LTCC raw material tape material, substrate and preparation method

A technology of raw material tape and inorganic material, applied in the field of substrate and preparation, LTCC raw material tape material, can solve the problem of difficult and low melting point metal co-firing, etc., and achieve the effect of good co-firing performance, smooth surface and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

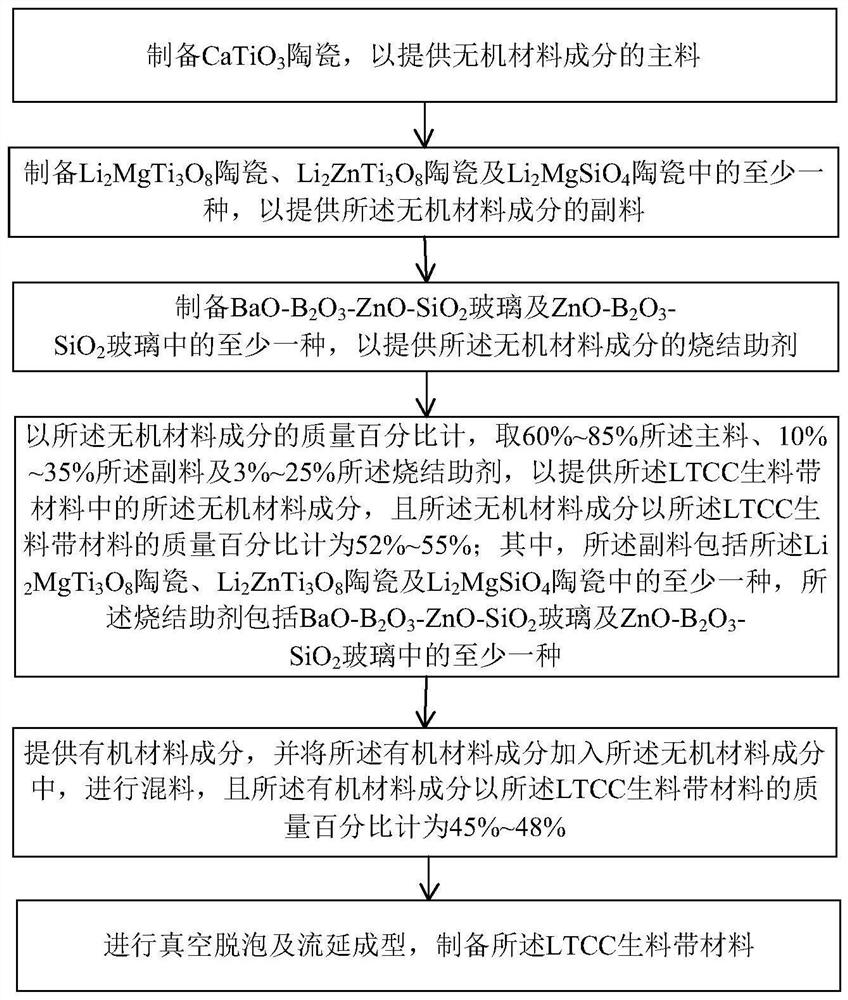

Embodiment 1

[0049] This embodiment provides a LTCC raw tape material, in which the LTCC raw tape material includes 52% to 55% of inorganic material components, and 45% to 48 % of organic material components, wherein, based on the mass percentage of the inorganic material components, it includes 60% to 85% of main materials, 10% to 35% of auxiliary materials and 3% to 25% of sintering aids, and the main materials include CaTiO 3 (CT) ceramics, the auxiliary material includes Li 2 MgTi 3 o 8 (LMT) ceramics, Li 2 ZnTi 3 o 8 (LZT) ceramics and Li 2 MgSiO 4 At least one of (LMS) ceramics, the sintering aid comprising BaO—B 2 o 3 -ZnO-SiO 2 (BBZS) glass and ZnO-B 2 o 3 -SiO 2 At least one of (ZBS) glass.

[0050] Specifically, the inorganic material composition may include values within any range of 52%, 53%, 54%, 55%, etc., and the organic material composition may include values within any range of 45%, 46%, 47%, 48%, etc. value. In terms of the mass percentage of the inorga...

Embodiment 2

[0095] This embodiment provides an LTCC substrate, the LTCC substrate includes the LTCC raw tape material in Embodiment 1, and the LTCC raw tape material will not be introduced here.

[0096] This embodiment also provides a method for preparing an LTCC substrate, which includes preparing the LTCC raw tape material by the method described in Embodiment 1, and stacking the LTCC raw tape materials to form a green body, and At room temperature, heat up to 500°C at a heating rate of 1°C / min, hold at 500°C for 3 hours for debinding, and then raise the temperature to 890°C-920°C at a heating rate of 5°C / min after debinding is completed Keeping the temperature for 2 hours to 4 hours to complete the sintering, so as to prepare the LTCC substrate.

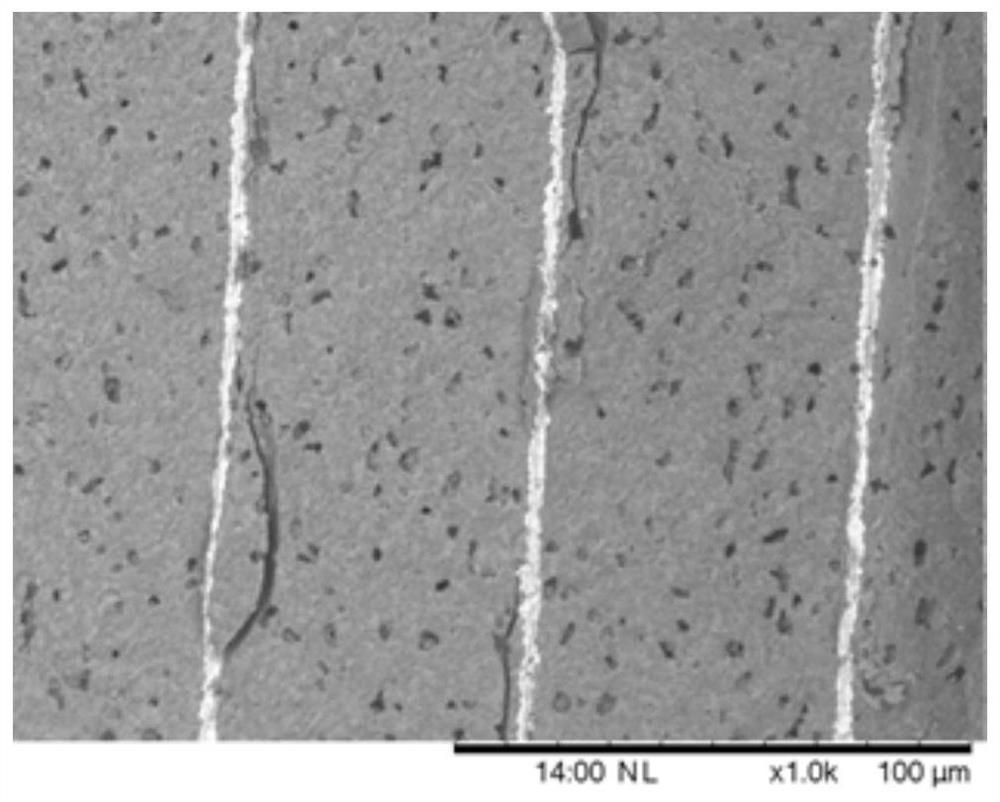

[0097] Specifically, the LTCC raw tape material can be cut into a required size, such as 100mm×100mm, cross-laminated such as 10 layers, 8 layers, etc., vacuumed, and isostatically pressed into a green body, and then Put the biscuit into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com