Pipeline weld joint automatic labeling method based on Revit platform

An automatic labeling and pipeline technology, which is applied in image analysis, image enhancement, instruments, etc., can solve the problems of time-consuming and laborious, less application, cumbersome operation of machinery, etc., and achieve the effect of accurate labeling, precise size and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

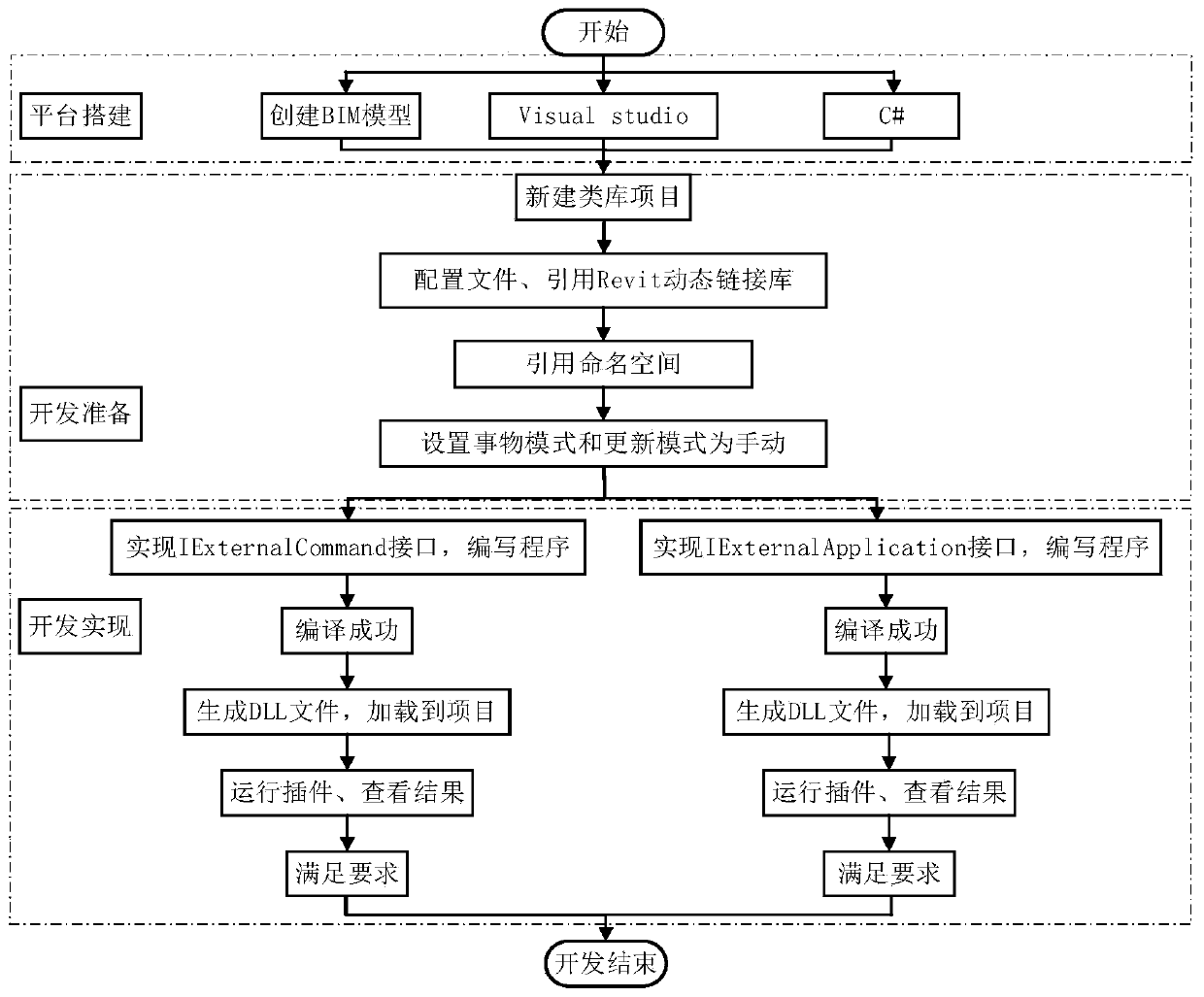

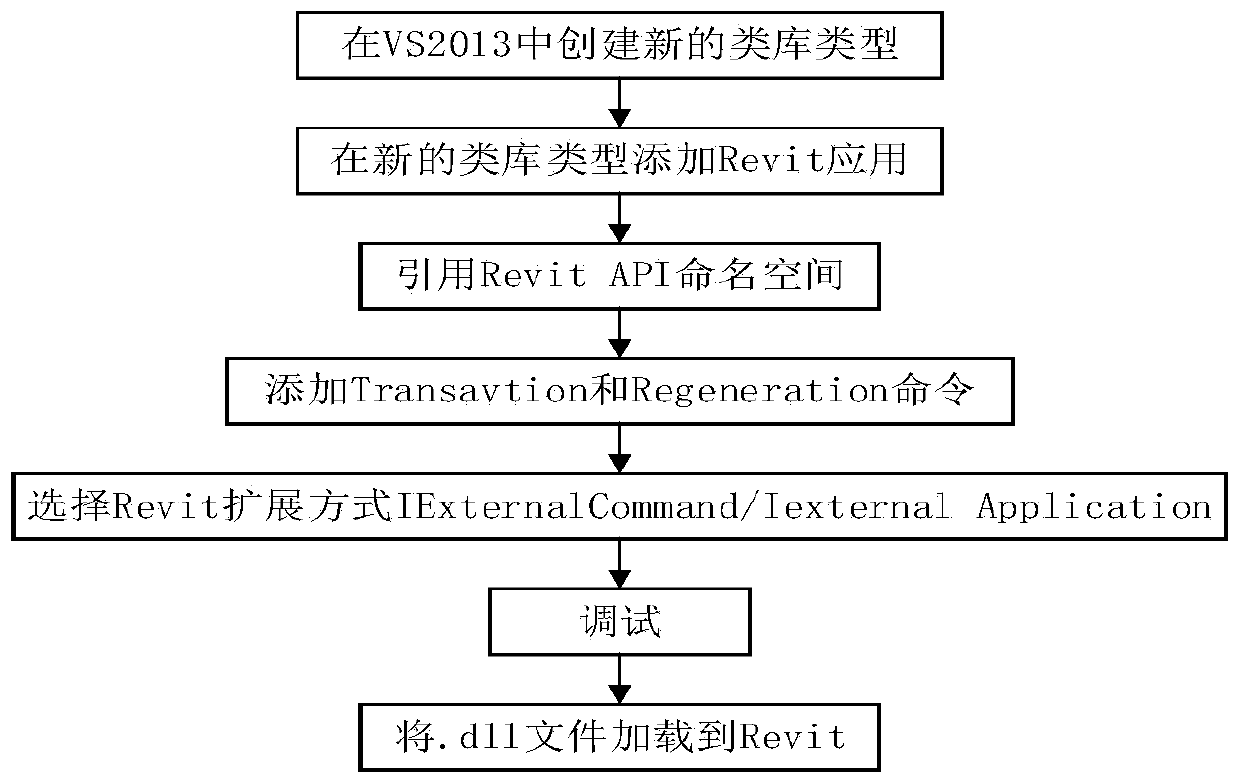

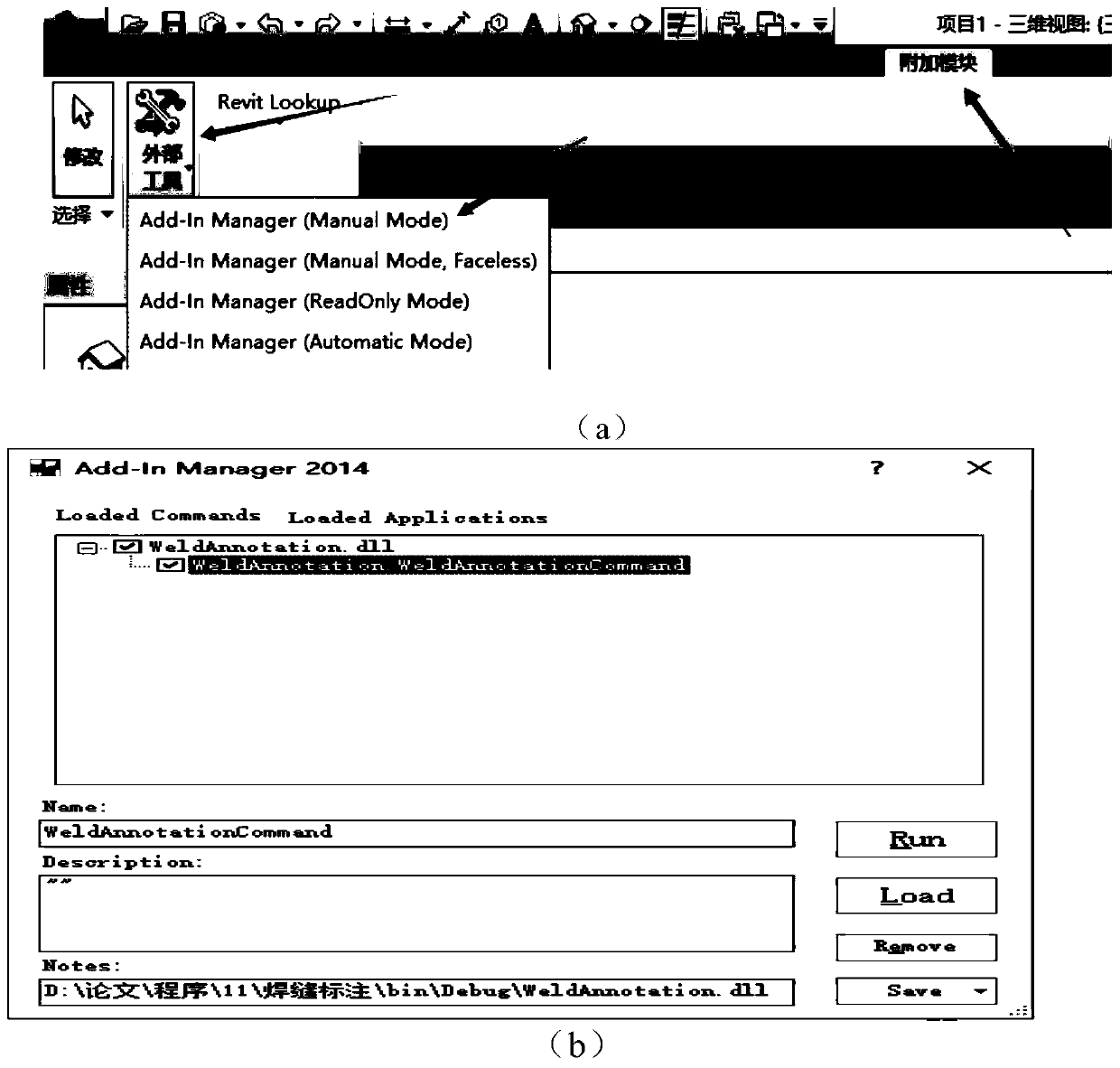

[0026] refer to figure 1 and figure 2 , the present invention a kind of pipeline welding seam automatic labeling method based on Revit platform, comprising:

[0027] Step 1: Determine the hardware and software configuration, establish a BIM model, determine development tools, and create a platform;

[0028] Step 1.1 Hardware recommended configuration:

[0029] 1) Processor: Intel(R) Xeon(R) CPU E3-1230 V2@3.3.GHz; 2) Memory: 8.00GB; 3) Graphics card: AMD Radeon HD5700 Series (two pieces;) 4) Hard disk: 1TB5) Others Configuration: keyboard, mouse.

[0030] Step 1.2 Software recommended configuration:

[0031] 1) Operating system: Microsoft Windows 10 64-bit Ultimate; 2) Graphics support software: Autodesk Revit 2015, Chinese version; 3) Development tools: Visual Studio 2013, Revit 2015SDK; 4) Development language: C#; 5) .NET framework: .N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com