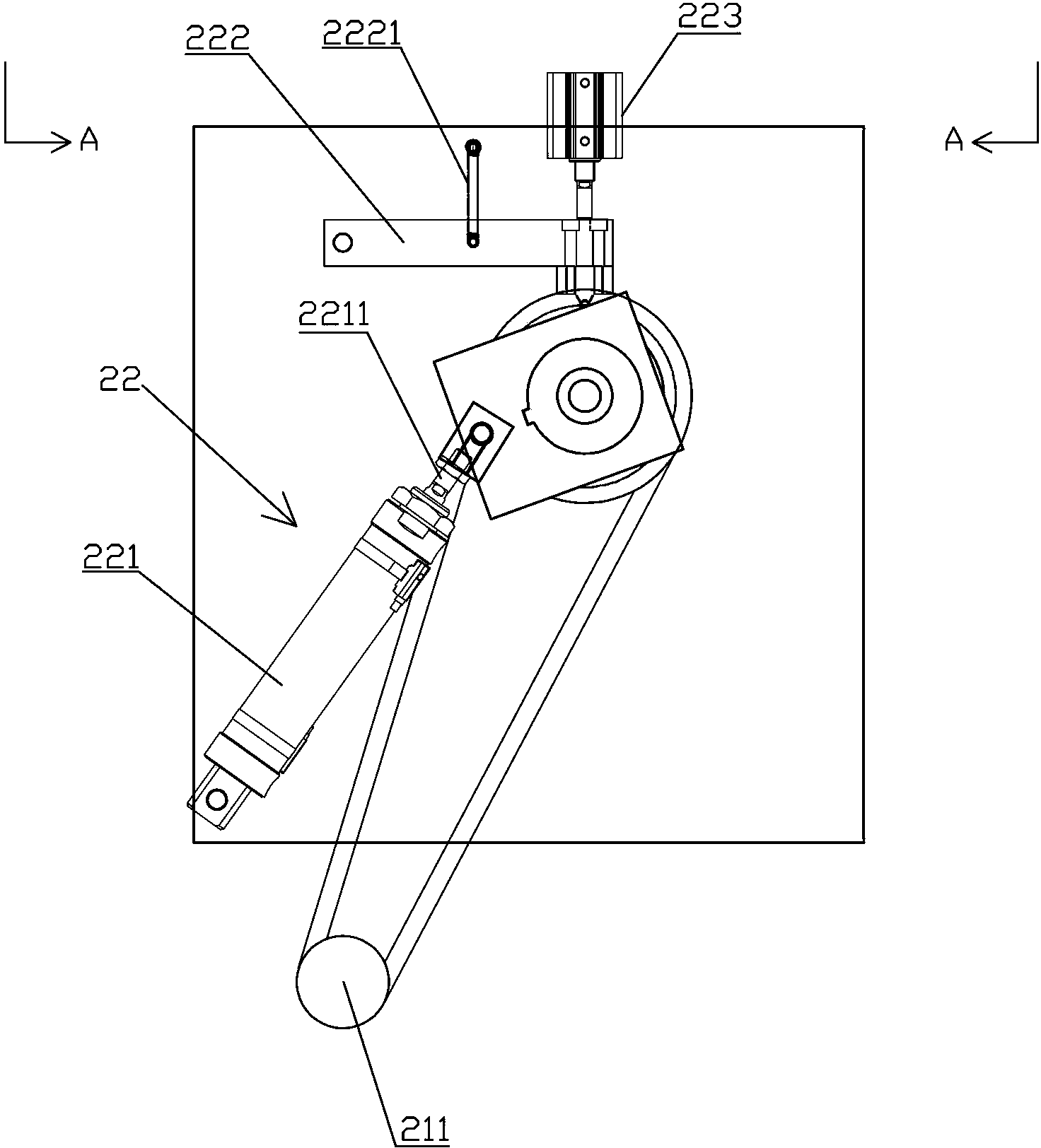

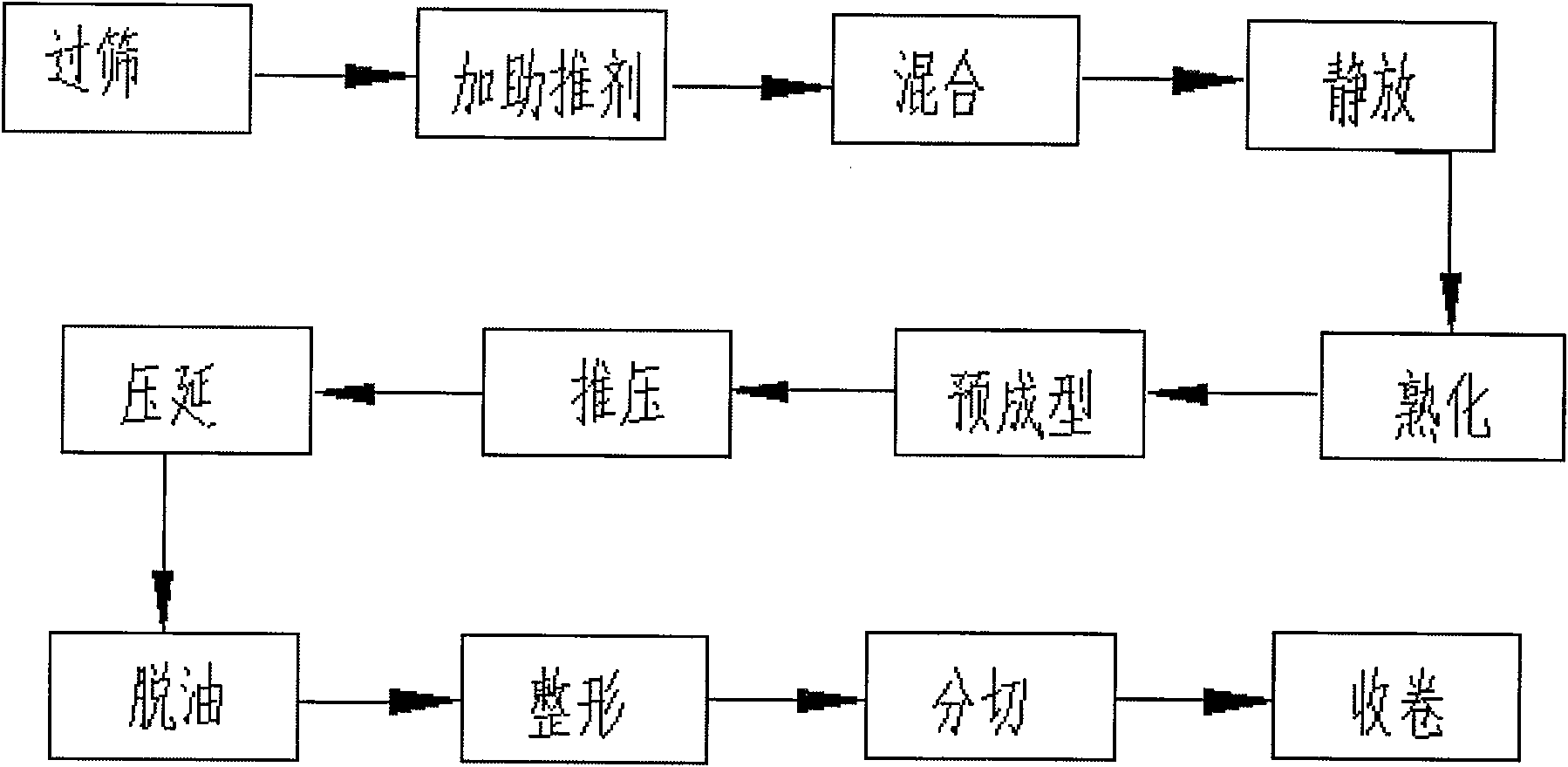

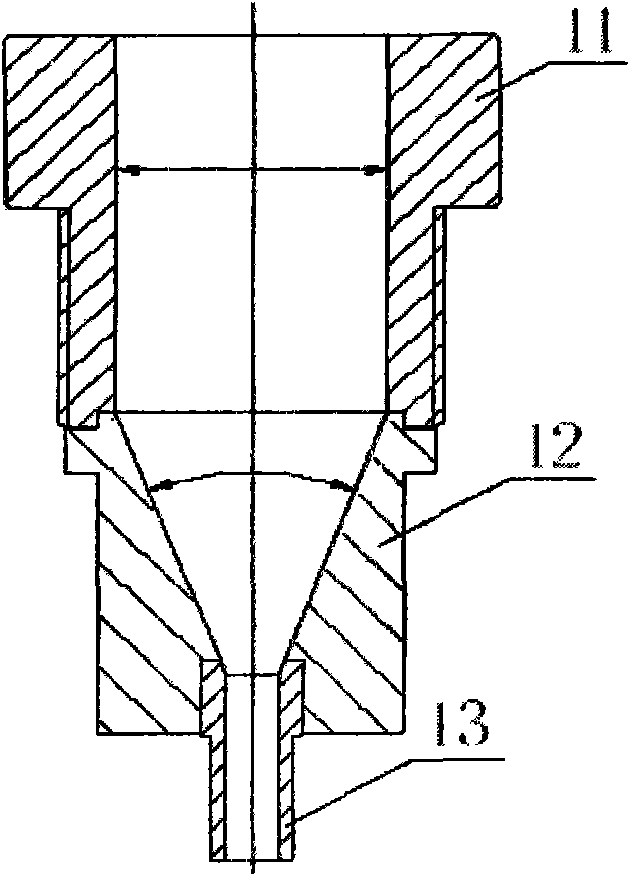

The invention provides a manufacturing method of a colored polytetrafluoroethylene (PTFE) thread seal tape for winding and sintering, comprising the following steps: sifting polytetrafluoroethylene (PTFE) dispersion resins, adding a propellant for mixing, curing the mixed materials after standing for 24 hours, prepressing to squeeze out a molded blank, calendering the blank by two rolls, removing the propellant, after shaping, slitting and rolling, finally obtaining the colored PTFE thread seal tape for winding and sintering. The colored PTFE thread seal tape for winding and sintering prepared in the invention is a major breakthrough of the manufacturing technology of ordinary thread seal tapes; the compactness, electric insulation and voltage resistance are enhanced dramatically; manufacturing electric wires by the winding and sintering method is also a major breakthrough in the electric wire manufacturing techniques; easy operation and lower cost ensure the possibility of popularizing the high-end product fluoroplastics electric wires for civil use.

Owner:四会市生料带厂有限公司

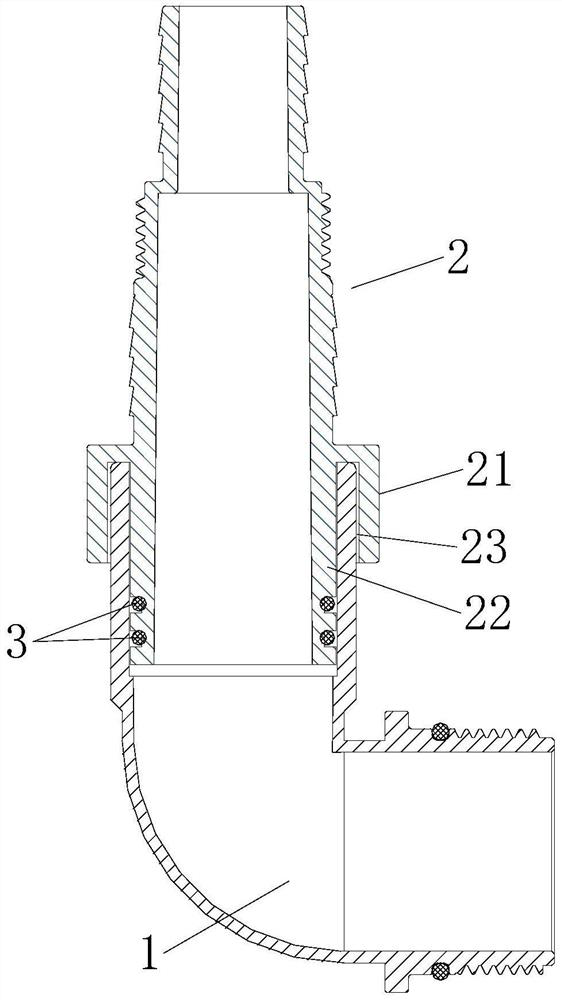

Safety valve type underwater fixed-depth releasing device

InactiveCN103935490AImprove reliabilityEasy pressure adjustmentEqualizing valvesSafety valvesSteel ballEngineering

The invention aims to provide a safety valve type underwater fixed-depth releasing device, which comprises a filter, a safety valve and a releasing mechanism, wherein the filter is fixed at the water inlet of the safety valve; the water outlet of the safety valve is connected with the releasing mechanism; a tacking bolt is pressed against a bearing bar; the bearing bar is used for bearing pressure load on both sides; an adjusting screw cap can be moved up and down on the outer surface of a lower valve body through a screw thread, and the pressure of the safety valve can be adjusted by adjusting a pressure regulating spring; the adjusting screw cap is connected with the lower valve body through a screw thread, the adjusting screw cap and the lower valve body are sealed through a sealing ring, and a locking nut can be used for preventing the adjusting screw cap from rotating freely; an upper valve body is connected with a valve body interface through a taper thread and is wound with a thread seal tape for sealing; the valve body interface is sealed with an upper cover through a sealing ring, and an interface pressure plate is used for compressing the valve body interface onto the upper cover through a bolt; the sealing cover is used for performing end face static seal between the sealing ring and the upper cover, and limiting a steel ball from rolling outwards. The safety valve type underwater fixed-depth releasing device is high in loading bearing capacity, light in weight, small in size and easy to install.

Owner:HARBIN ENG UNIV

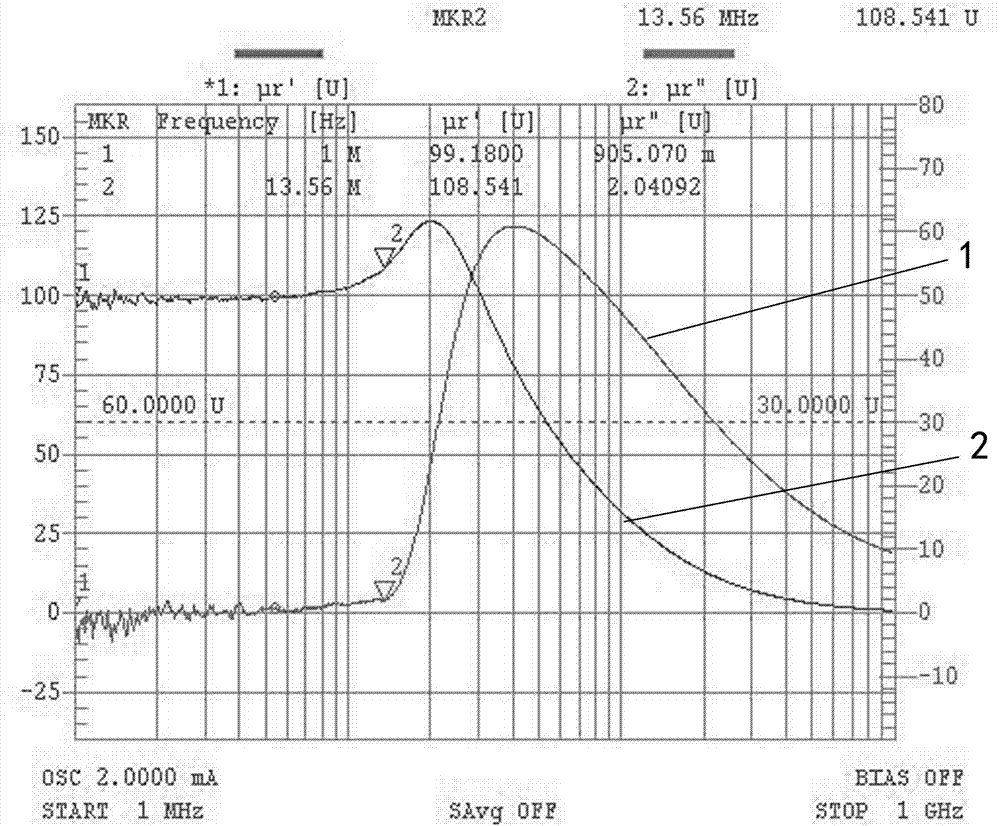

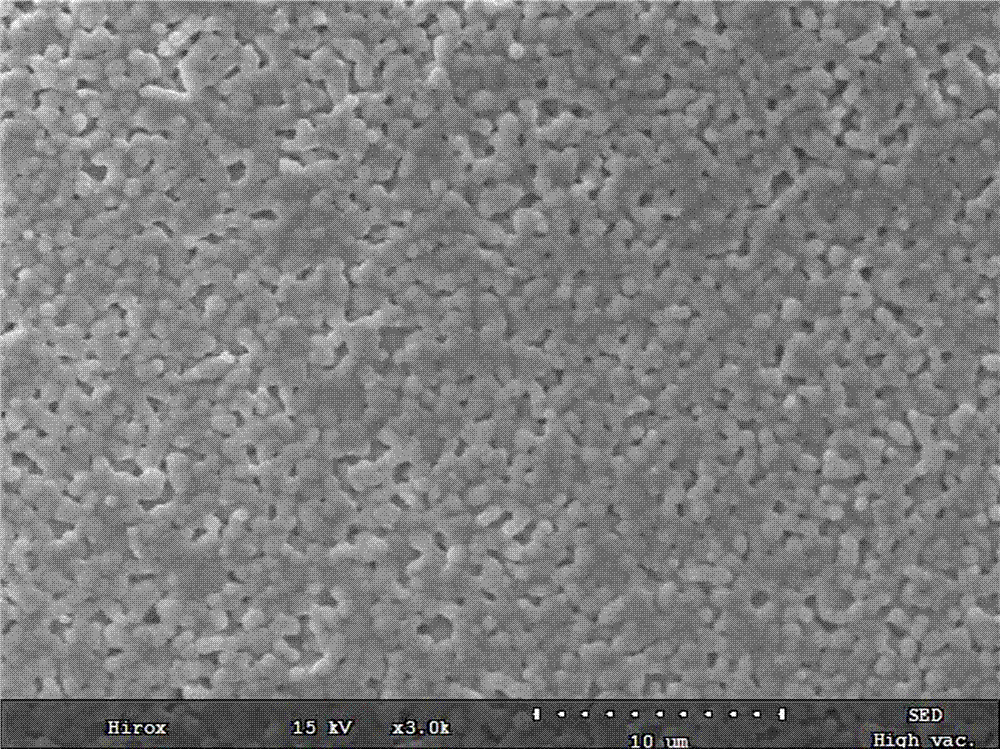

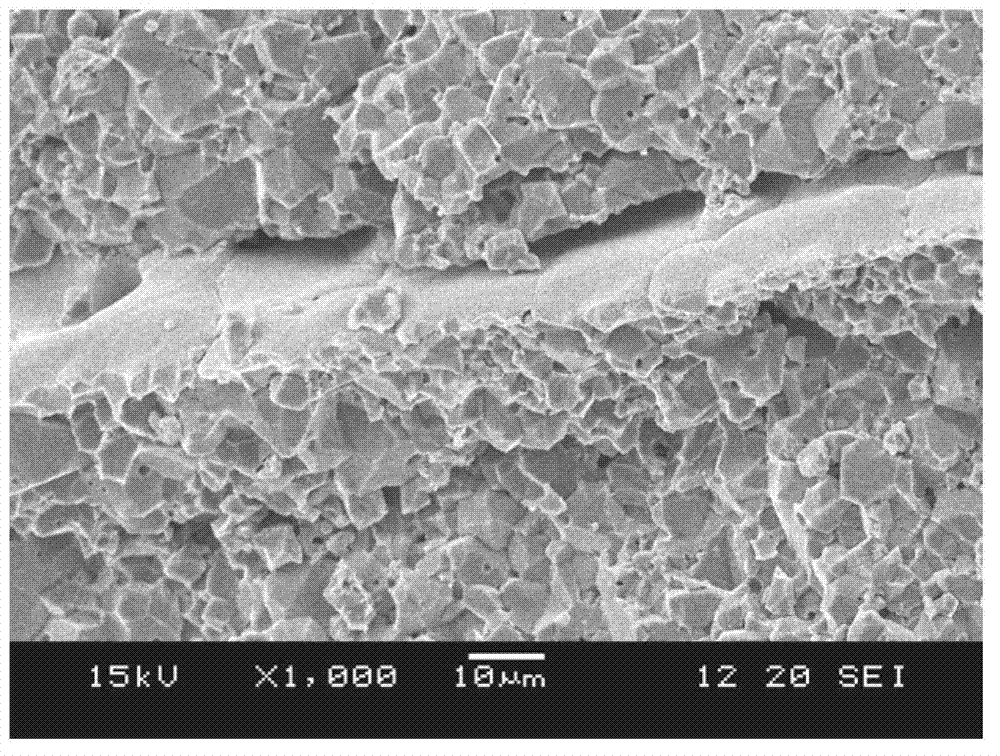

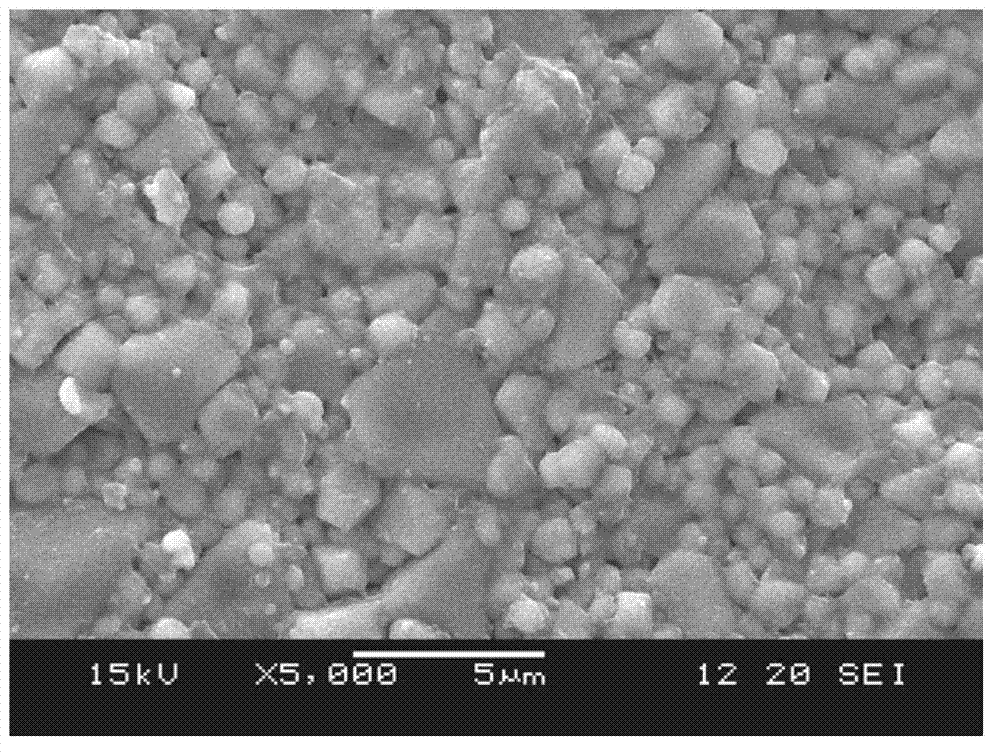

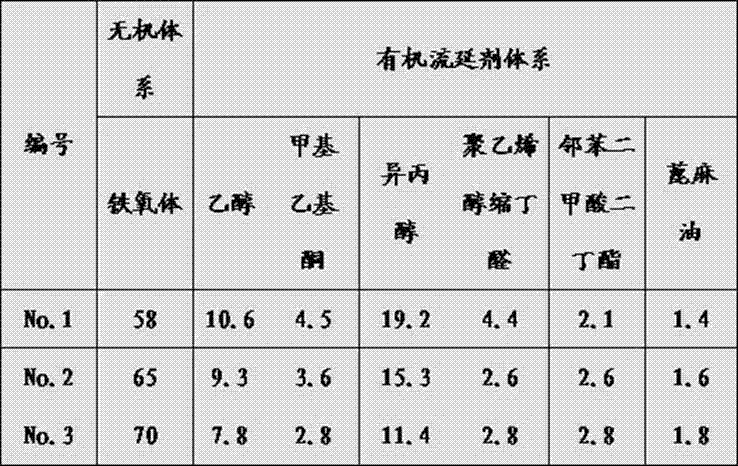

Preparation method of flexible sintered ferrite films

The invention discloses a preparation method of flexible sintered ferrite films, including: 1) preparing slurry, to be specific, adding ferrite powder and solvent into a ball-mill tank according to a preset ratio, performing ball milling; 2) filtering the slurry, to be specific, pouring prepared slurry from the ball-mill tank; 3) performing flow-casting, to be specific, casting a flat and even tape on a steel strip or a PET (polyethylene terephthalate) film by steel strip flow casting or PET film flow casting, and drying the tape in a drying oven; 4) performing lamination, to be specific, laminating the unsintered tape by a pressing machine according to thickness requirements of the film; 5) performing isostatic pressing, to be specific, performing isostatic pressing on the laminated tape; 6) cutting the tape, to be specific, cutting the tape into desired sizes; 7) performing latex discharging, to be specific, performing latex discharging at 0 to 450 DEG C at a temperature increasing speed of 0.5 DEG C / minute; 8) performing sintering, to be specific, performing sintering at 980 DEG C for 2 hours at a temperature increasing speed of 2 DEG C / minute; 9) performing laminating, to be specific, laminating the PET single-sided and double-sided adhesive films on the ferrite films by the aid of a laminating machine; and 10) performing squashing, to be specific, squashing the ferrite films.

Owner:SHENZHEN MICROGATE TECH

Chip inductance element manufactured by low-temperature co-firing ferrite unsintered tape

The invention provides a chip inductance element manufactured by a low-temperature co-firing ferrite unsintered tape. The chip inductance element is characterized in that the precise positioning punching is carried out on the ferrite unsintered tape; a screen printing method is adopted, and sliver paste is fully filled in through holes; sliver paste conductor patterns are printed on the unsintered tape, meanwhile, in order to prevent Ag diffusion caused by overhigh temperature in the use process of a device, a low-temperature glass protection coating is then printed on the sliver paste pattern surface, and the device failure caused by the Ag diffusion is prevented; the printed unsintered tape is sequentially placed into a tight lamination mold according to the predesigned layer number andthe sequence, and a complete multilayer base plate blank body is formed through isostatic pressing; the blank body subjected to isostatic pressing is divided into specific small blocks; the specific small blocks are put into a furnace, the temperature is raised to 450 DEG C, the heat preservation is carried out for 3 hours, the glue discharge is carried out, then, the temperature is raised to 900DEG C, and the heat insulation sintering is carried out; in the temperature reduction process, the temperature is controlled to be lowered to 250 DEG C in 10 hours, and then, the natural cooling along with the furnace is carried out; and the sliver brushed seal end of the sintered electric element is manufactured into the electrode, and the chip inductance element is obtained.

Owner:JIANGSU HUAXING ELECTRONICS CO LTD

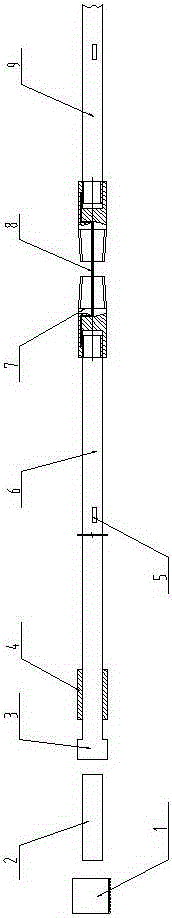

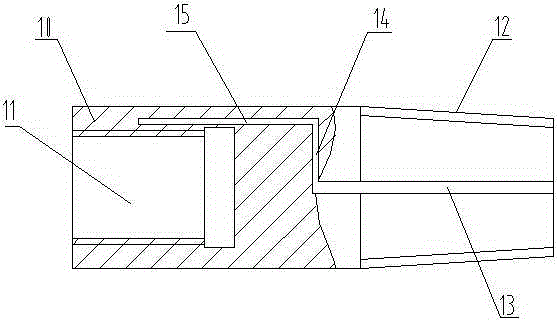

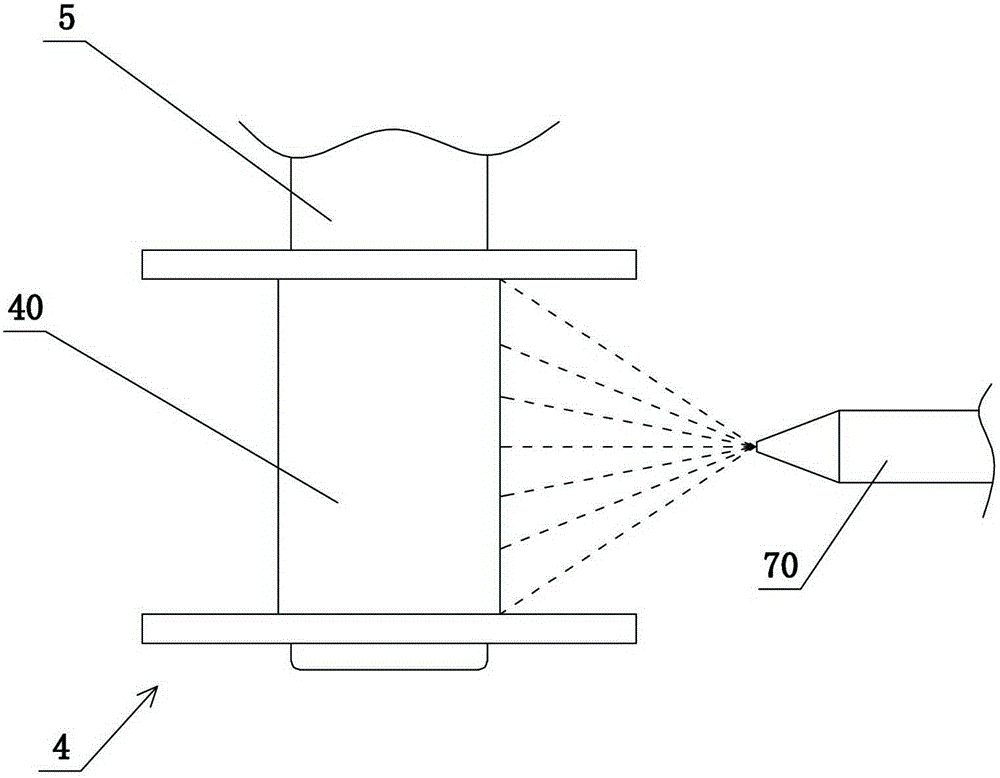

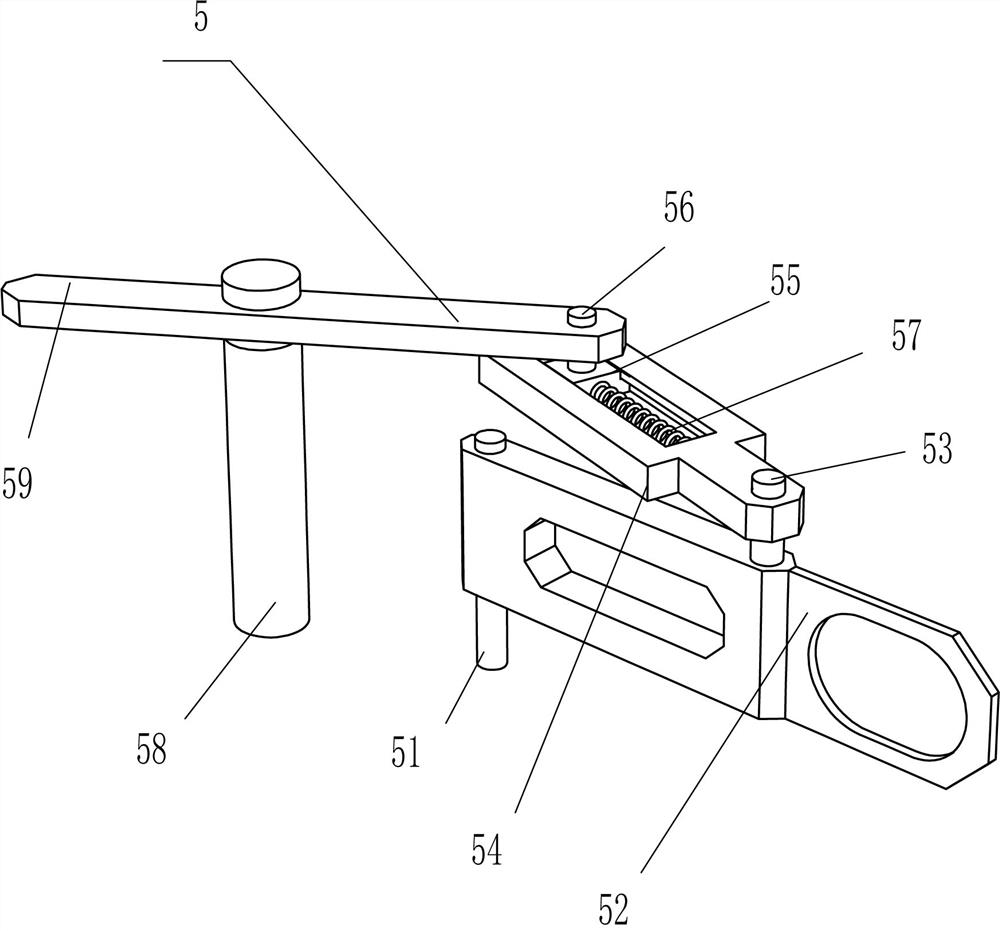

Clamping device of Hopkinson pull bar test-piece and experimental method

ActiveCN105300792AShorten experiment timeEasy to installStrength propertiesShock waveConnection type

The invention discloses a clamping device of a Hopkinson pull bar test-piece and an experimental method and belongs to the field of shock dynamics experiment. The experimental device is used in pairs. One end of an adapter is in threaded connection with an incident bar or transmission bar, and the threaded clearance is filled with thread seal tape so as to avoid the damage of shock wave to connecting thread; and the other end of the adapter is provided with a square groove to be connected to a flat test-piece. The square groove which matches the test-piece undergoes plane machining into tiny serrated teeth so as to increase frictional force during clamping. The outer rim of the adapter is processed into taper thread which matches a nut. When the clamping device is in use, clamping force perpendicular to the groove surface is provided by screwing-in the nut. According to the invention, the problem that screw thread is not easy to process in a composite material and high-strength glue is nonuniform during gluing process can be greatly avoided, connection type of a fibrous composite material under dynamic tension is studied, and a forceful foundation is laid for the constitutive relation of the fibrous composite material under dynamic tension.

Owner:TAIYUAN UNIV OF TECH

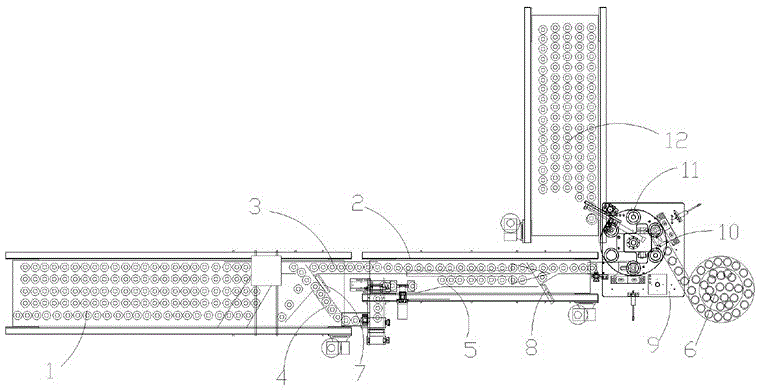

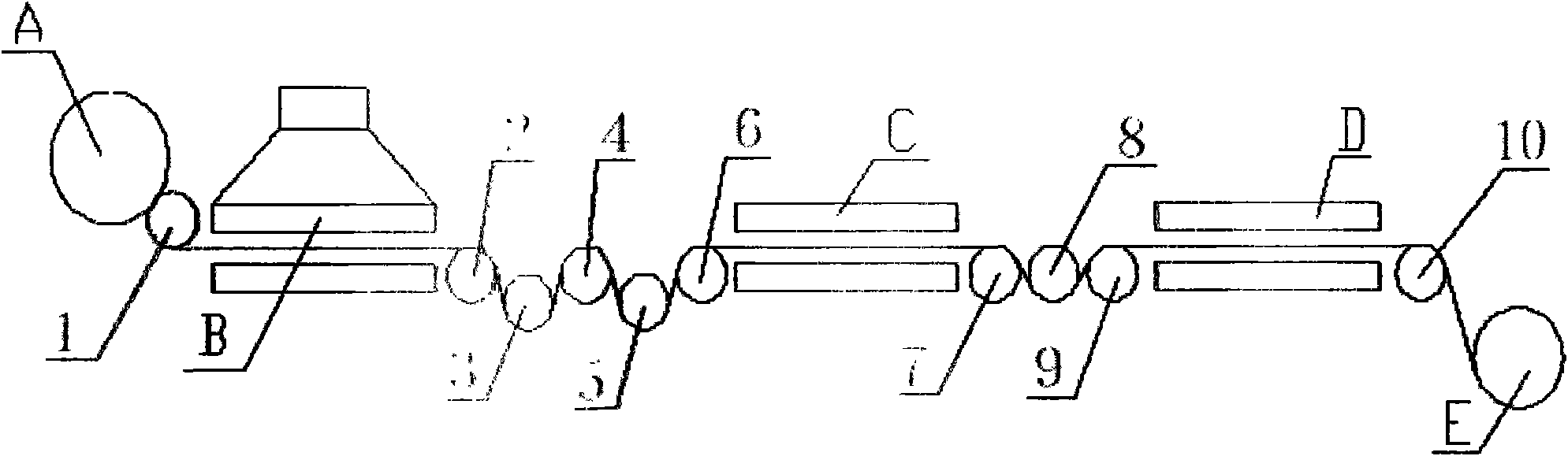

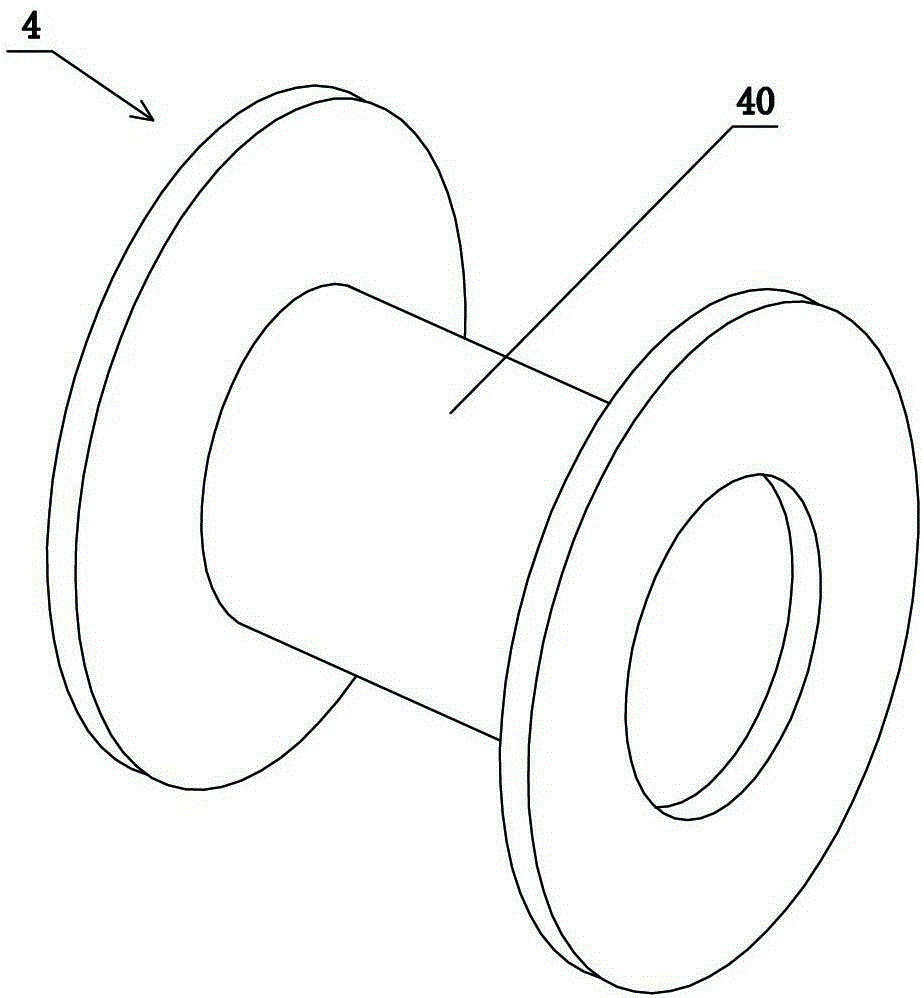

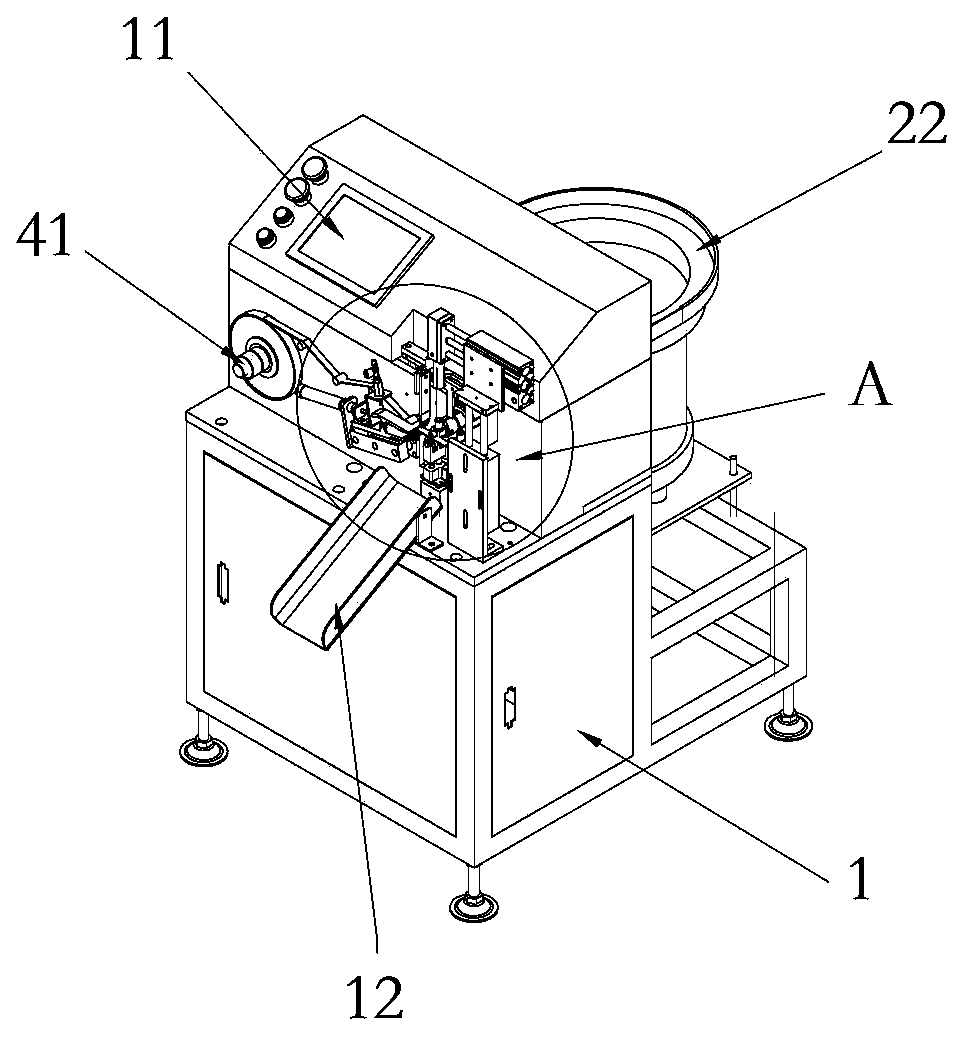

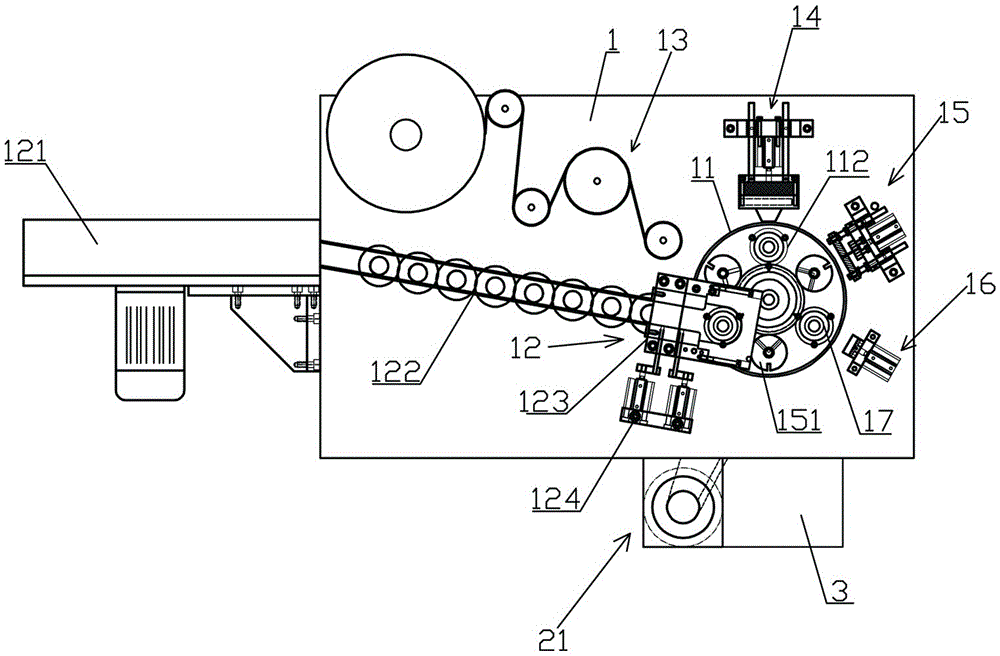

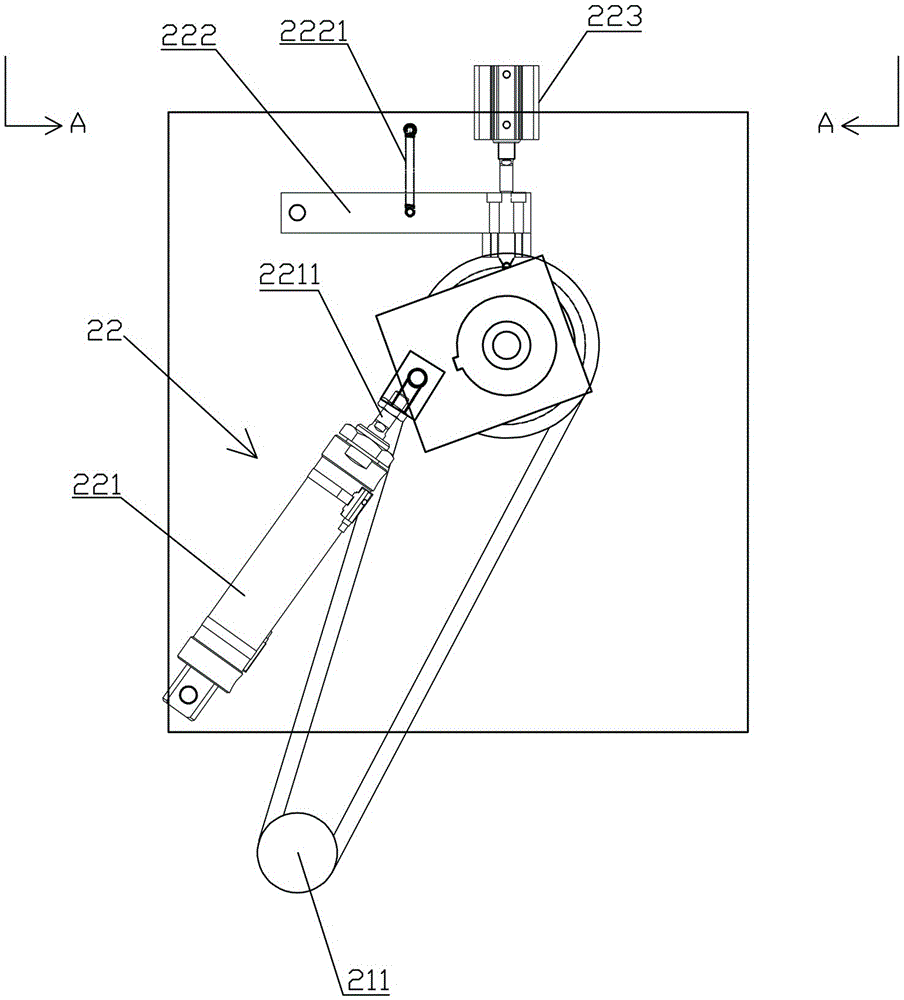

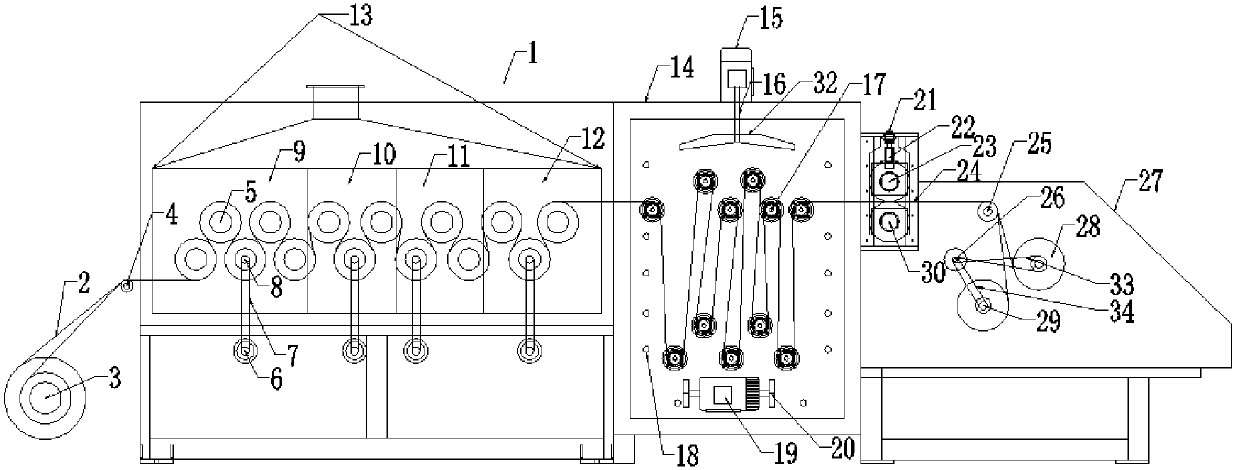

Automatic casing and packaging machine of thread seal tapes

ActiveCN106516248AReduce manufacturing costNo manual operationPackaging machinesAutomatic controlEngineering

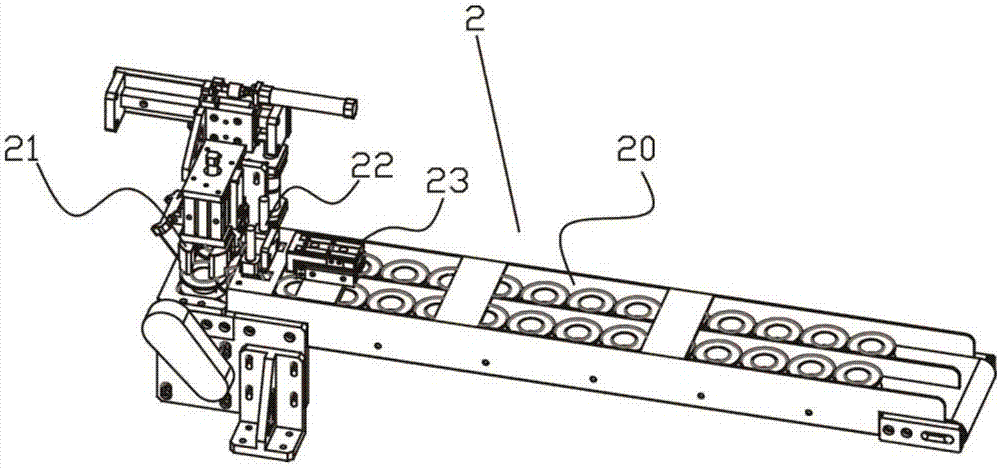

The invention provides an automatic casing and packaging machine of thread seal tapes. The machine comprises a material core conveying device used for conveying material cores, a spool conveying device used for conveying spools, a material outputting device used for conveying fastened finished products and a fastening mechanism used for fastening the material cores and the spools and conveying fastened materials to the material outputting device. According to the machine, the material cores are conveyed orderly through the material core conveying device, the back surfaces of the material cores can be separated and turned over by an overturning mechanism, then the material cores enter the fastening mechanism to be fastened to the material shells, full-automatic control is adopted in the fastening process, manual operation is not needed, the fastened finished products are automatically conveyed into the material outputting device to be automatically output, the automation degree is high, the manpower and material resources are greatly saved, and the production cost of enterprises is greatly lowered.

Owner:FUJIAN CHUN FLAG MACHINERY IND & TRADE

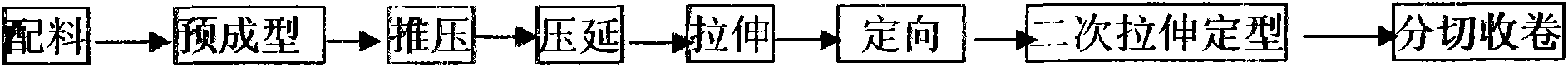

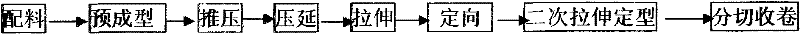

Preparation method of polytetrafluoroethylene thread seal tape film for communication cable

ActiveCN101642960AGood flexibilityImprove moisture resistanceFlat articlesUltrasound attenuationDielectric loss

The invention discloses a preparation method of polytetrafluoroethylene thread seal tape film for communication cable, comprising the following steps: proportioning and pretreating, performing, bulldozing, rolling, drawing, orienting, second drawing and forming and cutting and winding. The polytetrafluoroethylene thread seal tape film prepared by the invention has good comprehensive performance and particularly has very low dielectric constant and dielectric loss angle tangent; the thread seal tape film can not be affect by the changes of frequency and temperature so as to effectively reduce the attenuation and loss of transmission and greatly improve the transmission rate; in addition, the prepared communication cable has good softness and humidity resistance and can be used for a long time at -65 DEG C to 260 DEG C.

Owner:四会市生料带厂有限公司

Concrete with-mold backfill grouting system and grouting method for vault of tunnel

PendingCN108316950AGood fluidity and pumpabilityHigh strengthUnderground chambersTunnel liningClerestoryPolytetrafluoroethylene

The invention discloses concrete with-mold backfill grouting system and grouting method for a vault of a tunnel. The problems which exist in an existing backfill grouting way and that a device is manyin investment, the construction period is long and the backfill grouting of a disengagement area is incompact are solved. A vault of a secondary lining trolley (6) is provided with a backfill grouting opening (7); the end of a backfill grouting pipe (1) passages through a ring flange (8) and then is inserted into the backfill grouting opening; a port of the backfill grouting pipe is top-stuck ona primarily lined waterproof layer (5); a polytetrafluoroethylene tape is wound on the outer side of a crisscross grouting groove (3); a polytetrafluoroethylene tape is stuck on a pipe orifice of thebackfill grouting pipe; a pressure sensor (13) is arranged in a pipe orifice of the lower end of the backfill grouting pipe; the pipe orifice of the lower end of the backfill grouting pipe is connected with a connecting sleeve; (16); the lower end of the connecting sleeve is connected with a grout delivery pipe (18) and a grouting pump; backfill grouting grout is arranged in the grouting pump. thedefect of a cavity in a secondarily lined vault is eliminated to the maximum extent.

Owner:CHINA RAILWAY 19TH BUREAU GRP 3RD

Strip cutter for polytetrafluoroethylene sealing tape for thread sealing

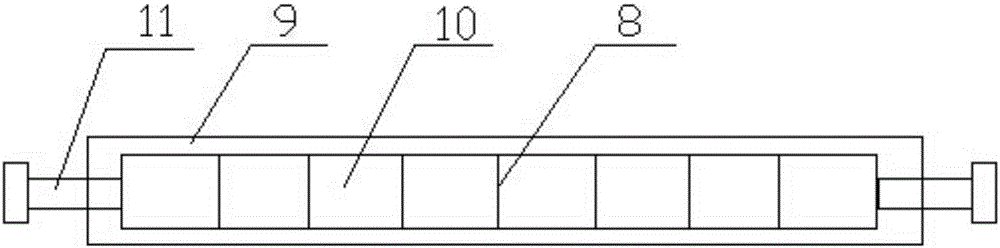

InactiveCN105035826AAvoid stretchingIncrease productivityArticle deliveryWebs handlingMotor driveReducer

The invention discloses a strip cutter for polytetrafluoroethylene sealing tape for thread sealing. The strip cutter comprises a rack, a motor, a speed reducer, a decoiling device, tension rollers, a cutting device and a coiling device. The cutting device is arranged between the decoiling device and the coiling device. The decoiling device, the tension rollers, the cutting device and the coiling device are arranged on the rack. The tension rollers are arranged on the two sides of the cutting device. The coiling device comprises an upper coiling device body and a lower coiling device body, wherein the upper coiling device body and the lower coiling device body are used for containing tape winding cylinders. The sealing tape passing through the cutting device conducts cylinder winding through the upper coiling device body and the lower coiling device body. The motor drives the coiling device to rotate. The speed reducer is connected between the motor and the coiling device. The strip cutter has the beneficial effects that the strip cutter for the polytetrafluoroethylene sealing tape cuts original wide sealing tape into sealing tape which is narrow in upper part and lower part in a spaced manner, cylinder winding is carried out, the production efficiency can be improved, and the sealing tape can be prevented from being drawn and deformed.

Owner:TIANJIN TIANSUBINHAI PTFE PLASTIC PROD

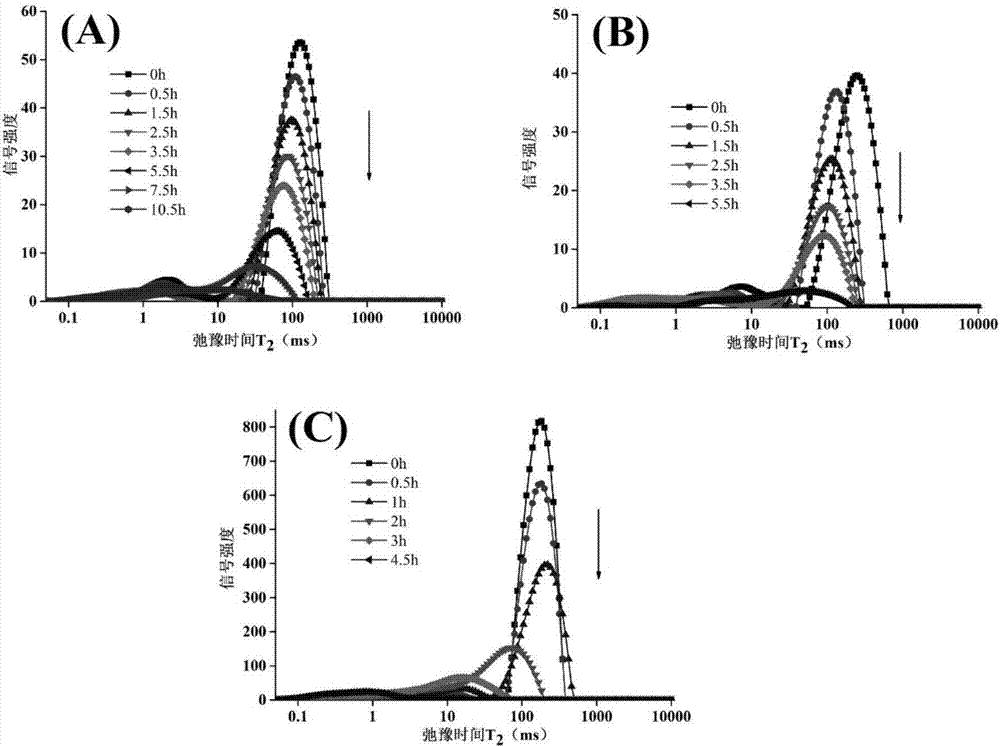

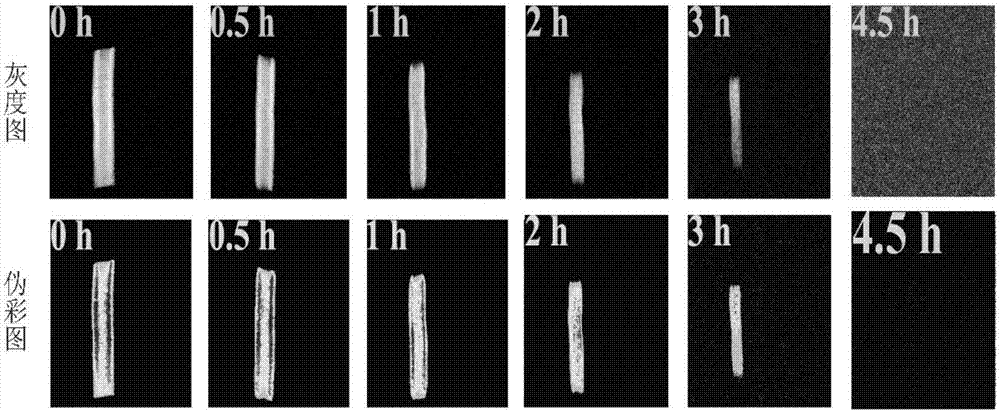

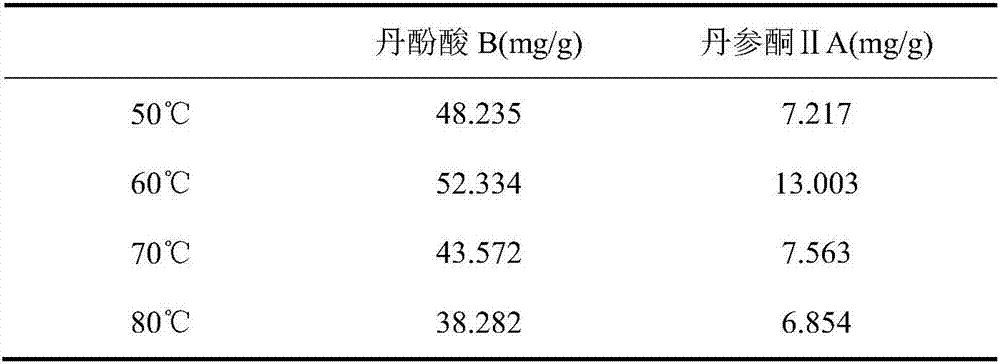

Nondestructive testing method for water distribution in drying process of roots of red-rooted salvia

ActiveCN107091852AReduce water contentReduce energy exchangeWater resource assessmentAnalysis using nuclear magnetic resonanceBound waterRoom temperature

The invention discloses a nondestructive testing method for water distribution in the drying process of roots of red-rooted salvia. Roots of red-rooted salvia samples with different drying times and different drying temperatures are coated with thread seal tapes in a sealed mode, and the coated roots of red-rooted salvia samples are placed for 3-5min at room temperature; a T2 spectrogram and proton density weighed images are obtained through the low-field nuclear magnetic resonance technology, the positions of 10 ms and 100 ms in the T2 spectrogram serve as boundaries, bound water exists at the positions of 0.1-10 ms, water not likely to flow exists at the positions of 10-100 ms, free water exists at the positions of 100-1,000 ms, the peak integral area serves as the relative content of the water, and therefore the relative content of the bound water, the relative content of the water not likely to flow and the relative content of the free water are obtained; distribution positions of the water in the roots of red-rooted salvia samples in the roots of red-rooted salvia samples are obtained according to the proton density weighed images, therefore, the distribution states of the bound water, the water not likely to flow and the free water of the roots of red-rooted salvia samples with the different drying times and the different drying temperatures are obtained, and then the water distribution in the drying process of the roots of red-rooted salvia is obtained.

Owner:SHANDONG ANALYSIS & TEST CENT

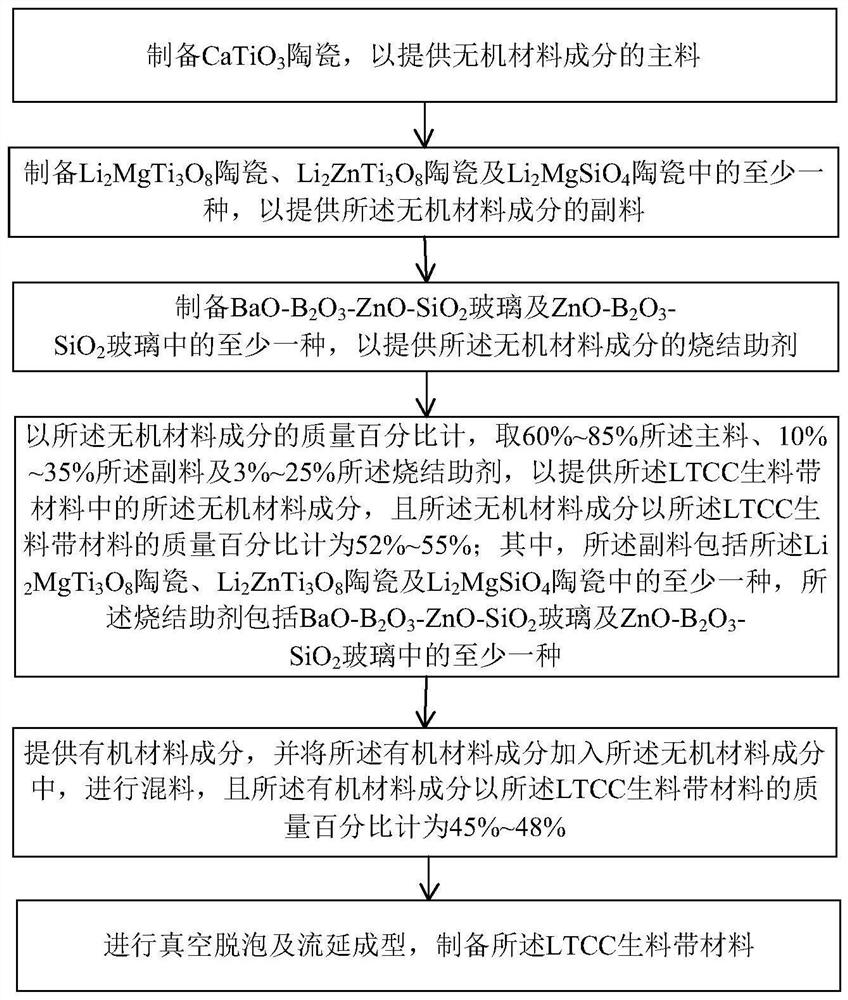

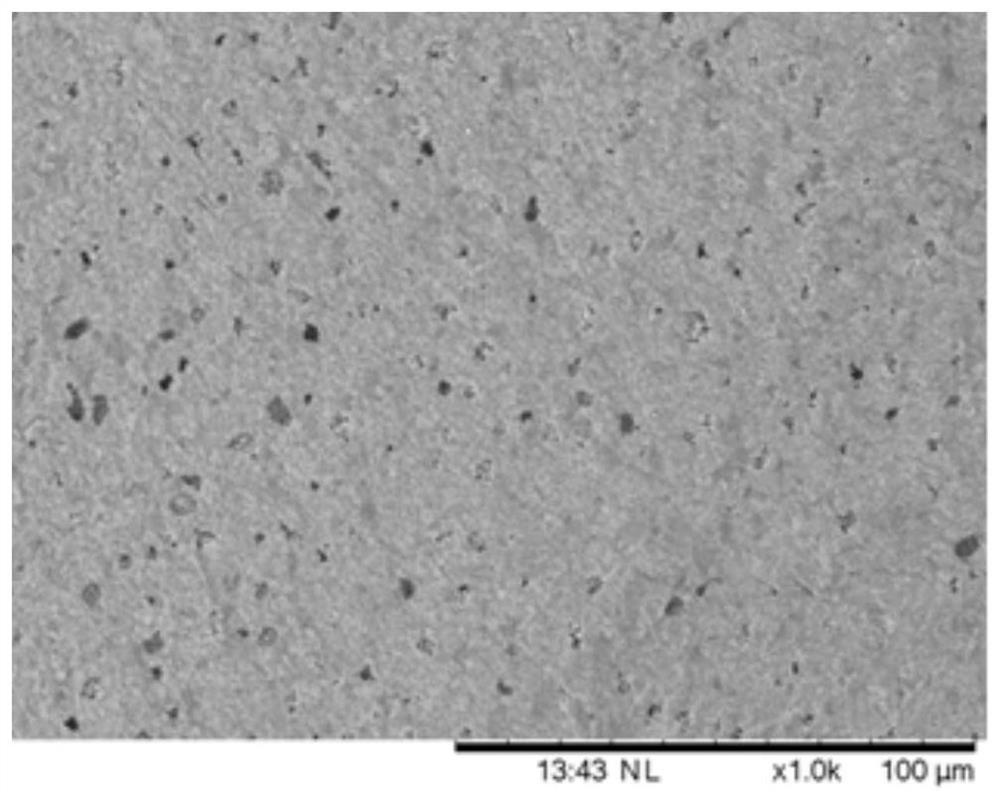

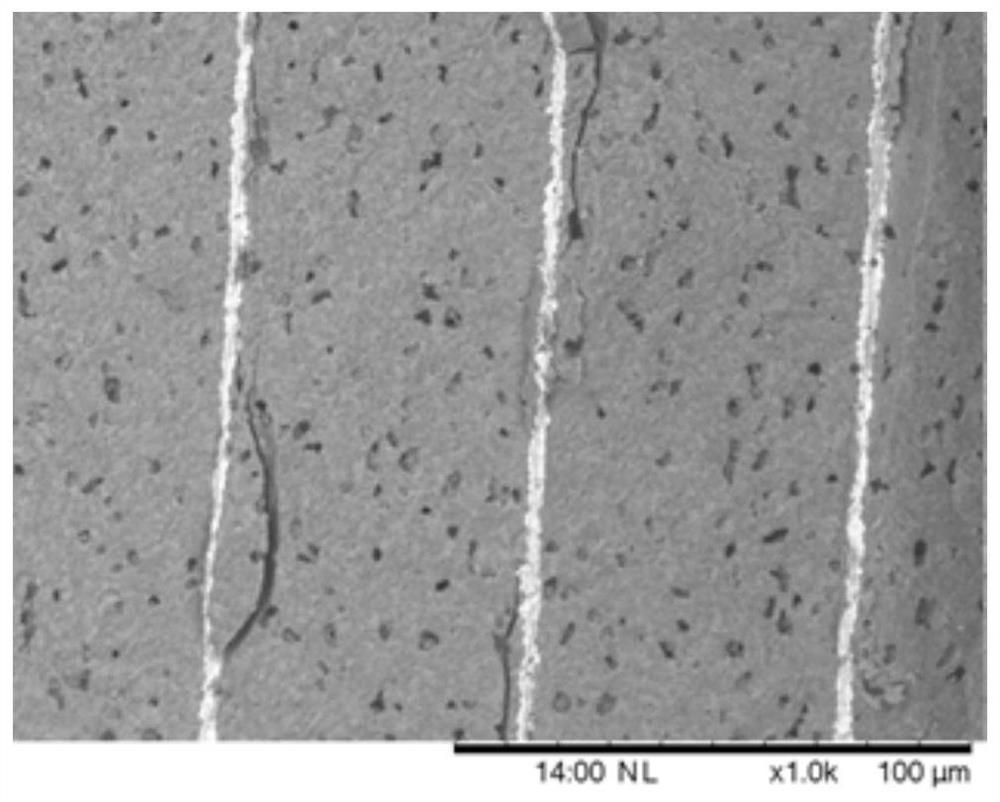

LTCC raw material tape material, substrate and preparation method

The invention provides an LTCC raw material tape material, a substrate and a preparation method. Li-based ceramic with relatively low sintering temperature is adopted in inorganic material components, so that the dielectric constant of a mixture can be effectively adjusted in the sintering process, and the sintering assisting effect can be achieved. In organic material components, a solvent is selected from an alcohol-ketone mixed solvent which is low in boiling point, easy to volatilize and good in solubility with the binder, so that the tape casting effect is good, and the LTCC raw material tape material which is smooth in surface and uniform in thickness is formed. The medium-high dielectric constant LTCC teflon tape material and the LTCC substrate which have the dielectric constant of 40-80, the dielectric loss of 1.0*10<-3> to 2*10<-3> and good cofiring performance with low-melting-point metal slurry can be prepared.

Owner:上海晶材新材料科技有限公司 +1

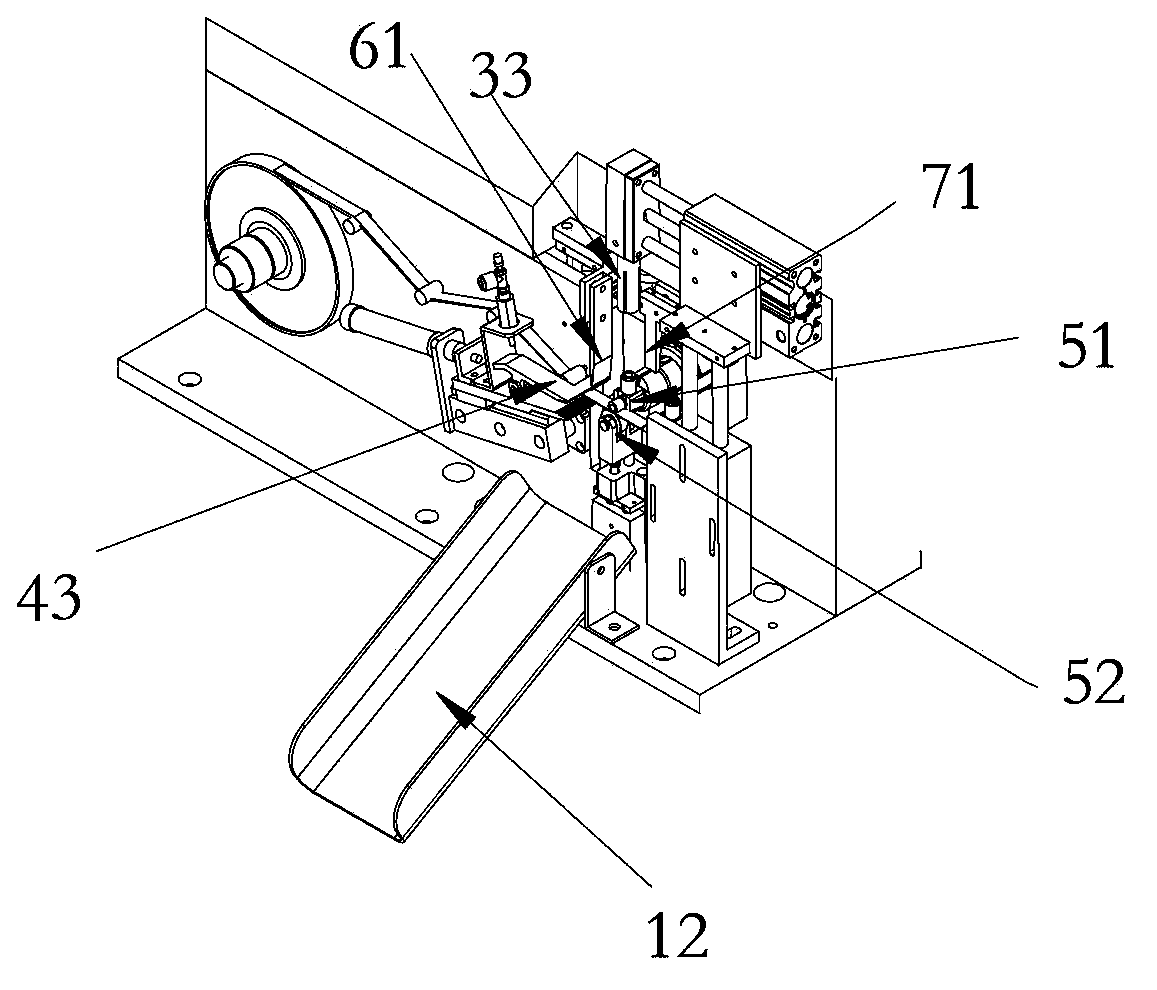

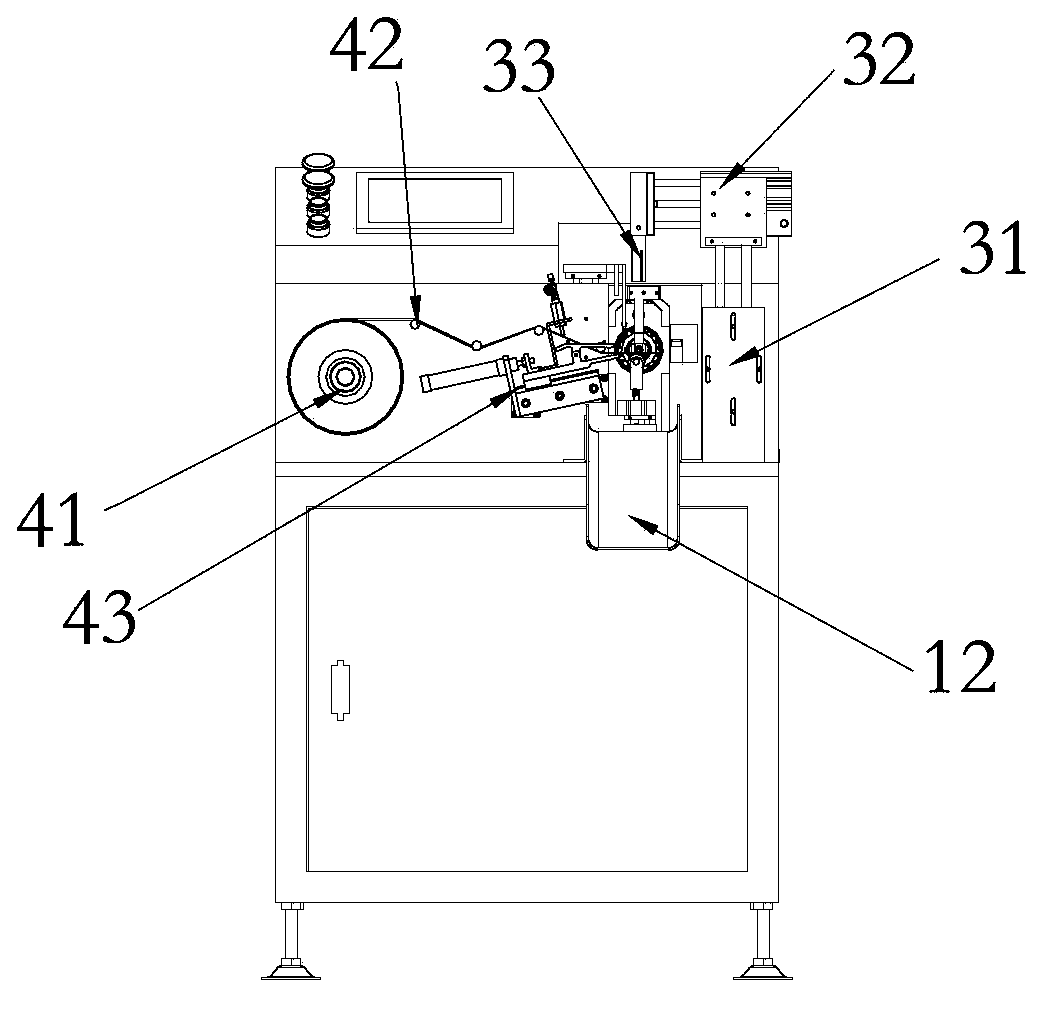

Labeling mechanism for thread seal tapes

PendingCN107985705ARealize automatic labelingImprove labeling efficiencyLabelling machinesThread seal tapeMechanical engineering

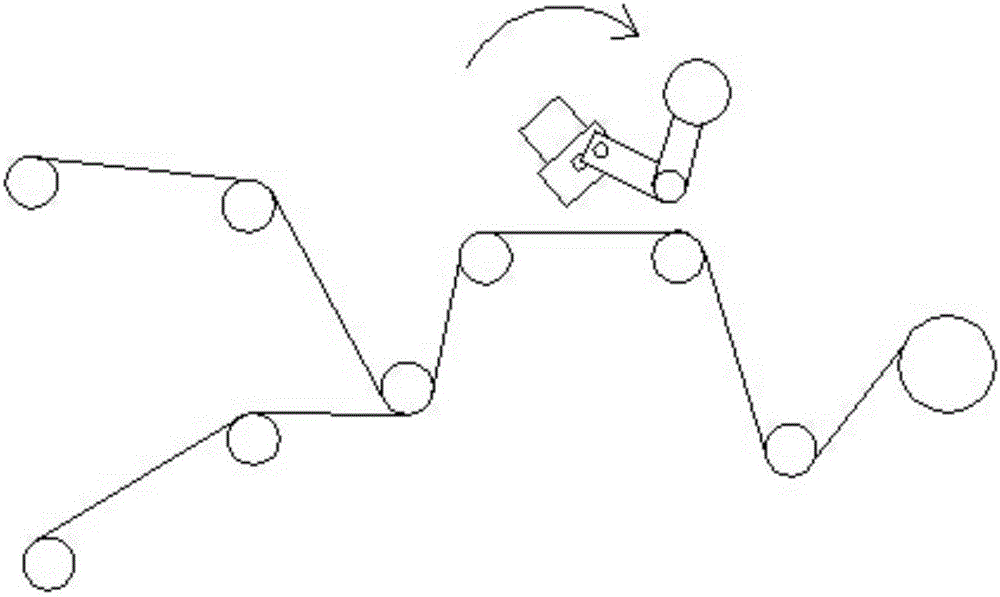

The invention discloses a labeling mechanism for thread seal tapes. The labeling mechanism comprises a workbench, wherein a rotary table is arranged on the workbench, and fixed seats allowing placement of the thread seal tapes are arranged in the circumferential direction of the rotary table; a thread seal tape conveying mechanism, a thread seal tape label tearing mechanism and a thread seal tapelabeling mechanism are arranged in the circumferential direction of the rotary table in sequence. According to the labeling mechanism for the thread seal tapes, automatic labeling of the thread seal tapes is realized, and labeling efficiency of the thread seal tapes is substantially improved.

Owner:宁波聚华光学科技有限公司

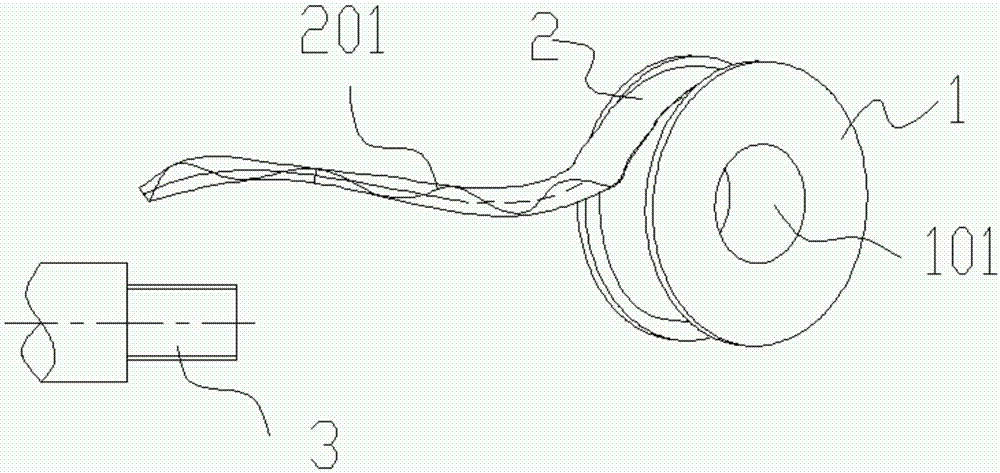

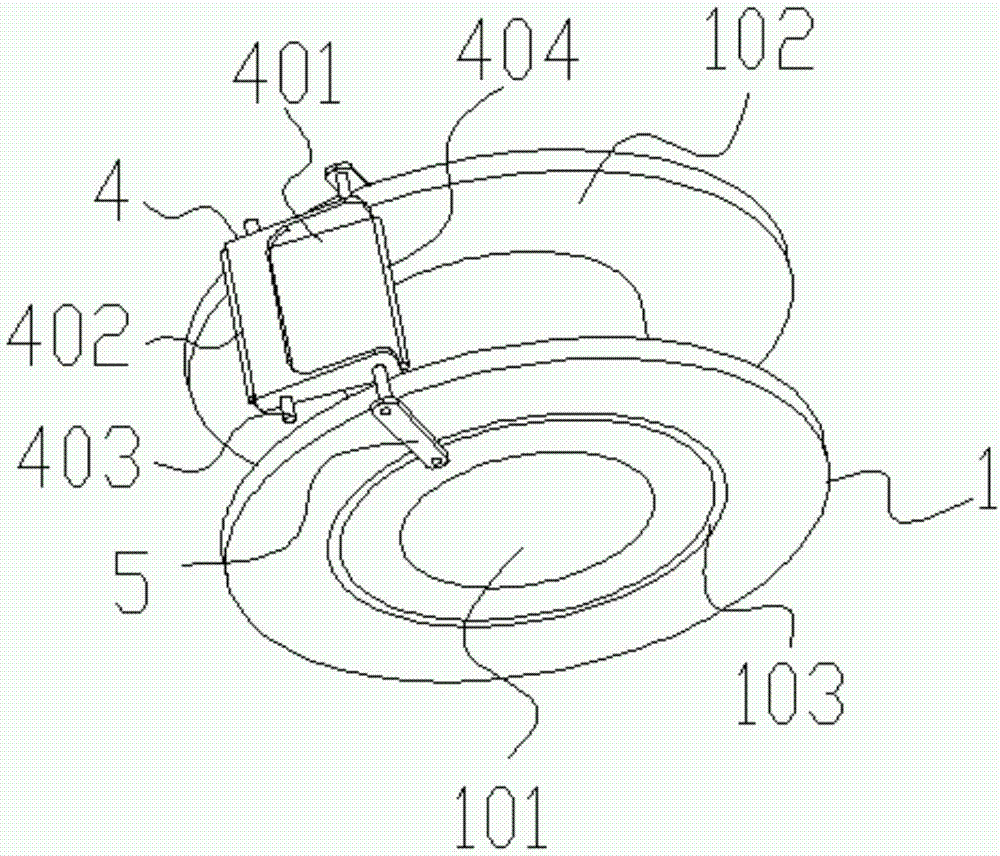

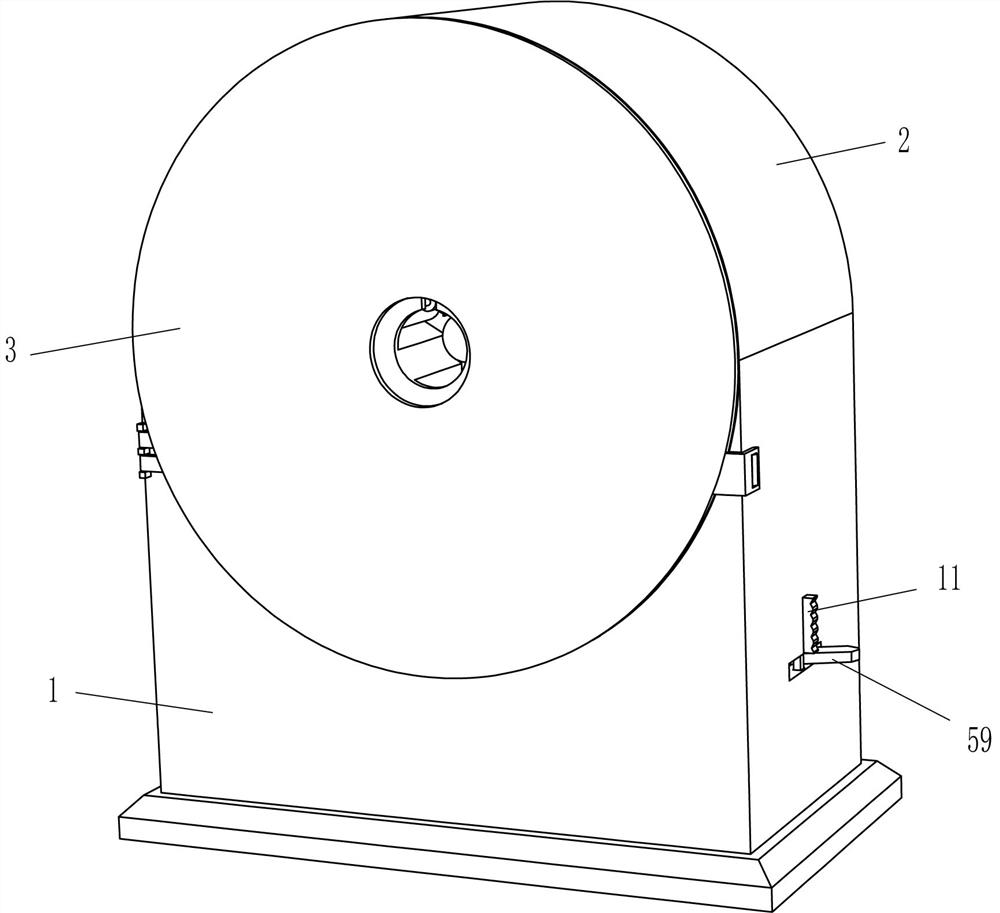

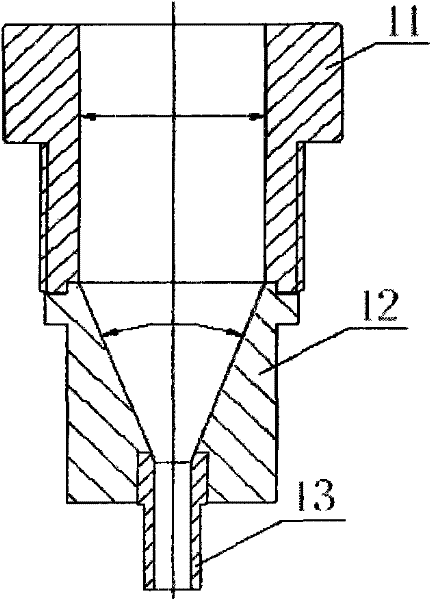

Anti-twisting winding core barrel for winding of water pipe connector PTFE thread seal tape and anti-twisting mechanism of anti-twisting winding core barrel

The invention discloses an anti-twisting winding core barrel for winding of water pipe connector PTFE thread seal tape and an anti-twisting mechanism of the anti-twisting winding core barrel, and belongs to the field of building materials. The anti-twisting winding core barrel is mainly suitable for water heating device installation and comprises a winding core barrel body, the center of the winding core barrel body is provided with a central hole, and the two sides of the winding core barrel body are provided with side walls; a hollow setting-out head rotating around the winding core barrel body is arranged between the two side walls and connected to the winding core barrel body through rotary arms movably connected with the winding core barrel body; and the front end of the setting-out head is smaller than the tail end of the setting-out head, and the PTFE thread seal tape is fed from the tail end and discharged from the front end. According to the anti-twisting winding core barrel for winding of the water pipe connector PTFE thread seal tape and the anti-twisting mechanism of the anti-twisting winding core barrel, twisting of the PTFE thread seal tape during using is avoided, construction is convenient, wasting is avoided, meanwhile, materials are saved, and the construction period is shortened.

Owner:朱卫东

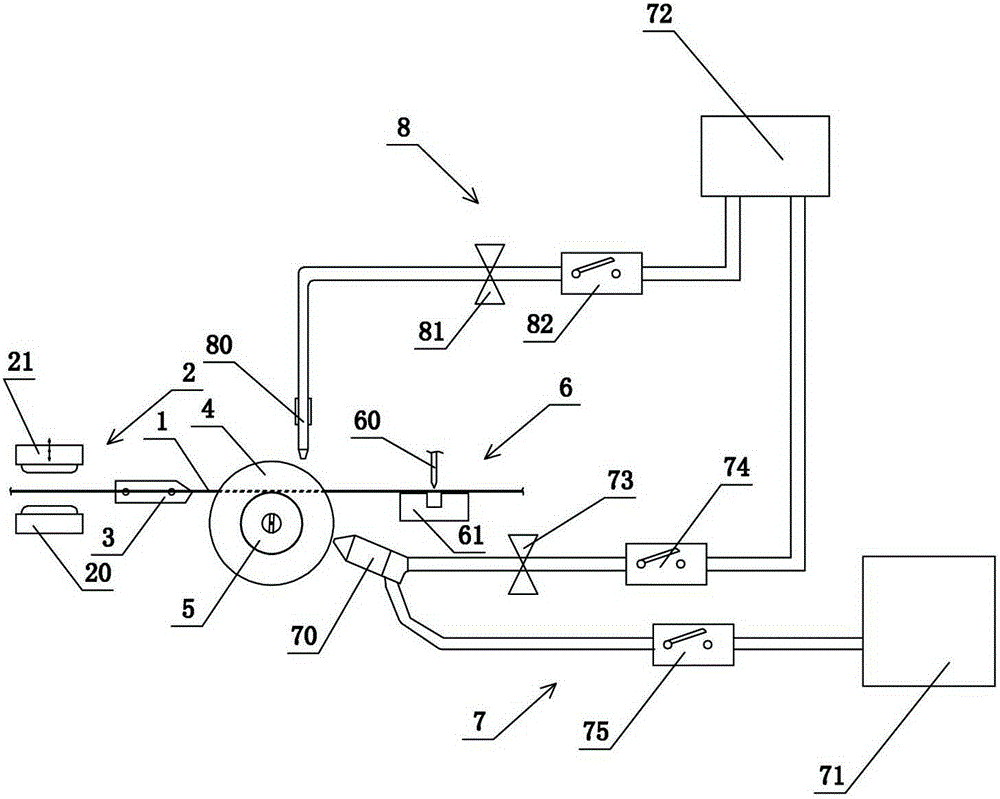

Automatic liquid feeding and tape head winding method for thread seal tape

An automatic liquid feeding and tape heat winding method for thread seal tape comprises the following steps that the rotation opening motion, the liquid feeding motion, the tape head preliminary attaching motion, the tape head depth attaching motion and the rewinding motion are carried out. According to the automatic liquid feeding and tape heat winding method for the thread seal tape, the principle that liquid has certain adhesive force between two attaching surfaces is fully utilized so as to complete the processes of automatic liquid feeding and tape head winding; and manners of vertical blowing and side blowing are adopted to achieve the aim that the tape head segment is efficiently, rapidly and flatly pressed on a hollow wheel framework, so that in the whole process, the automatic tape head winding working procedure can be achieved within only one or two seconds, the completing effect is ideal, and the technology quality is greatly improved. The tape head segment can be completely attached to the groove bottom cylinder face of the hollow-wheel framework, the appearance of a product seems flat, neat and tidy, and the quality is good.

Owner:黄聪伟

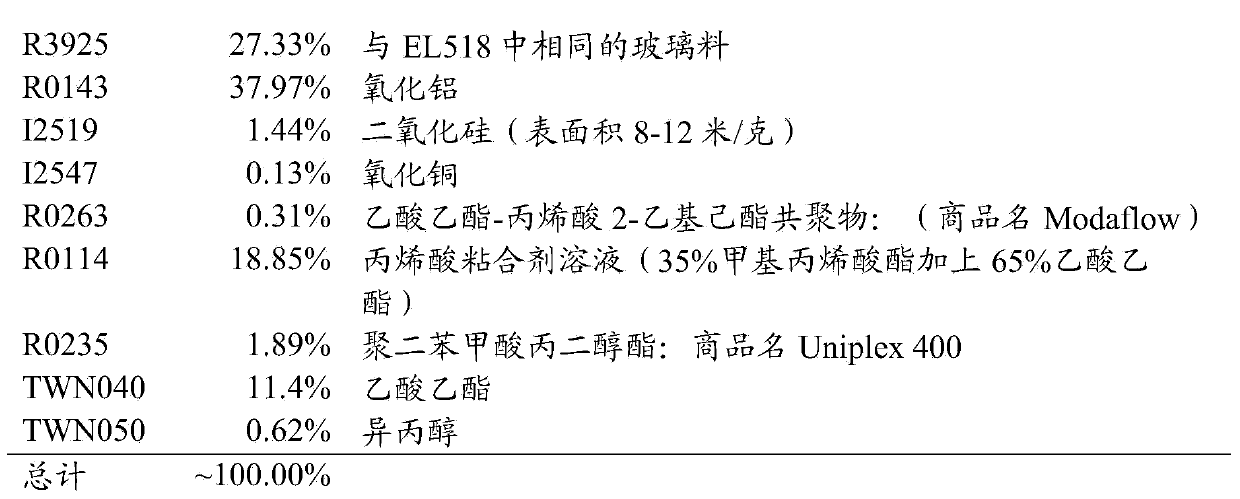

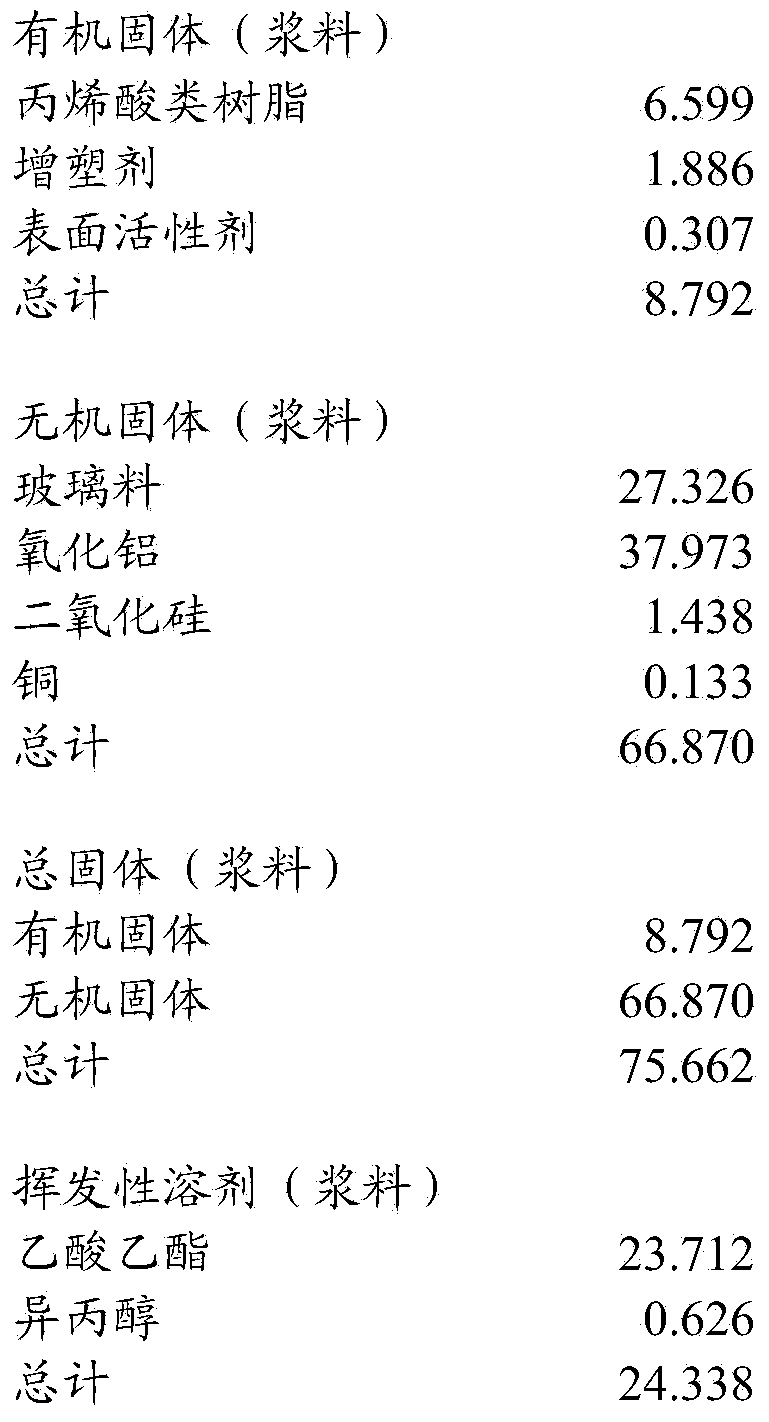

Compositions for low K, low temperature co-fired composite (LTCC) tapes and low shrinkage, multi-layer LTCC structures formed therefrom

ActiveCN103748048AQuartz/glass/vitreous enamelsPrinted circuit manufactureGreen tapeComposite laminates

The present invention provides novel compositions for LTCC green tapes having low K values and low shrinkage and composite laminates of ten to twenty layers or more of green tapes together with conventional LTCC green tapes.

Owner:DUPONT ELECTRONICS INC

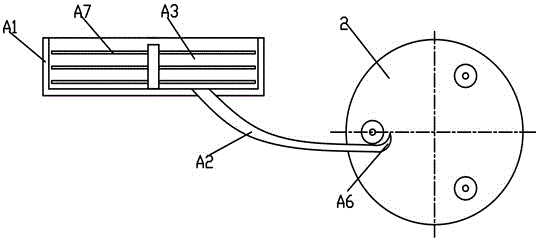

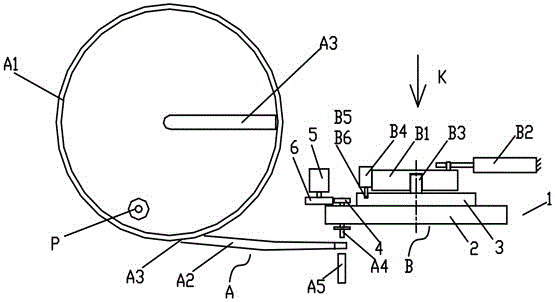

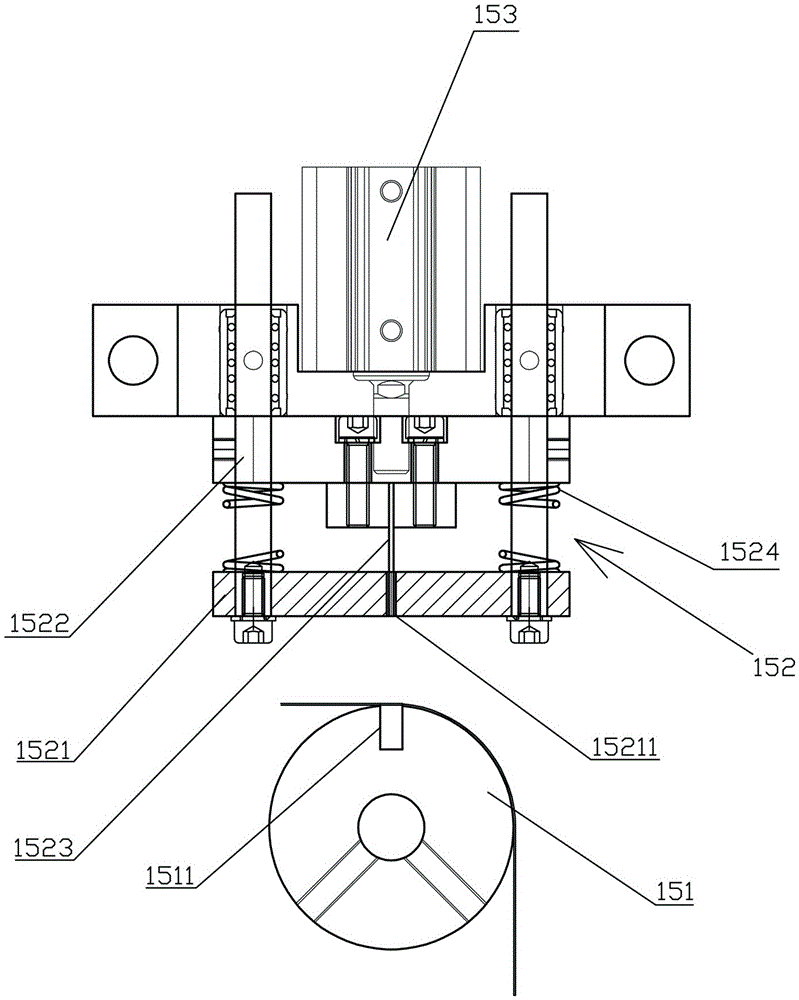

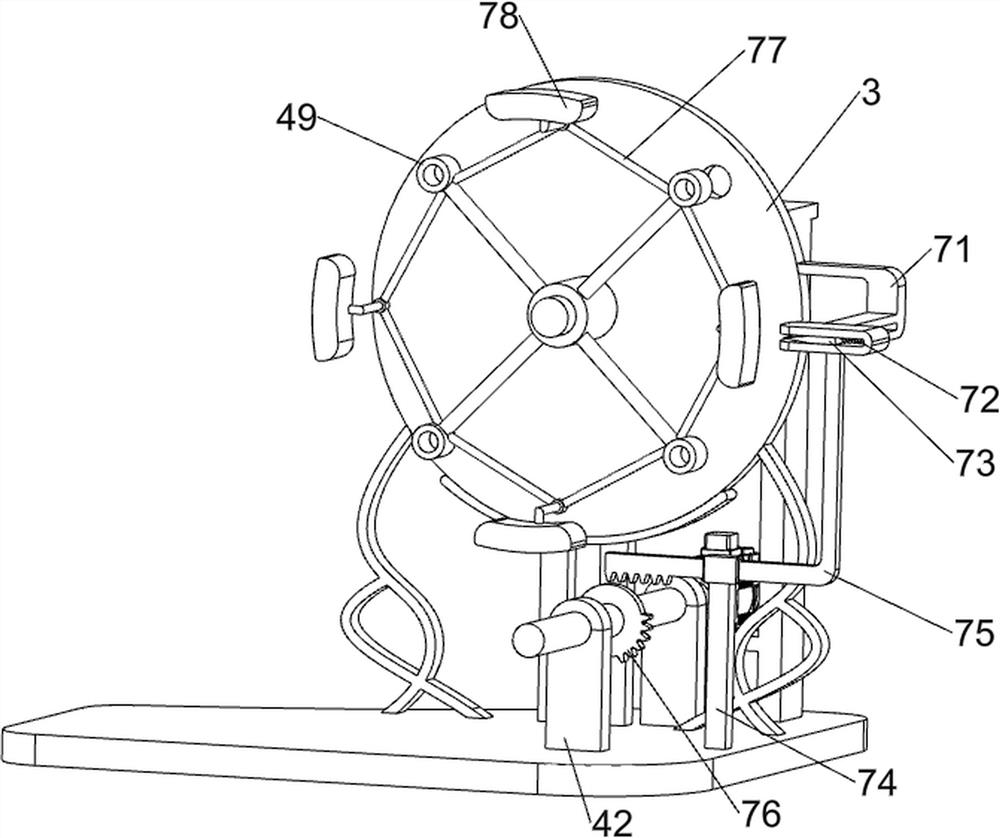

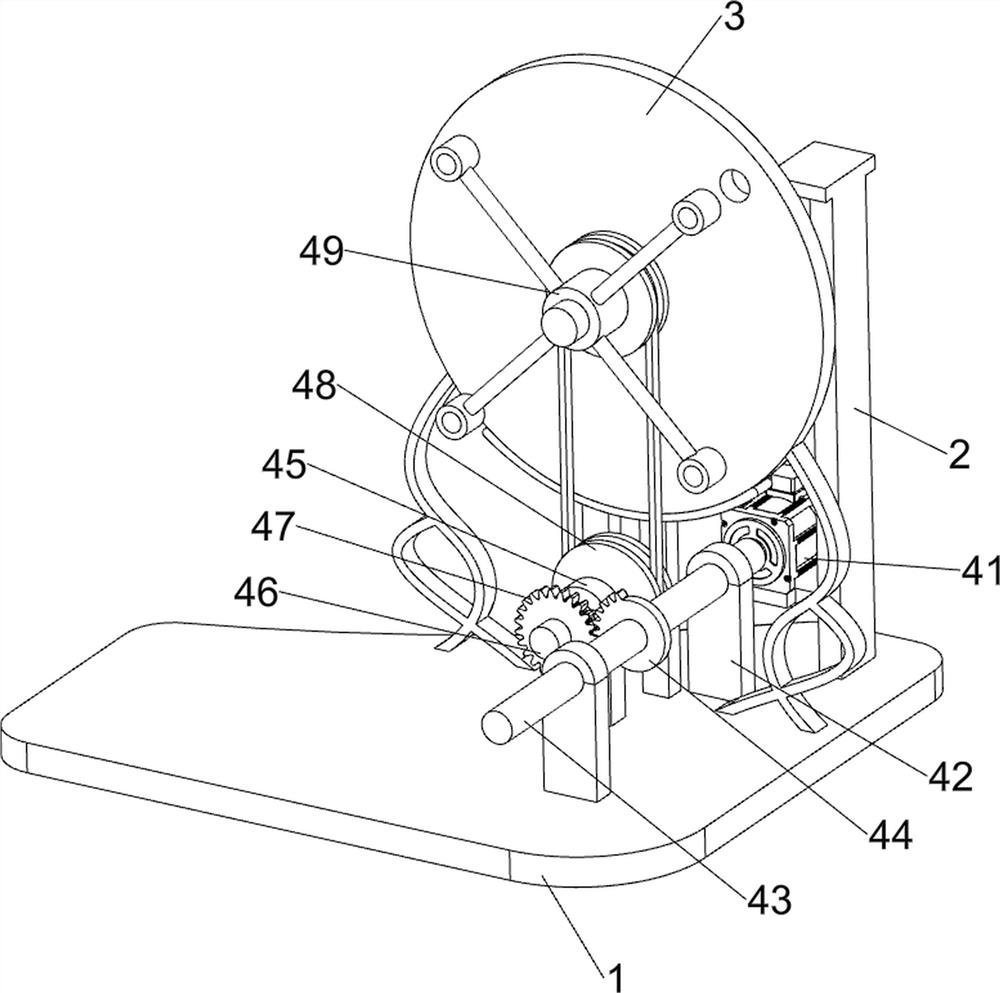

Thread seal tape roll core action device and work method thereof

ActiveCN105923375ASimple structureReasonable designConveyor partsRotary conveyorsEngineeringThread seal tape

The invention relates to a thread seal tape roll core action device and a work method thereof. The thread seal tape roll core action device is characterized by comprising a machine body, an outer rotary table arranged on the machine body, and a middle rotary table which is fixedly connected with the outer rotary table and is coaxial with the outer rotary table, a thread seal tape feeding driving and acting mechanism is arranged on the lateral side of the outer rotary table to be used for feeding a roll core, and a thread seal tape rotary table driving and acting mechanism is arranged on the rear side of the middle rotary table to be used for driving a rotary table of the roll core to rotate. The thread seal tape roll core action device is simple in structure and reasonable in design, and mechanical automation of thread seal tape roll core conveying and station converting can be achieved easily.

Owner:FUJIAN CHUN FLAG MACHINERY IND & TRADE

Thread seal tape winding equipment

The invention discloses thread seal tape winding equipment. The thread seal tape winding equipment comprises a support, a feeding device, a fetching device, a conveying device, a winding device, a cutting device and a pushing and discharging device, and the feeding device, the fetching device, the conveying device, the winding device, the cutting device and the pushing and discharging device are arranged on the support. The thread seal tape winding equipment can decompose an original assembly process, an automatic device replaces the original assembly process, the production efficiency is improved, the labor cost is lowered, labor intensity is relieved, the quality of finished products is ensured, and yield is improved.

Owner:GREE ELECTRIC APPLIANCES INC

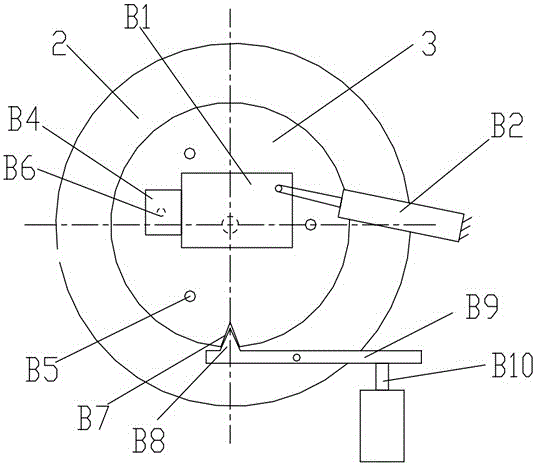

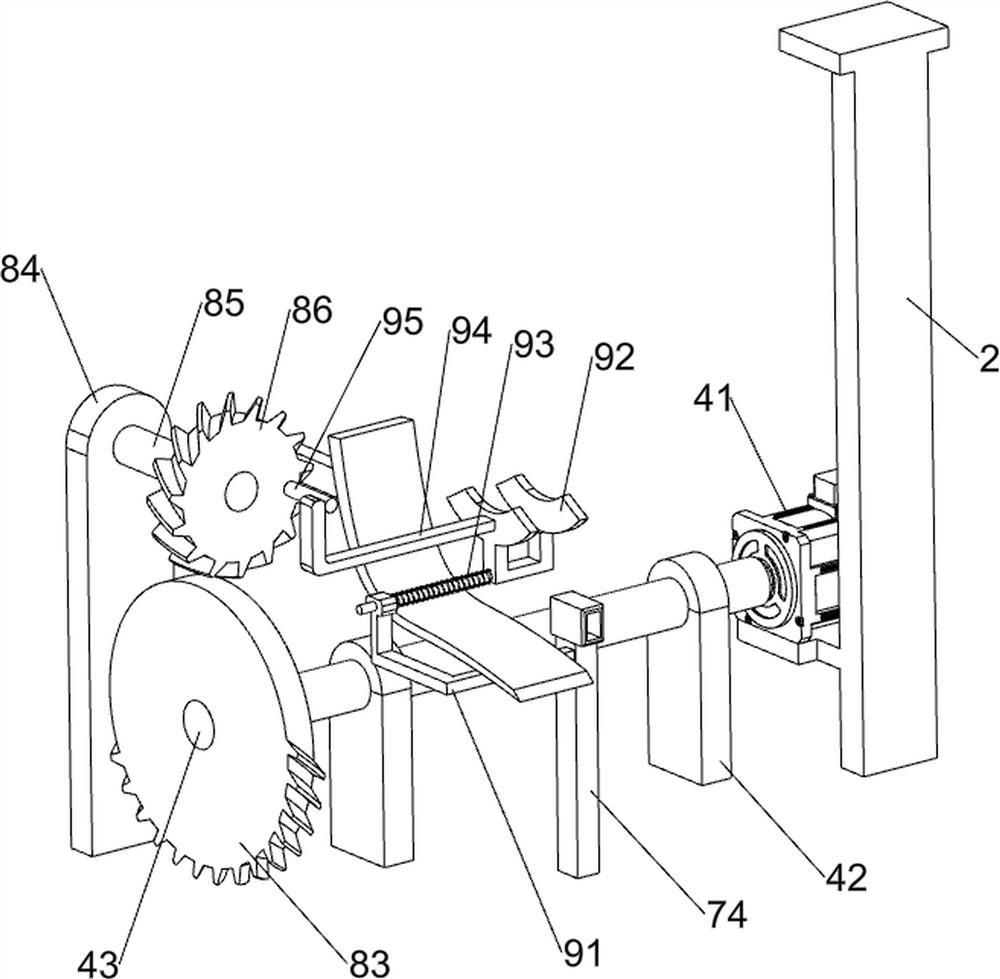

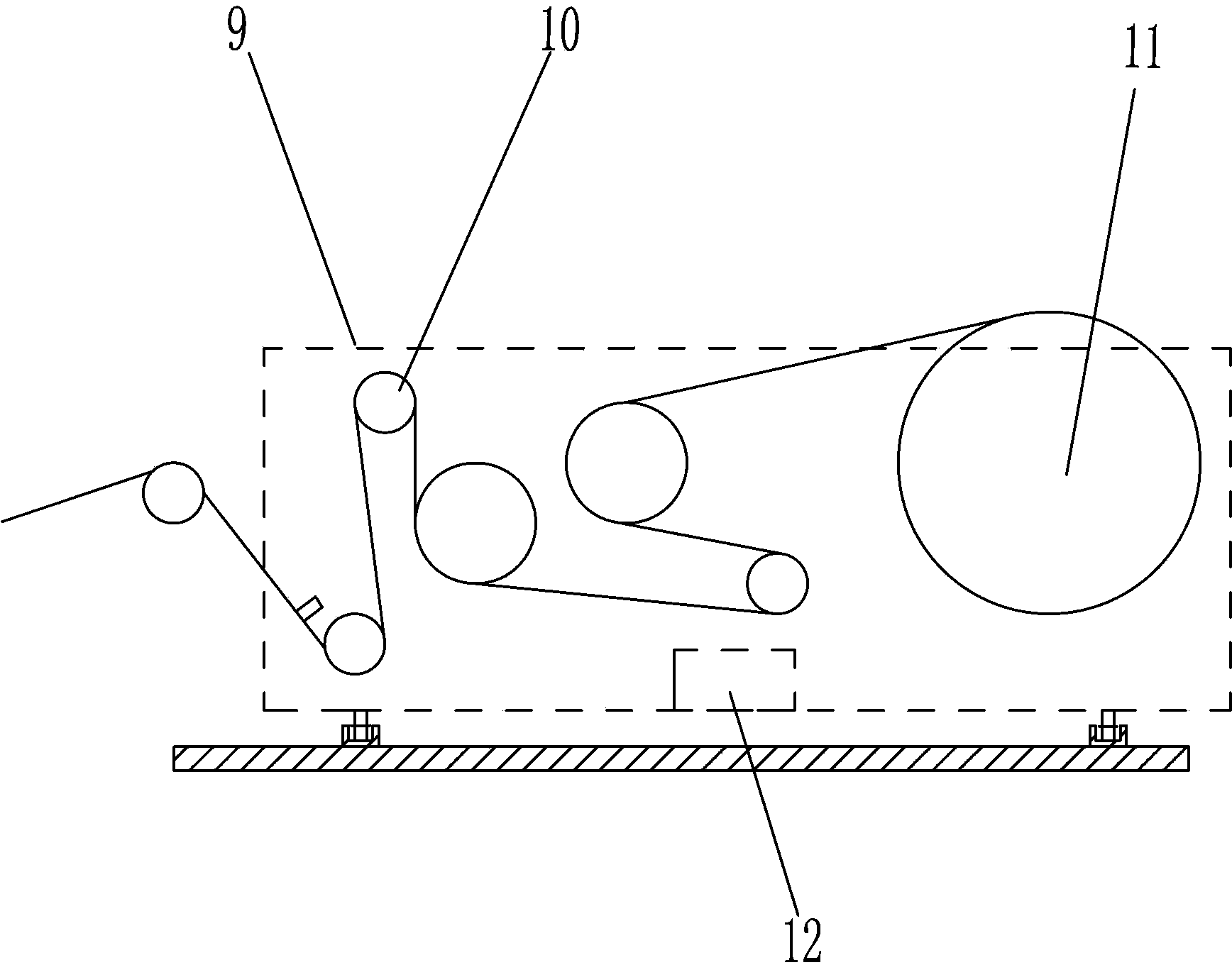

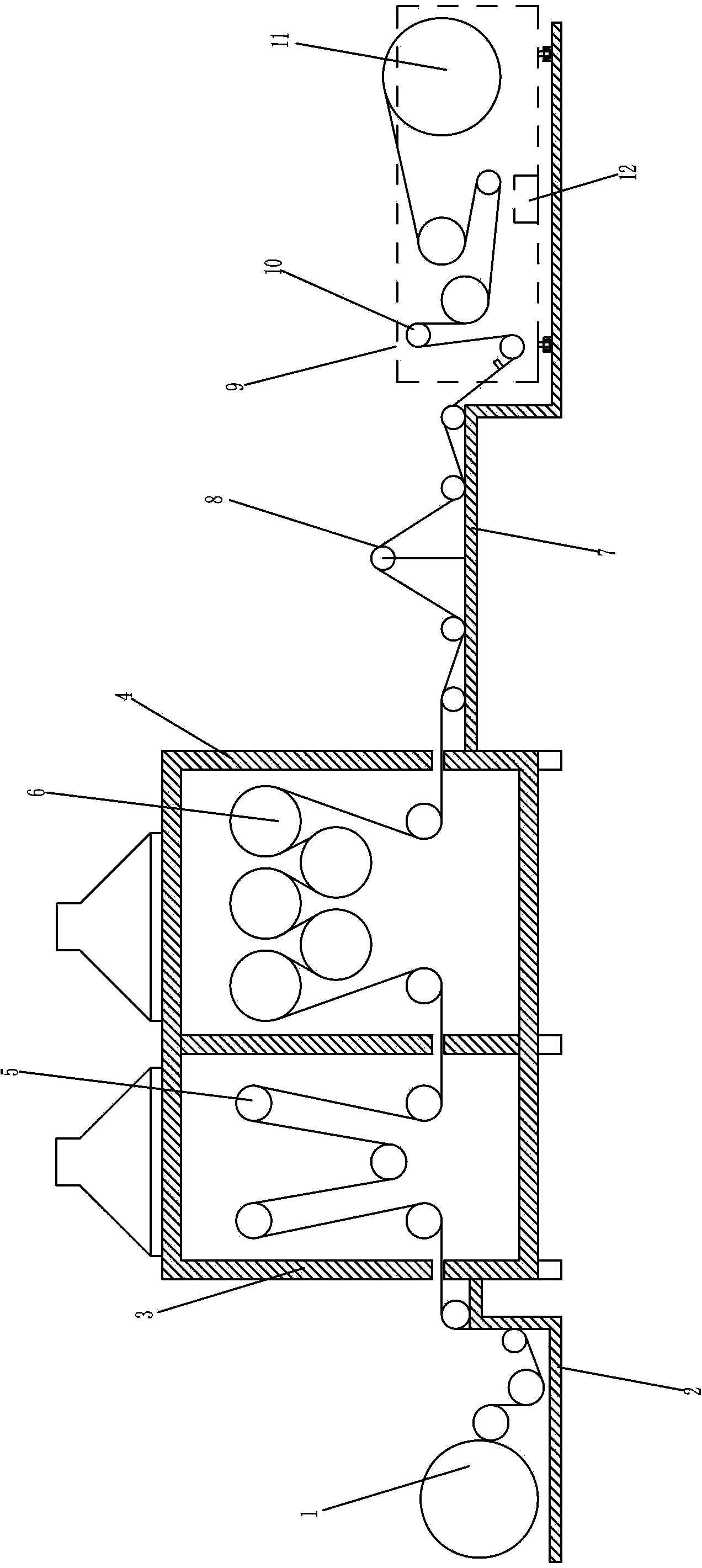

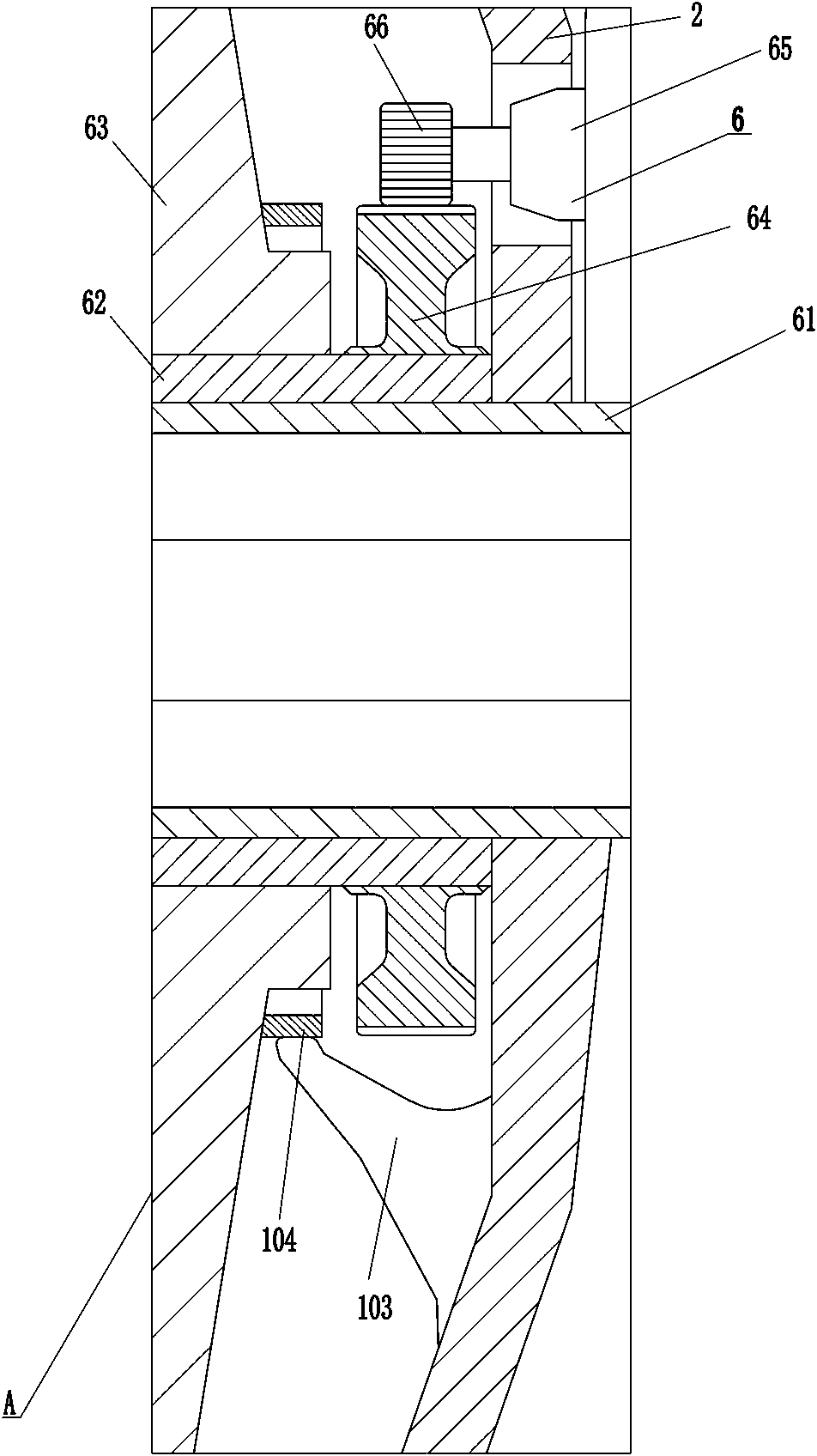

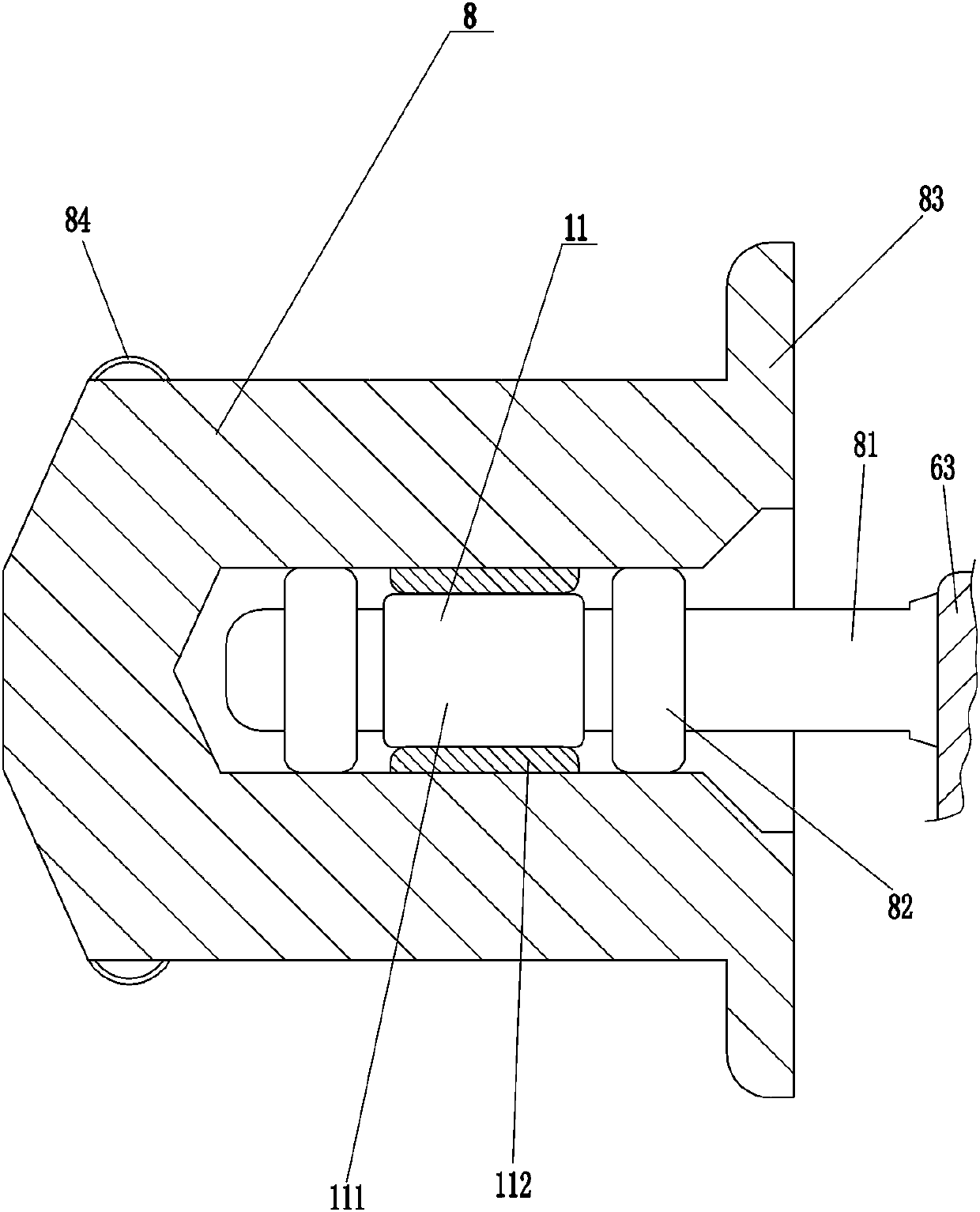

A fully automatic raw material tape splitting machine

ActiveCN103449264BEasy to controlRealize fully automated operationWebs handlingWinding machineControl system

The invention disclose a full-automatic thread seal tape roll separator which comprises a frame body, a power driving mechanism and a control system, wherein a rotatable scale division rotary table is mounted on the frame body; a central rotating shaft and three rotating shafts are arranged on the scale division rotary table; the central rotating shaft is used for driving the scale division rotary table to rotate, and the three rotating shafts are uniformly distributed along the circumference of the scale division rotary table and can rotate independently; a roll core supplying device, a feeding device, a bonding device, a cutting-off device, a tail pressing device and an unloading device of thread seal tapes are sequentially mounted on the frame body on the outer side of the scale division rotary table in the clockwise direction; the roll core supplying device is used for automatically supplying roll cores for the rotating shafts of the scale division rotary table; the feeding device is used for conveying the thread seal tapes to the roll cores on the scale division rotary table and winding; the bonding device is used for bonding the thread seal tapes on the roll cores; the cutting-off device is used for cutting off the thread seal tapes; the tail pressing device is used for pressing the cutting-off thread seal tapes. The full-automatic thread seal tape roll separator has the advantages that the full-automatic operation of thread seal tape roll separation is achieved, the rolled length of the thread seal tapes is controlled accurately, and the production efficiency is improved.

Owner:FUJIAN CHUN FLAG MACHINERY IND & TRADE

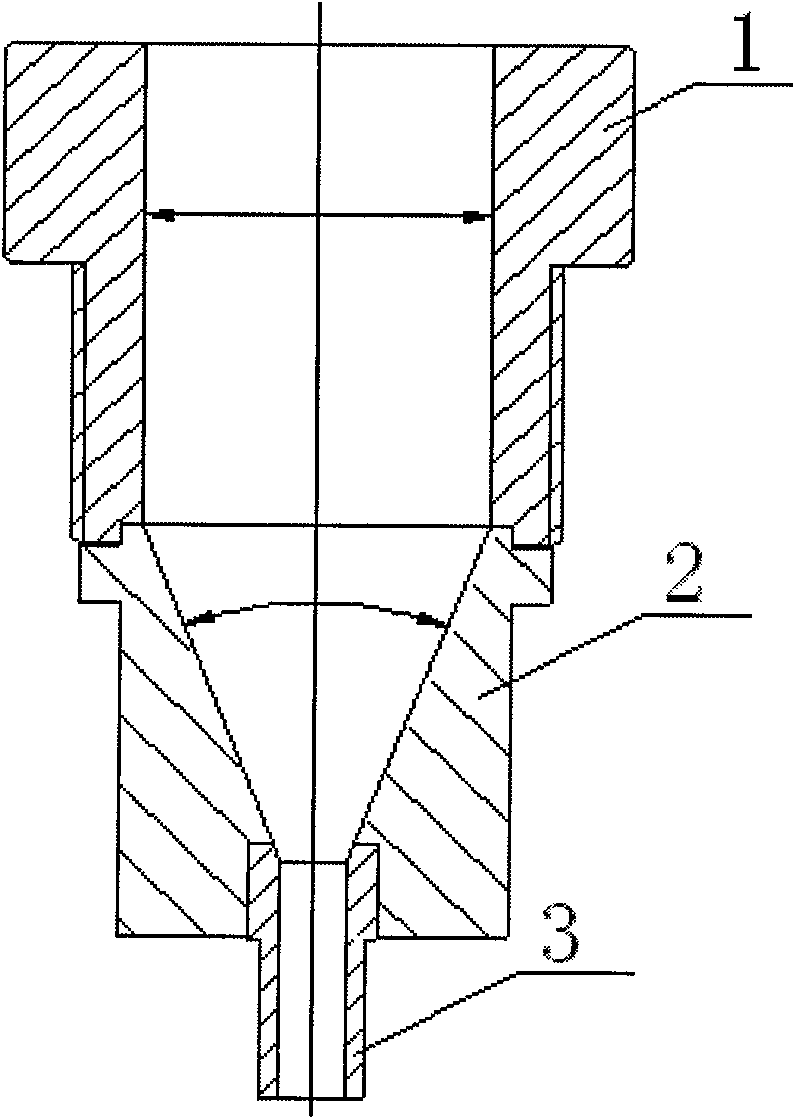

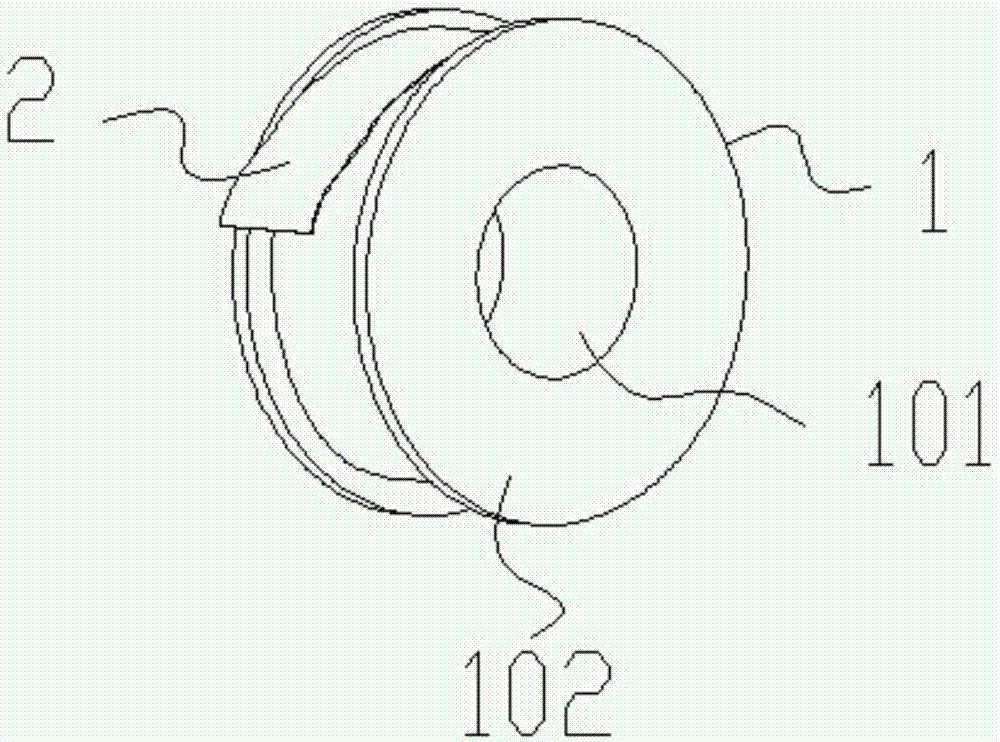

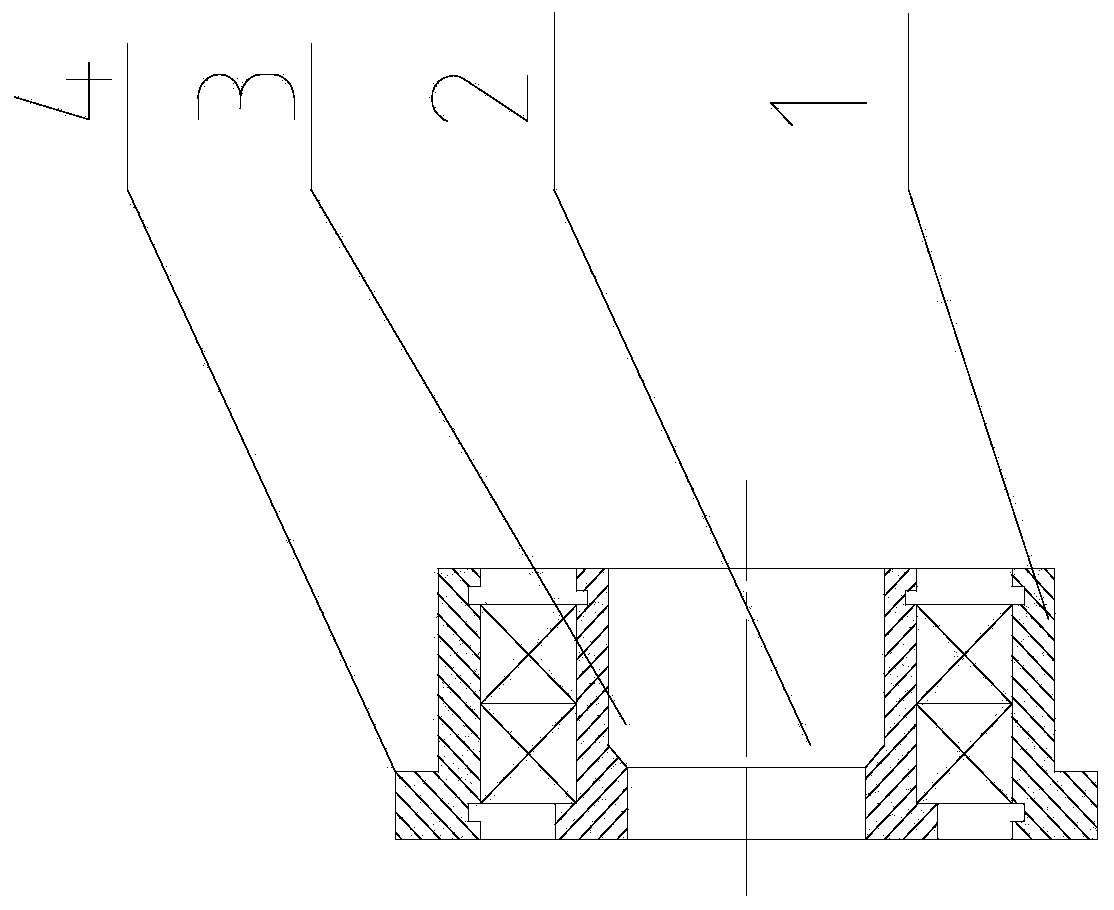

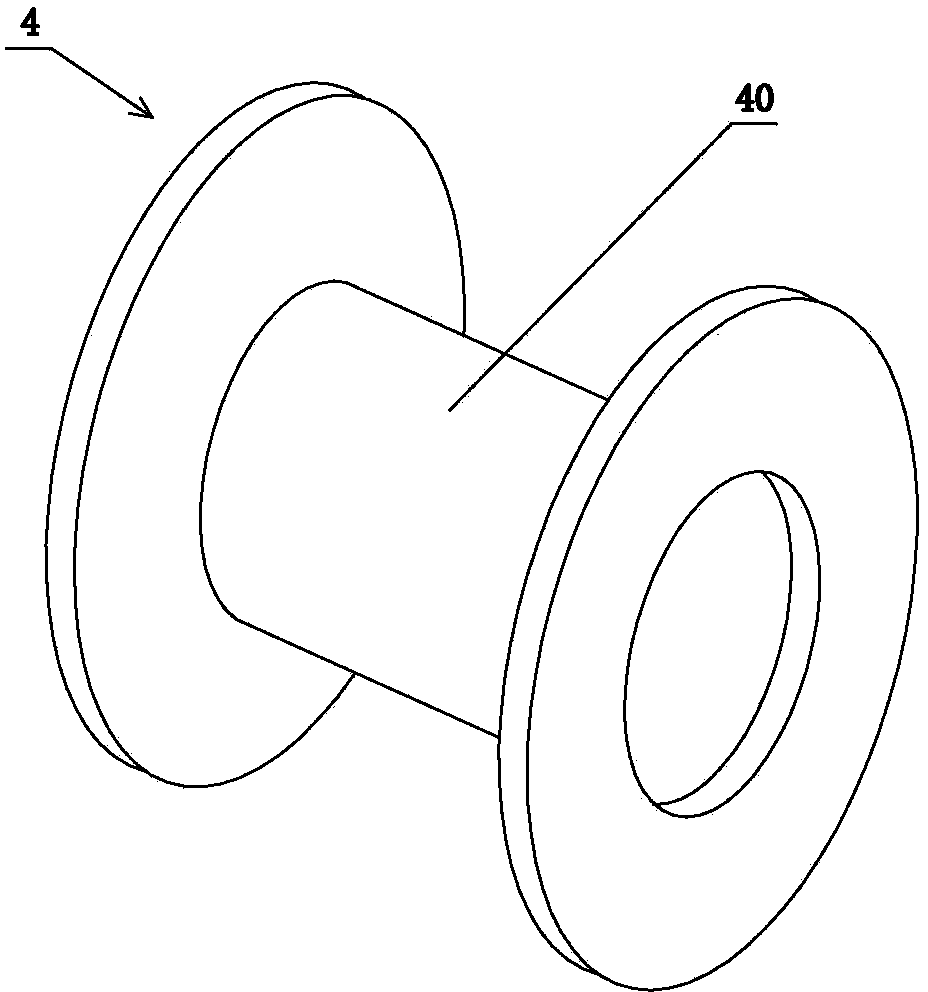

Hose clamp for clearing machine for thread seal tape on braking hose of freight wagon

The invention relates to a hose clamp for a clearing machine for a thread seal tape on a braking hose of a freight wagon. The hose clamp consists of a main body 1, a center clamping hole 2, a bearing block 3 and a flange 4. The hose clamp has the advantages that the braking hose is firmly clamped and the thread seal tape is easy to clear.

Owner:NINGXIA ZHONGYUAN TIANYU TECH

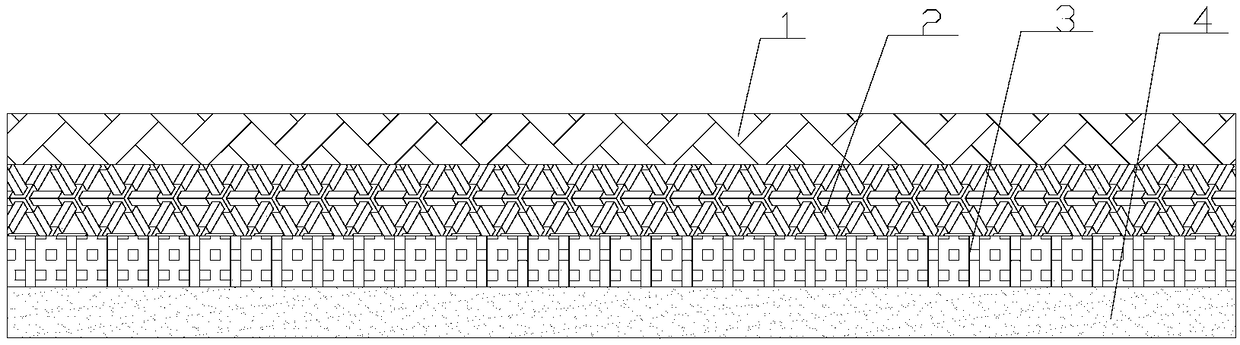

Hemp tape for installing water heating pipes

InactiveCN108180287AHigh strengthImprove toughnessEngine sealsSynthetic resin layered productsEngineeringThread seal tape

The invention discloses a hemp tape for installing water heating pipes. The hemp tape comprises Teflon tape, jute and a nylon plastic tape, wherein an adhesive layer for adhering the Teflon tape and the nylon plastic tape is arranged between the Teflon tape and the nylon plastic tape; the jute adhered between the Teflon tape and the nylon plastic tape by an adhesive layer is arranged between the Teflon tape and the nylon plastic tape; and the jute is uniformly distributed in an interlayer, which is formed by the adhesive layer, between the Teflon tape and the nylon plastic tape. Compared withthe prior art, the hemp tape disclosed by the invention has the following advantages that the Teflon tape, the jute and the nylon plastic tape are adhered together to form a composite sealing tape; and the hemp tape is high in strength, good in toughness, simple and convenient to use and good in sealing effect.

Owner:宁波市利和智能科技有限公司

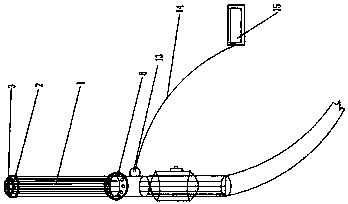

PTFE tape numerical control film drawing machine

PendingCN107720394AExtended pathExtend heating timeArticle deliveryWebs handlingNumerical controlHeating time

The invention discloses a PTFE tape numerical control film drawing machine which comprises a film drawing machine body; the film drawing machine body comprises an unwinding device, a heating and stretching device, a high-temperature shaping device, a thickness measuring device and a winding device; a locating shaft is arranged on one side of the heating and stretching device; two layers of rollingshafts are arranged in the high-temperature shaping device, and are connected through a tape; a second motor is arranged at the upper end of the high-temperature shaping device; a second driving shaft is arranged at the lower end of the second motor; a first fan is arranged at the lower end of the second driving shaft; a double-head motor is arranged at the lower end of the inner wall of the high-temperature shaping device; second fans are arranged at the two ends of the double-head motor; and a plurality of heat dissipation holes are formed in the high-temperature shaping device. By using the closed type high-temperature shaping device, the heating time of the tape is lengthened, and the problems that the production efficiency is low and the production quality is poor due to the fact that the continuous heating efficiency on a PTFE tape is low when a common tape drawing machine machines the PTFE tape are solved.

Owner:FUJIAN CHUN FLAG MACHINERY IND & TRADE

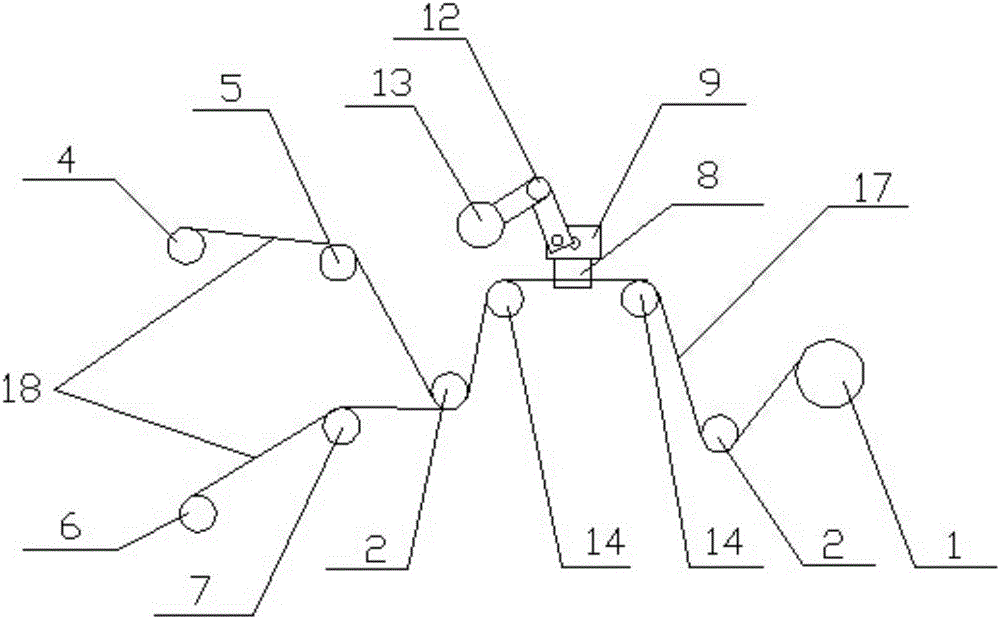

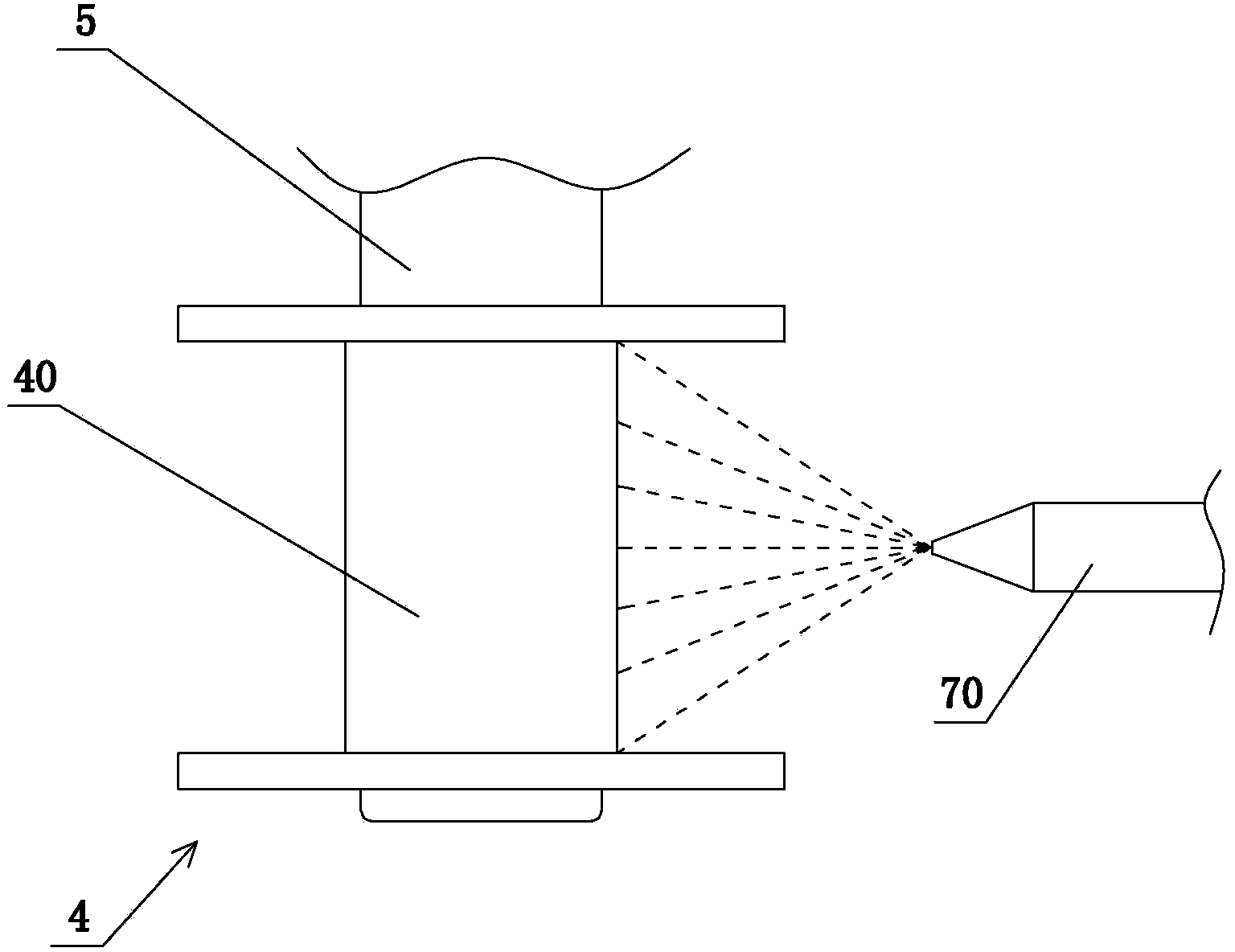

Equipment for winding and coil dividing of pipeline PTFE thread seal tape

The invention relates to coil dividing equipment, in particular to equipment for winding and coil dividing of a pipeline PTFE thread seal tape. The invention aims at providing the equipment for the winding and coil dividing of the pipeline PTFE thread seal tape which can be used for automatically feeding and quickly winding a PTFE tape on a roll core. The equipment for the winding and coil dividing of the pipeline PTFE thread seal tape comprises a base, a motor support frame and an installing frame, wherein the base is used for installing the whole equipment, the motor support frame is arranged on one side of the upper part of the base, and the installing frame is arranged on the side, close to the motor supporting frame, of the upper portion of the base. According to the equipment, the effects that automatic feeding can be conducted, and the PTFE tape can be rapidly wound around the roll core are achieved, the roll core with the to-be-wound PTFE tape is placed on a discharging frame,a pushing plate moves front and back, and therefore the roll core can be moved to the upper parts of the first clamping blocks on the two sides, and therefore, the effect of automatic feeding can be achieved.

Owner:杭州美孚塑胶制品有限公司

Winding machine used for polytetrafluoroethylene tape stretching device

InactiveCN103434873AEnsure consistencyQuality improvementWebs handlingWinding machineThread seal tape

The invention relates to a winding machine used for a polytetrafluoroethylene tape stretching device. The winding machine comprises a winding machine rack, wherein the winding machine rack is provided with a winding guide roll and a winding shaft; the winding shaft is provided with a sensor used for detecting the polytetrafluoroethylene tape; the winding shaft is connected with an opposite side motor. When the winding machine disclosed by the invention is used for winding the stretched polytetrafluoroethylene tape in the winding machine, the polytetrafluoroethylene tape is detected by the sensor on the winding shaft; if the edge of the polytetrafluoroethylene tape is deviated, the winding shaft is regulated by the opposite side motor to guarantee the consistency of the edge of the polytetrafluoroethylene tape in the winding process, and finally, the edge of the polytetrafluoroethylene tape finishing winding is tidy and consistent. The product is attractive, the quality is improved, and the whole equipment is simple to manufacture and has low cost.

Owner:ZHEJIANG SONGHUA NEW MATERIAL CO LTD

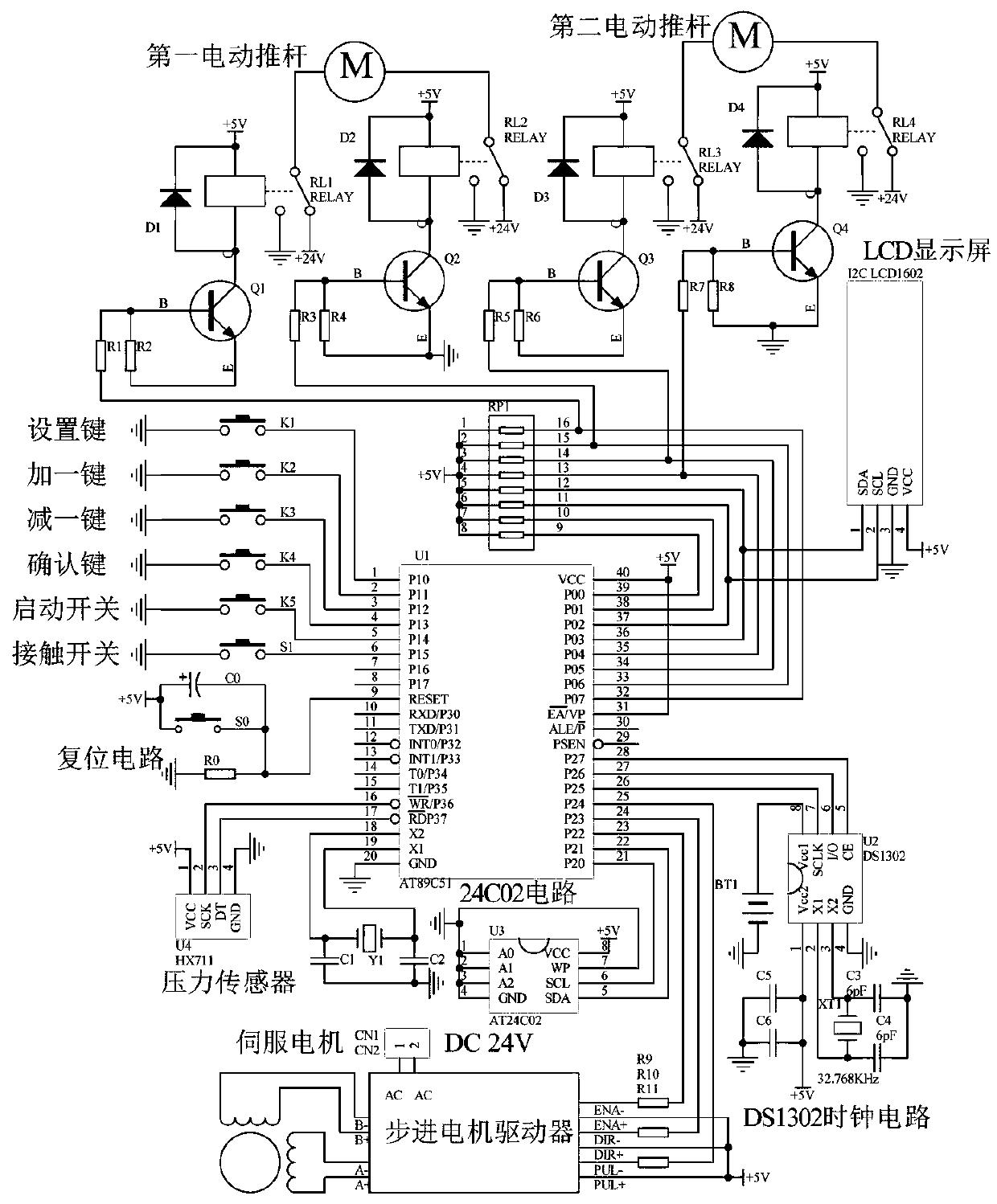

Water pipe threaded opening thread seal tape winder for road construction

ActiveCN110980402AFirmly connectedSealing is not affectedFilament handlingArchitectural engineeringThread seal tape

The invention relates to a thread seal tape winder, in particular to a water pipe threaded opening thread seal tape winder for road construction. With the water pipe threaded opening thread seal tapewinder for road construction of the invention adopted, winding thickness can be guaranteed, the connection of water pipes can be facilitated, and the sealing performance of the water pipes will not beinfluenced. The water pipe threaded opening thread seal tape winder for road construction comprises a handle, a protective cover and the like, wherein the handle is connected with the protective cover. According to the water pipe threaded opening thread seal tape winder for road construction of the invention, the working time of a rotating mechanism can be set according to the diameter of a waterpipe through a setting key, a one-plus key, a one-minus key and a confirmation key, and therefore, winding thickness can be guaranteed, the connection of water pipes can be facilitated, the sealing performance of the water pipes is not affected; and a centering assembly can play a role in centering, so that the device of the invention can be fixed, and therefore, a thread seal tape can be wound more orderly.

Owner:ZHENGTAI GRP

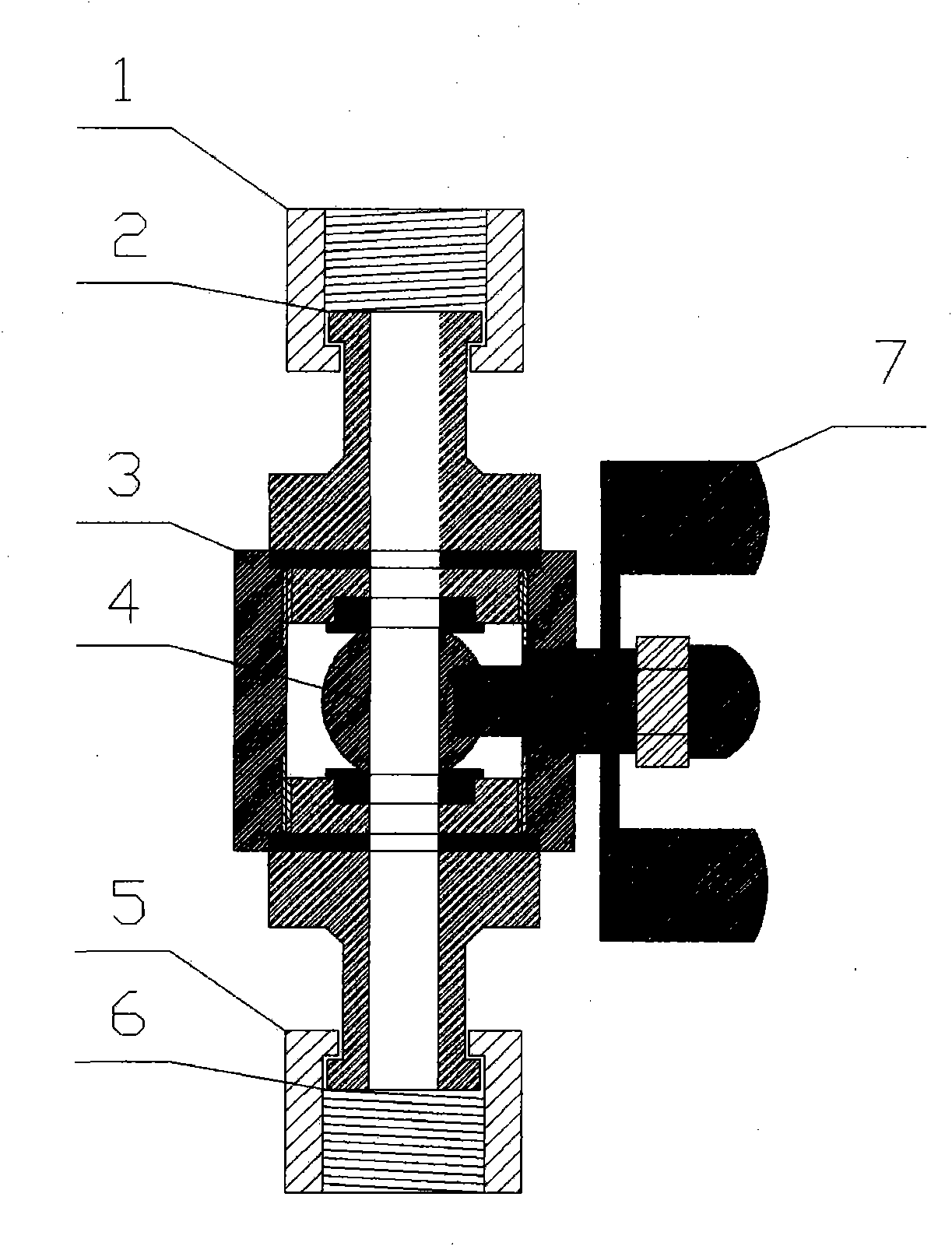

Double-end universal fast mounting instrument valve

The invention discloses a double-end universal fast mounting instrument valve which is composed of an upper connection adjusting nut (1), an upper sealing ring (2), a valve body (3), a ball valve clack (4), a lower connection adjusting nut (5), a lower sealing ring (6) and operating handles (7). The double-end universal fast mounting instrument valve is characterized in that integrated type structural design is adopted, and the upper connection adjusting nut (1), the lower connection adjusting nut (5), the upper sealing ring (2), the lower sealing ring (6) and the like are integrated on the valve body (3). When butt joint is carried out on the threaded portion of an instrument and the instrument valve, sealing by thread seal tape is not needed, the connecting part can be adjusted in a universal mode, and thus the double-end universal fast mounting instrument valve is simpler and more convenient to mount. The problems that a common copper instrument valve needs to be sealed by the thread seal tape and is prone to leakage and difficult to adjust in direction are solved. Compared with the prior art, double-end loose joint inner threaded connection is adopted for the upper connection adjusting nut (1) and the lower connection adjusting nut (5), hard seal is adopted between the upper sealing ring (2) and a metal end face and between the lower sealing ring (6) and the metal end face, the thread seal tape does not need to be used any more, leakage is prevented thoroughly, directions of the valve body (3) and the instrument connected with the valve body (3) can be freely adjusted, and the instrument can be turned on and off and observed conveniently.

Owner:蒋介中

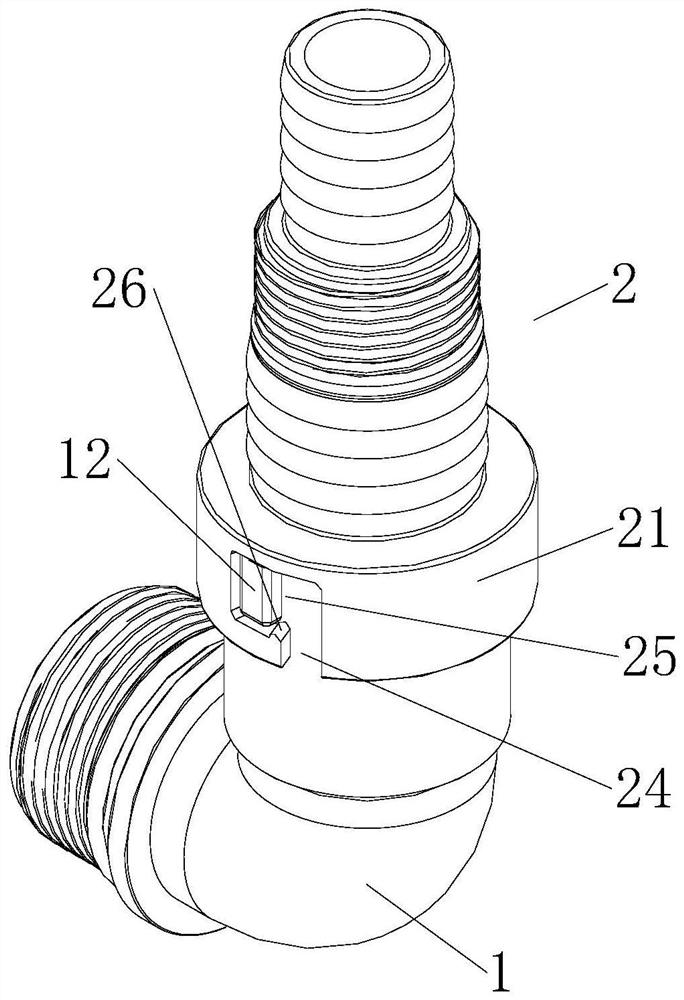

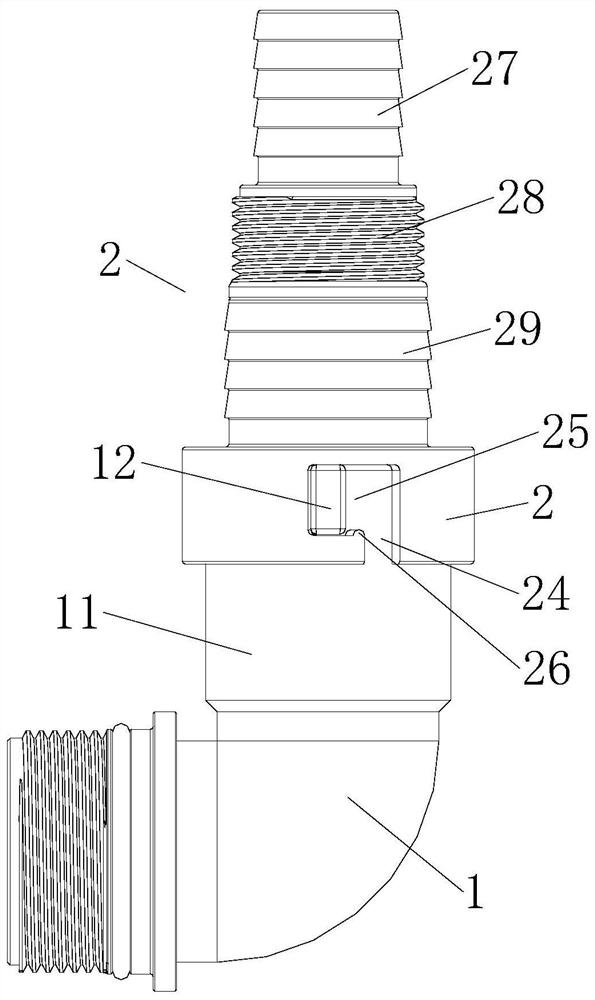

Clamping hook type quick connector device

The invention relates to a water pump connector connecting device, in particular to a clamping hook type quick connector device, which comprises a water outlet connector, one end of the water outlet connector is fixed to a water pump, a sleeve is arranged at the other end of the water outlet connector, and at least two clamping hooks are arranged on the outer circle face of the sleeve in an annular array mode; a pipe connector, wherein a positioning pipe and a fixing sleeve are arranged at the bottom of the pipe connector, the fixing sleeve is located at the top of the positioning pipe, an annular connecting groove is arranged between the fixing sleeve and the positioning pipe, and clamping grooves are arranged on the fixing sleeve; a sealing element mounted on the positioning pipe; and the positioning pipe is inserted into the sleeve, the sleeve is inserted into the connecting groove, the clamping grooves are inserted into the clamping hooks, the clamping grooves correspond to the clamping hooks one to one, and the sealing element seals the positioning pipe and the sleeve. According to the clamping hook type quick connector device provided by the invention, the clamping grooves on the pipe connector is matched with the clamping hooks on the water outlet connector to achieve fixed connection, disassembly and assembly can be achieved by rotating the pipe connector, sealing is achieved through the sealing element, thread seal tape winding is not needed, tools are not needed, labor and trouble are saved, and the disassembly and assembly speed is high.

Owner:SUZHOU WODA GARDEN MACHINERY

Minitype teflon tape winding device for hydraulic engineering

PendingCN112239109AEasy to operateImprove work efficiencyScrew threaded jointsThread seal tapeHydraulic engineering

The invention relates to a winding device, in particular to a minitype teflon tape winding device for hydraulic engineering. The technical scheme is how to design the minitype teflon tape winding device which can quickly wind a water pipe instead of persons, is convenient to operate, is high in working efficiency and is time-saving and labor-saving. The minitype teflon tape winding device for hydraulic engineering comprises a square shell and a front cover, wherein a cylindrical shell is mounted on one side of the square shell; and the front cover is hinged to one side which is located outsidethe square shell and is in contact fit with an opening of the cylindrical shell. According to the minitype teflon tape winding device for hydraulic engineering disclosed by the invention, the teflontape covers a discharging device, the head of the teflon tape is pulled and is then moved to a proper position; and a person picks up the water pipe, and enables the water pipe to pass through the front cover and contact with the discharging device; and moreover, a driving device is started and then runs, the discharging device is driven through operation of the driving device to be rotated positively, and the teflon tape is driven through positive rotation of the discharging device so as to be rotated positively and is wound on a threaded part of the water pipe; and thus, the teflon tape is wound on the threaded part of the water pipe without needing manual operations, and therefore, the winding device is convenient to operate and is high in working efficiency.

Owner:杨敏姗

Method for automatically winding tape head of thread seal tape

The invention relates to a method for automatically winding a tape head of thread seal tape. The method includes the following steps: rotation opening movement, liquid feeding movement, tape head initial attachment movement, tape head depth attachment movement and rewinding movement. According to the method for automatically winding the tape head of the thread seal tape, the principle that liquid has certain attachment force between the two attached surfaces is adopted for completing the process of automatically winding the tape head, a tape head section is efficiently, rapidly and flatly pressed on an empty wheel frame in the vertical air blowing mode and the lateral air blowing mode, the process of automatically winding the tape head can be achieved within only one to two seconds in the whole process, the completion effect is ideal, and the process quality is greatly improved. The tape head section can be completely attached to the groove bottom cylindrical face of the empty wheel frame, and therefore products are smooth, neat and tidy in appearance and good in condition.

Owner:黄聪伟

Preparation method of polytetrafluoroethylene thread seal tape film for communication cable

ActiveCN101642960BGood flexibilityImprove moisture resistanceFlat articlesDielectric lossEngineering

The invention discloses a preparation method of polytetrafluoroethylene thread seal tape film for communication cable, comprising the following steps: proportioning and pretreating, performing, bulldozing, rolling, drawing, orienting, second drawing and forming and cutting and winding. The polytetrafluoroethylene thread seal tape film prepared by the invention has good comprehensive performance and particularly has very low dielectric constant and dielectric loss angle tangent; the thread seal tape film can not be affect by the changes of frequency and temperature so as to effectively reduce the attenuation and loss of transmission and greatly improve the transmission rate; in addition, the prepared communication cable has good softness and humidity resistance and can be used for a long time at -65 DEG C to 260 DEG C.

Owner:四会市生料带厂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com