Apparatus for removing and polishing optical material, method of use and application thereof

An optical material and active reaction technology, applied in polishing devices and optical material removal fields, can solve the problems of narrow effective working range of working parameters, radio frequency electromagnetic pollution, and high processing cost, and can overcome sample surface and subsurface damage, and the scope of application Wide, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

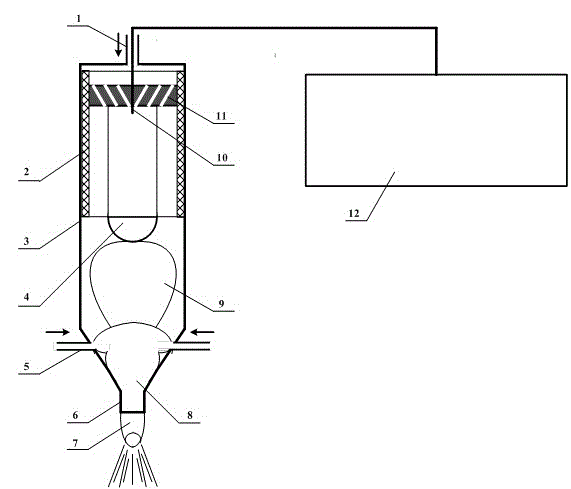

[0035] After the arc spindle-shaped nitrogen plasma area is formed, the active reaction gas inlet 5 at the side end of the spray gun is opened, and the sulfur hexafluoride gas enters the discharge channel at a pressure of 0.030Mpa. In this embodiment, the active gas inlets are set as two symmetrically distributed road. When SF 6 After entering, the ions in the nitrogen plasma area collide with it in a cascade, and under the action of high-energy nitrogen ions, the sulfur hexafluoride gas is ionized to form a secondary cascade collision plasma area containing a high concentration of active fluorine ions8 . Under the continuous pressure of the subsequent working gas, the generated cascade plasma region is constrained by the inverted trumpet-shaped jet nozzle 6 to form a jet flame 7 with a maximum diameter of 6-8mm. The mass is light, so it concentrates on the top of the flame body to form a blue fluoride ion region, and the blue fluoride ion region acts on the surface of optic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com