Patents

Literature

202results about How to "Realize automatic labeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Personalized and synergistic integration network multimedia search and enquiry method

InactiveCN101334796AImplement queryRealize automatic labelingSpecial data processing applicationsPersonalizationMultimedia search

The invention discloses a network multimedia searching and inquiry method integrating individualization and collaboration, which includes the following steps: (1) existing semantic information is adopted to automatically mark media object semanteme; (2) a user sub-file containing user information and personal preferences is established and a searching system sorts and optimizes the searched results according to the intention of the user; (3) the weight of each key phrase in the user sub-file is dynamically adjusted according to relevant feedbacks of the user so as to more accurately reflect the user intention; (4) a multi-layer sub-file mode respectively including the user sub-file, group sub-file and community sub-file is established and a succession and sharing mechanism is preserved between layers so as to both strive for sameness and allow the existence of difference and support a mass storage; (5) multi-modal information is converged and analyzed for multimedia semantic understanding so as to realize the cross-modal multimedia object searching. The invention can accurately learn about the intention of users and realize the high-accurate, individualized and cross-modal multimedia searching.

Owner:ZHEJIANG NORMAL UNIVERSITY

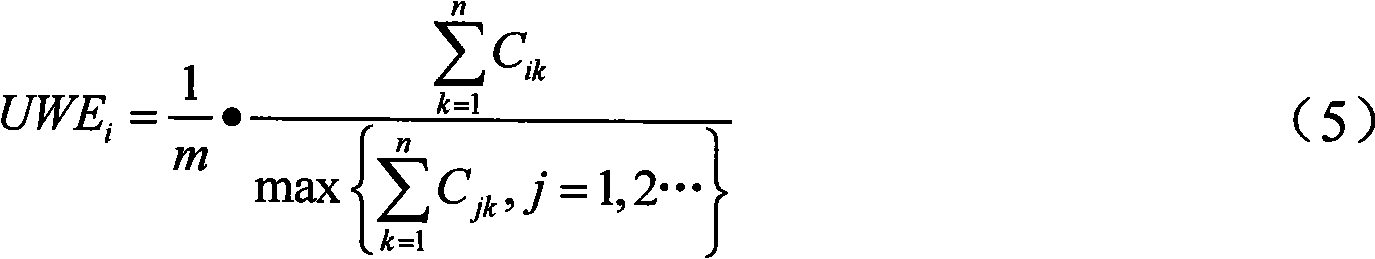

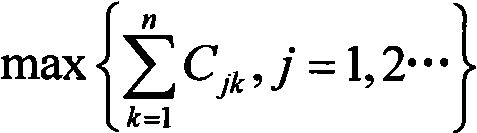

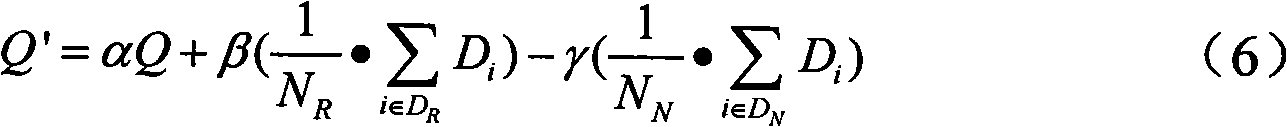

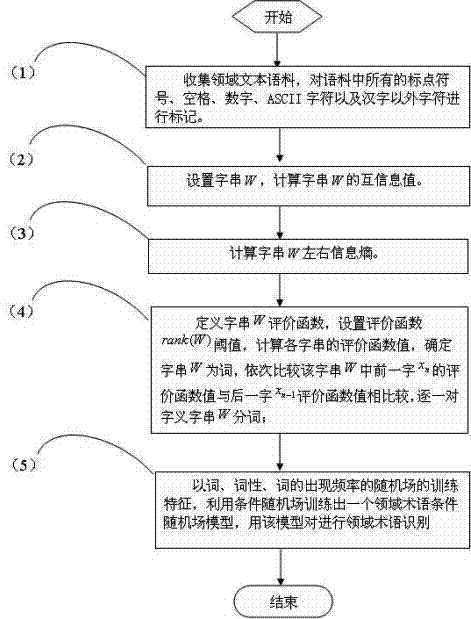

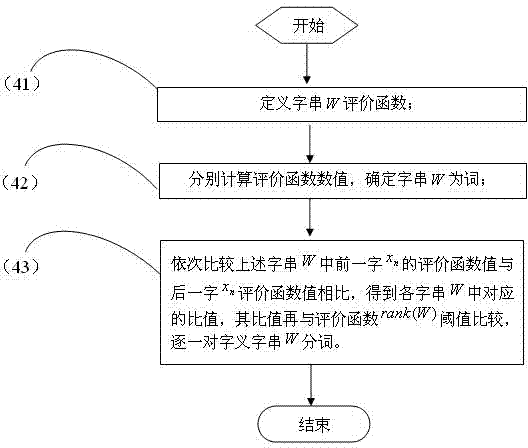

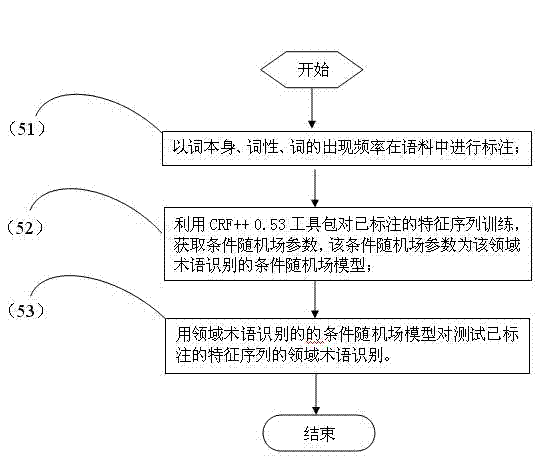

Chinese domain term recognition method based on mutual information and conditional random field model

InactiveCN103049501ASolve data sparsityRealize automatic labelingSpecial data processing applicationsConditional random fieldChinese characters

The invention discloses a Chinese domain term recognition method based on mutual information and a conditional random field model. The Chinese domain term recognition method includes the following steps: (1) gathering domain text corpus and marking all the punctuations, spaces, numbers, ASSCII (American Standard Code for Information Interchange) characters and characters except Chinese characters in the corpus; (2) setting character strings and computing the mutual information values of the character strings, (3) computing the left comentropy and the right comentropy of every character string, (4) defining character string evaluation function, setting evaluation function threshold, computing the evaluation function values of every character string, determining that every character string is a word, comparing in sequence the evaluation function value of the former character with the evaluation function value of the latter character in the character string and segmenting character meaning character strings one by one, (5) utilizing conditional random fields to train a conditional random field model and recognizing domain terms with the conditional random field model. When the Chinese domain term recognition method is used to recognize terms, the data sparsity of legitimate terms is overcome, the amount of calculation of conditional random fields is reduced, and the accuracy of the Chinese domain term recognition is improved.

Owner:SHANGHAI UNIV

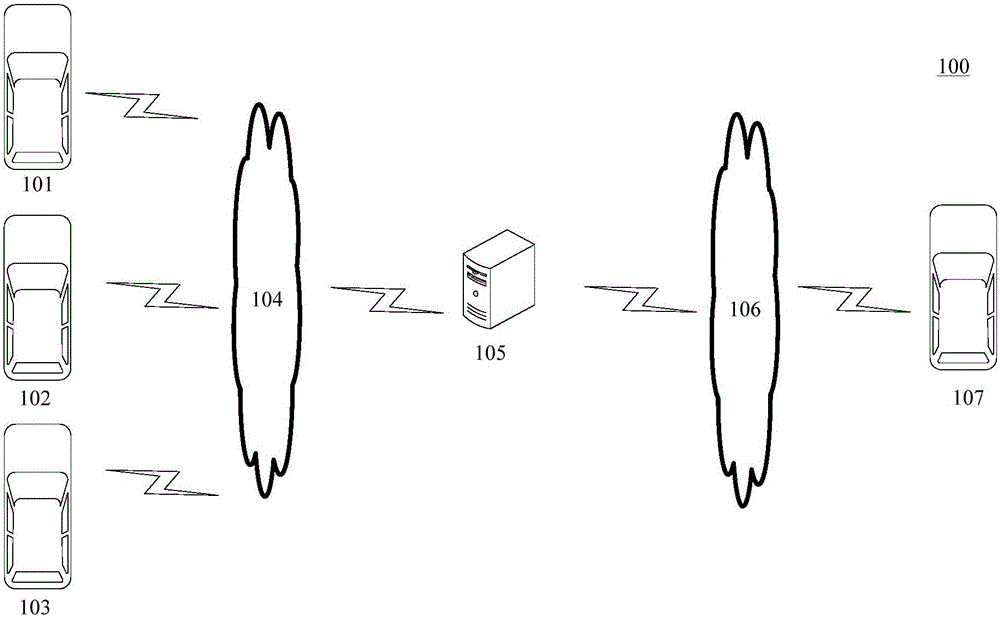

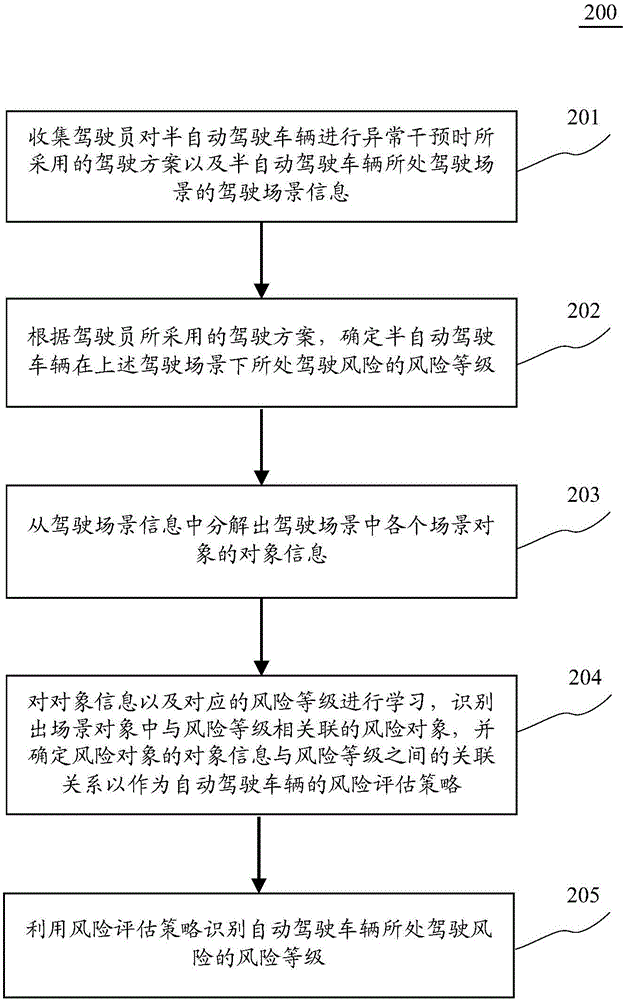

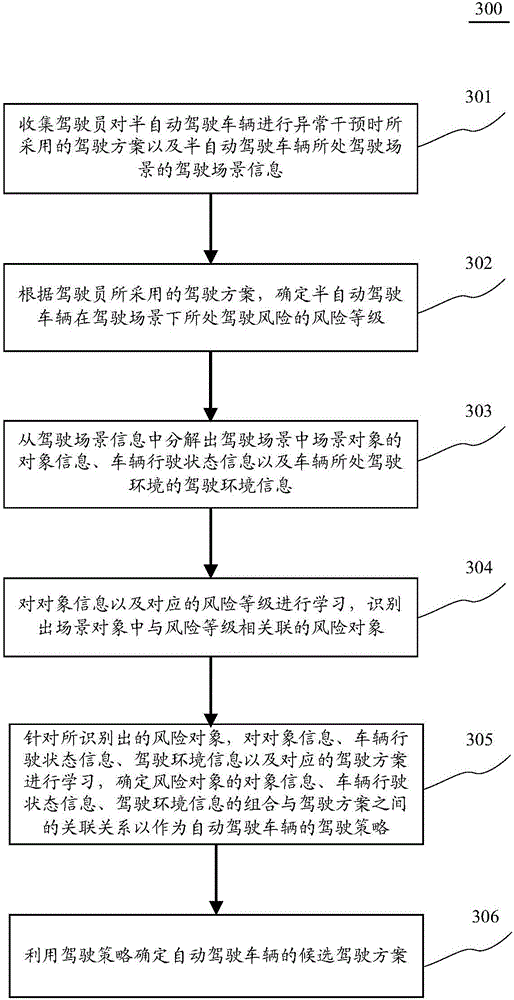

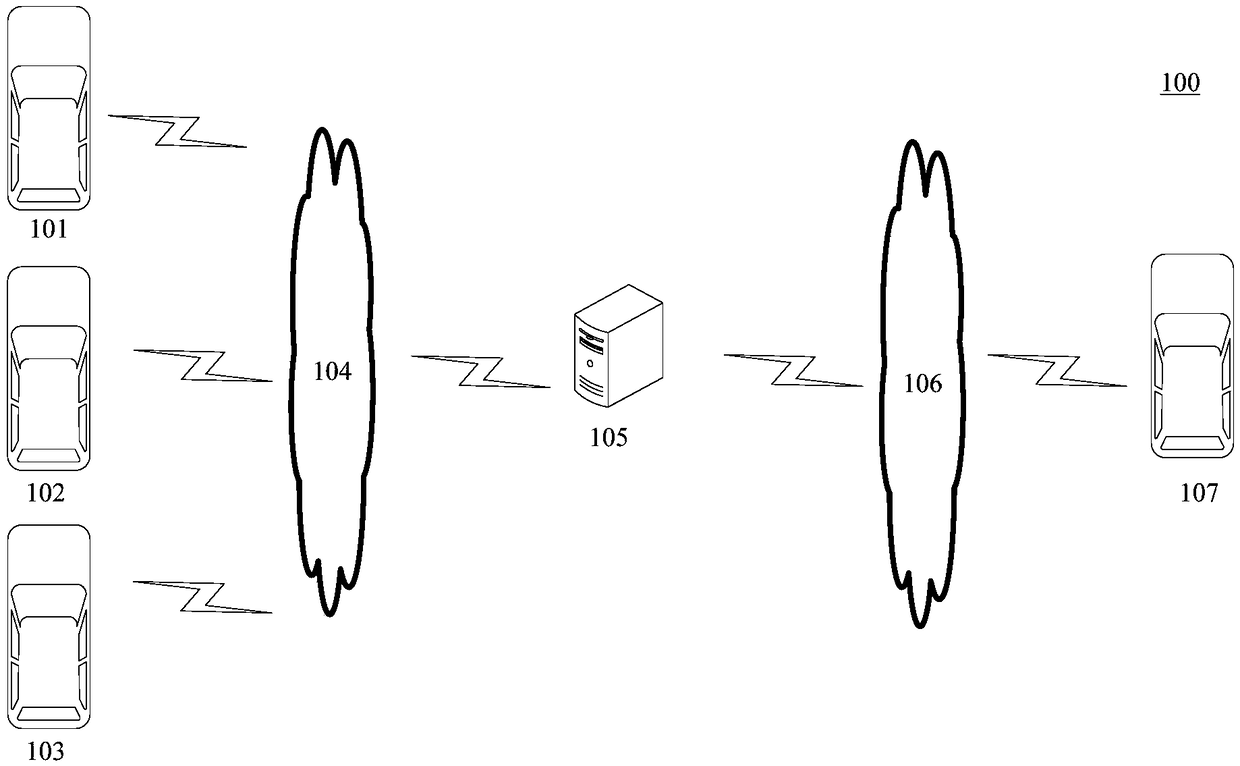

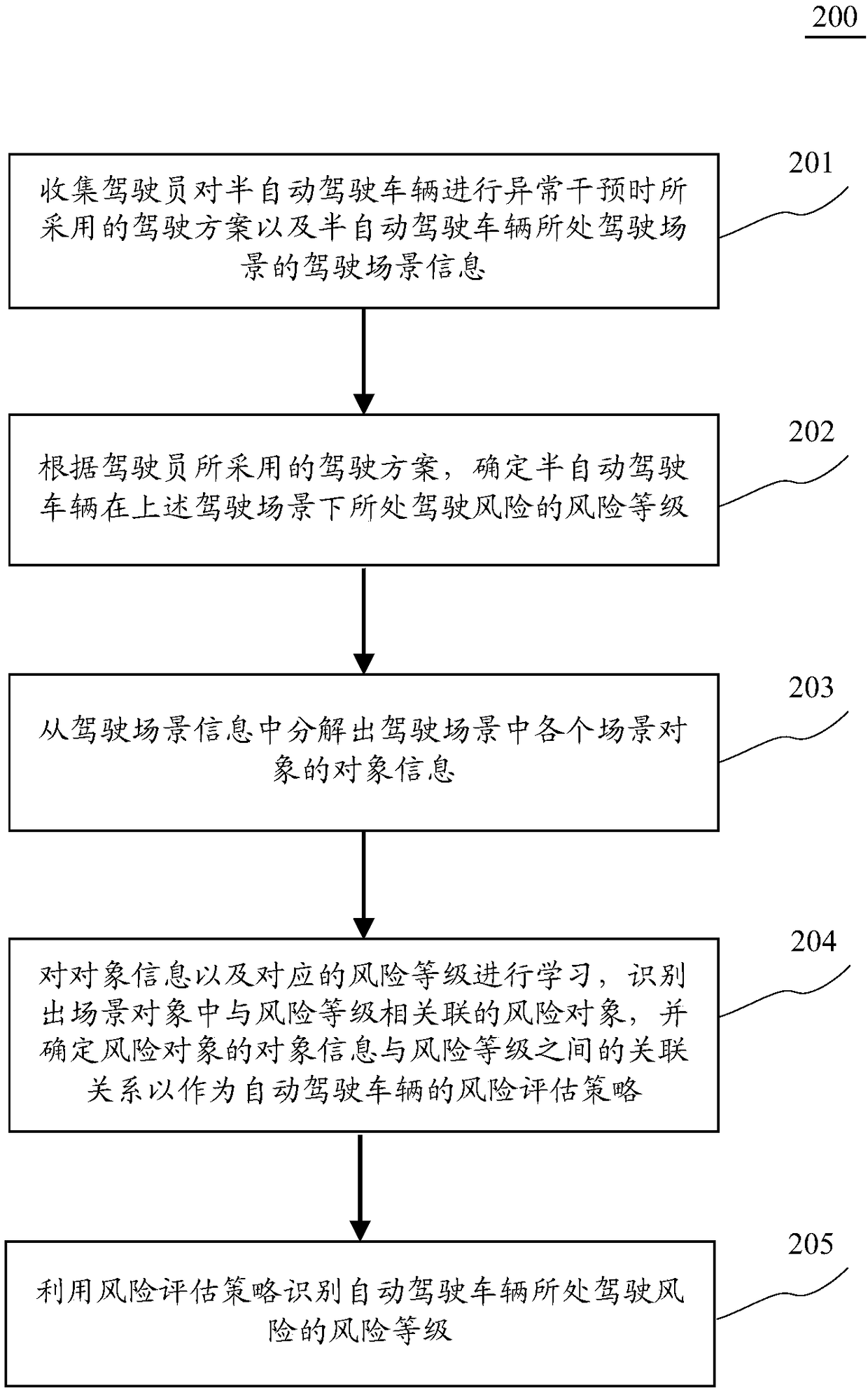

Method and device for operating autonomous vehicle

ActiveCN106347359ARealize automatic labelingReduce workloadExternal condition input parametersResourcesDriving riskAutopilot

The invention discloses a method and a device for operating an autonomous vehicle. According to one embodiment, the method comprises the following steps: collecting driving schemes adopted by a driver when the driver performs exception interfering on semi-autonomous vehicle and driving scene information of the semi-autonomous vehicle in driving scenes; determining the risk grades of driving risks of the semi-autonomous vehicle in the driving scenes according to the driving schemes adopted by the driver; decomposing object information of all scene objects in the driving scenes from the driving scene information; learning the object information and the corresponding risk grades, recognizing risk objects relevant to the risk grades in the scene objects, and determining the association relationship between the object information of the risk objects and the risk grades, so as to serve as a risk assessment strategy of the autonomous vehicle; recognizing the risk grade of the driving risk of the autonomous vehicle through the risk assessment strategy. The embodiment realizes the automatic recognition of the driving risk of the autonomous vehicle.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

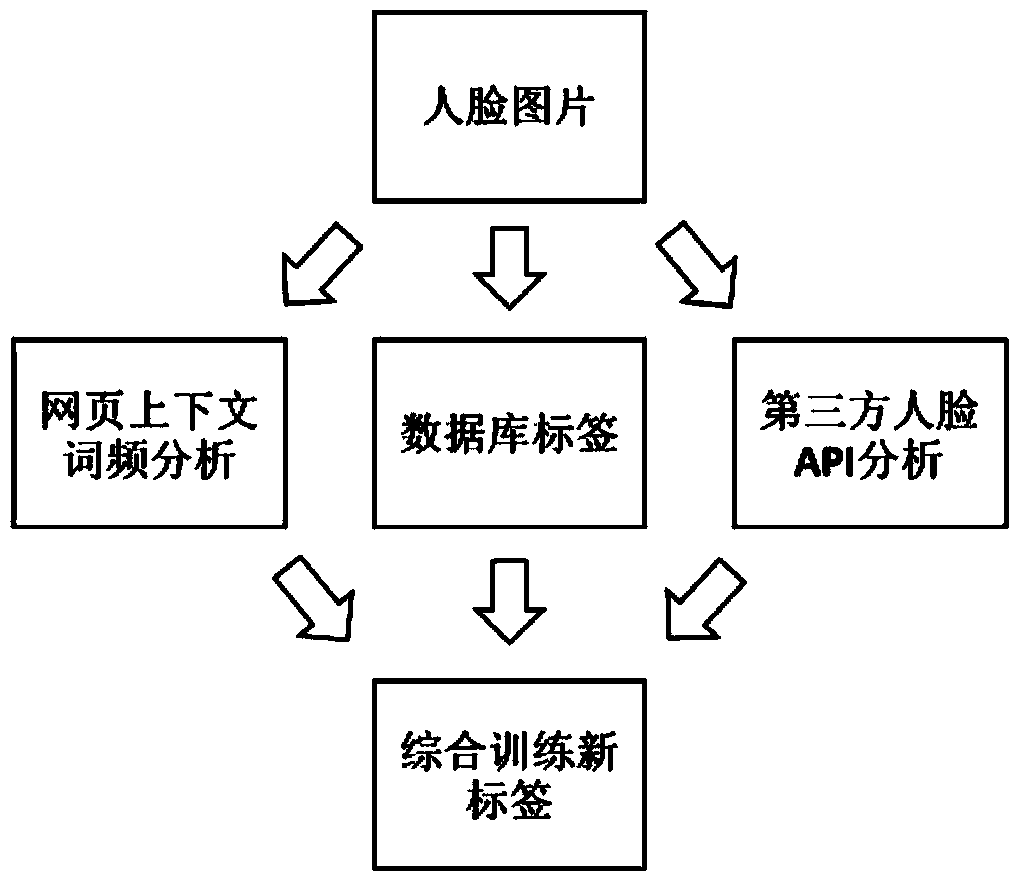

Face image gender marking method and face gender detection method

ActiveCN103824053AImprove efficiencyRealize automatic labelingCharacter and pattern recognitionSpecial data processing applicationsImaging technologyContextual information

The invention discloses a face image gender marking method and a face gender detection method. The detection method includes the following steps that: 1) face images and context information thereof are obtained; 2) the genders of each of obtained face images to be marked is marked; 3) feature vectors of each of gender marked images are extracted, and a machine learning algorithm is utilized to train the face images which have been subjected to gender marking so as to generate a face gender recognition model; and 4) as for face images to be detected, the feature vectors of the face images to be detected are extracted, and the face gender recognition model is utilized to perform gender detection on the face images to be detected. The gender of each of the obtained faces to be marked is marked in the following manners that: name keywords of candidates are extracted from the context information of the images, and a network is searched, and the method returns a result webpage; the genders of the images are determined according to the word frequency of gender relevant words in the result webpage; and a face image technology platform and a face attribute analysis algorithm are respectively adopted to detect the genders of the images; and the gender of the images are marked based on above recognition results. With the face image gender marking method and the face gender detection method of the invention adopted, face image marking efficiency and gender detection efficiency can be greatly improved.

Owner:BEIJING KUANGSHI TECH

Method, device and system for automatically labeling target object in image

ActiveCN109584295ARealize automatic labelingEasy to getImage enhancementImage analysisThree-dimensional spaceReference image

The embodiment of the invention discloses a method, device and system for automatically labeling a target object in an image, and the method comprises the steps: obtaining an image training sample which comprises a plurality of images, each image is obtained through the shooting of the same target object, and the adjacent images have the same environmental feature points; Taking one image as a reference image, determining a reference coordinate system, and creating a three-dimensional space model based on the reference three-dimensional coordinate system; When the three-dimensional space modelis moved to the position where a target object is located in the reference image, determining position information of the target object in the reference three-dimensional coordinate system; And respectively mapping the three-dimensional space model to the image plane of each image according to the respective corresponding camera attitude information determined by the environmental feature pointsin each image. According to the embodiment of the invention, automatic image labeling can be carried out more accurately and effectively, and the universality of the method is improved.

Owner:ALIBABA GRP HLDG LTD

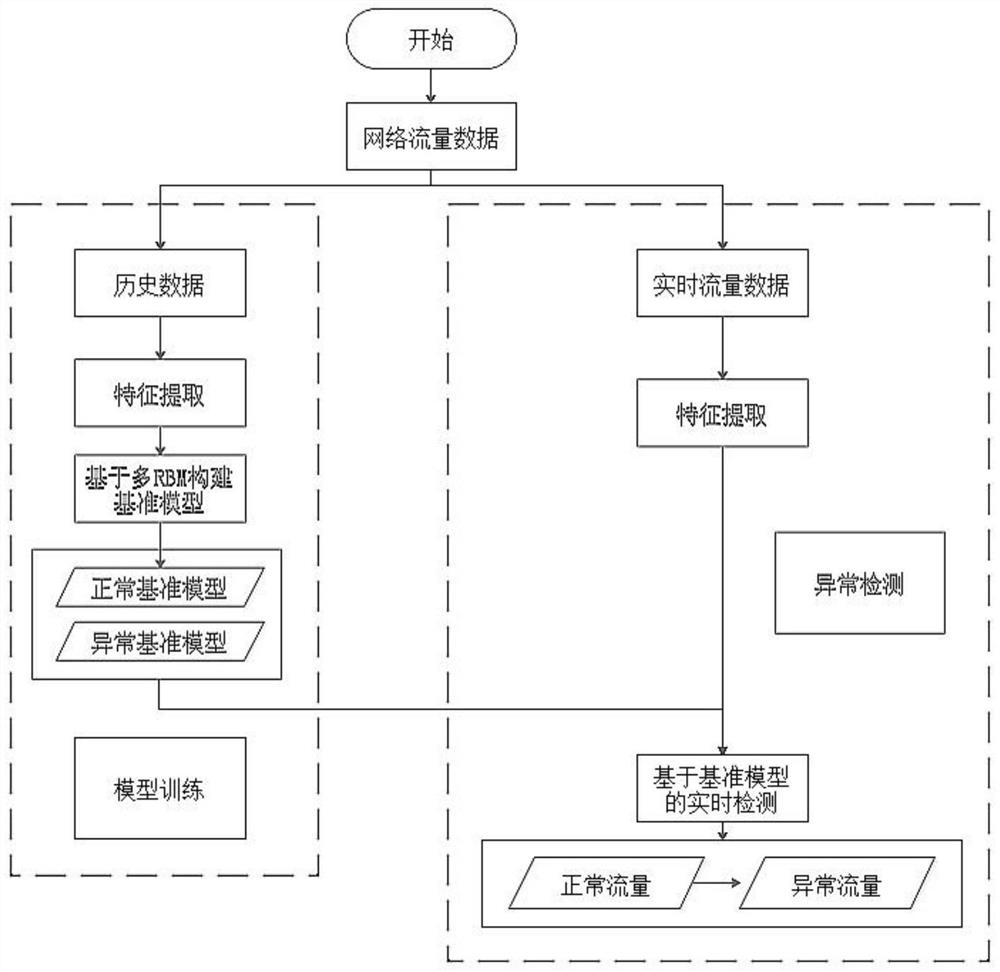

Abnormal flow detection system and method

PendingCN111832647AReduce complexityImprove detection accuracyCharacter and pattern recognitionNeural architecturesCluster algorithmReference model

The invention provides an abnormal flow detection system and method, and the system comprises a flow feature analysis and selection module which screens flow features according to the flow features ofa ubiquitous power IOT, and carries out the dimension reduction of the flow features through a KPCA algorithm; a flow reference model construction module which is used for extracting flow characteristics after dimension reduction, constructing a restricted Boltzmann machine model based on an RBM model and an SOM clustering algorithm and training to complete construction of a reference model; a flow benchmark model training module which is used for carrying out anomaly degree division on the trained benchmark model according to a comparison divergence degree algorithm, and dividing the benchmark model into a normal benchmark model and an abnormal benchmark model; and an abnormal flow detection module which is used for extracting and calculating flow characteristics to be detected, and carrying out abnormal flow detection according to the similarity between the output of the reference model and the original input characteristic data. According to the invention, the automatic category labeling of the traffic data can be completed, and the network traffic anomaly detection accuracy is relatively high.

Owner:SHANGHAI JIAO TONG UNIV +1

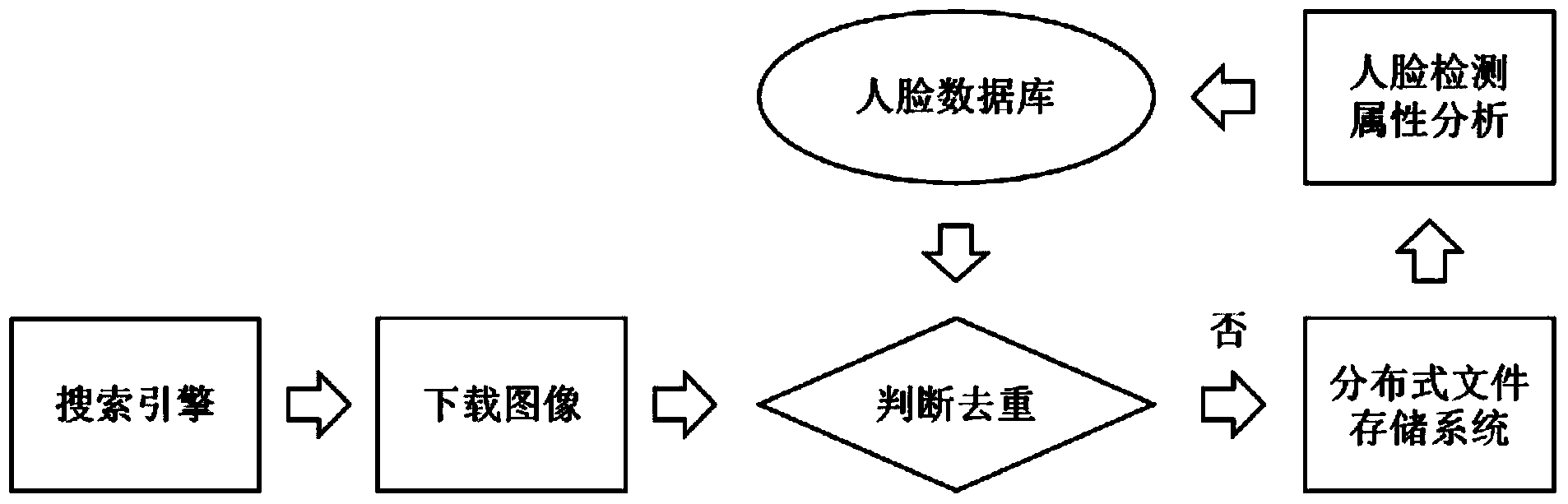

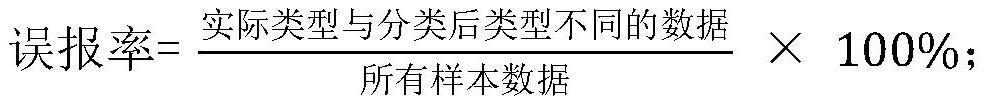

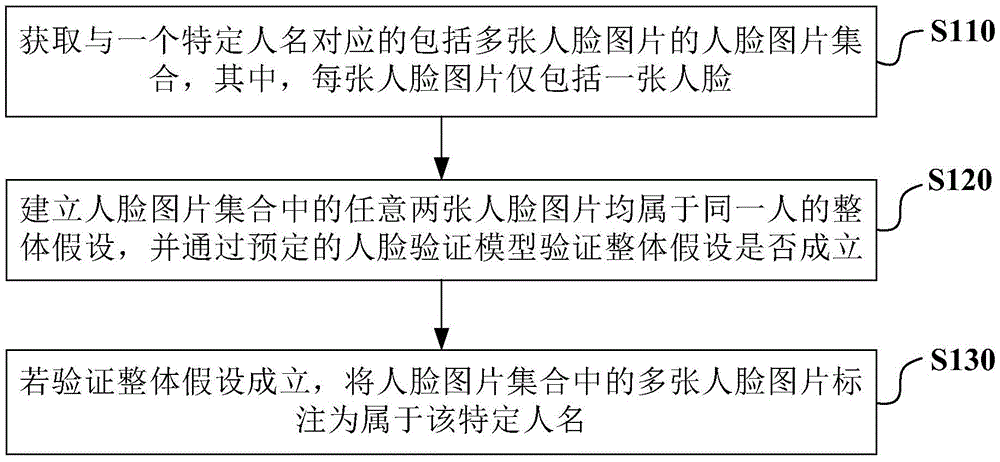

Method and apparatus for labeling face images

ActiveCN105468760ARealize automatic labelingQuick screeningWeb data indexingCharacter and pattern recognitionPattern recognitionThe Internet

The invention provides a method and an apparatus for labeling face images. The method comprises: acquiring a face image set which corresponds to a specific personal name and comprises a plurality of face images, wherein each face image only comprises one face; establishing a whole object assumption that both random face images in the face image set belong to the same person, and verifying whether the whole object assumption is tenable by a predetermined face verification model; and if verifying the whole object assumption is tenable, labeling the plurality of face images in the face image set as a result that the face images in the face image set belong to the specific personal name. According to the scheme, a great number of images crawled from the Internet can be rapidly discriminated and screened, error images are efficiently removed, labor and time cost of labeling the face images is greatly saved, and a powerful guarantee is provided for a subsequent face identification model based on automatic labeling, which has high face image training accuracy; and meanwhile, according to the scheme, an existing data monopoly in the industry can be broken through, which is convenient for popularization of a face identification technology, thereby promoting the progress of the technology.

Owner:BEIJING QIHOO TECH CO LTD

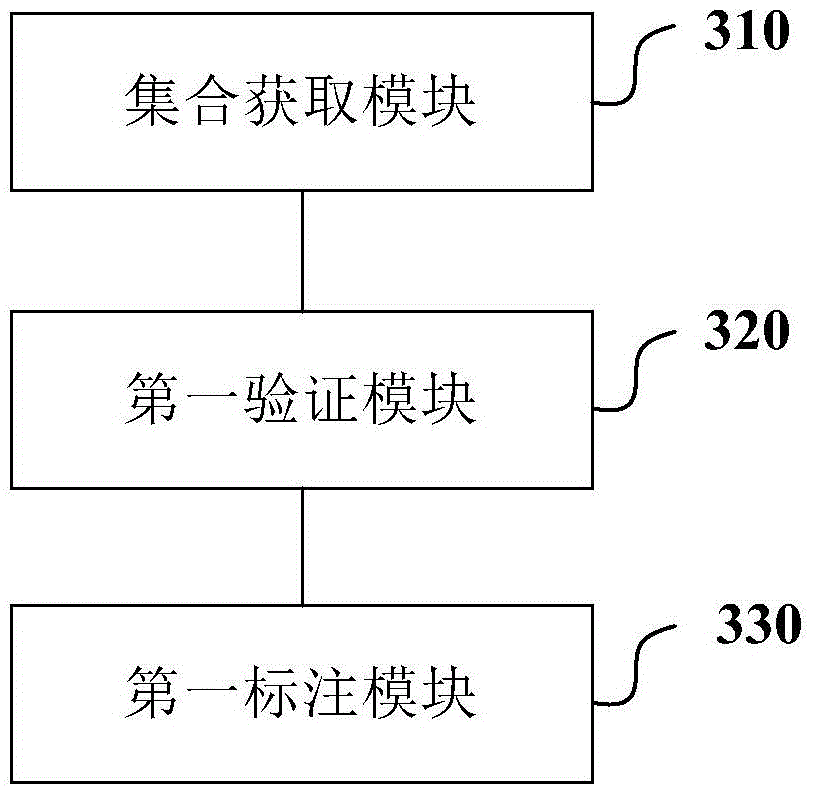

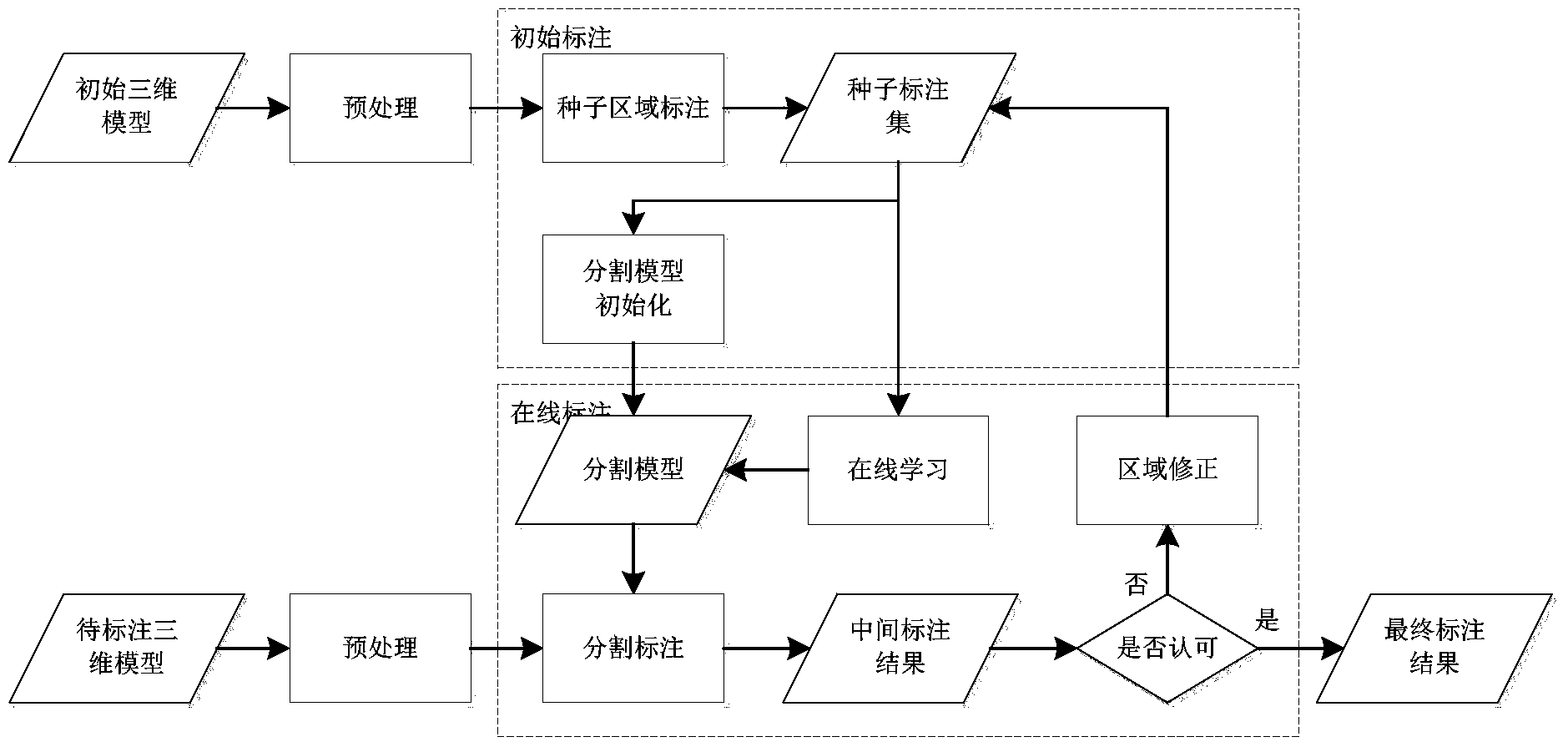

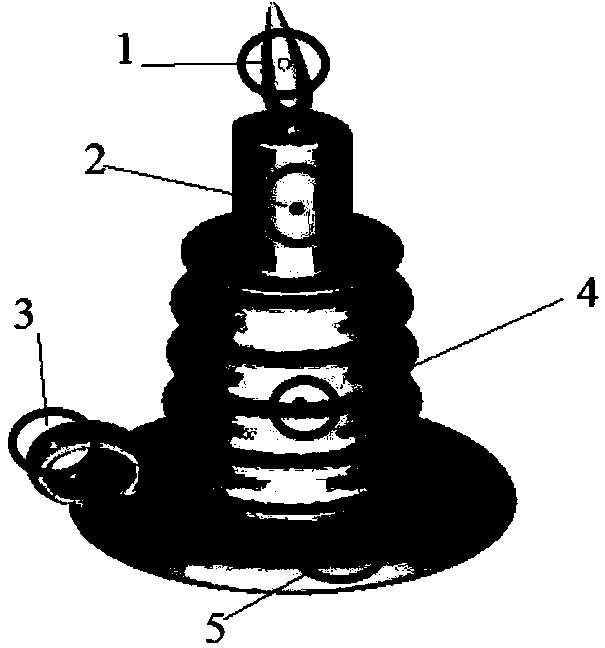

Online marking method for three-dimensional model component

InactiveCN103971415ARealize automatic labelingImage data processingPattern recognitionOnline learning

The invention discloses an online marking method for a three-dimensional model component. The method includes the following steps that preprocessing is conducted, and features and over-segmentation pieces of triangular patches are obtained; initial marking is conducted, a segmentation model is initialized, seed area marking is conducted on an initial three-dimensional model which is input by a user, a seed marking set is obtained, online learning is conducted on the seed marking set, and the partition model is learned; online marking is conducted, the segmentation model is used for conducting segmentation marking on an input three-dimensional model of the same type, a middle marking result is obtained, whether the result is approved or not is judged by the user, if yes, the process is over, and the middle marking result is a final marking result, and if not, the user conducts area correction on the middle marking result, the seed marking set is obtained, online learning is conducted on the seed marking set, the segmentation model is updated, the updated segmentation model is used for conducting segmentation marking on the three-dimensional model, the middle marking result is obtained, continuous iteration is conducted until the middle marking result is approved by the user, and the final three-dimensional model marking result is obtained.

Owner:NANJING UNIV

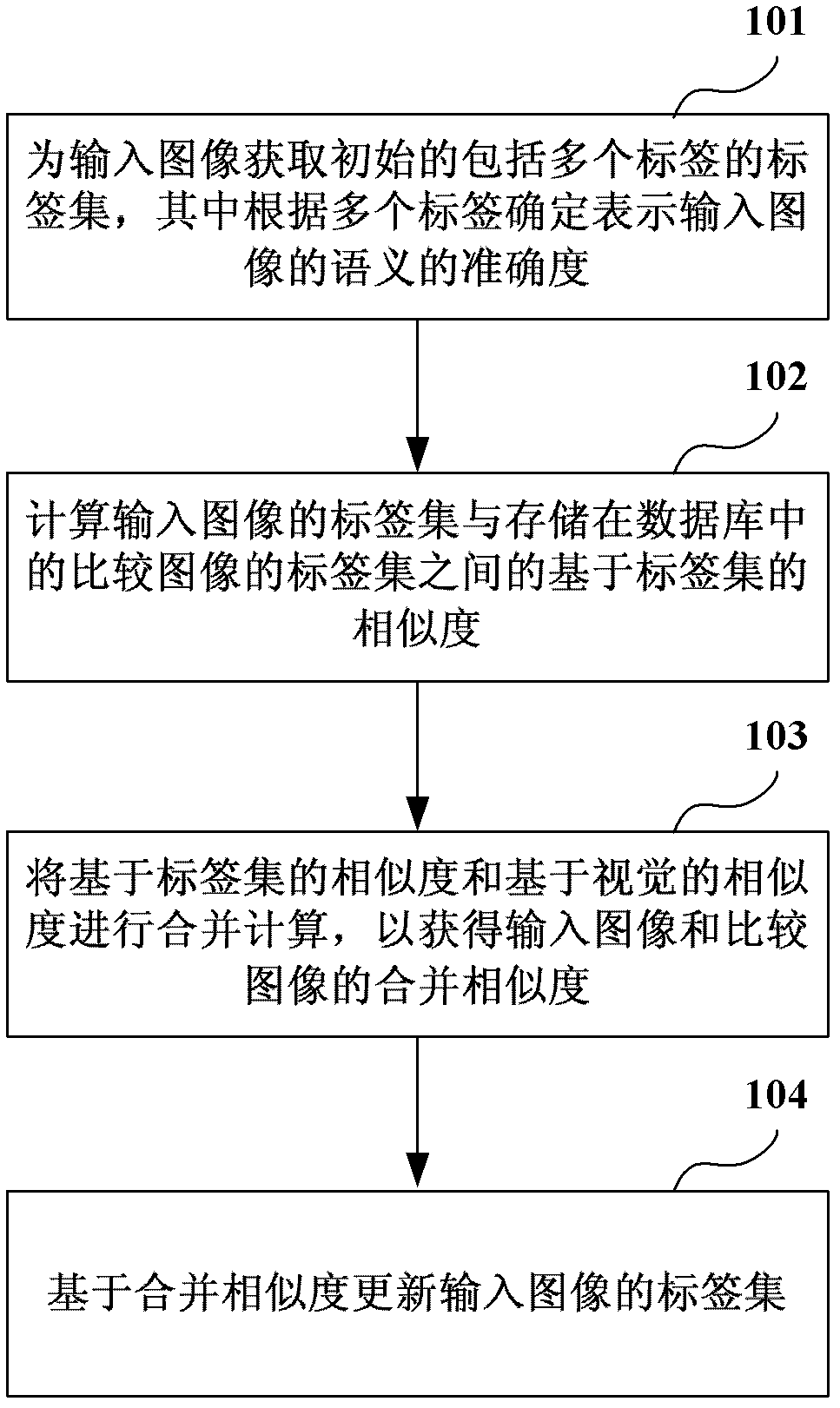

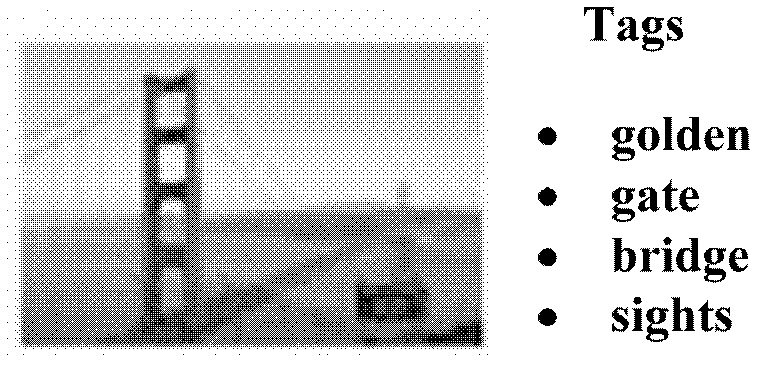

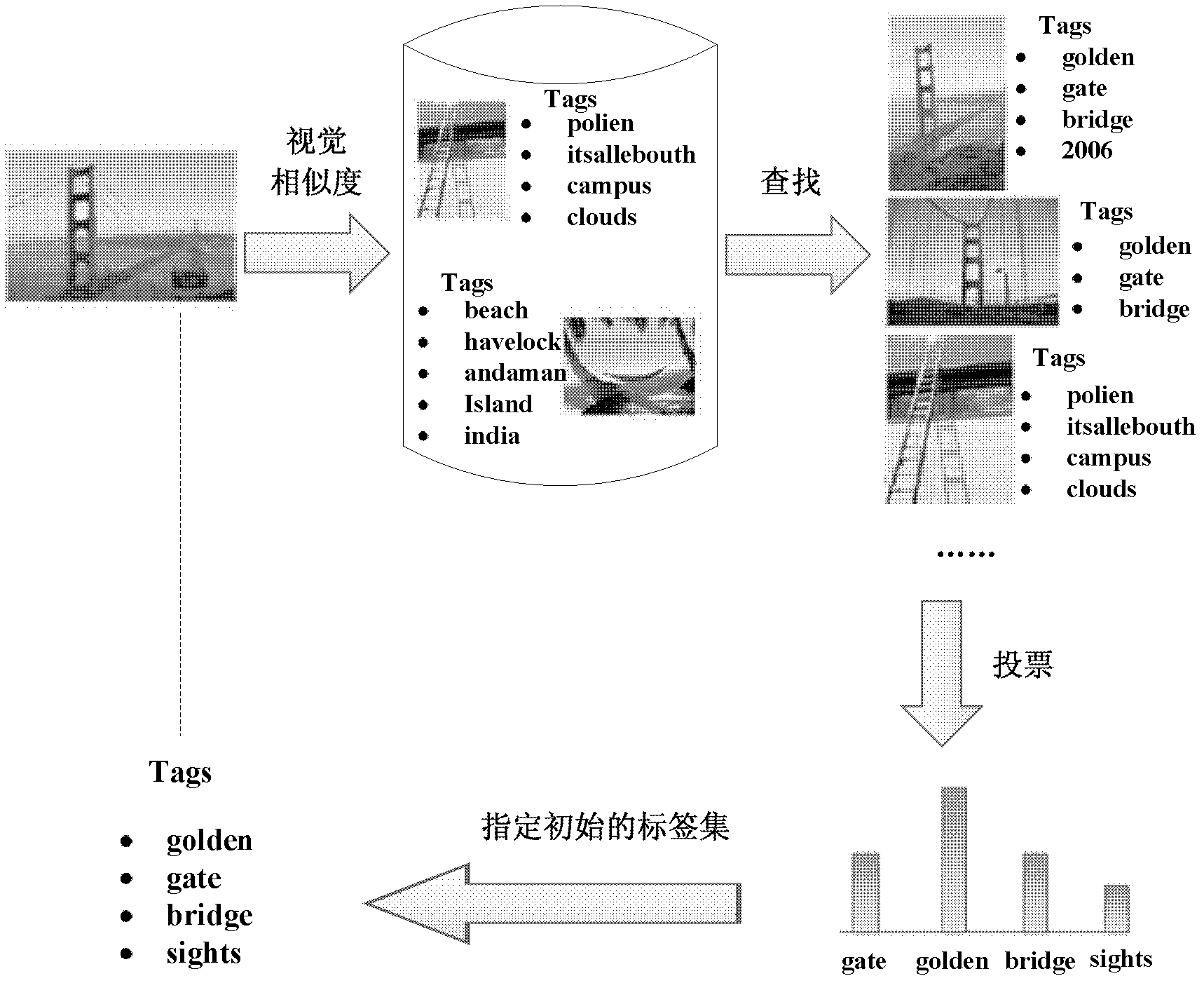

Image annotation method and device thereof

ActiveCN102880612ARealize automatic labelingImprove accuracySpecial data processing applicationsPattern recognition

The embodiment of the invention provides an image annotation method and a device thereof. The image annotation method comprises the steps that an initial label set comprising a plurality of labels is obtained for an input image; the label set based similarity degree between the label set of the input image and a label set of a comparison image stored in a data base is calculated; the label set based similarity degree and the vision based similarity degree are subjected to consolidation, so as to obtain the consolidated similarity degree between the input image and the comparison image; and the label set of the input image is updated based on the consolidated similarity degree. According to the embodiment of the invention, low level characteristics and high level semantics of the image can be considered at the same time; the precision of image annotation can be improved; the automatic label annotation is realized; and the annotation efficiency is improved.

Owner:FUJITSU LTD

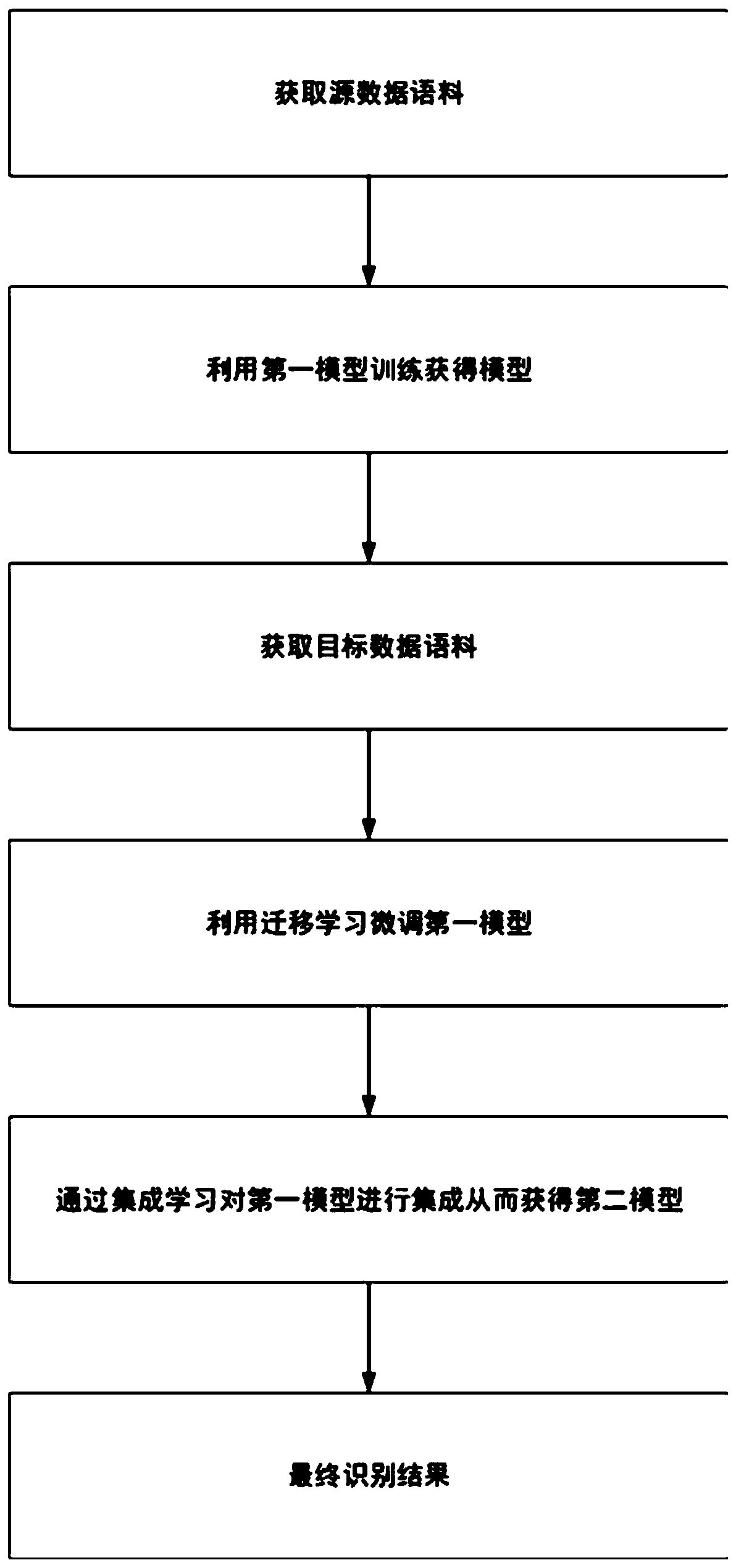

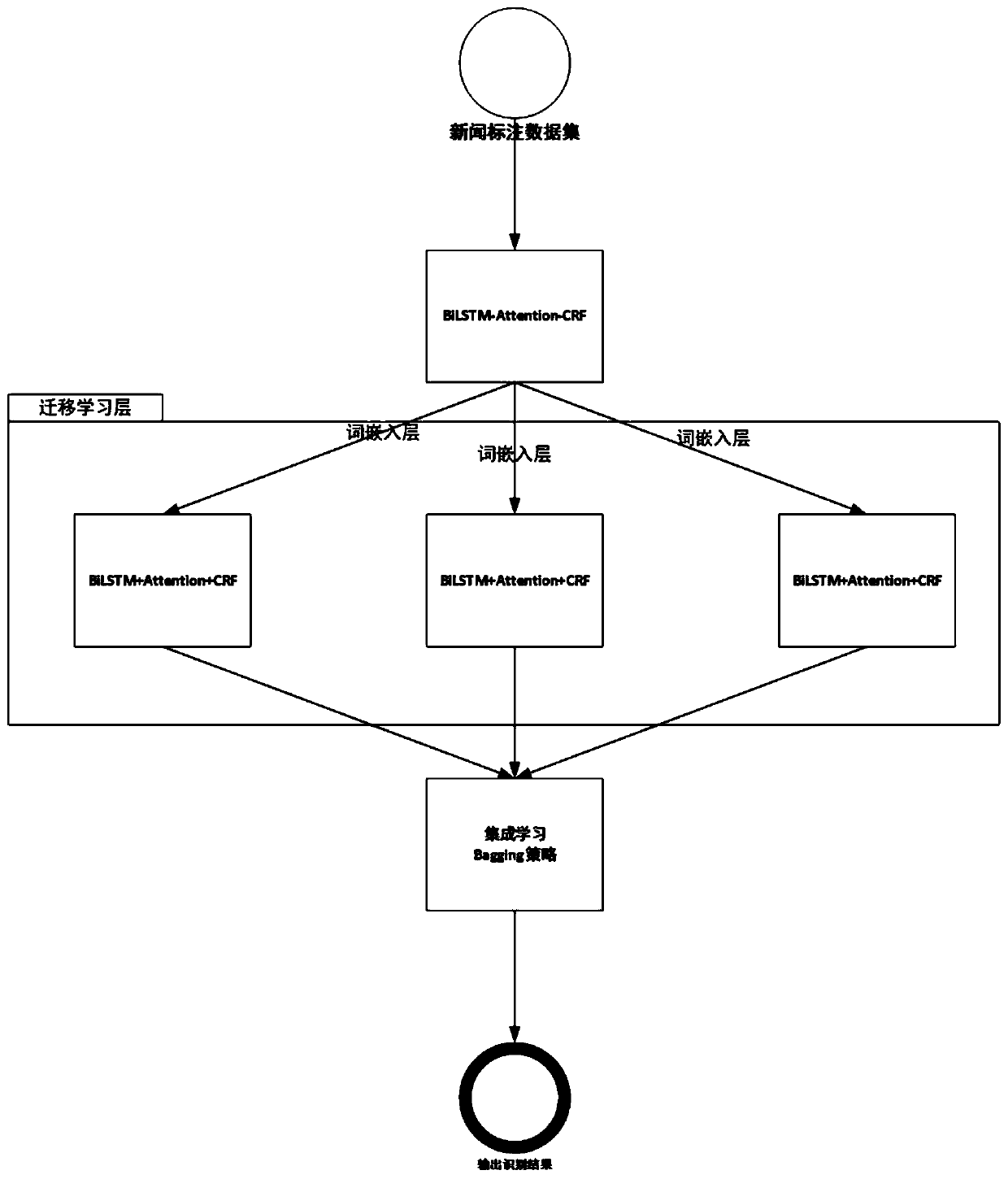

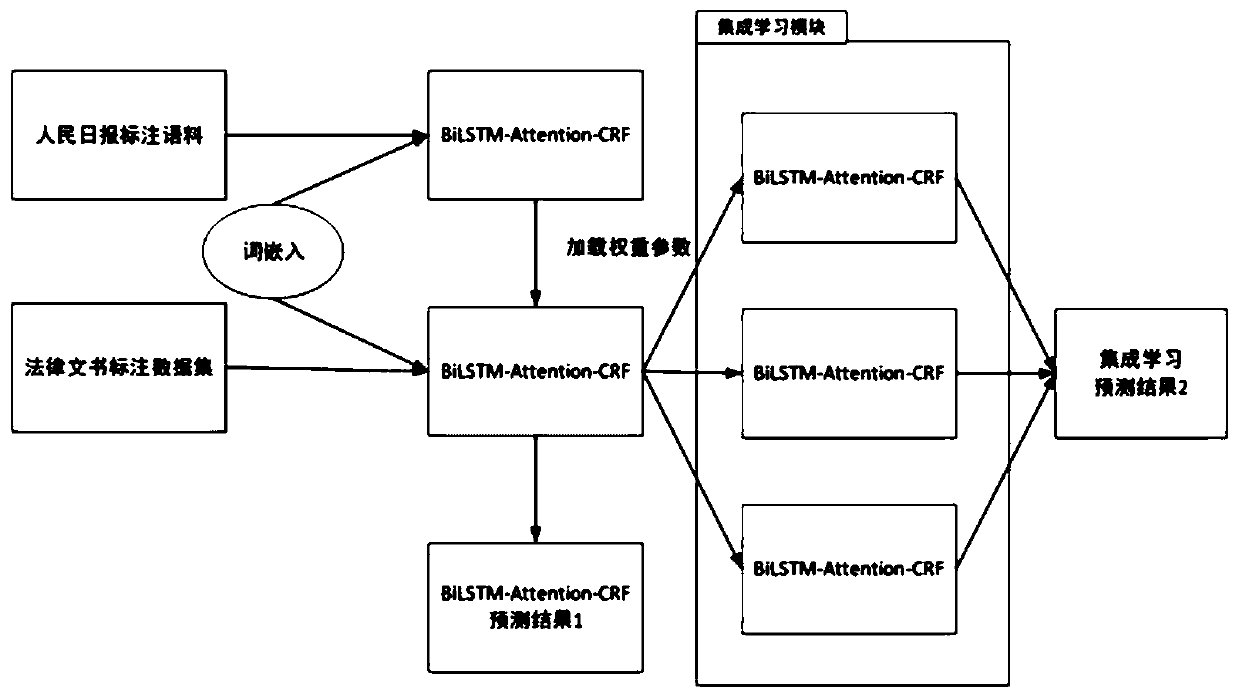

Named entity identification method and system for legal instrument multi-strategy fusion

ActiveCN110807328AReduce the burden onRealize automatic labelingEnsemble learningNatural language data processingNamed-entity recognitionEngineering

The invention discloses a named entity recognition method and system for legal document multi-strategy fusion, and the method comprises the following steps: building a source data corpus, carrying outthe part-of-speech tagging and sequence tagging of the source data corpus, and carrying out the model pre-training; training the labeled data through a BiLSTM-Attention-CRF (Bipolar Long Short Term Memory-Attention-Content Random Field) model to obtain a trained first model; improving the trained first model; establishing a target data corpus, randomly extracting data from the target data of thelegal instrument, and generating a plurality of training sets; carrying out transfer learning on the plurality of training sets, and training the improved first model to obtain models trained by the plurality of training sets; and integrating the models trained by the plurality of training sets by adopting a voting mechanism in ensemble learning to obtain a second model, and performing named entity identification of legal documents by the second model to obtain a final named entity identification result. According to the method, the accuracy and recall rate of named entity recognition are improved under the condition of insufficient annotation corpora.

Owner:SOUTH CHINA NORMAL UNIVERSITY

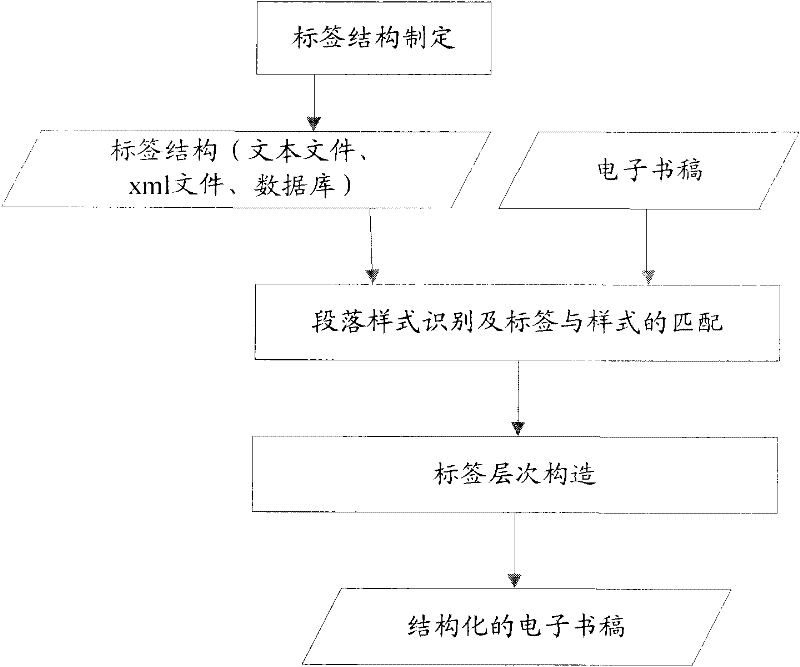

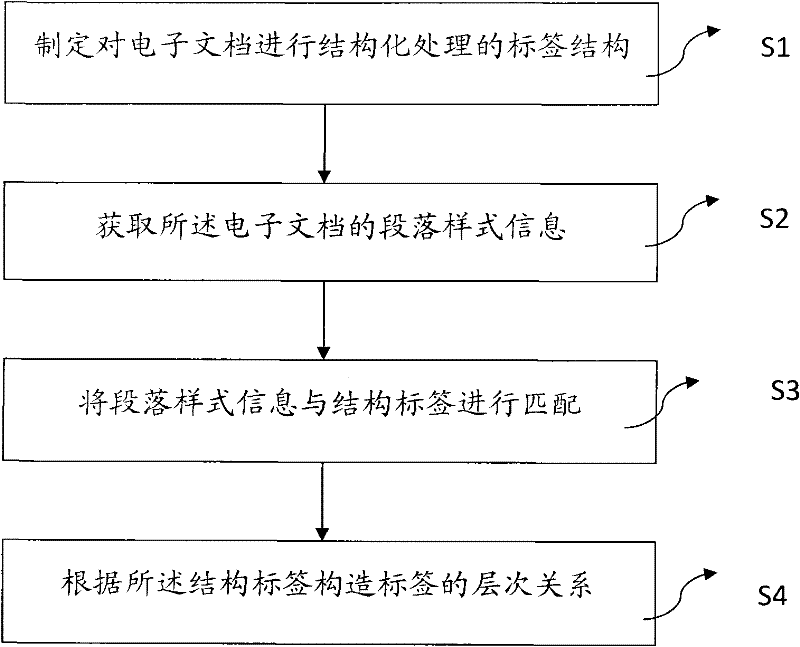

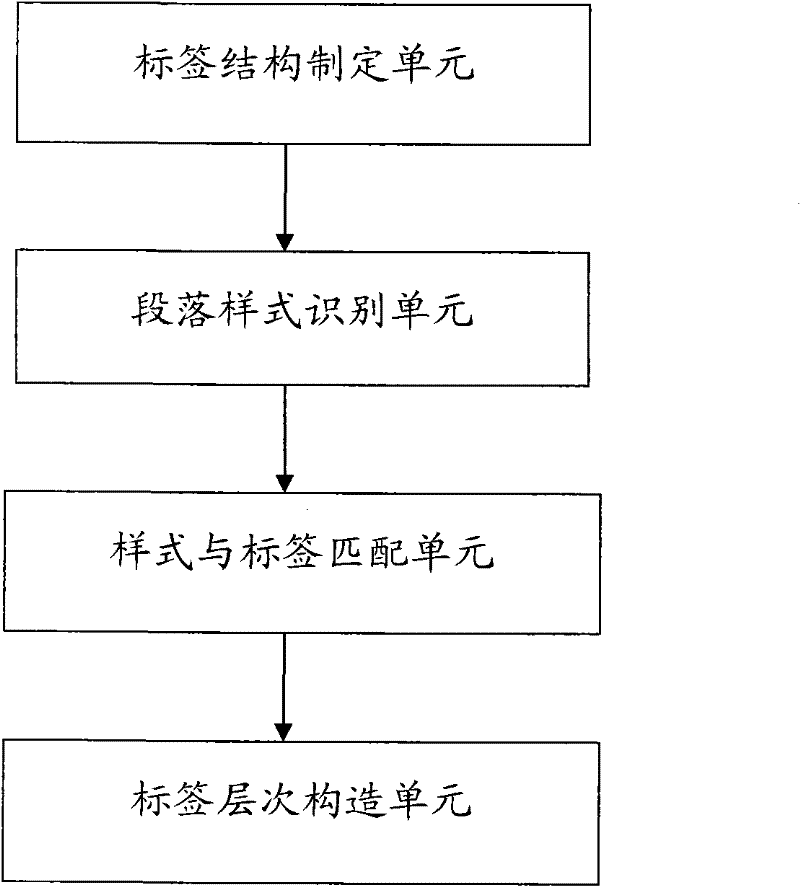

Method and system for carrying out structured processing on electronic document

InactiveCN102479248ARealize automatic labelingImplement structured processingSpecial data processing applicationsElectronic documentDatabase

The invention relates to the field of digital publishing, in particular to an electronic document processing technology, and provides a method and system for carrying out structured processing on an electronic document. The method comprises the following steps of: a step S1 of establishing a structure tag for carrying out structured processing on the electronic document; a step S2 of identifying a paragraph style and acquiring information of the paragraph style of the electronic document; a step S3 of matching the information of the paragraph style with the structure tag; and a step S4 of constructing a hierarchical relation of the tag according to the structure tag. The invention effectively overcomes the defects that in the prior art, the tag cannot be automatically added for the document, the hierarchical relation of the document cannot be shown and the processing efficiency is low.

Owner:BEIJING HOPE SOFTWARE

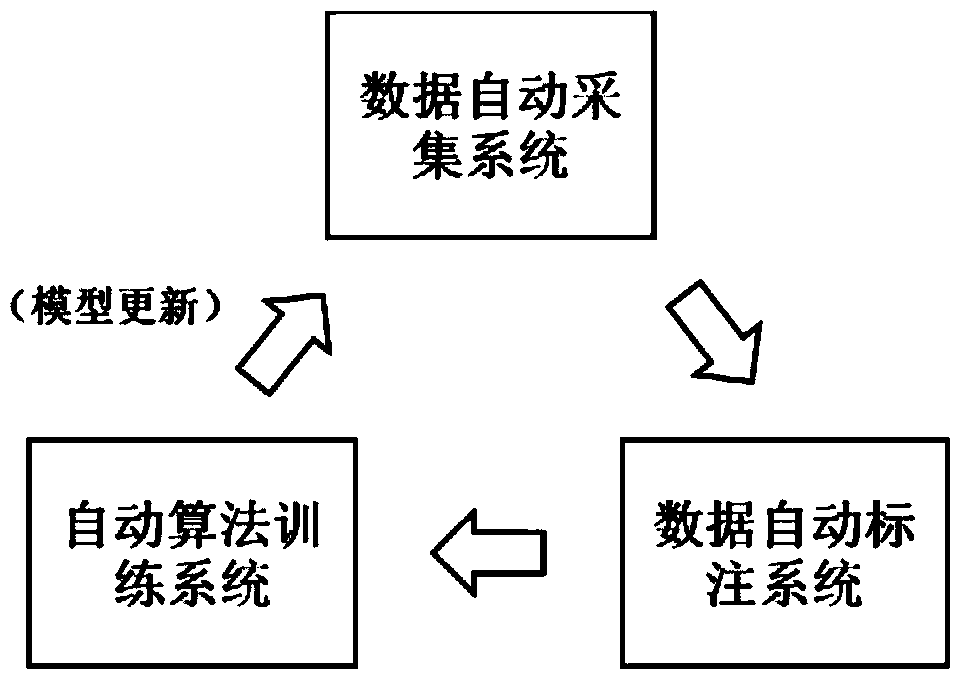

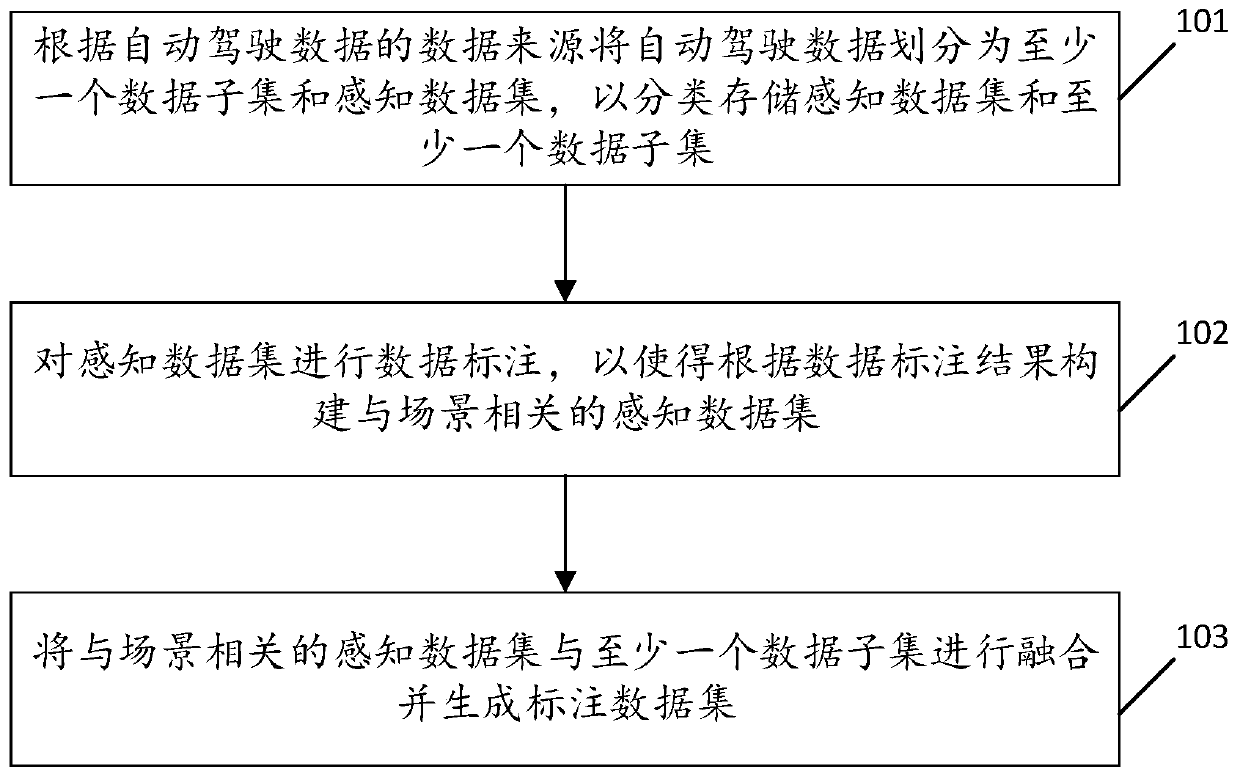

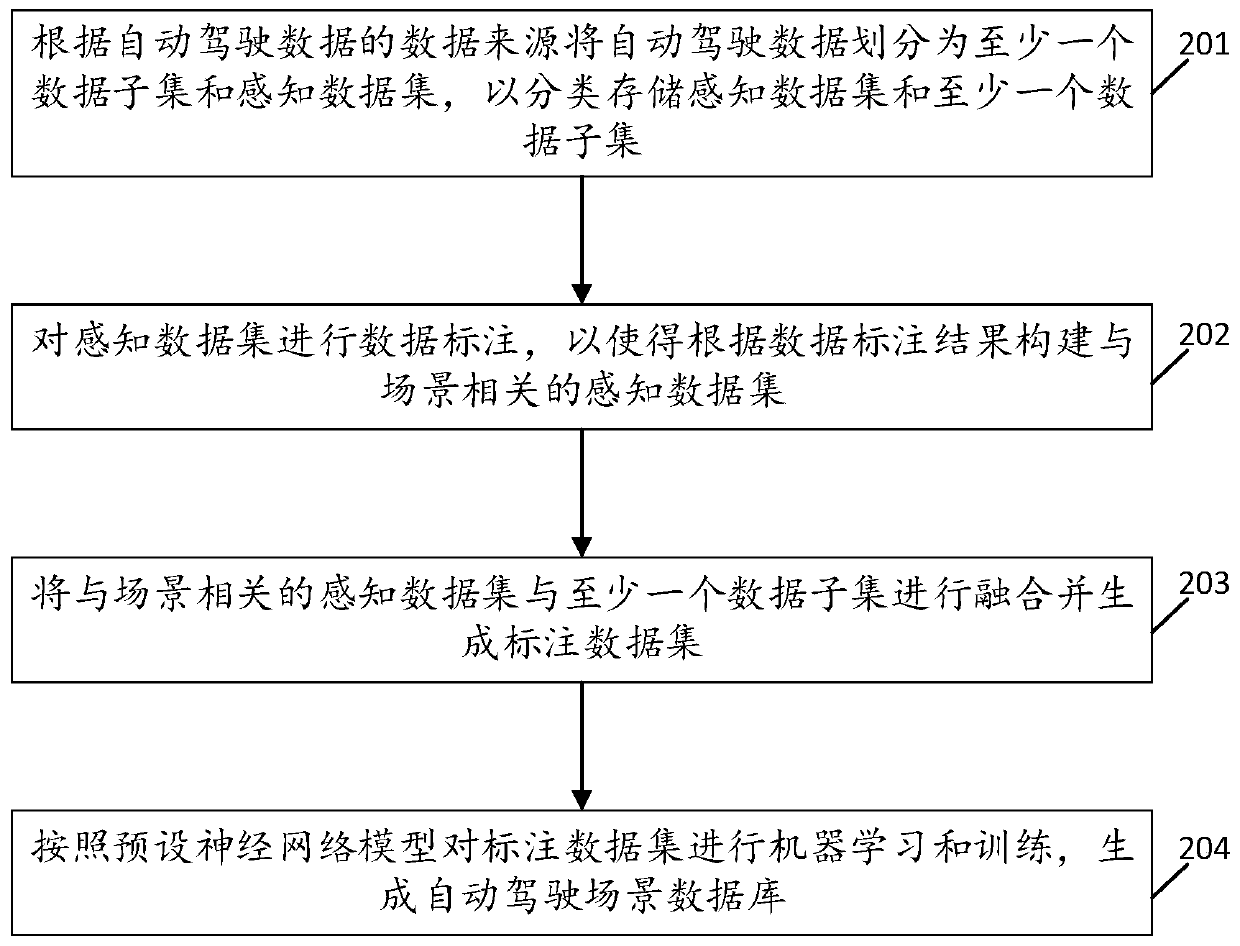

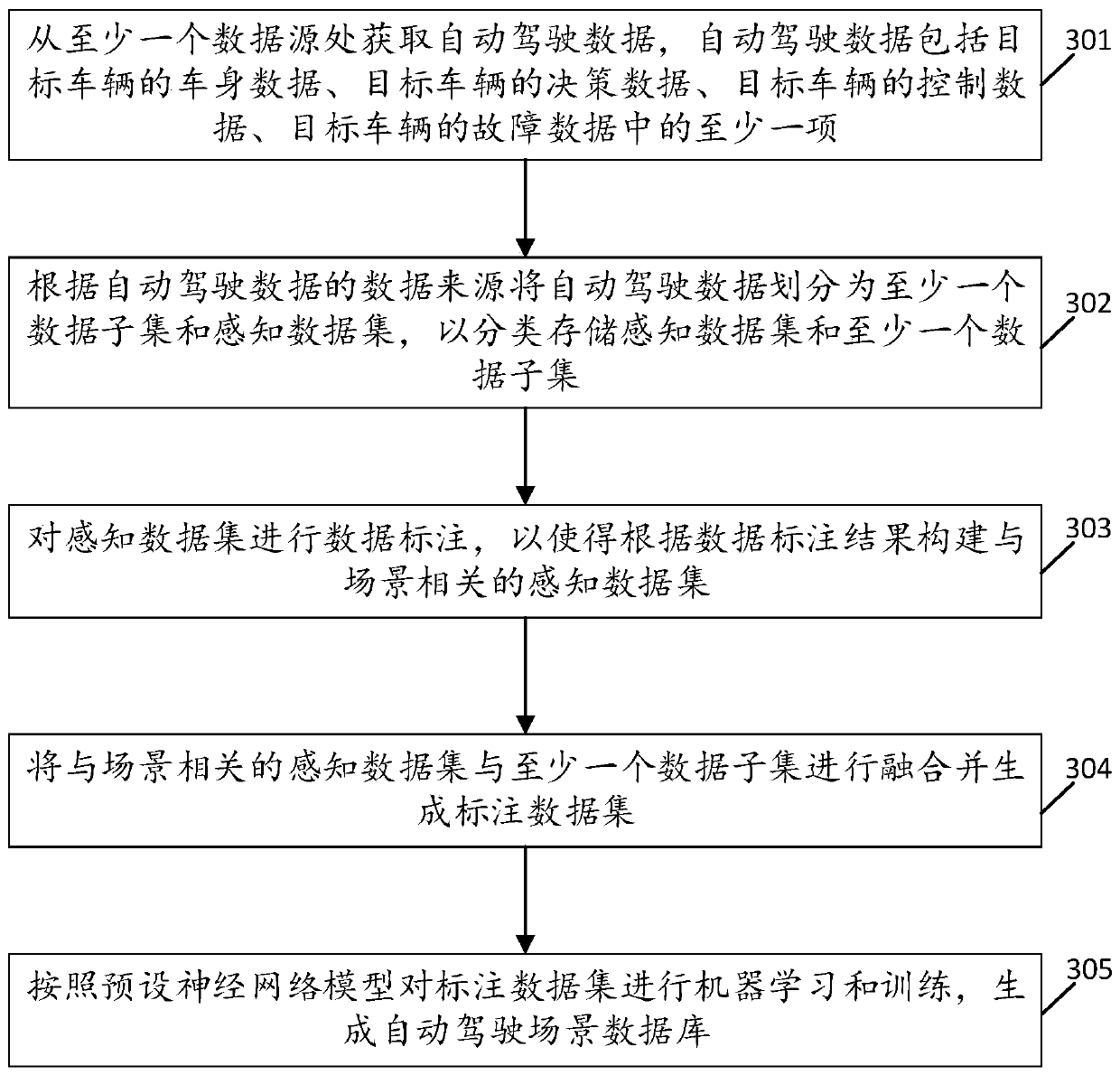

Automatic driving data labeling method, cloud control platform and storage medium

PendingCN111178454ARealize automatic labelingIncrease the value of dataData processing applicationsCharacter and pattern recognitionData OriginSensing data

The invention discloses an automatic driving data labeling method, a cloud control platform and a storage medium. The labeling method of the automatic driving data comprises the following steps: dividing the automatic driving data into at least one data subset and a perception data set according to a data source of the automatic driving data so as to store the perception data set and the at leastone data subset in a classified manner; then performing data annotation on the perception data set so as to construct a perception data set related to the scene according to a data annotation result;and fusing the perception data set related to the scene with the at least one data subset and generating an annotation data set. According to the method and the device, automatic labeling of the automatic driving data is realized, a data basis is disclosed for testing of the automatic driving vehicle, and a driving scene is analyzed by utilizing related data, for example, whether the current automatic driving vehicle runs normally or not is judged according to the sensing data.

Owner:BEIJING AUTOMOTIVE IND CORP +1

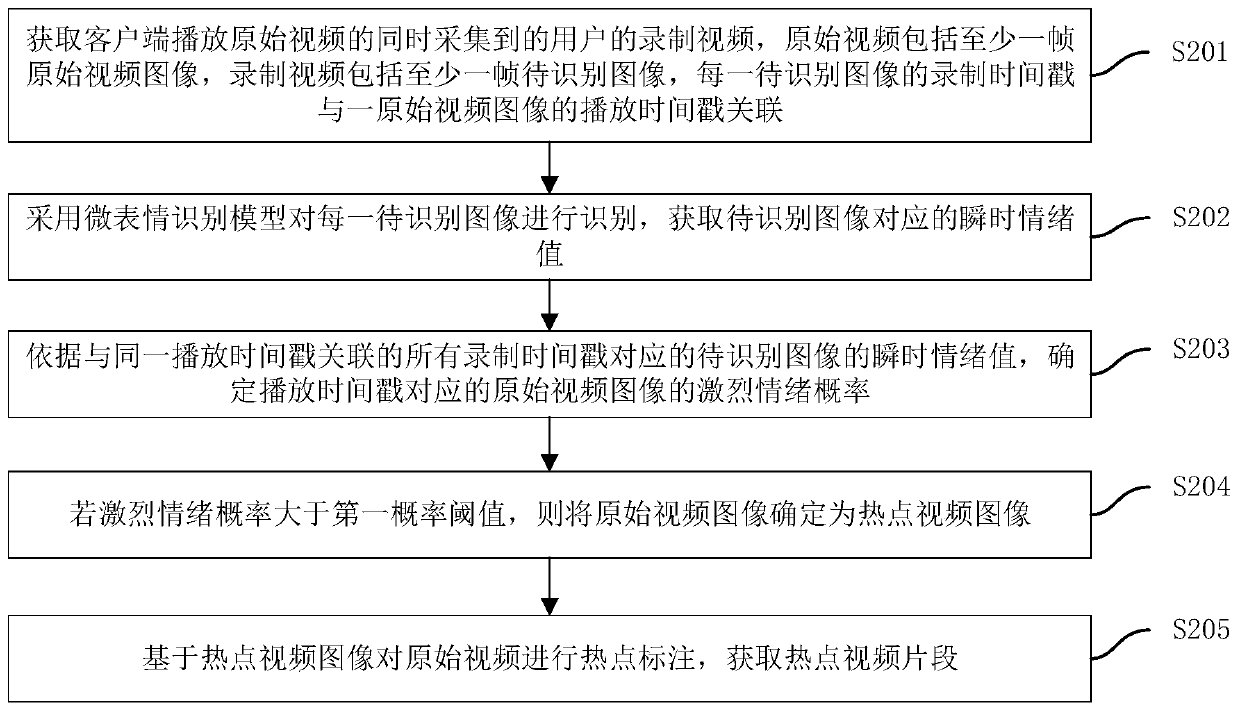

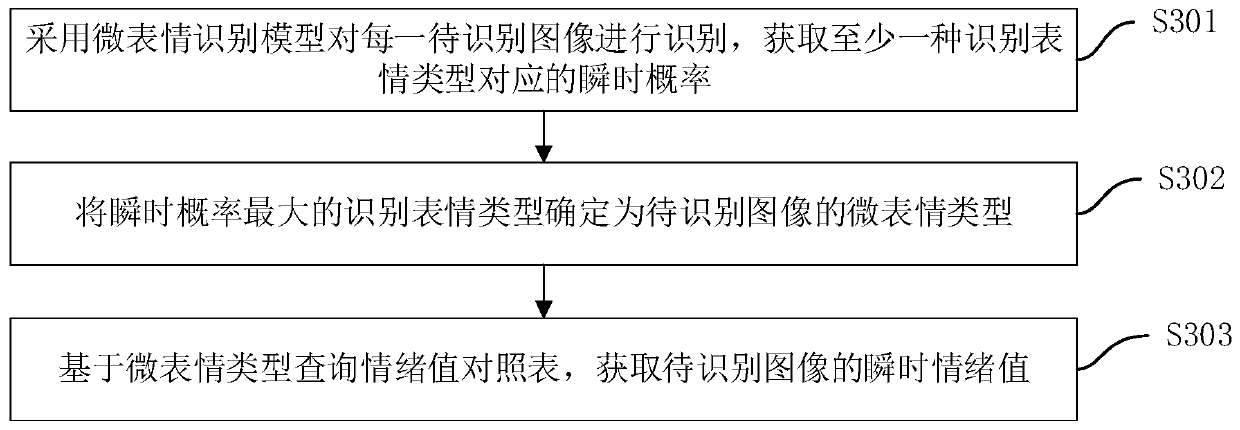

Hot video annotation processing method and device, computer equipment and storage medium

ActiveCN109819325AEnsure objectivityGuaranteed accuracyTelevision system detailsCharacter and pattern recognitionVideo annotationVideo image

The invention discloses a hot video annotation processing method and device, computer equipment and a storage medium. The method comprises the steps that a user recorded video collected while a clientplays an original video is acquired, the original video comprises at least one frame of original video image, the recorded video comprises at least one frame of to-be-identified image, each to-be-identified image is identified by adopting a micro expression identification model, and an instantaneous emotion value corresponding to the to-be-identified image is acquired. And according to the instantaneous emotion value, an intense emotion probability of the original video image corresponding to the playing time stamp is determined, if the intense emotion probability is greater than a first probability threshold, the original video image is determined as a hot video image, and hot spot marking is performed on the original video based on the hot video image to obtain a hot video clip. According to the method, the hotspot video clip can be automatically labeled, and the efficiency of labeling the hotspot video clip is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

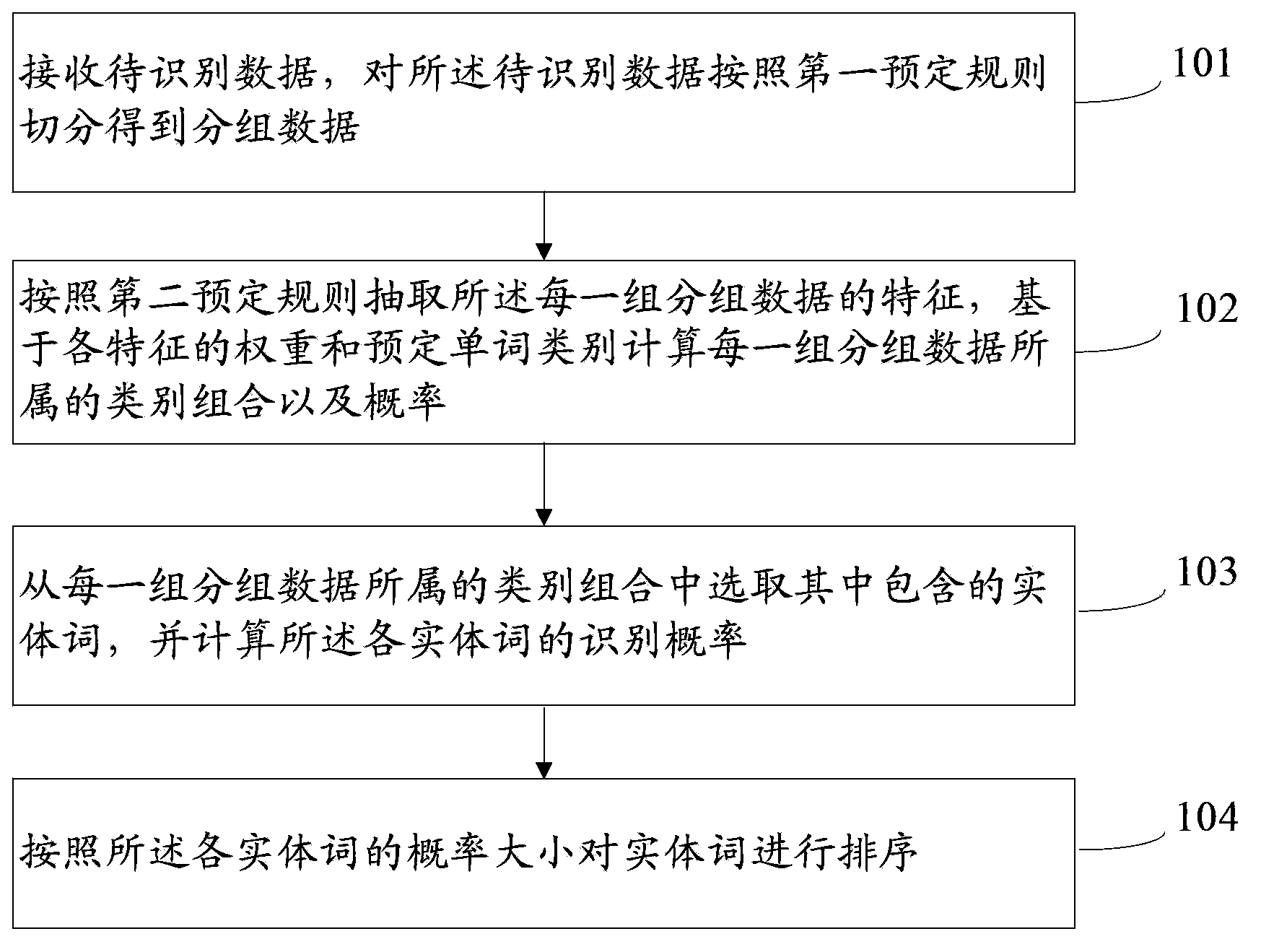

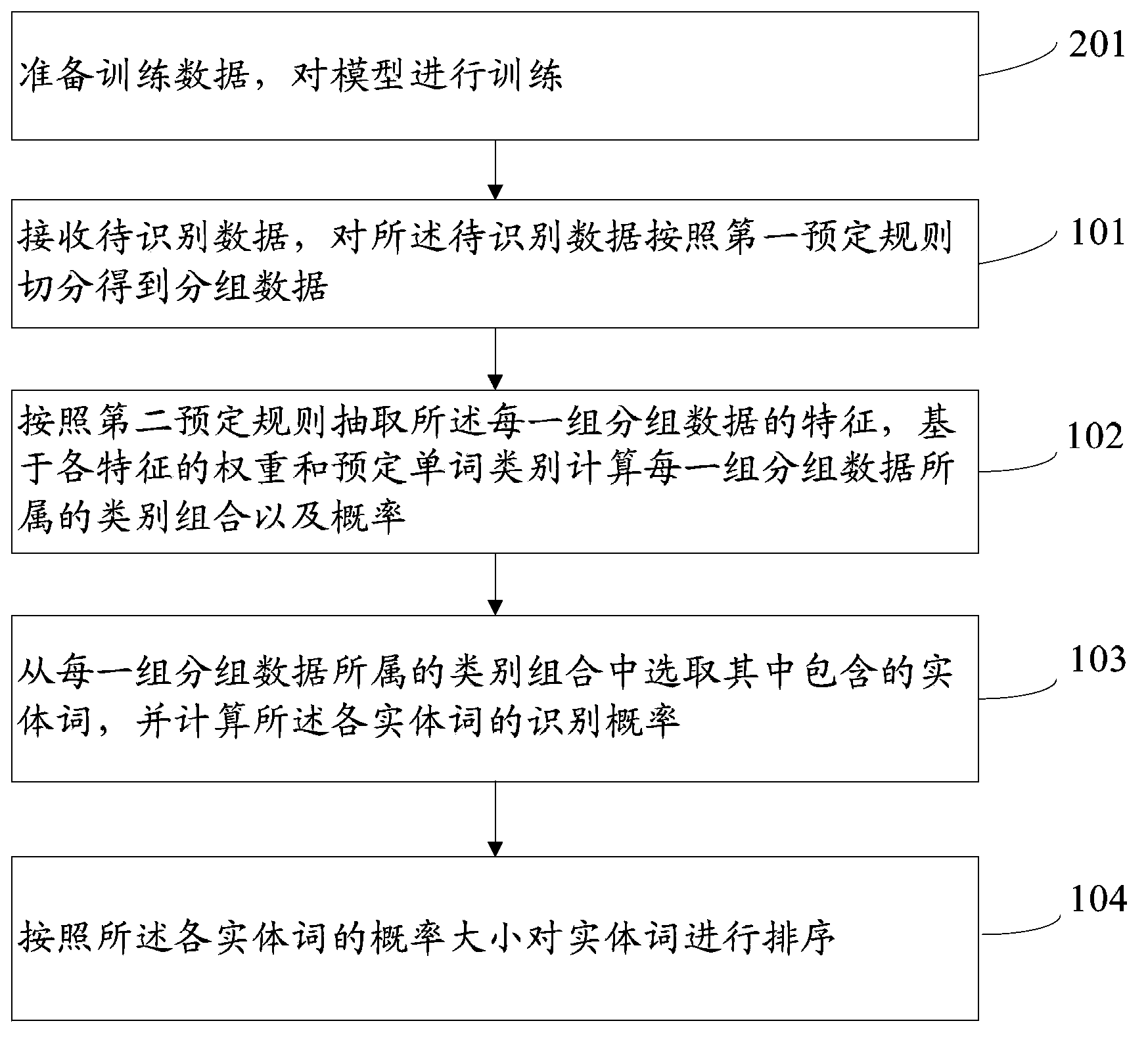

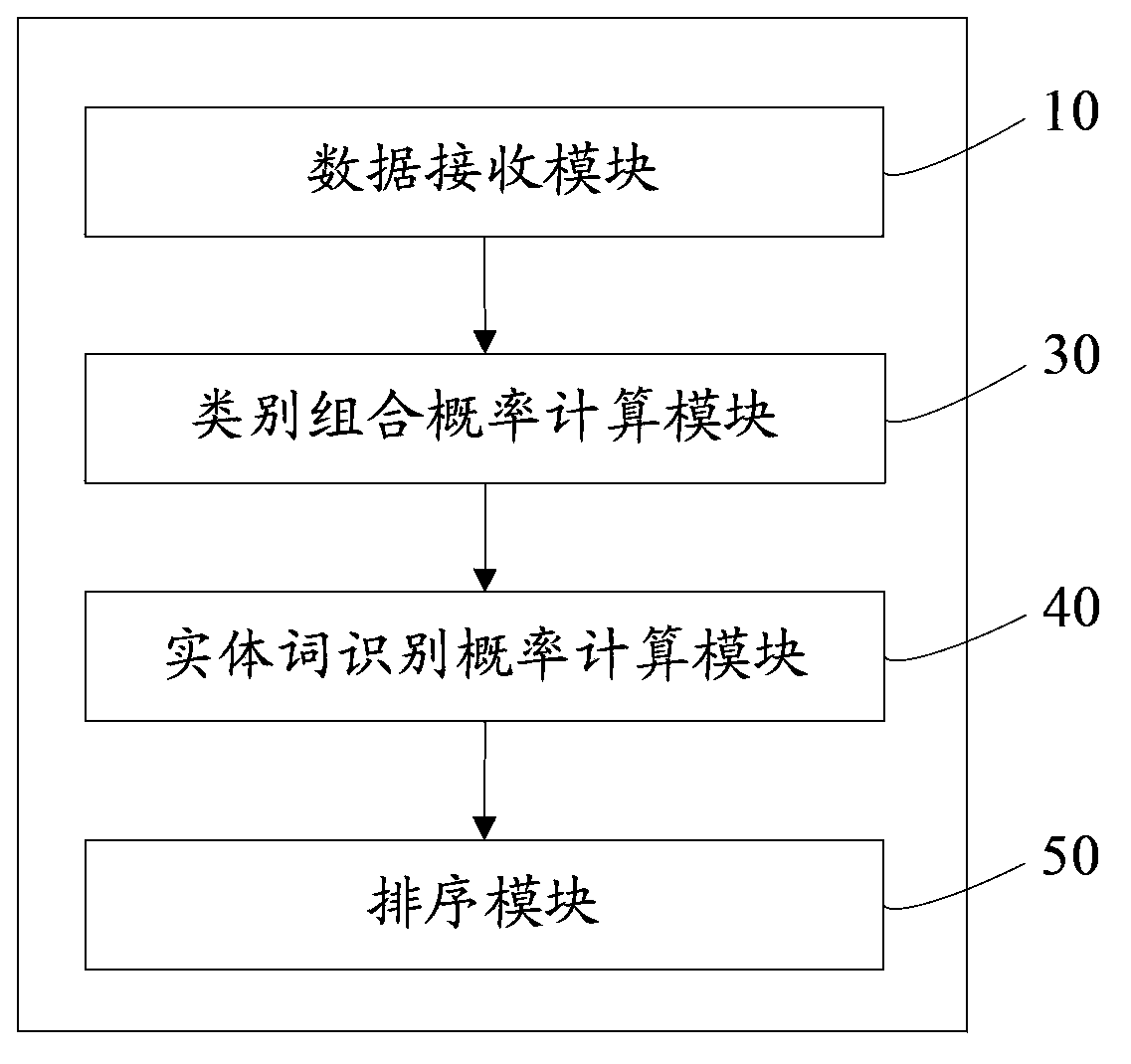

Method and device for identifying entity words

ActiveCN103678336AQuick identificationTimely updateNatural language data processingSpecial data processing applicationsIdentification deviceData mining

Owner:ALIBABA GRP HLDG LTD

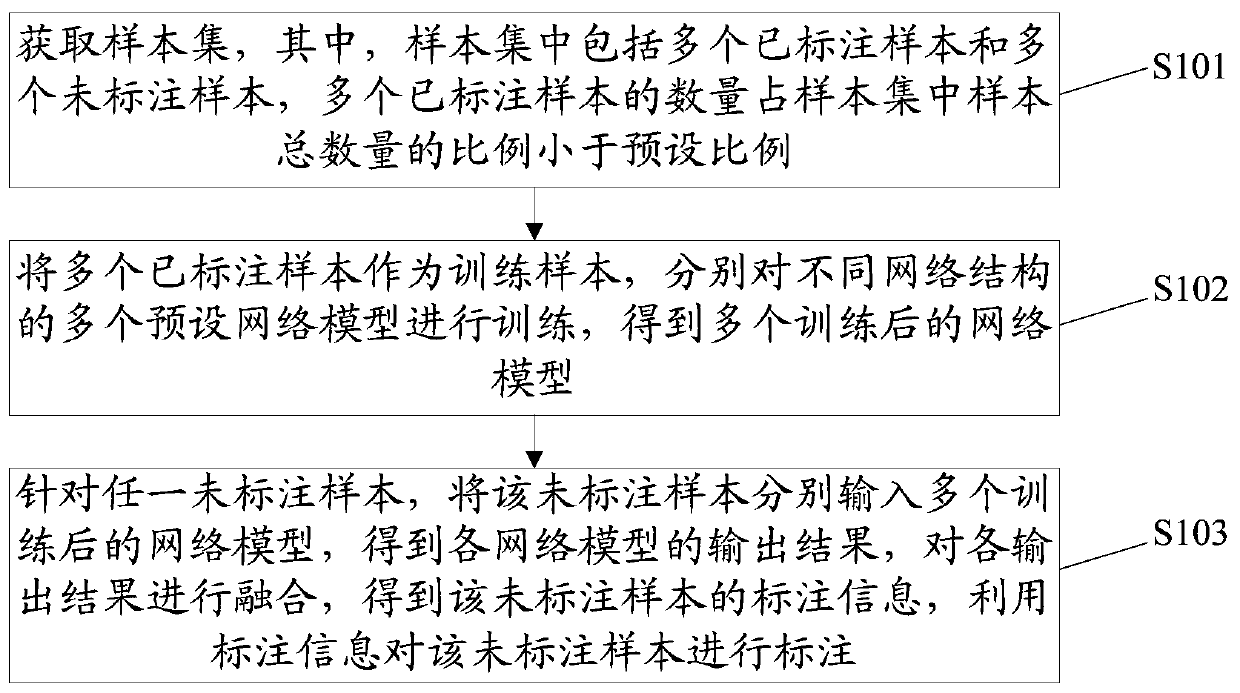

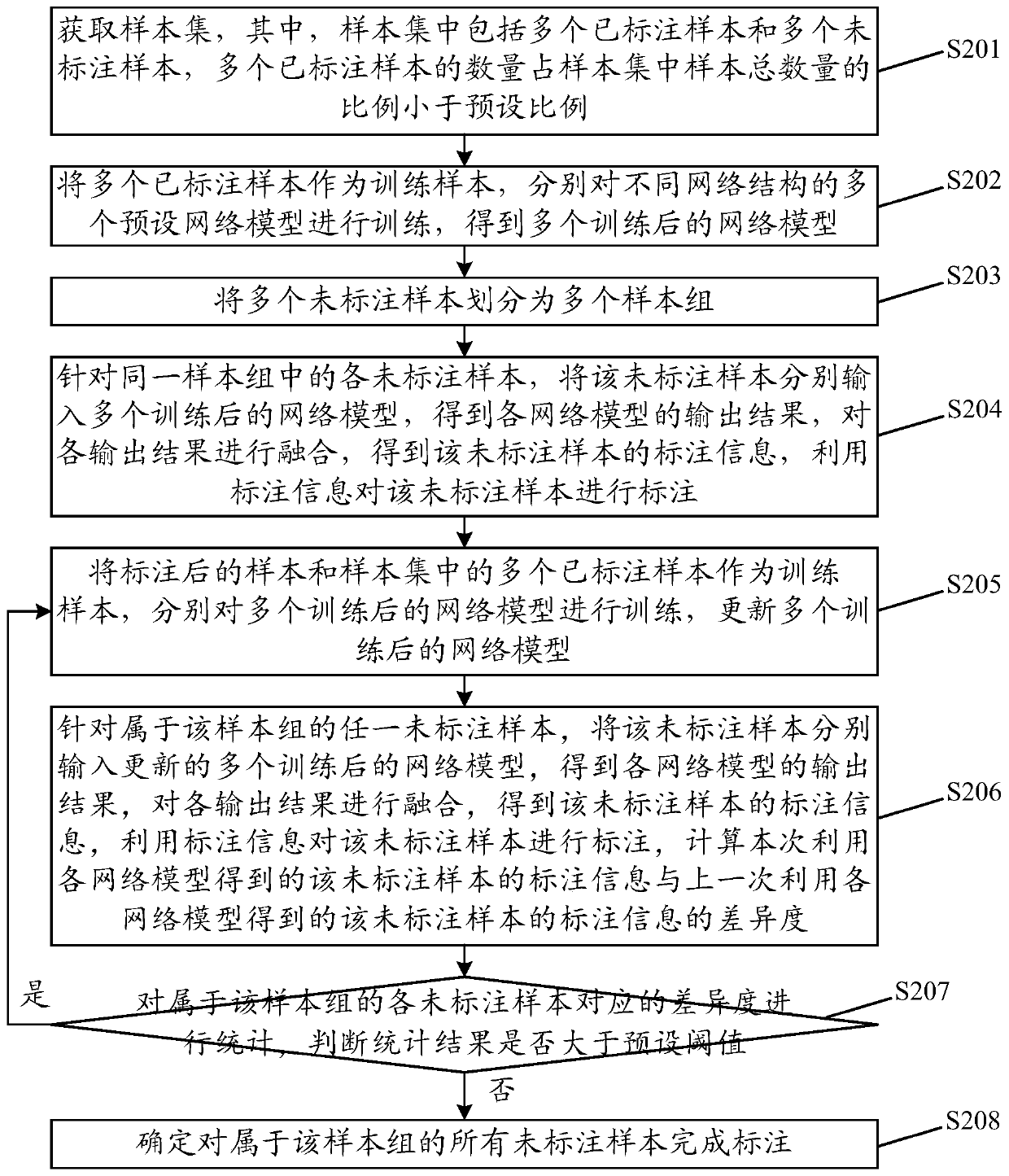

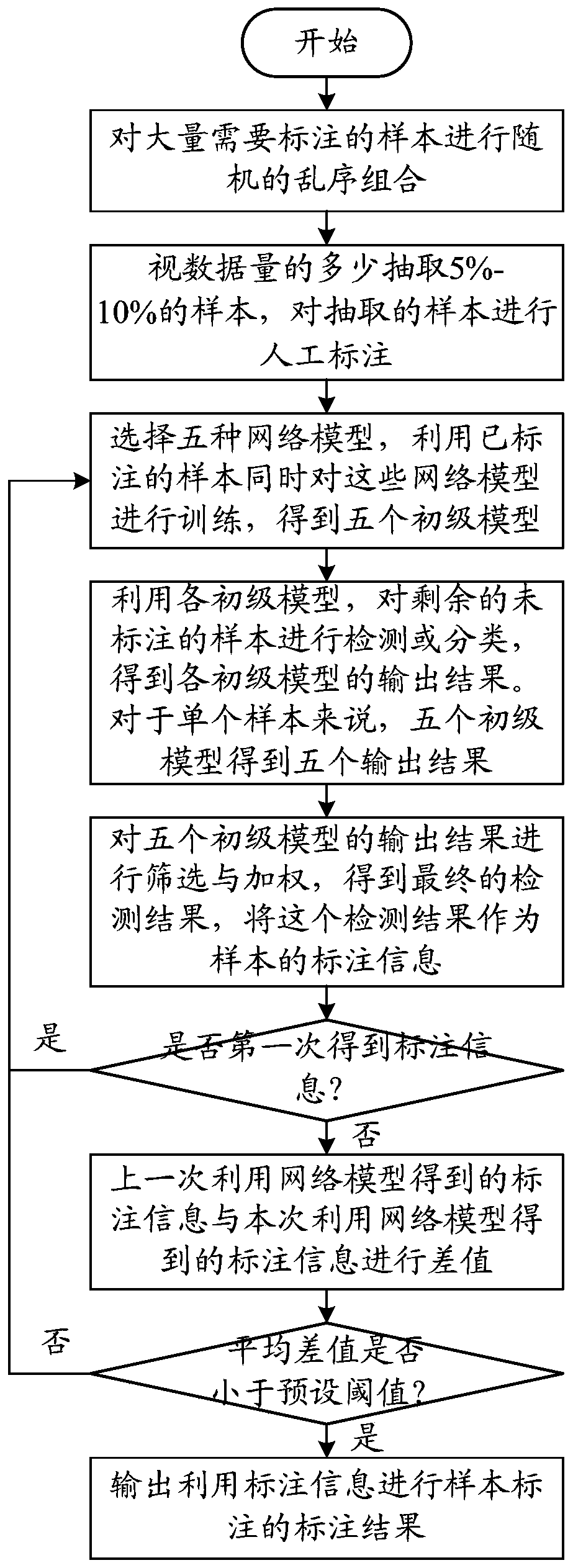

Sample labeling method and device, server and machine readable storage medium

PendingCN110889463AImprove labeling efficiencyRealize automatic labelingCharacter and pattern recognitionNetwork structureEngineering

The embodiment of the invention provides a sample labeling method and device, a server and a machine readable storage medium. The method comprises the steps of obtaining a sample set, taking a plurality of labeled samples in the sample set as the training samples, and respectively training a plurality of preset network models of different network structures to obtain the plurality of trained network models; aiming at any one unlabeled sample in the sample set, respectively inputting the unlabeled sample into the plurality of trained network models to obtain an output result of each network model, fusing the output results to obtain the labeling information of the unlabeled sample, and labeling the unlabeled sample by utilizing the labeling information. The sample set comprises the plurality of labeled samples and the plurality of unlabeled samples, the ratio of the number of the labeled samples to the total number of the samples in the sample set is smaller than a preset ratio, and thelabeling personnel only need to label a small number of samples, so that the workload of manual labeling is reduced, the risks of wrong labeling and missing labeling of manual labeling are reduced, and the sample labeling efficiency is improved.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

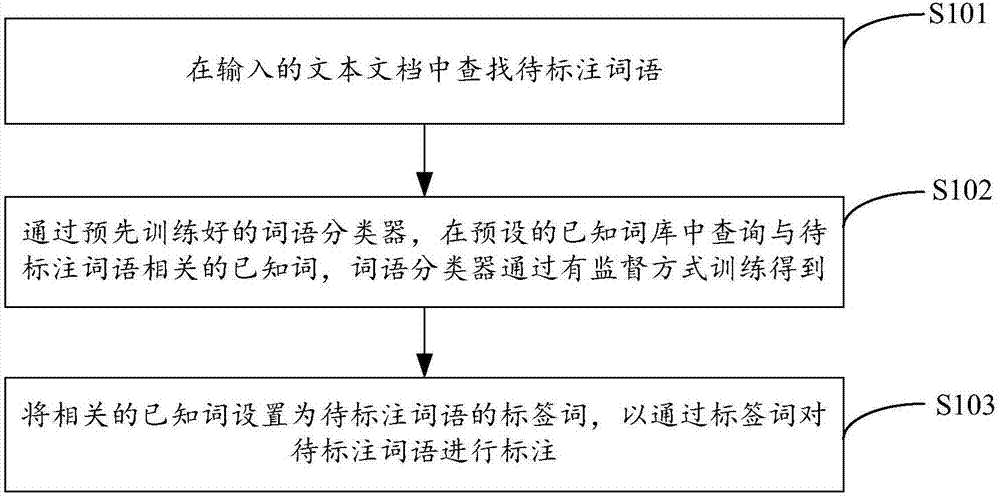

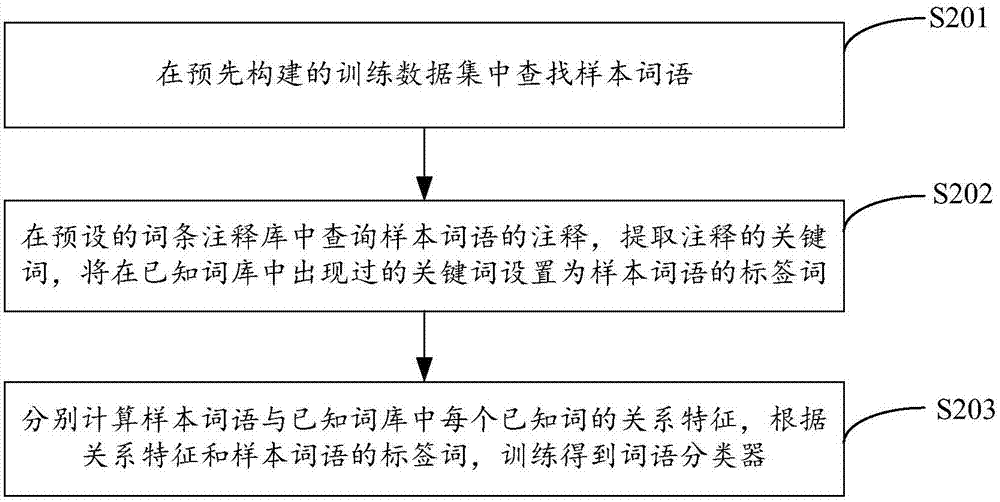

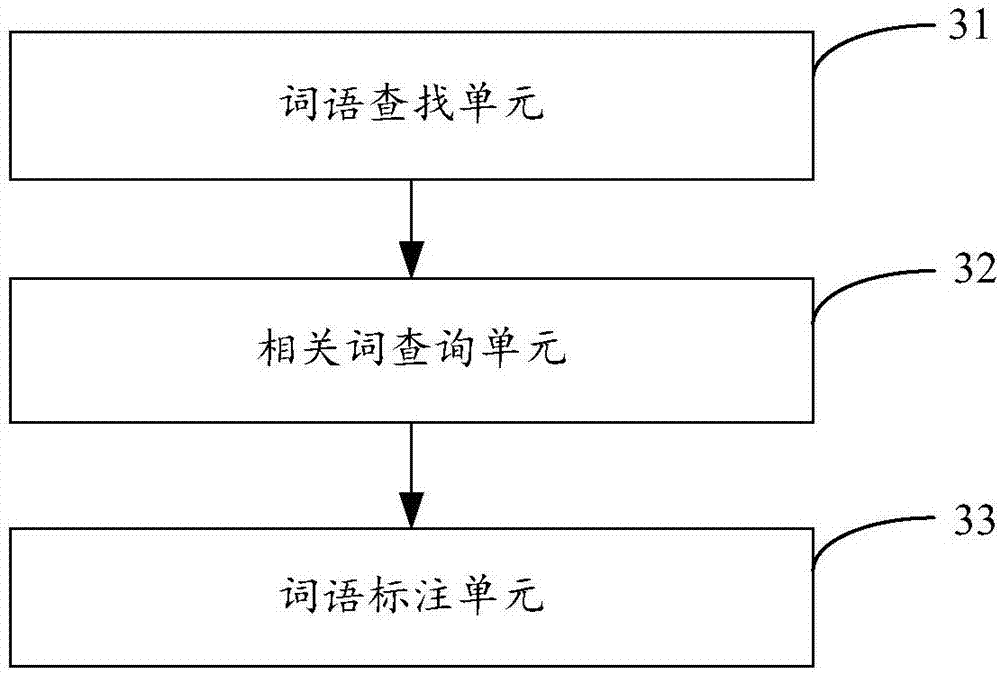

Word tag based word labeling method and device, server and storage medium

ActiveCN107480200AImprove the efficiency of annotation interpretationReduce manpower consumptionSpecial data processing applicationsText database clustering/classificationAlgorithmDocumentation

The invention is suitable for the technical field of computers, and provides a word tag based word labeling method and device, a server and a storage medium. The method comprises the steps that to-be-labeled words are sought in an input text document, by means of a pre-trained word separator, known words related to the to-be-labeled words are sought in a preset known word bank, the related known words are set to be tag words of the to-be-labeled words, the to-be-labeled words are labeled through the tag words, the word classifier is obtained through training in a monitoring mode, the word classifier is trained in a monitoring mode, the known words serve as tag words, automatic to-be-labeled word labeling based on the word tags is achieved, the to-be-labeled word labeling efficiency is effectively improved, human consumption of to-be-labeled word labeling is lowered, and the accuracy and the recall rate of to-be-labeled word labeling are effectively increased.

Owner:SHENZHEN INST OF ADVANCED TECH

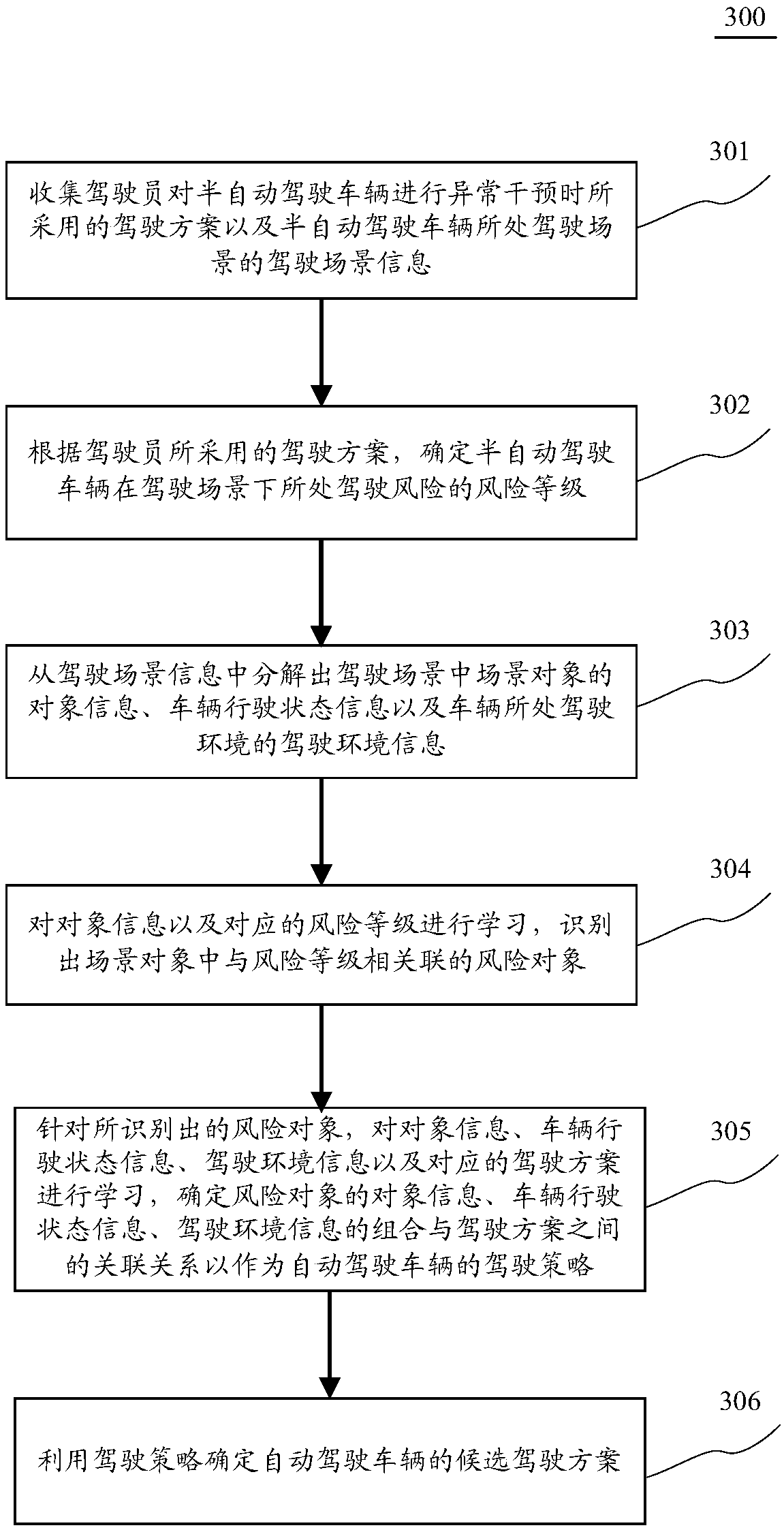

Method and device for operating autonomous vehicle

ActiveCN108773373ARealize automatic labelingReduce workloadExternal condition input parametersResourcesReal-time computingAutomotive engineering

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

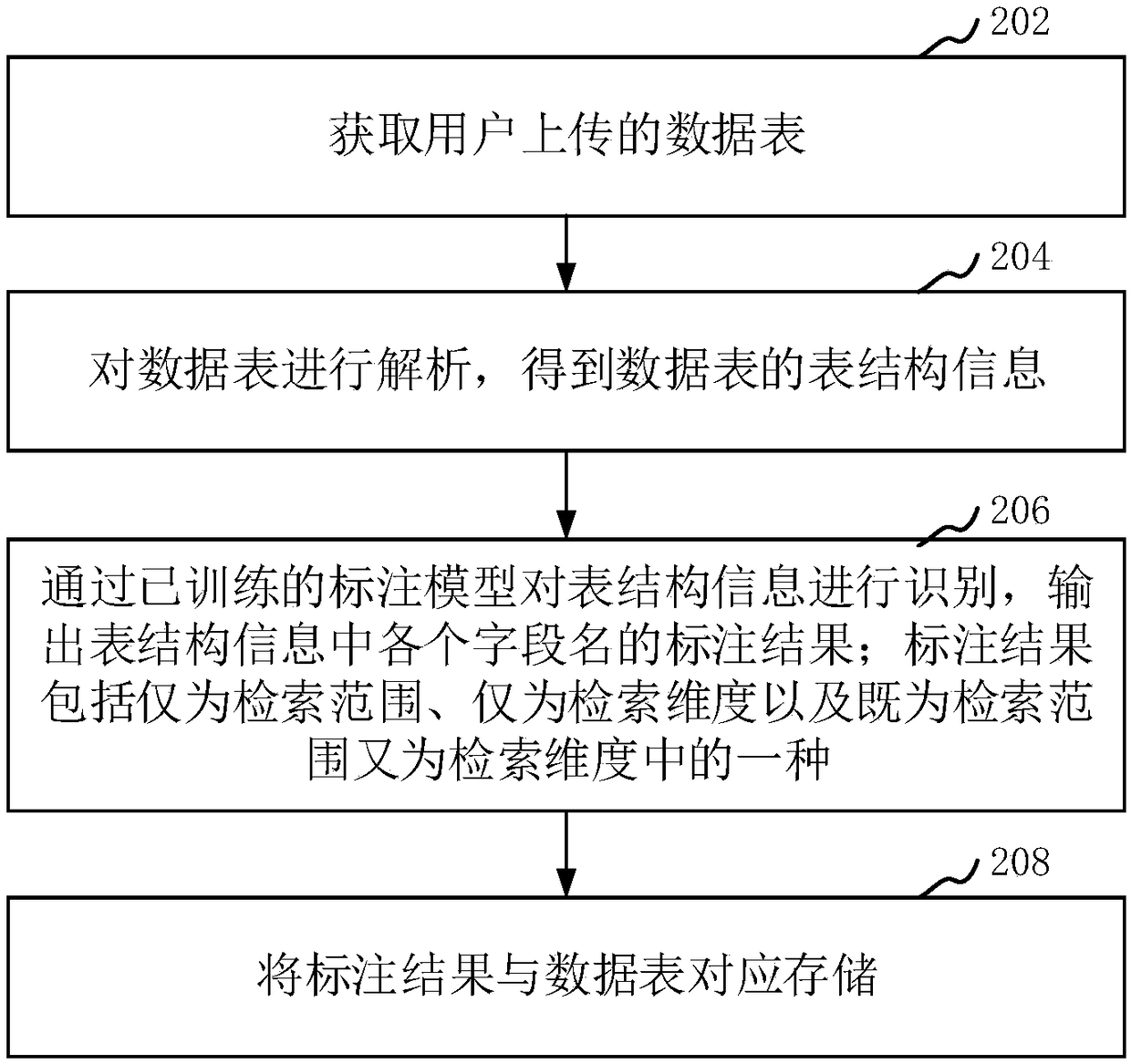

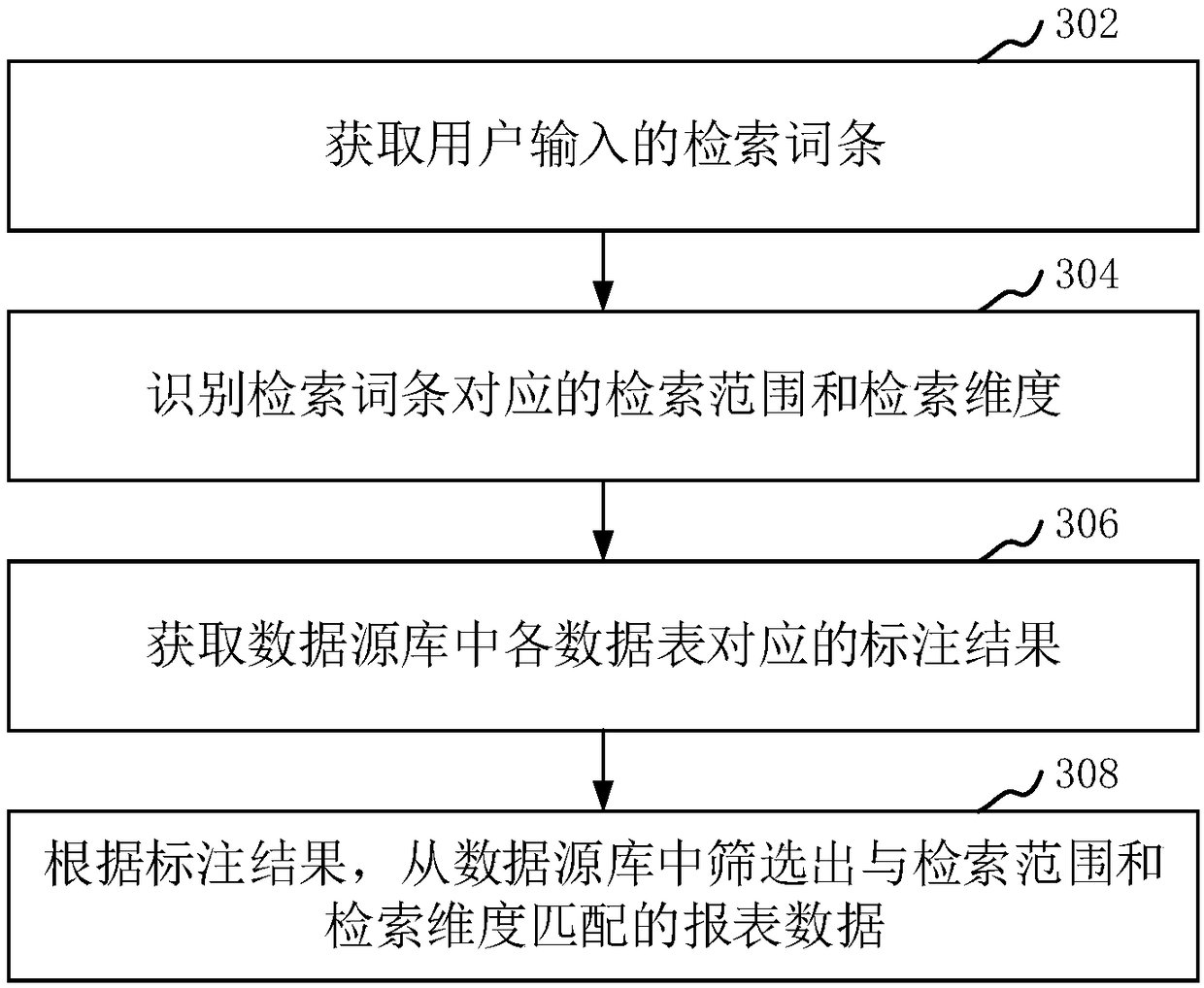

Data table processing method, apparatus, computer apparatus, and storage medium

PendingCN109299094AGet goodImprove labeling efficiencySpecial data processing applicationsDatabase indexingDatasheetEngineering

The present application relates to a data table processing method, an apparatus, a computer device and a storage medium. The present application relates to the technical field of data analysis. The data table processing method specifically comprises the following steps: acquiring a data table uploaded by a user; Analyzing the data table to get the table structure information; The table structure information is recognized by the trained annotation model, and the annotation results of each field name in the table structure information are output. The annotation results include only the retrievalscope, only the retrieval dimension, and both the retrieval scope and the retrieval dimension. The annotation result is stored in correspondence with the data table. The method can improve the labeling efficiency of the data table.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

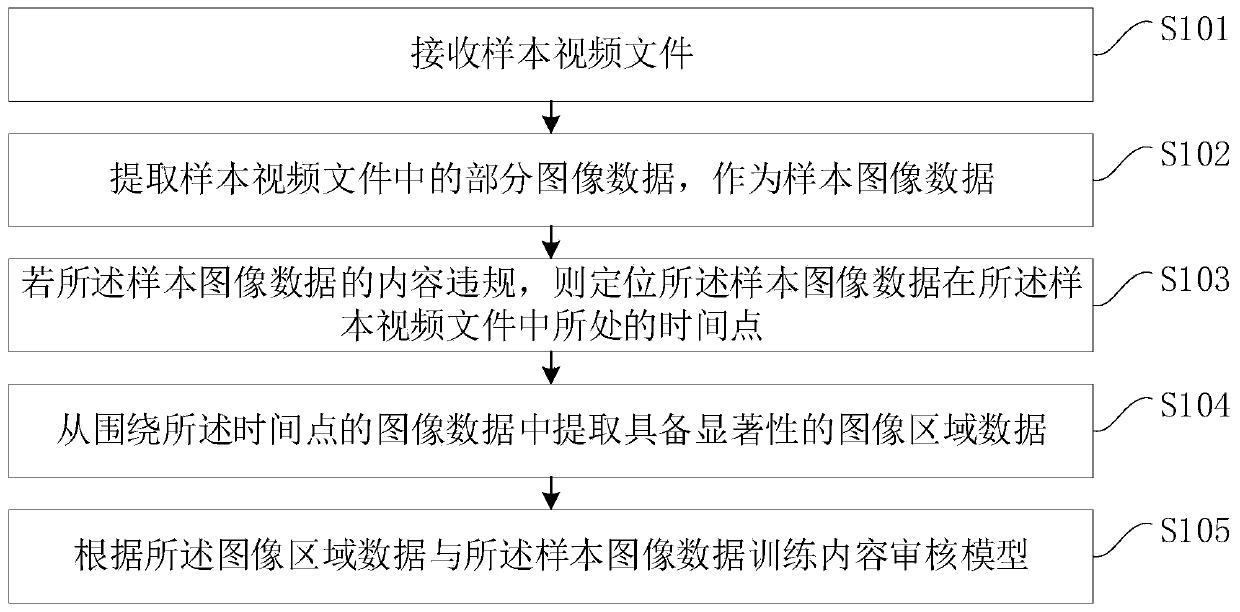

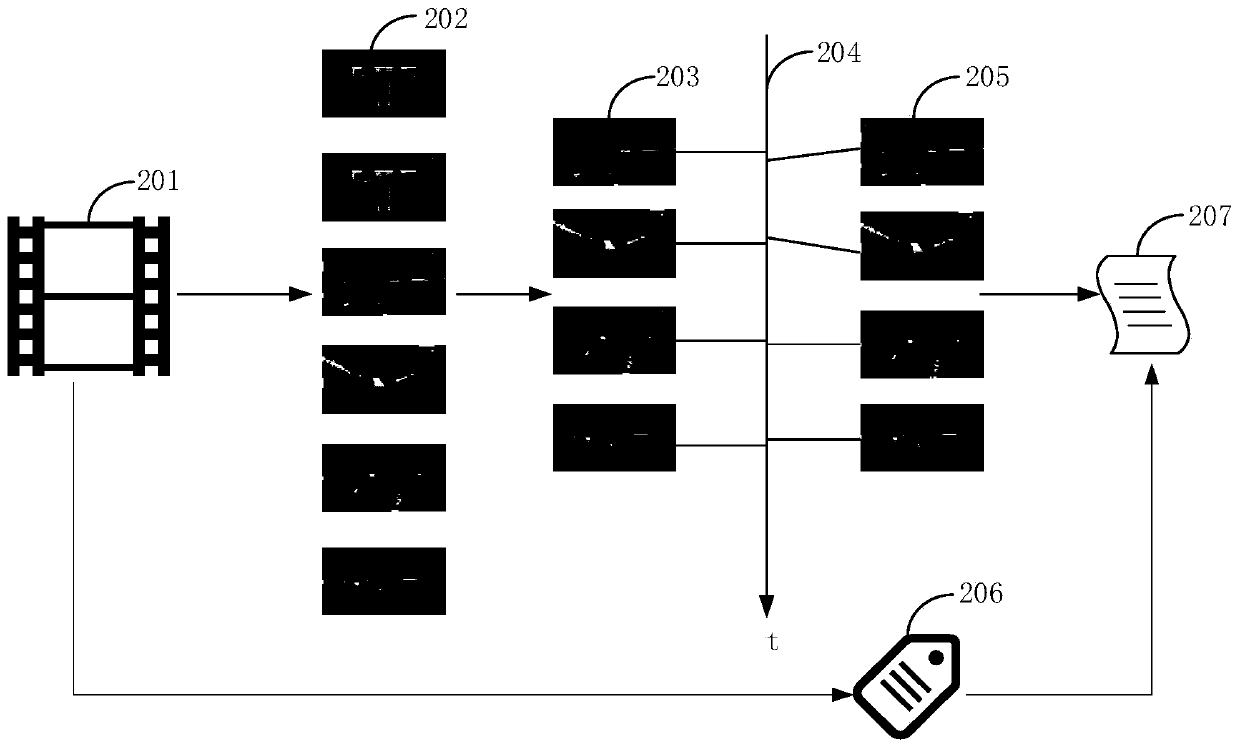

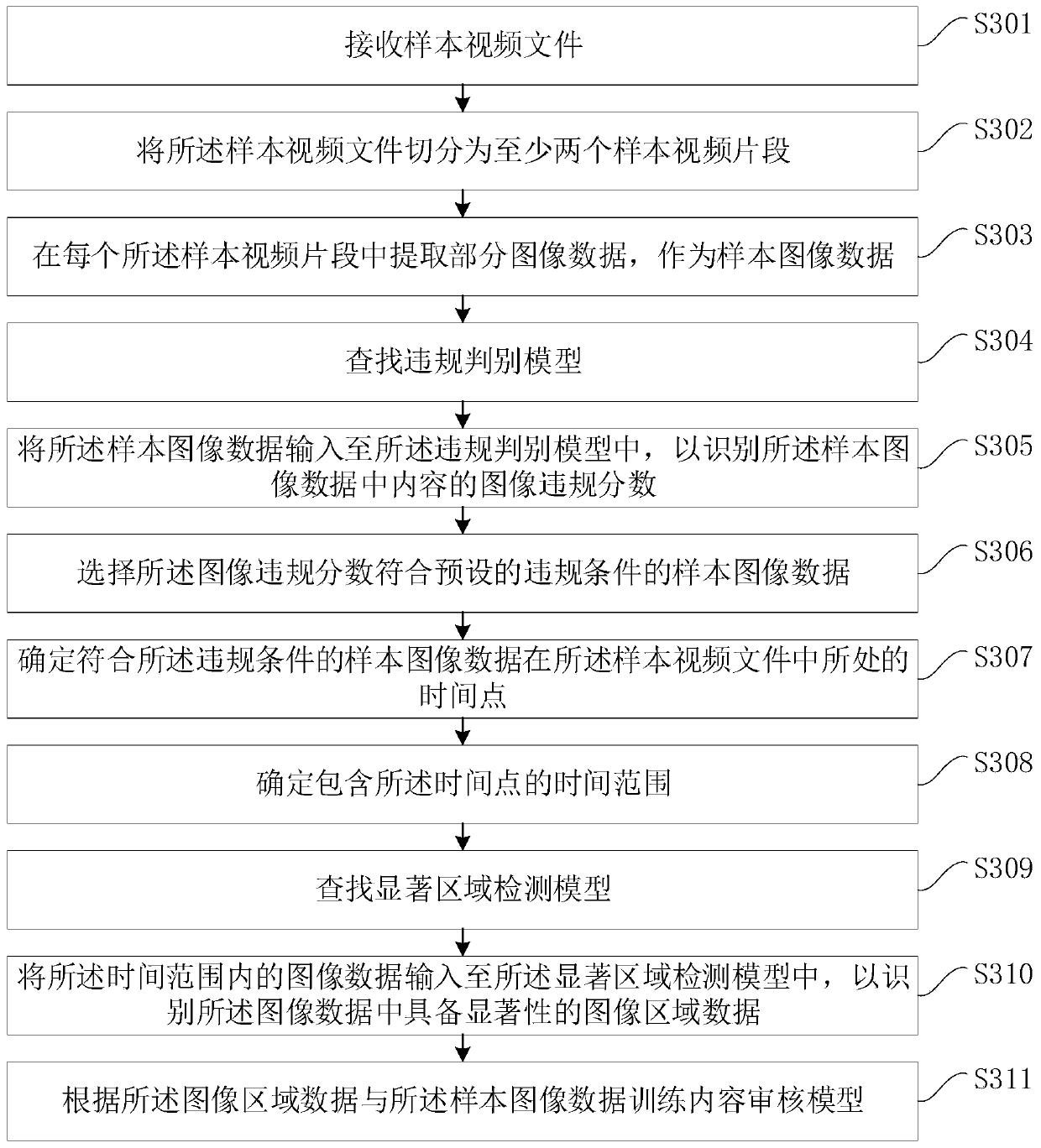

Training and auditing method and device of content auditing model, equipment and storage medium

ActiveCN110796098AGuaranteed performanceImprove efficiencyDigital data information retrievalGeometric image transformationSample imageEngineering

The embodiment of the invention discloses a training and auditing method and device of a content auditing model, equipment and a storage medium. The training method of the content auditing model comprises the following steps: receiving a sample video file; extracting partial image data in the sample video file as sample image data; if the content of the sample image data is illegal, positioning the time point of the sample image data in the sample video file; extracting image region data with significance from the image data surrounding the time point; and training a content auditing model according to the image region data and the sample image data. Sample image data of content violation is positioned in time, image area data with significance is positioned in space, features representingcontent violation can be rapidly sampled from a sample video file, and the quality of the features is improved in time and space dimensions, so that a content auditing model is trained, and the performance of the content auditing model can be ensured.

Owner:GUANGZHOU NETSTAR INFORMATION TECH CO LTD

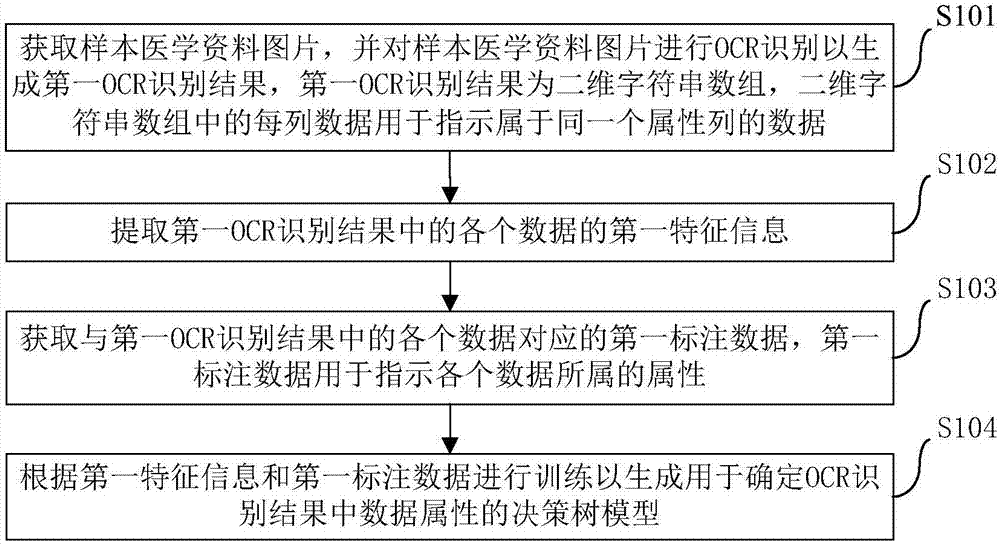

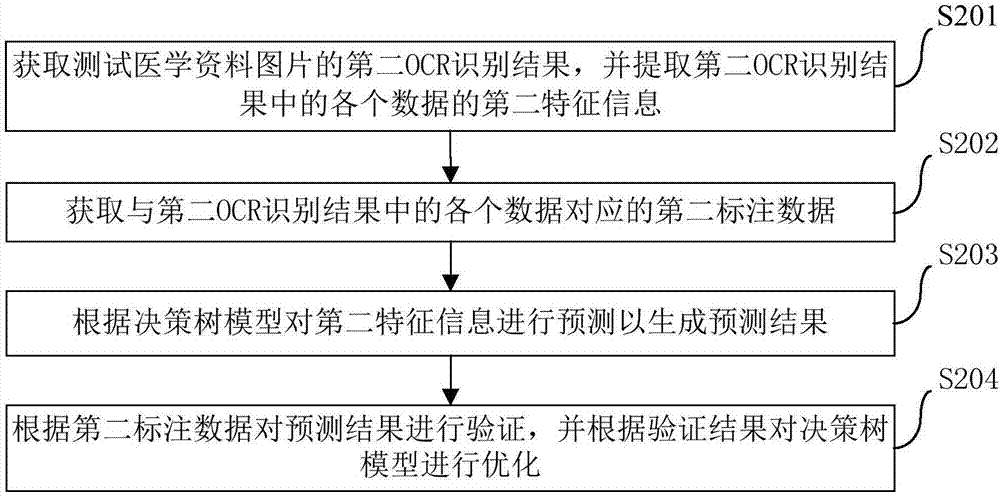

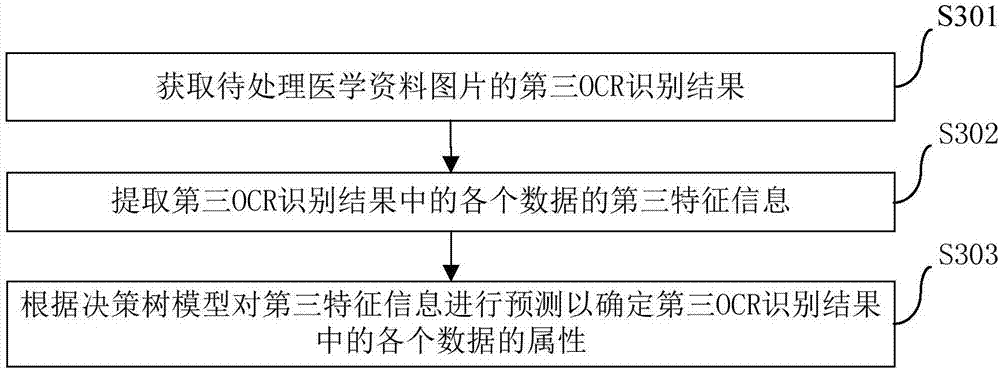

Decision tree model training method, and method and apparatus for determining data attributes in OCR result

ActiveCN107273883AReduce consumption costsImprove recognition efficiencyCharacter and pattern recognitionData PropertyArray data structure

The invention discloses a decision tree model training method, and a method and an apparatus for determining data attributes in an OCR result. The decision tree model training method comprises the steps of obtaining a sample medical data picture, and performing OCR on the sample medical data picture to generate a first OCR result, wherein the first OCR result is a two-dimensional character string array, and each column of data in the two-dimensional character string array is used for indicating data which belongs to a same attribute column; extracting first feature information of each piece of data in the first OCR result; obtaining first labeled data corresponding to each piece of the data in the first OCR result, wherein the first labeled data is used for indicating an attribute which each piece of the data belongs to; and performing training according to the first feature information and the first labeled data to generate a decision tree model used for determining the data attributes in the OCR result. According to the method, the purpose of automatically labeling the data attributes in the recognition result is achieved; the consumption cost in a to-be-recognized picture recognition process is effectively reduced; and the recognition efficiency is improved.

Owner:天方创新(北京)信息技术有限公司

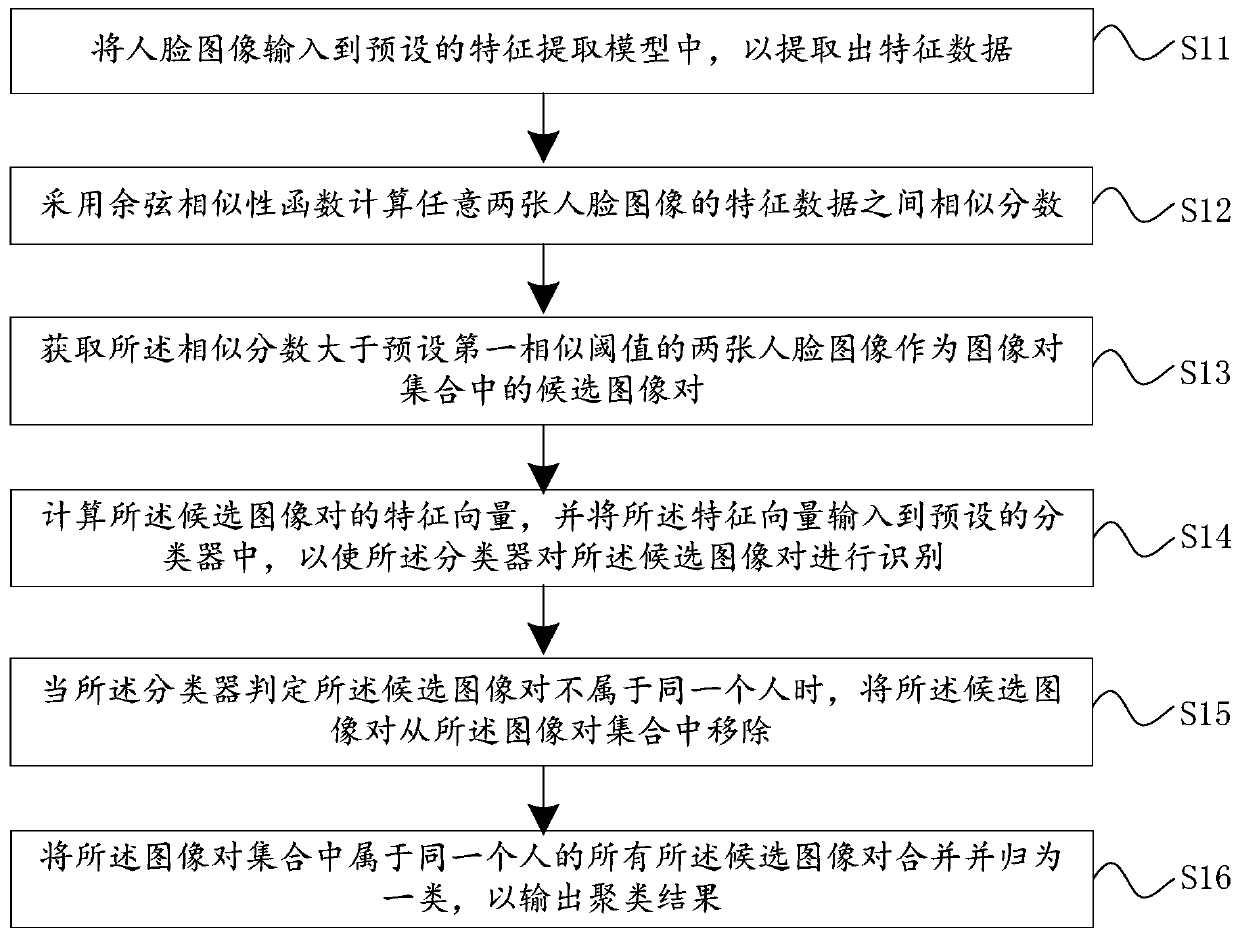

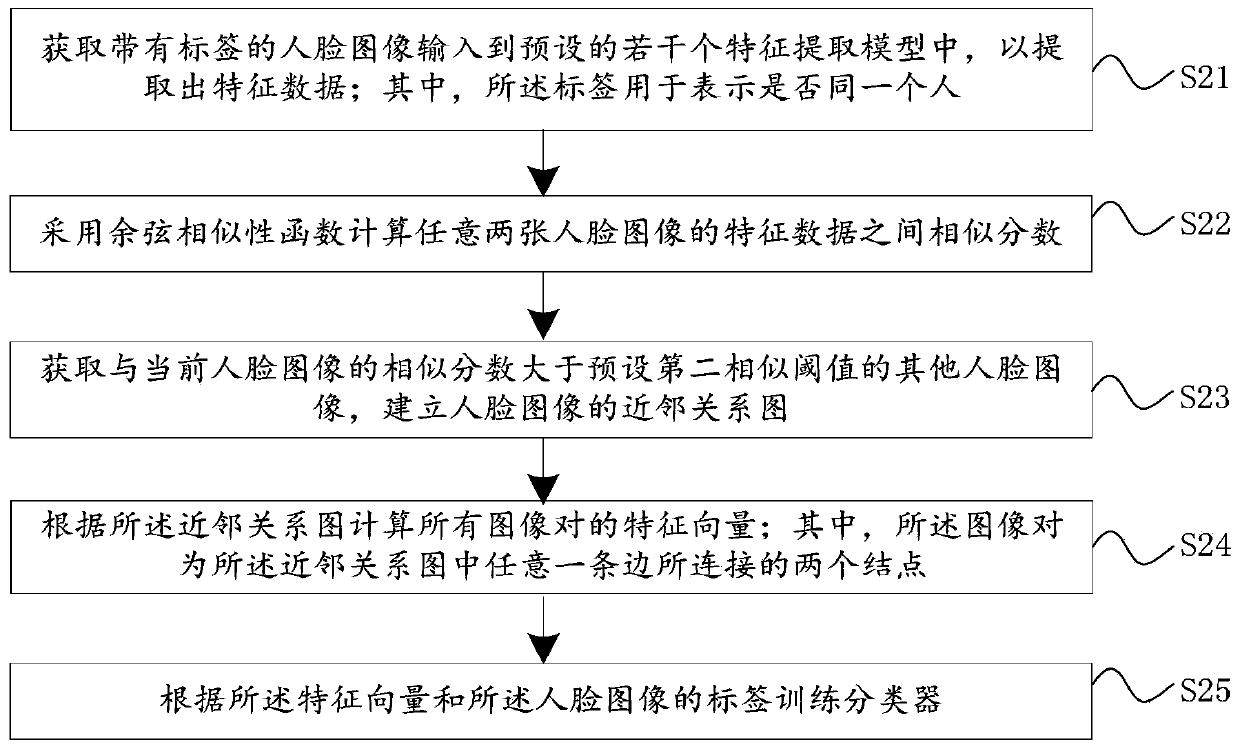

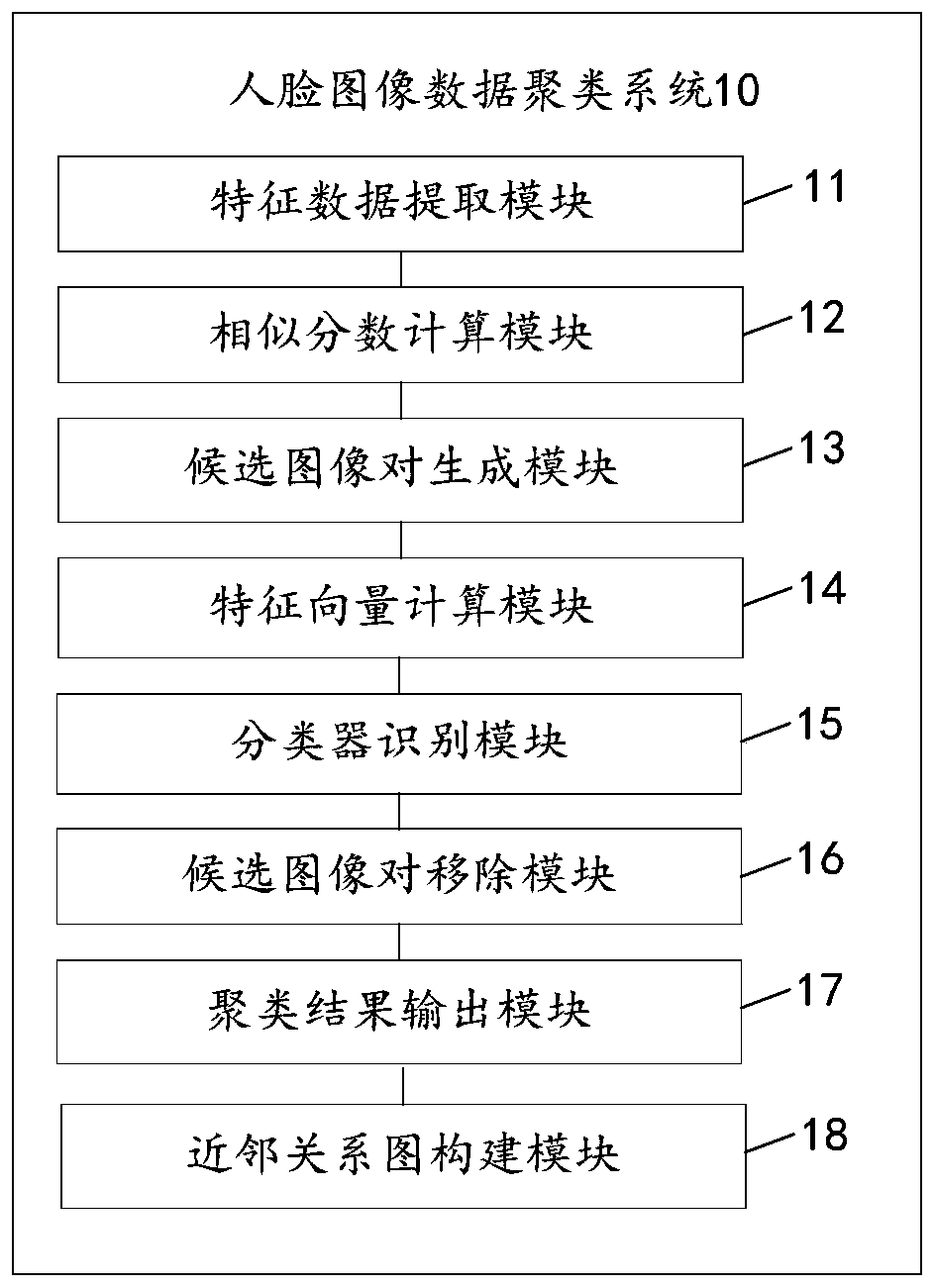

Face image data clustering method, system and device

ActiveCN110458078AReduce clustering biasRealize automatic labelingCharacter and pattern recognitionCosine similarityCluster systems

The invention discloses a face image data clustering method, which comprises the steps of inputting a face image into a preset feature extraction model to extract feature data; calculating a similarity score between the feature data of any two face images by adopting a cosine similarity function; acquiring two face images of which the similarity scores are greater than a preset first similarity threshold as candidate image pairs in the image pair set; calculating feature vectors of the candidate image pairs, and inputting the feature vectors into a preset classifier to enable the classifier toperform recognition; when the classifier judges that the candidate image pairs do not belong to the same person, removing the candidate image pairs from the image pair set; and merging and classifying all candidate image pairs belonging to the same person in the image pair set into one class. The invention further discloses a face image data clustering system and a face image data clustering device. By adopting the embodiment of the invention, the clustering deviation can be effectively reduced according to the distribution characteristics of the human face samples collected in the real scene.

Owner:GOSUNCN TECH GRP

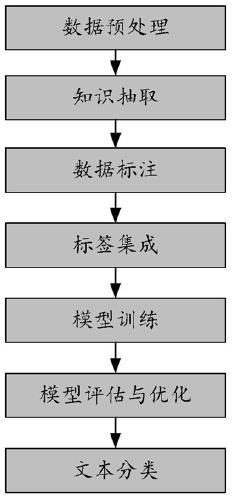

Short text classification method based on multiple weak supervision integration

ActiveCN111444342AHandling Imbalanced Classification Problems EfficientlyImbalanced Classification Problem SolvingNatural language data processingSpecial data processing applicationsOriginal dataClassification methods

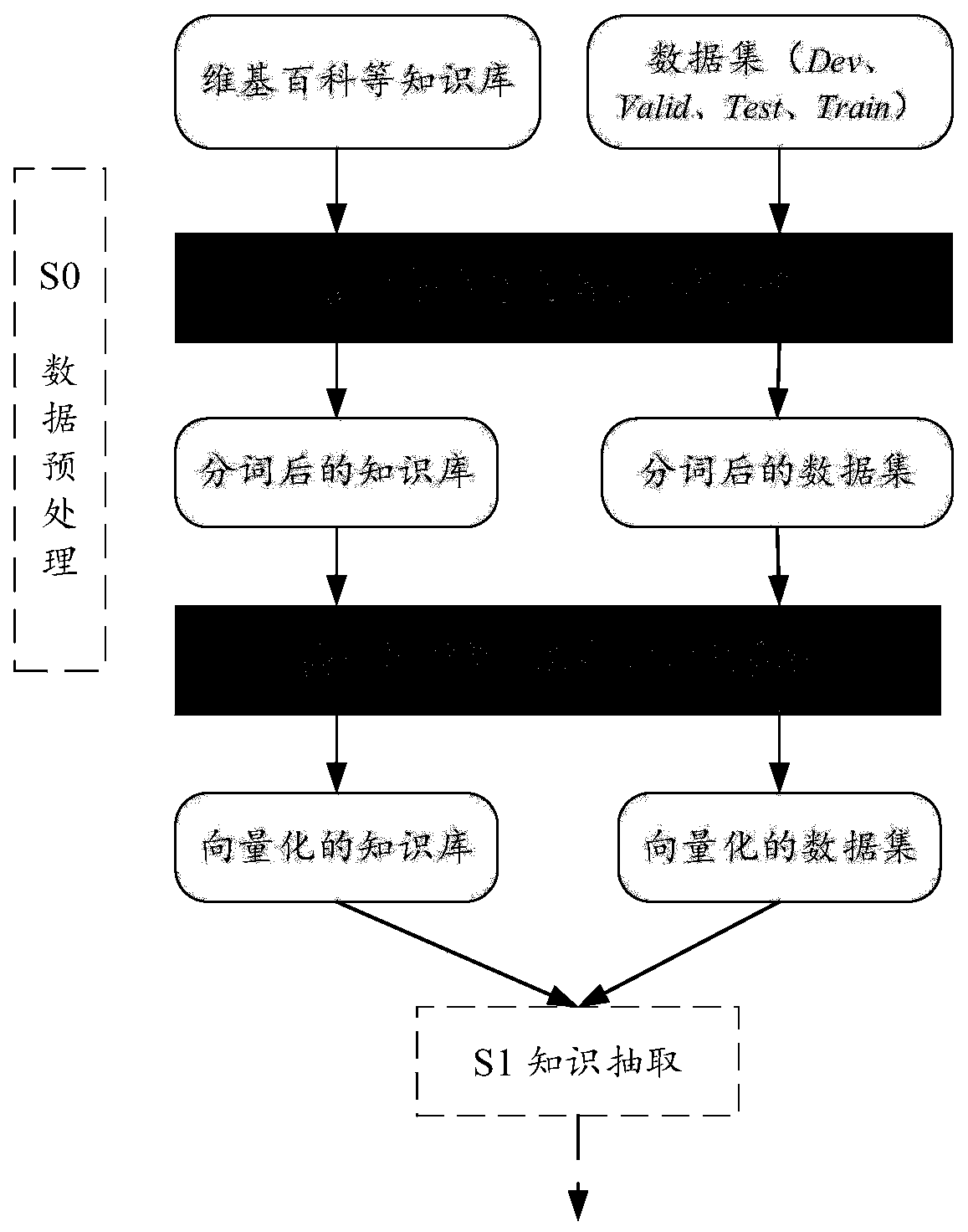

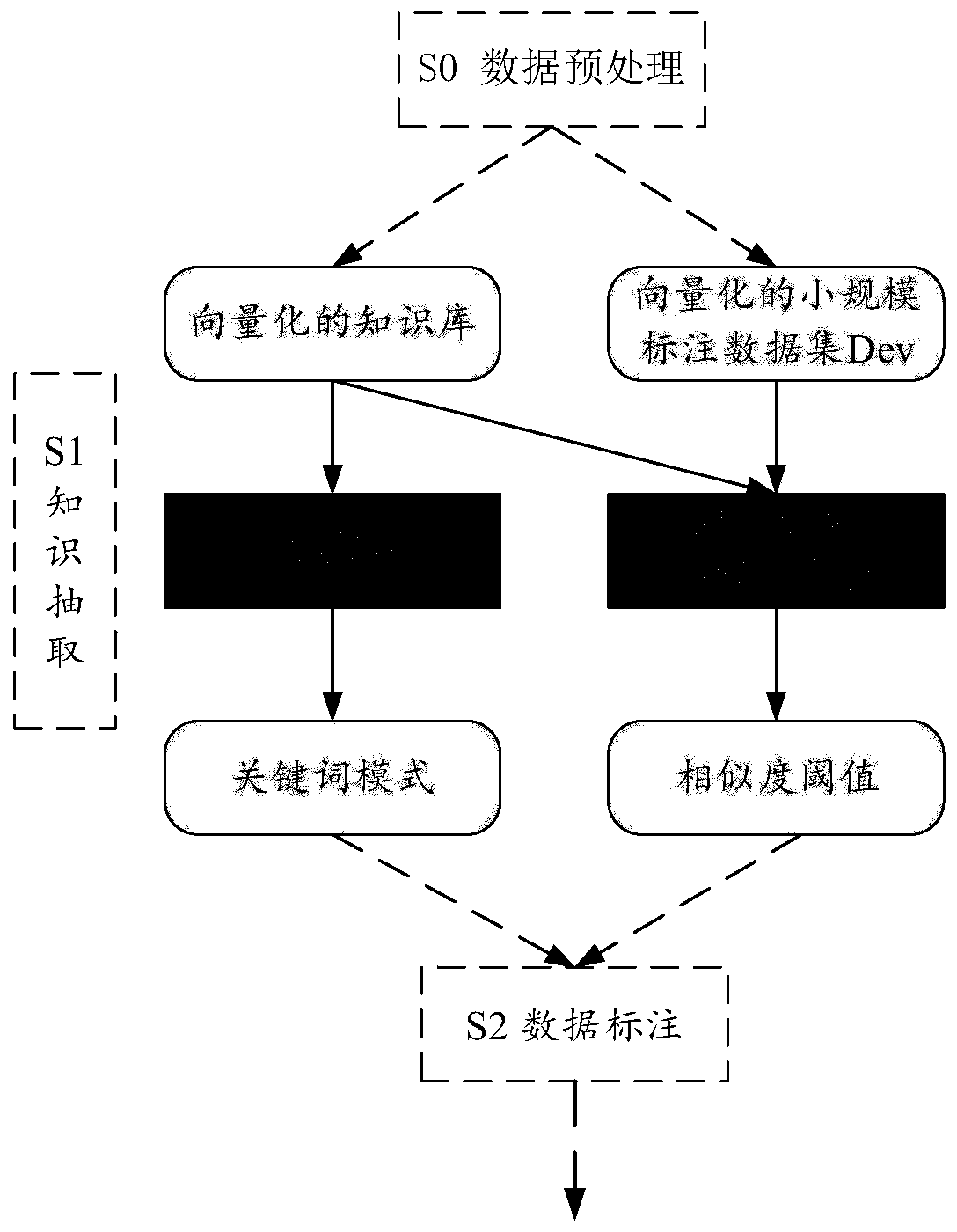

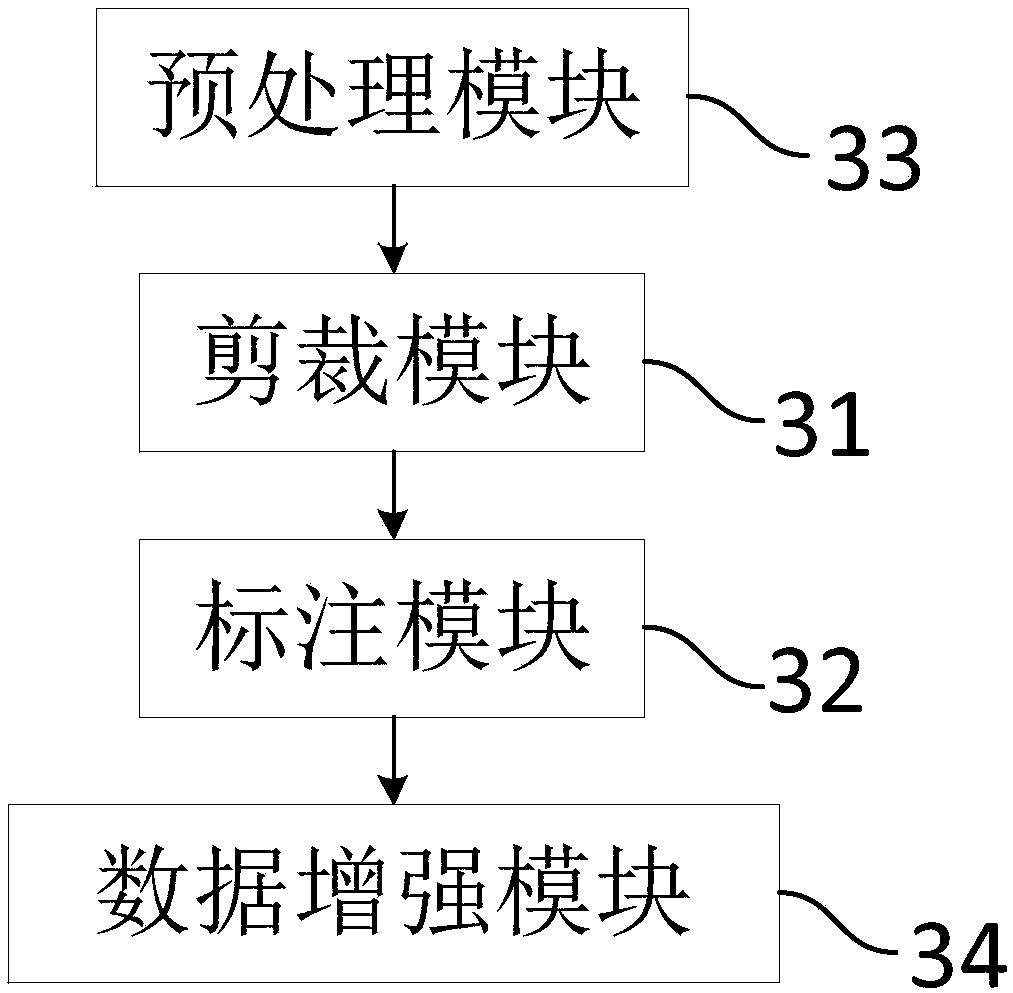

The invention discloses a short text classification method based on multiple weak supervision integration, and the method comprises the steps: obtaining an original data set and a knowledge base, andcarrying out the data preprocessing; carrying out knowledge extraction on the preprocessed data; representing the extracted knowledge as an annotation function, and using the annotation function for data annotation; carrying out label integration through a conditional independent model; training a classification model based on a full-connection neural network; evaluating and optimizing the classification model to obtain an optimal model; and performing short text classification by utilizing the optimal model. According to the short text classification method based on multiple weak supervisionintegration, explicit knowledge and implicit knowledge are completely expressed in a mode of combining keyword matching, regular expression and remote supervision clustering; by means of probability labels generated by a label integration mechanism, automatic labeling of label-free data is achieved, the problem of data sparsity of short texts is relieved, and the problem of unbalanced classification of the short texts is effectively solved.

Owner:湖南董因信息技术有限公司

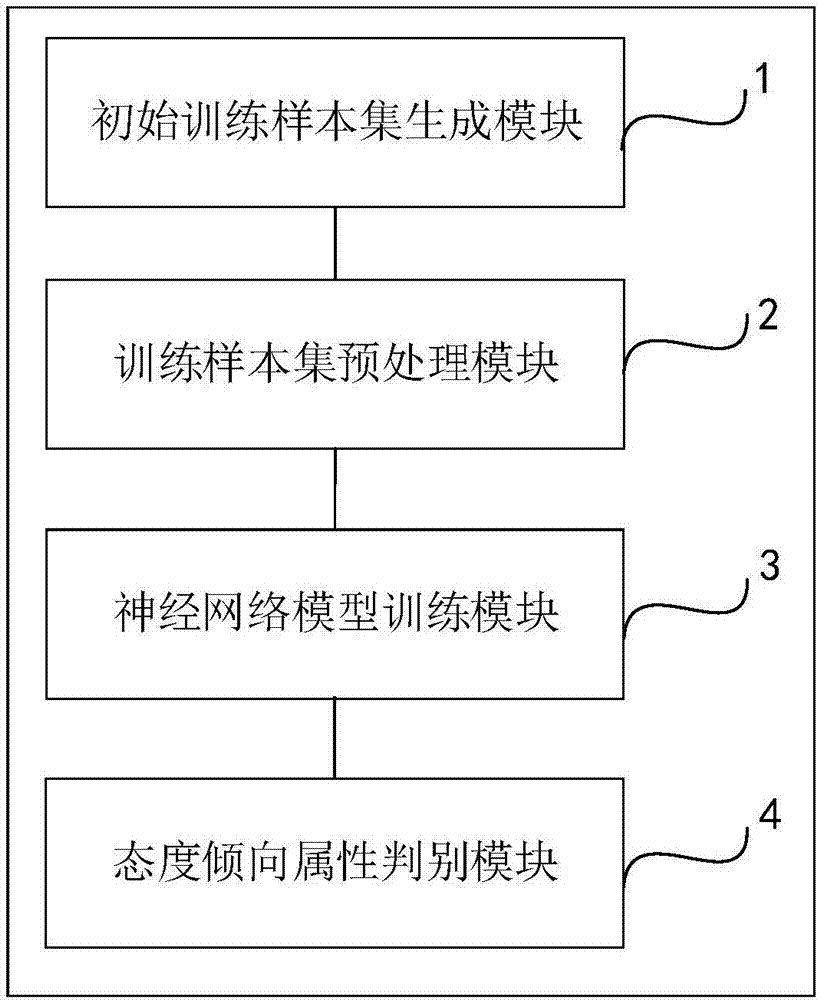

Attitude trend analysis method and system applied to field of stock news

InactiveCN107122351AAutomate analysisImprove efficiencyCharacter and pattern recognitionNatural language data processingNetwork modelAnalysis method

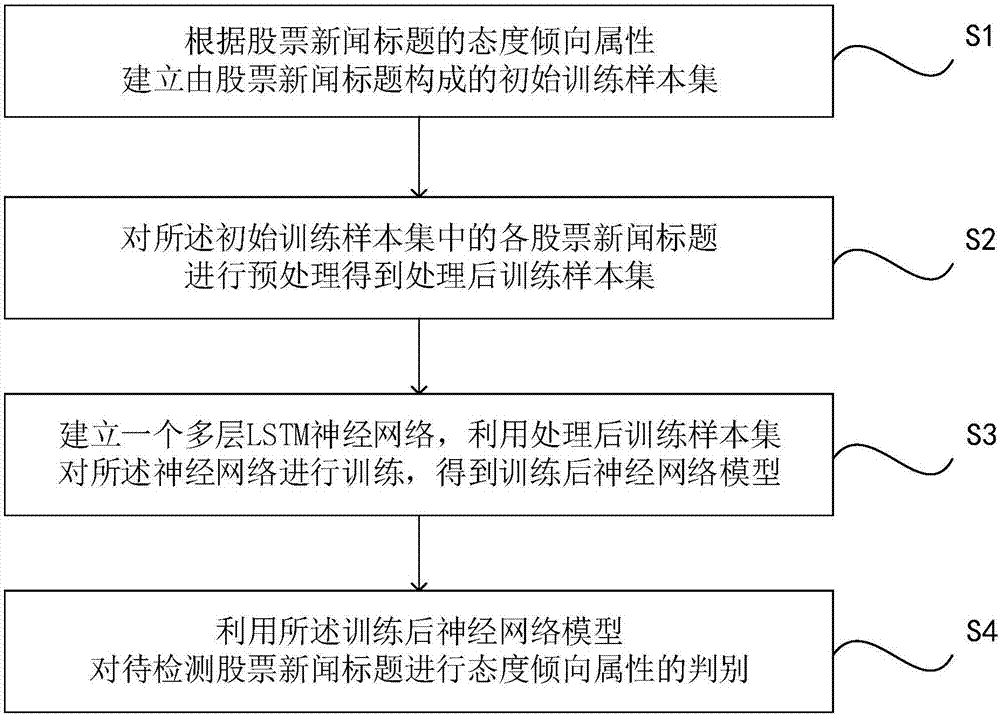

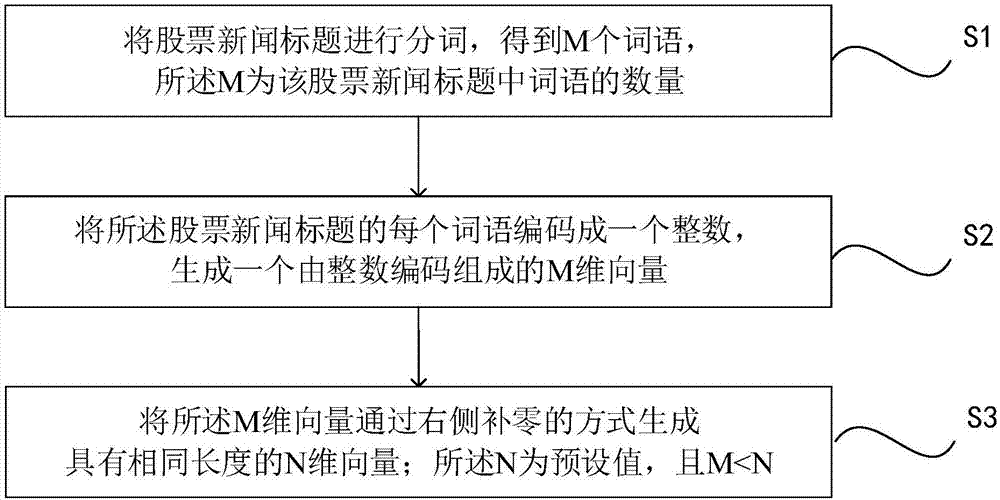

The present invention discloses an attitude trend analysis method applied to the field of stock news. The method comprises: according to an attitude trend attribute of a stock news headline, establishing an initial training sample set composed of stock news headlines; preprocessing each stock news headline in the initial training sample set to obtain a processed training sample set; establishing a multi-layer LSTM neural network made of an input layer, an intermediate layer and an output layer, and training the neural network by using the processed training sample set, to obtain a trained neural network model; and determining the attitude trend attribute of a to-be-detected stock news headline by using the trained neural network model, to obtain the attitude trend attribute of the to-be-detected stock news headline. The method provided by the present invention realizes automatic analysis of the attitude trend of massive stock news, improves efficiency of labeling, increases accuracy of labeling, and has great significance to assisting investment decision-making. The present invention further provides a corresponding attitude trend analysis system applied to the field of stock news.

Owner:灯塔财经信息有限公司

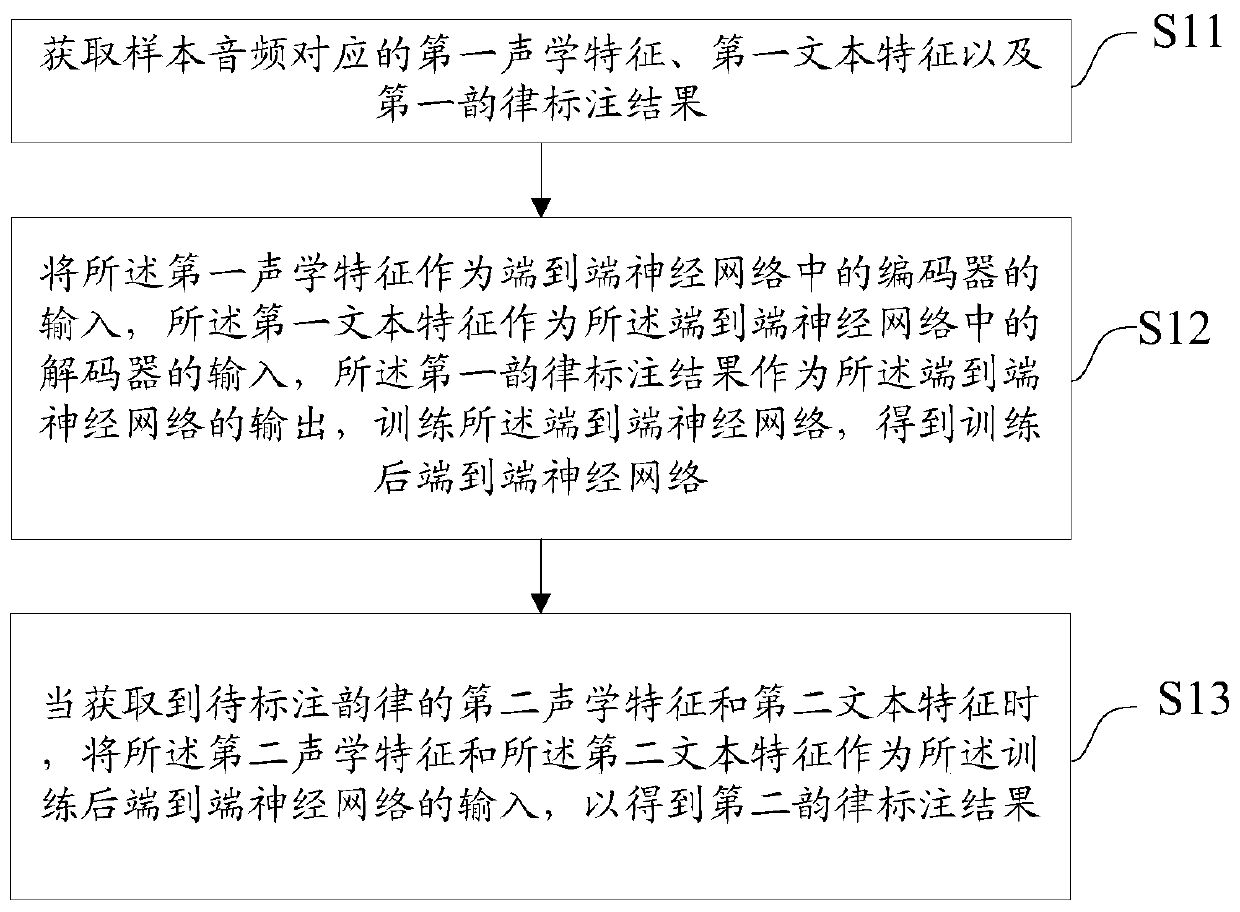

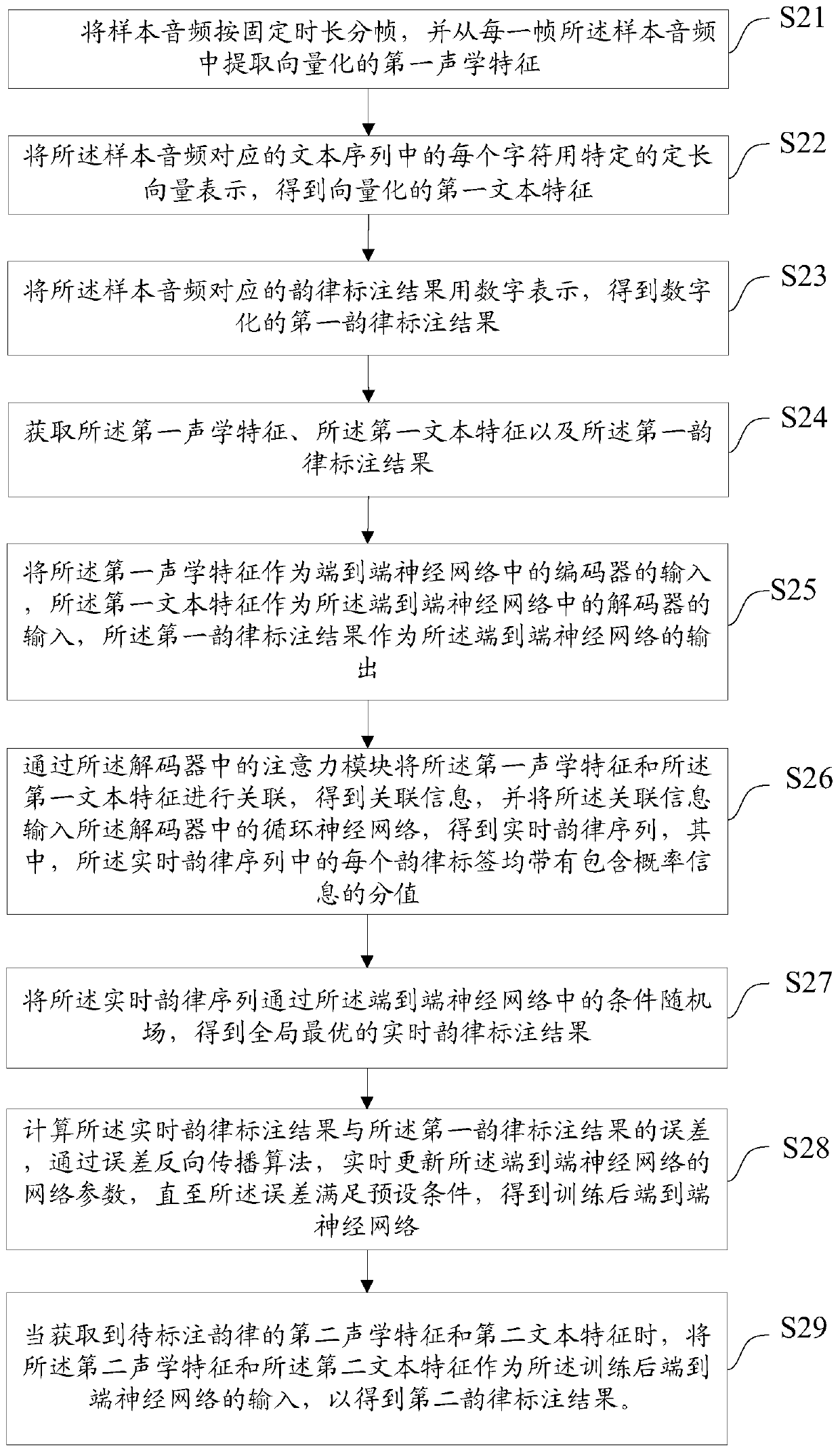

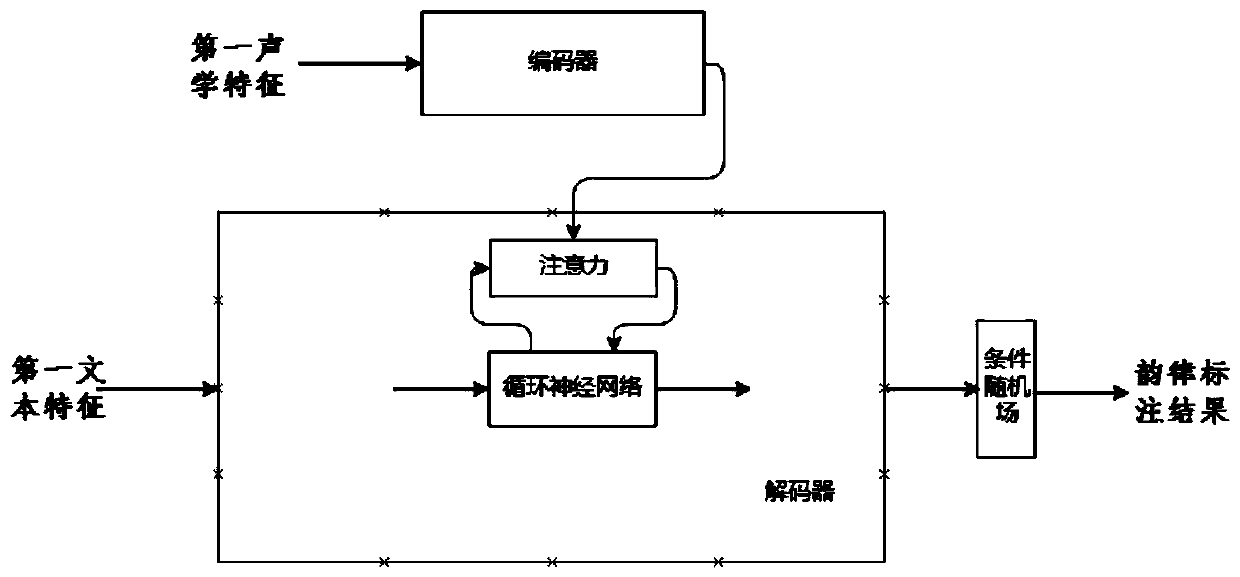

Prosodic labeling method, device and apparatus, and medium

ActiveCN110459202ARealize automatic labelingImprove accuracySpeech synthesisSpeech recognitionRhythm

The application discloses a prosodic labeling method, device and apparatus, and a medium. The method comprises the following steps: acquiring a first acoustic feature, a first text feature and a firstprosodic labeling result corresponding to a sample audio; the first acoustic feature serving as input of an encoder in an end-to-end neural network, the first text feature serving as input of a decoder in the end-to-end neural network, the first prosodic labeling result serving as an output of the end-to-end neural network, and the end-to-end neural network is trained to obtain a trained end-to-end neural network; and when a second acoustic feature and a second text feature of a to-be-labelled rhythm are obtained, directly outputting a second prosodic labeling result by utilizing the trainedend-to-end neural network. According to the prosodic labeling method, the acoustic features and the corresponding text features are effectively fused, thereby improving the accuracy of prosodic labeling.

Owner:ZHEJIANG TONGHUASHUN INTELLIGENT TECH CO LTD

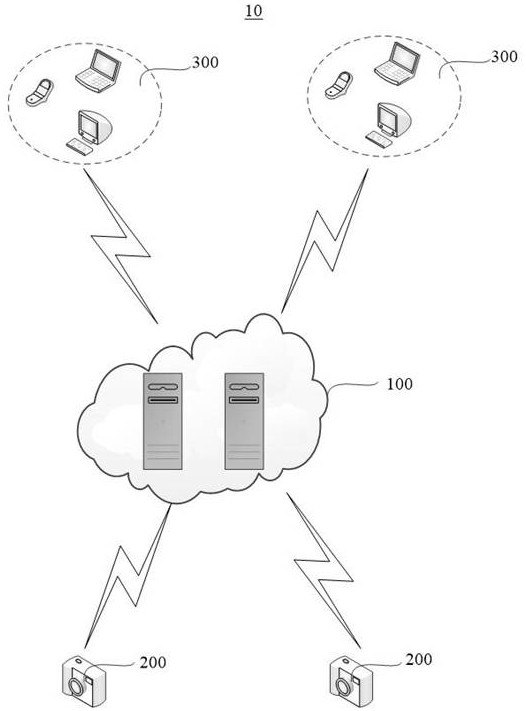

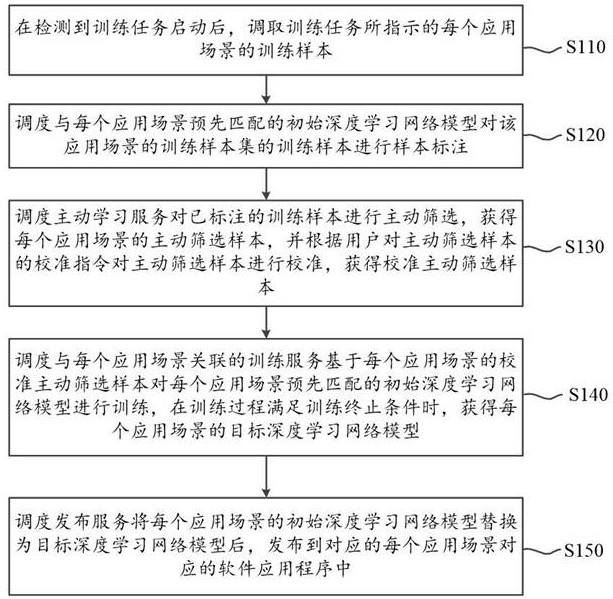

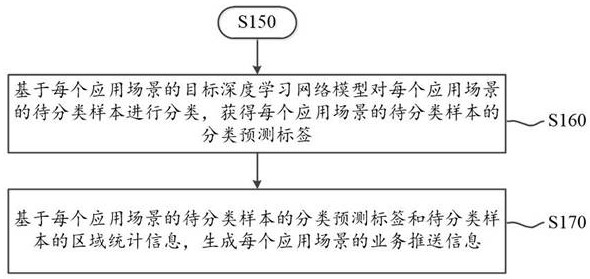

Model training method and device based on active learning and server

ActiveCN112434809AFlexible dockingReduce the number of labelsImage enhancementImage analysisEngineeringNetwork model

The embodiment of the invention provides a model training method and device based on active learning, and a server, and the method and device can automatically call a training sample of each application scene indicated by a started training task, and do not need a developer to manually export data for model training. After an initial deep learning network model matched with each application scenein advance is scheduled to perform sample labeling on training samples, an active learning service is scheduled to perform active screening on the labeled training samples, developers do not need to participate in labeling, the sample labeling number is effectively reduced, the active screening sample is calibrated according to a calibration instruction of a user, a training service associated with each application scene is flexibly scheduled to perform model training based on the calibrated active screening sample, and the model is published to a software application program corresponding toeach corresponding application scene; therefore, training services of different application scenarios can be flexibly docked, and automatic labeling, training and service updating of the training process are achieved.

Owner:CHENGDU DIANZE INTELLIGENT TECH CO LTD +1

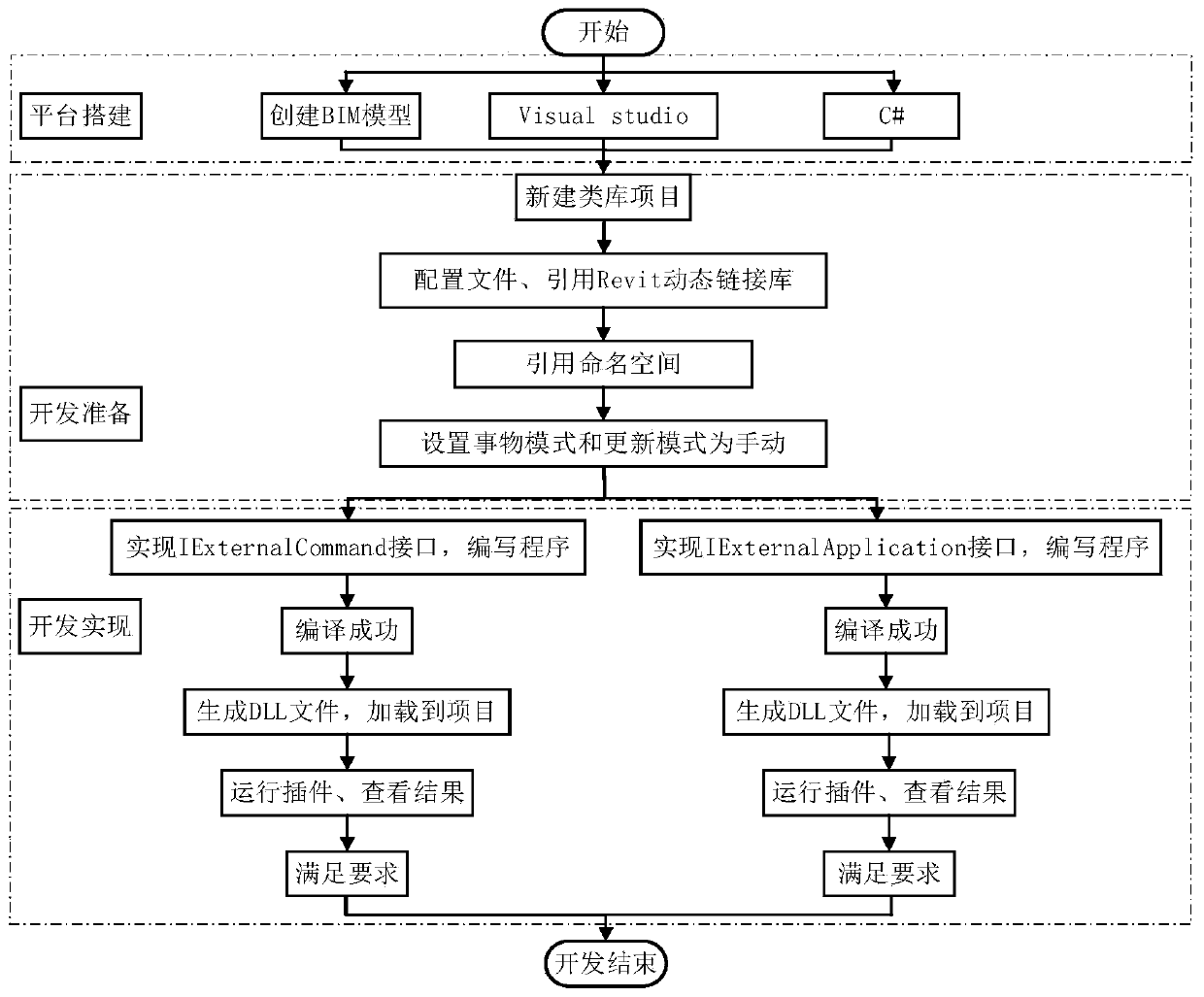

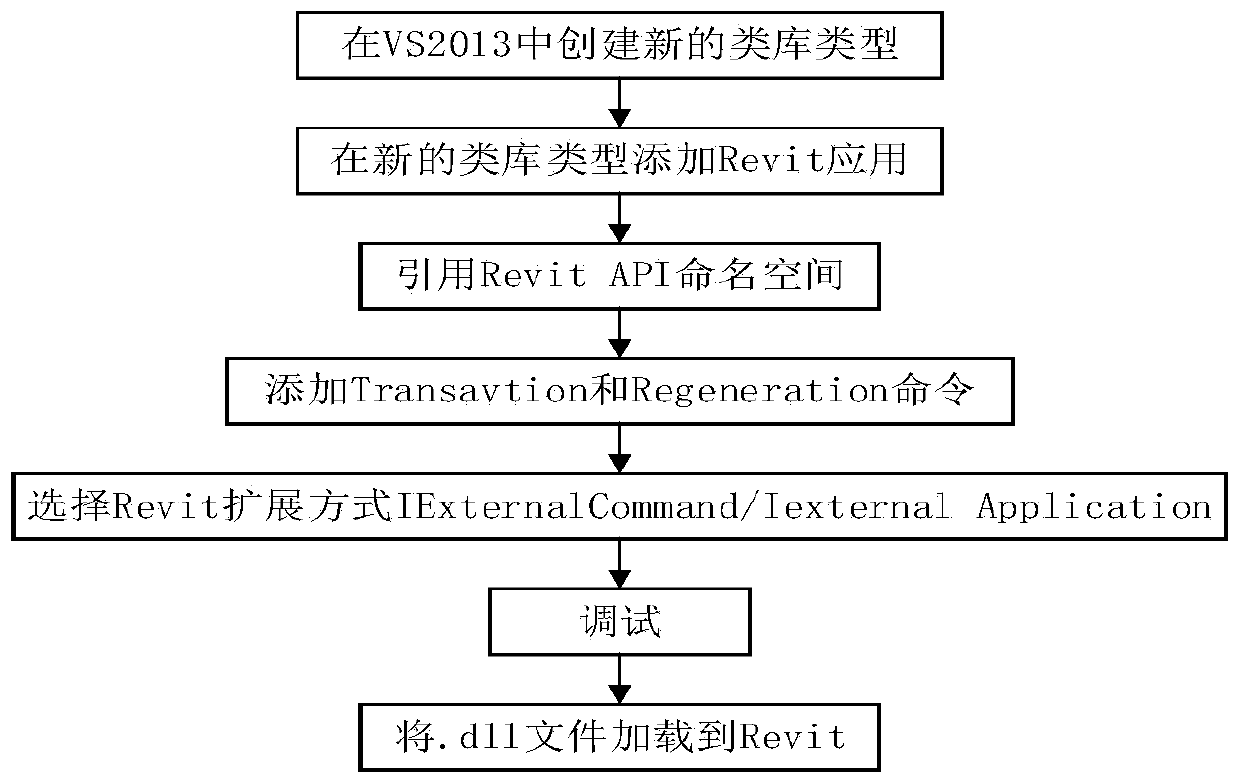

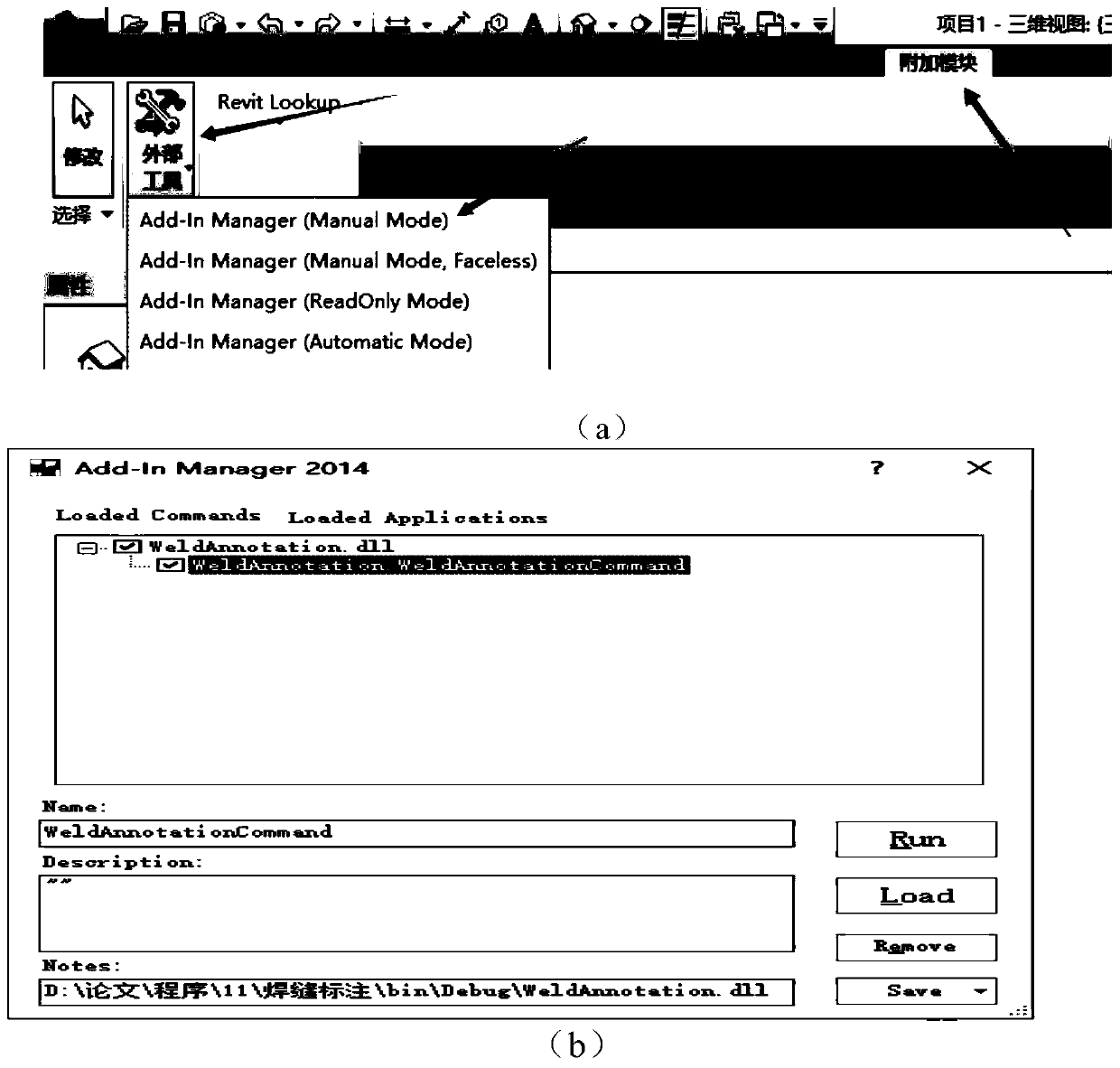

Pipeline weld joint automatic labeling method based on Revit platform

InactiveCN110930396ARealize programmatic controlRealize automatic labelingImage enhancementImage analysisGraphicsSoftware engineering

The invention relates to a pipeline weld joint automatic labeling method based on a Revit platform. The pipeline weld joint automatic labeling method comprises the following steps: 1, establishing a BIM of a pipeline, and establishing a platform by taking Revit as graphic support software; and 2, placing a workpiece under the platform, classifying pipe weld problems, carrying out pipeline weldingseam labeling analysis; filtering out all pipelines in the current three-dimensional view; traversing all pipelines to obtain parameter information of a starting end pipeline, a pipeline connector andall pipelines, calculating the length of the pipelines, solving the number of weld joints, sorting the pipeline connectors, labeling from the starting connector, calculating whether the length of thepipelines is larger than the length N of a single steel pipe or not, and conducting labeling at the position N automatically when the length is larger than N. The pipeline weld joint automatic labeling method has the advantages that (1) one-key labeling is realized quickly; (2) the labeling is accurate; (3) serial numbers can be marked, and pipeline diameter and material information can be pickedup; and (4) the size is accurate, the construction is more facilitated, and the weld joint position needing flaw detection can be quickly found.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

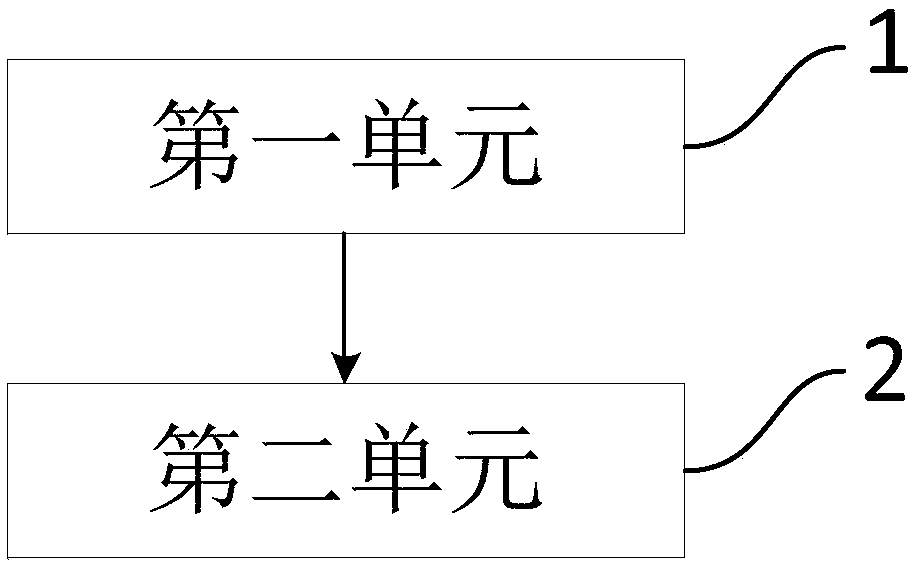

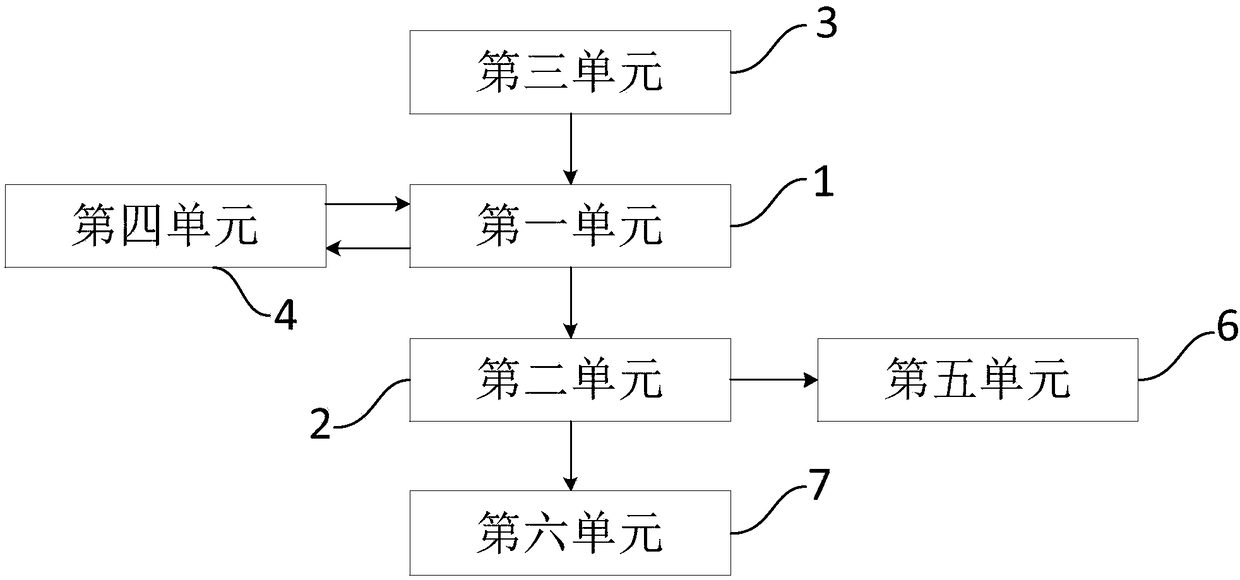

Satellite image ground object marking device and method

InactiveCN108470185AReduced Clarity RequirementsQuick annotationCharacter and pattern recognitionNeural architecturesSatellite imageComputer vision

The invention provides a satellite image ground object marking device and method; the satellite image ground object marking device comprises the following parts: a first unit configured to obtain a training set and extract ground object marking features of the training set, thus forming a training model, wherein the training set comprises a plurality of first satellite images with finished groundobject marking; a second unit configured to obtain the training model and marking ground objects in the second satellite image according to the training model. The satellite image ground object marking method comprises the following steps: extracting ground object marking features of the training set, forming the training model; marking the ground objects in the second satellite image according tothe training model. The satellite image ground object marking device and method can automatically mark the satellite image ground objects, can fast mark ground objects with high accuracy, and have low sharpness requirements for the satellite images.

Owner:北京佳格天地科技有限公司

Target position labeling method, device and equipment

PendingCN112132892ARealize automatic labelingImage enhancementImage analysisRadiologyNuclear medicine

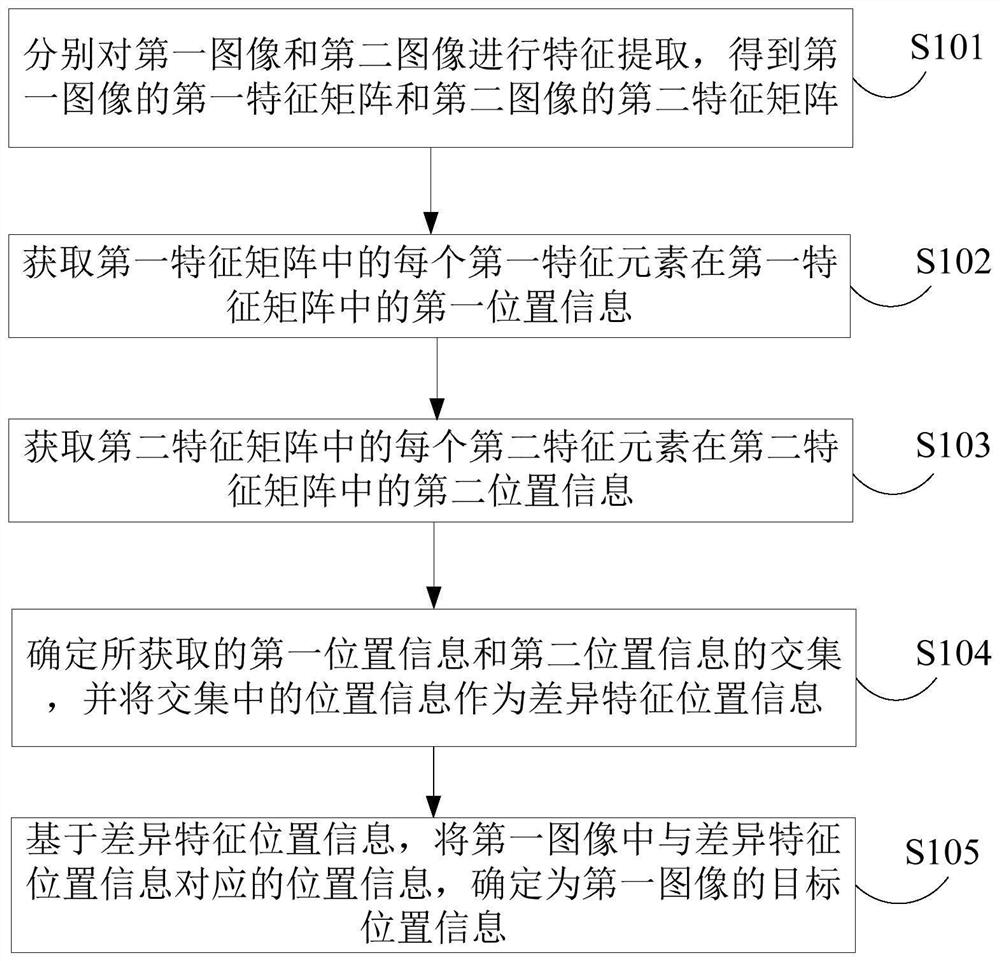

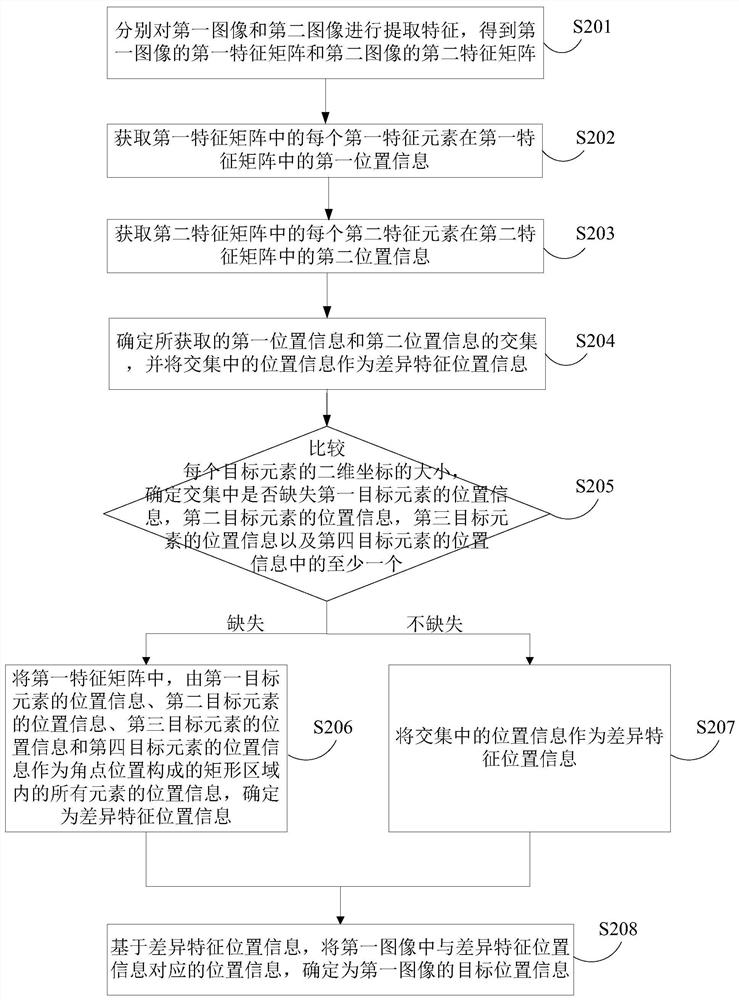

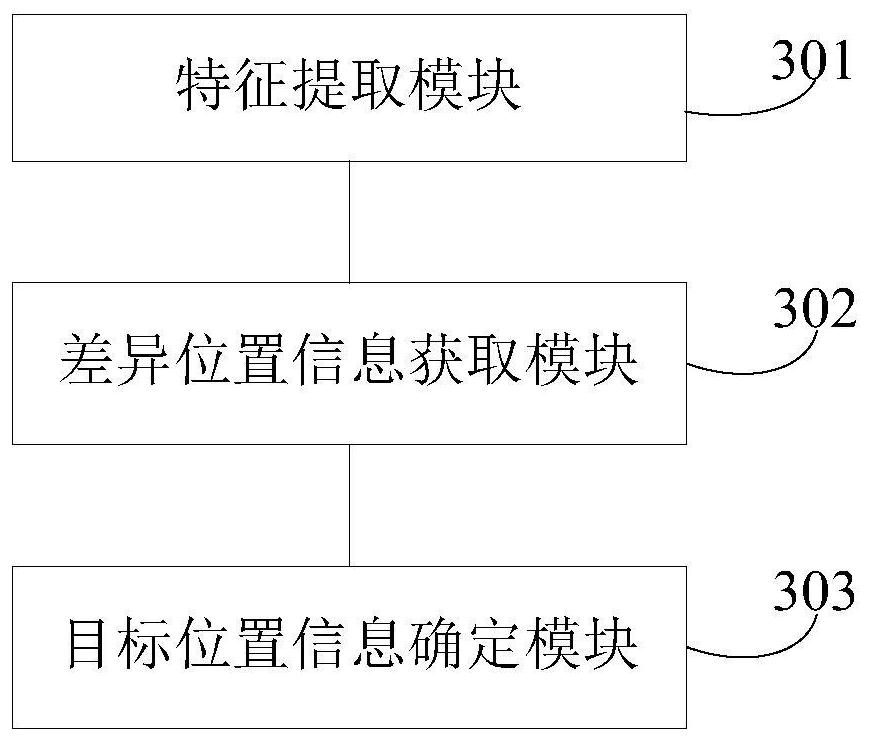

The embodiment of the invention provides a target position labeling method, device and equipment, and the method comprises the steps of carrying out the feature extraction of a first image and a second image, and obtaining a first feature matrix of the first image and a second feature matrix of the second image, wherein the type of the first image belongs to violation, the type of the second imagebelongs to non-violation, and the first image and the second image are obtained by shooting the same scene; obtaining first position information of each first feature element in the first feature matrix in the first feature matrix; obtaining second position information of each second feature element in the second feature matrix in the second feature matrix; and determining an intersection of theacquired first position information and the acquired second position information, and taking the position information in the intersection as difference feature position information; based on the difference feature position information, determining the position information corresponding to the difference feature position information in the first image as the target position information of the firstimage, i.e., the target position automatically marked by the first image.

Owner:HANGZHOU HIKVISION SYST TECH

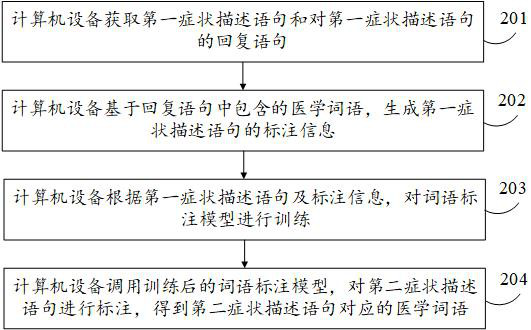

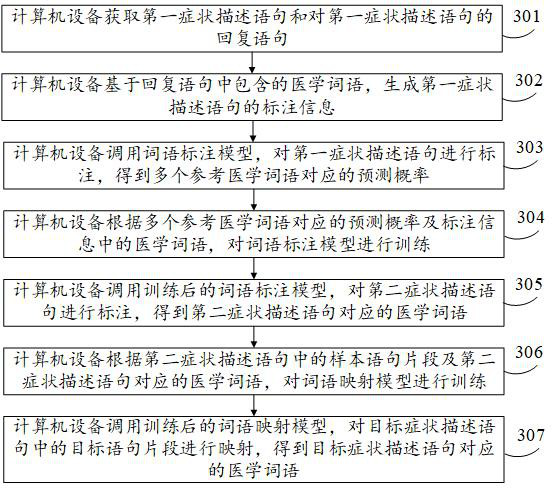

Medical word labeling method, medical word mapping method, medical word labeling device and medical word mapping equipment

ActiveCN112989767AImplementing Unsupervised TrainingImprove accuracyNatural language data processingData miningNursing

The embodiment of the invention discloses a medical word labeling method, a medical word mapping method, a medical word labeling device and medical word mapping equipment, and belongs to the technical field of computers. The method comprises the steps of obtaining a first symptom description statement and a reply statement for the first symptom description statement, generating annotation information of the first symptom description statement based on medical words contained in the reply statement, training a word annotation model according to the first symptom description statement and the annotation information, calling the trained word annotation model, and marking the second symptom description statement to obtain the medical word corresponding to the second symptom description statement, training the word marking model by adopting the first symptom description statement and the reply statement for the first symptom description statement, realizing unsupervised training of the word marking model, and further, through the trained word marking model, automatically labeling the symptom description statement. The manual labeling time is saved, and the labeling efficiency is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

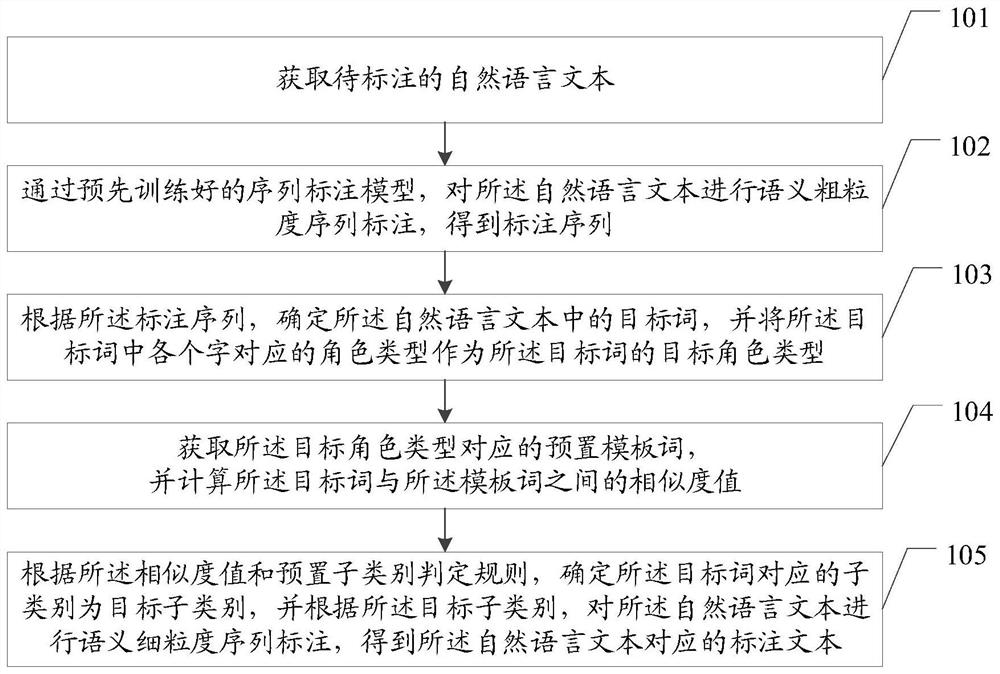

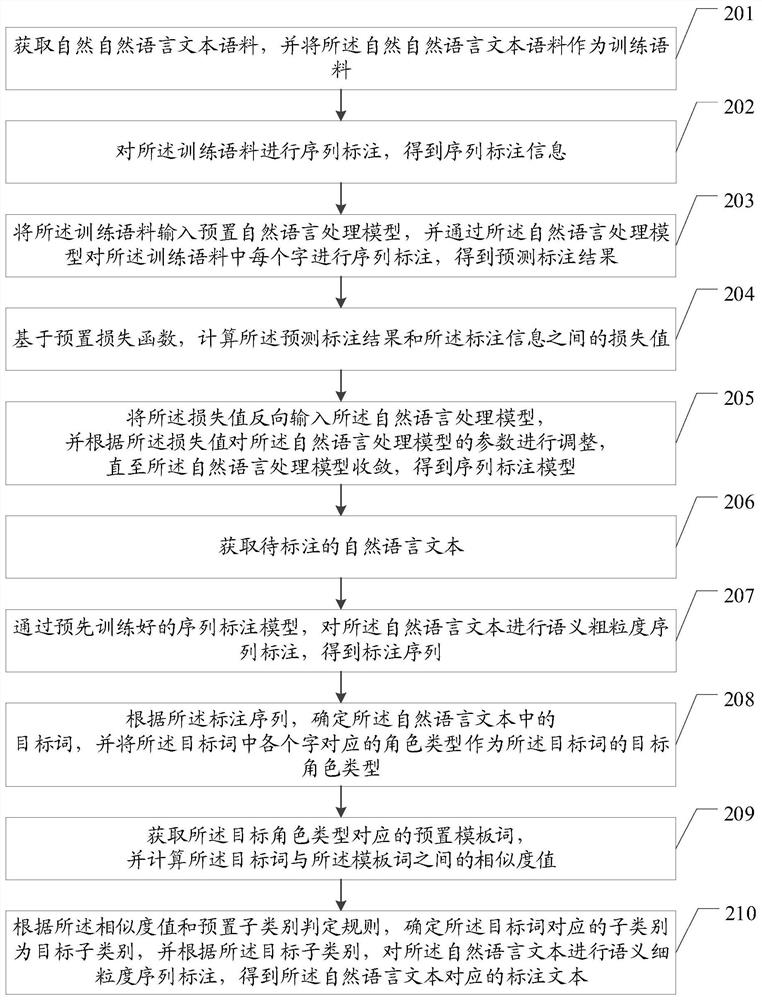

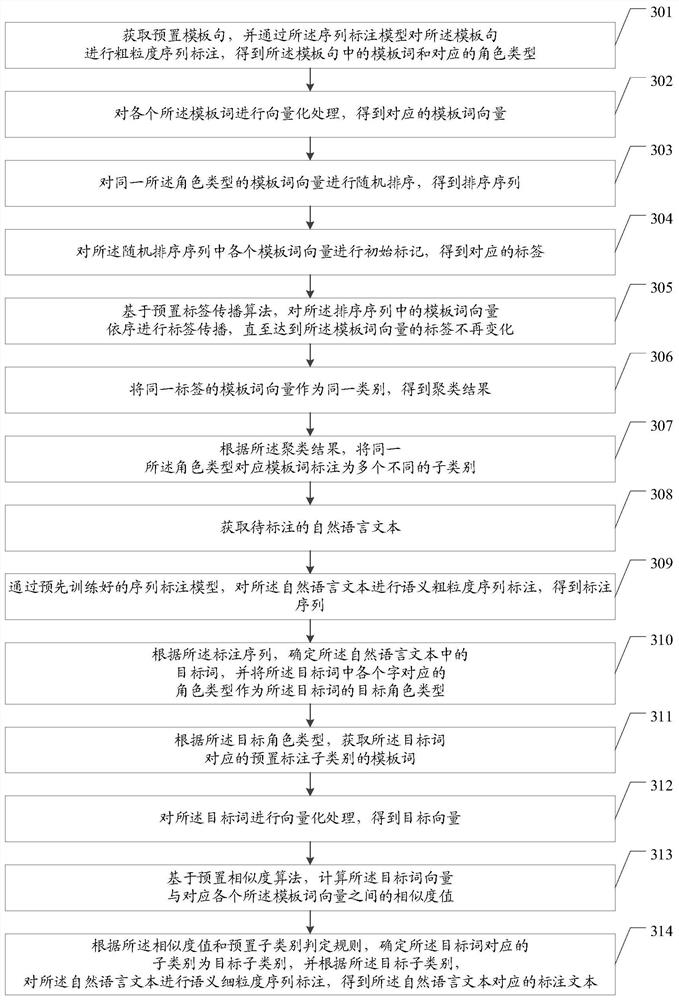

Natural language labeling method based on artificial intelligence and related equipment

ActiveCN111859983ARealize automatic labelingShorten the timeSemantic analysisSpecial data processing applicationsAlgorithmDegree of similarity

The invention relates to the field of artificial intelligence, and discloses a natural language labeling method based on artificial intelligence and related equipment. The method comprises the steps of obtaining a to-be-labeled natural language text; through a pre-trained sequence labeling model, carrying out semantic coarse-grained sequence labeling on the sequence labeling model to obtain a labeling sequence; determining a target word in a natural language text according to the labeling sequence, and determining a target role type of the target word; obtaining a preset template word corresponding to the target role type, and calculating a similarity value between the preset template word and the target role type; and according to the similarity value and a preset sub-category judgment rule, determining a sub-category corresponding to the target word as a target sub-category, and performing semantic fine-grained sequence labeling on the natural language text to obtain a labeled text.In addition, the invention further relates to a blockchain technology, and the natural language text to be labeled and / or the labeled text can be stored in the blockchain. According to the method, thecorpus annotation efficiency for language model training can be improved.

Owner:CHINA PING AN LIFE INSURANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com