A Laser Damage Threshold Testing System

A technology of laser damage threshold and testing system, which is applied in the direction of testing optical performance, etc., can solve the problems of long time-consuming measurement process, large error, measurement error, etc., to overcome the strong subjectivity of measurement, overcome the large random error, and prevent measurement effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

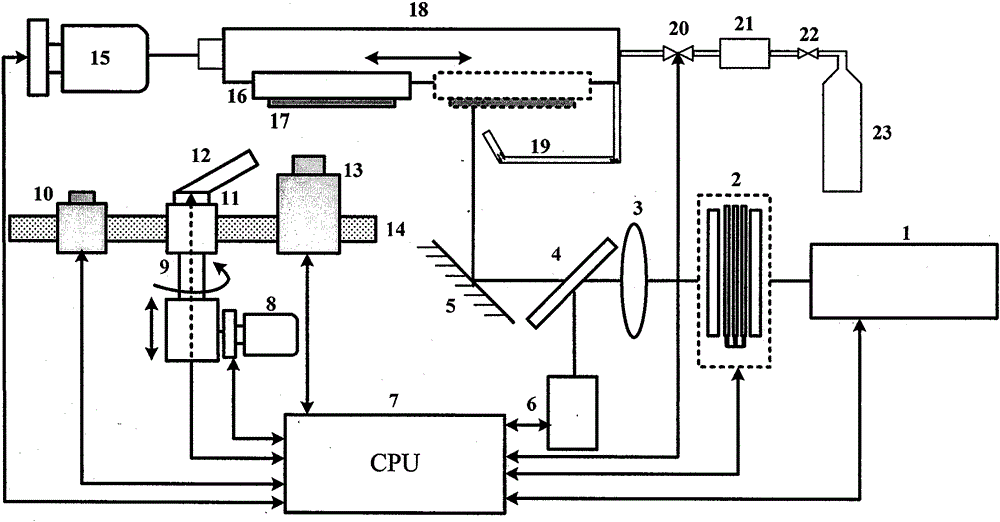

[0042] Such as figure 1 As shown, the high-energy laser (wavelength 1064nm, pulse width 12ns, single pulse energy can be adjusted in the range of 200mJ) emitted by Nd:YAG laser 1 passes through attenuator 2, focusing lens 3, beam splitter 4 and high reflector 5 converge on the sample to be tested. The output laser energy can be adjusted linearly within the range of 2-200mJ by using multiple sets of attenuation sheets combined with the attenuator 2 . Use a beam splitter to guide a small-energy laser into a laser test and analysis unit for energy beam analysis at a ratio of 100:1, and measure its parameters in real time.

[0043] According to the material properties of the test optical element or film sample, set the test laser energy range, and divide it into 10 equal parts, and irradiate 10 test points at each energy level in the order from high to low. Control the central processing unit 7 by programming, start the CCD clamping stage stepping drive motor and the sample stag...

Embodiment 2

[0046] Select the appropriate laser energy according to the specific conditions of the sample to be tested, such as figure 1 As shown, the software drives each console to adjust the focal length of the auxiliary light source and the CCD image acquisition unit. Use the same energy and the same time interval to perform multiple irradiation treatments on the same area of the sample to be tested (the number of irradiations is set at 5 to 100 times), and at the same time as each irradiation, use a low-magnification CCD image acquisition unit to implement Observe the irradiation area of the sample to be tested, stop the irradiation when obvious damage is found, and record the irradiation times as N. Drive the two-dimensional translation platform in the XY direction, move the irradiation area to another position, irradiate this area N-1 times with the same energy and the same time interval, and then switch the high-magnification CCD image acquisition unit to the observation posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com