Automatic liquid feeding and tape head winding method for thread seal tape

A kind of raw material tape and automatic technology, applied in the direction of thin material processing, winding strip, transportation and packaging, etc., can solve the problems of slow speed, insufficient flatness, low effect, etc., achieve good product image, improve process quality, ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be further described below with reference to the accompanying drawings.

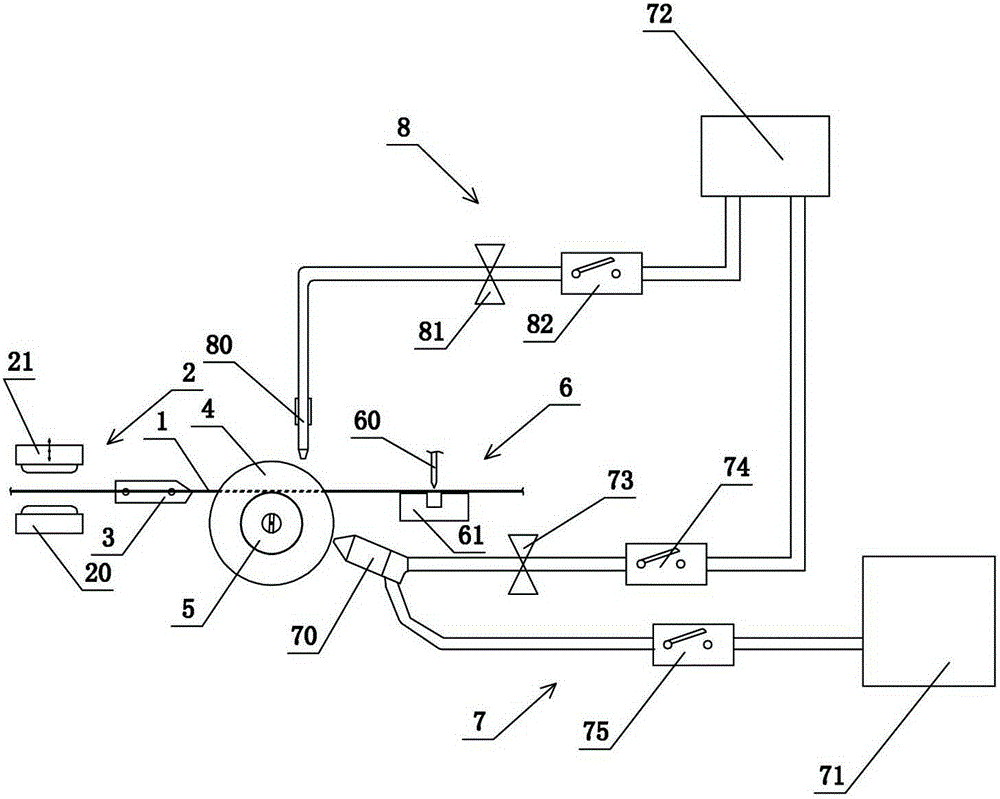

[0017] Refer to attached figure 1 , figure 2 and image 3 . A method for automatically filling a raw material tape with liquid and wrapping it on a tape head, comprising the following steps:

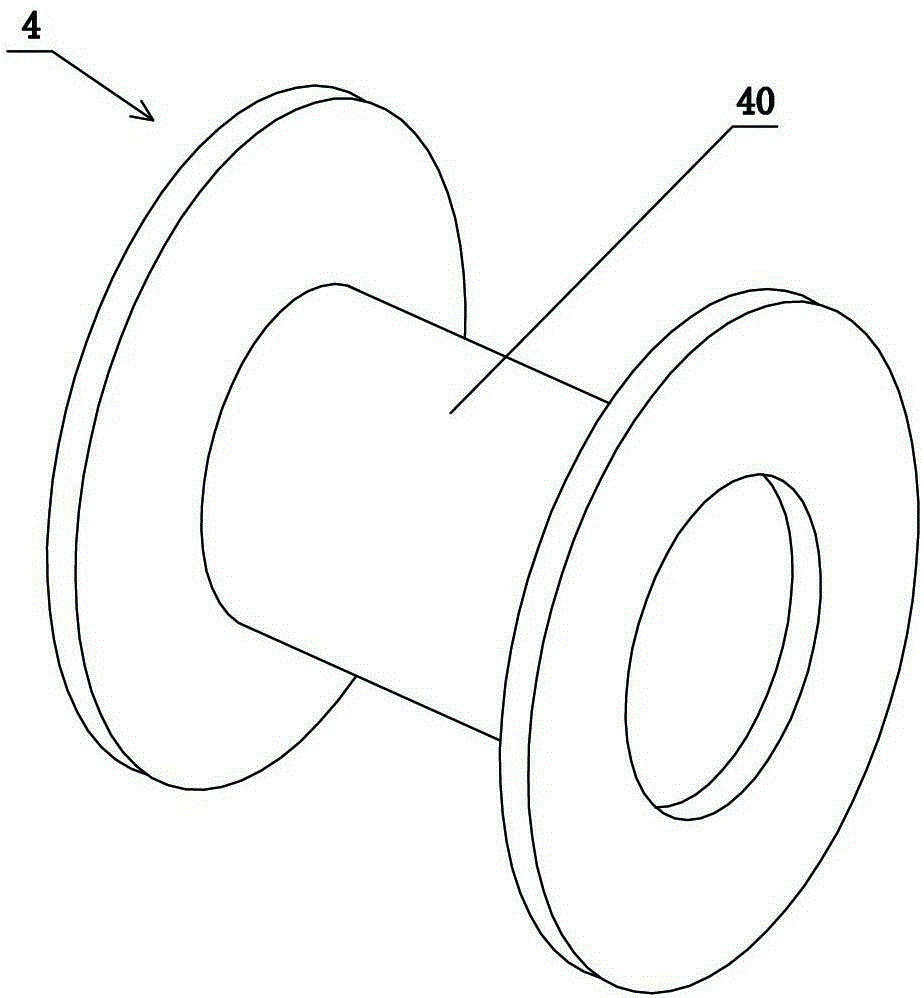

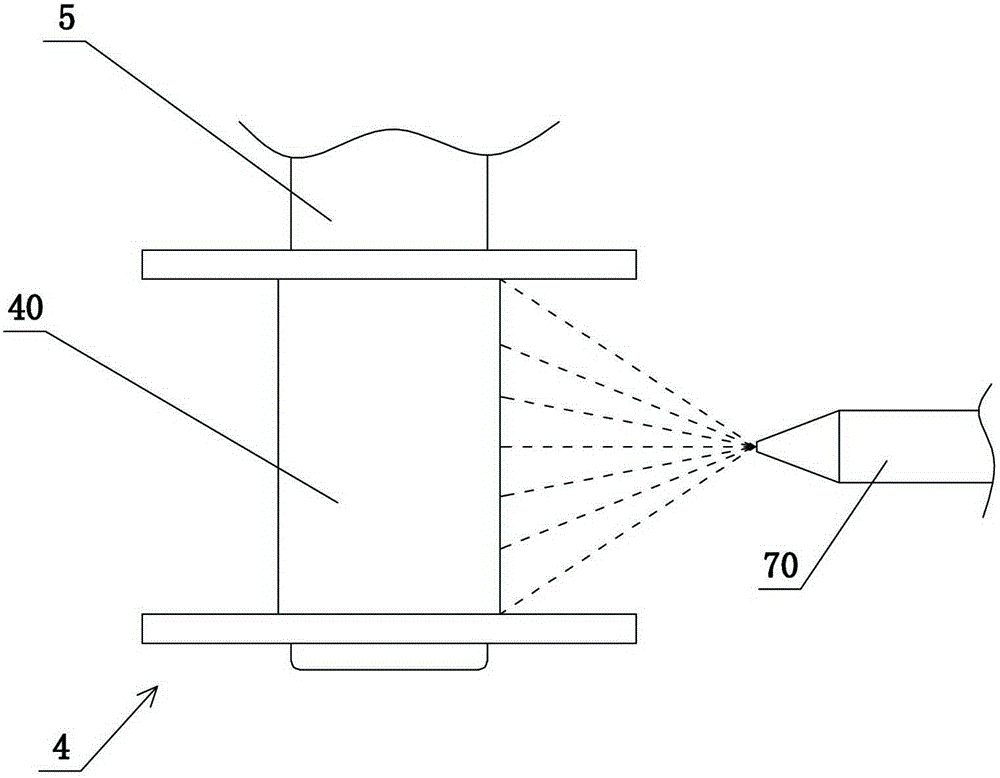

[0018] 1) Stretch the raw material belt 1 to be rolled across the brake belt device 2, the belt guide rail 3, the winding shaft 5 that can drive the empty wheel frame 4 to rotate, and the cutting device 6, and the stretched raw material The belt 1 is tangent to the bottom surface 40 of the cylindrical groove of the empty wheel frame 4, and the brake belt device 2 is activated to make it firmly and smoothly clamp the raw material belt 1, and then the winding shaft 5 is started to rotate at a certain speed, that is, Rotate and open action is finished.

[0019] 2) Start the aerosol injector 7 so that the aerosol spray head 70 on it sprays ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com