Patents

Literature

66results about How to "Easy pressure adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

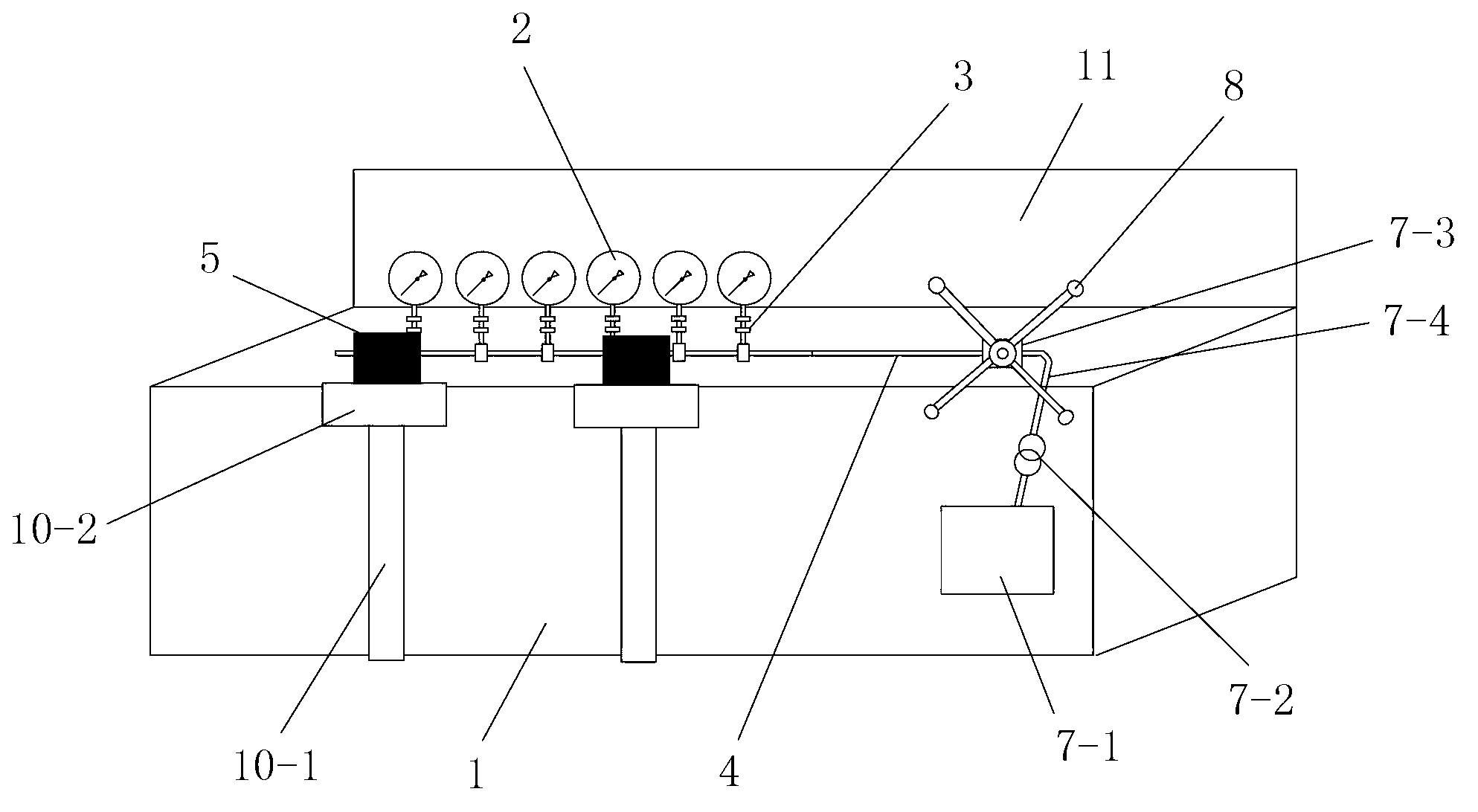

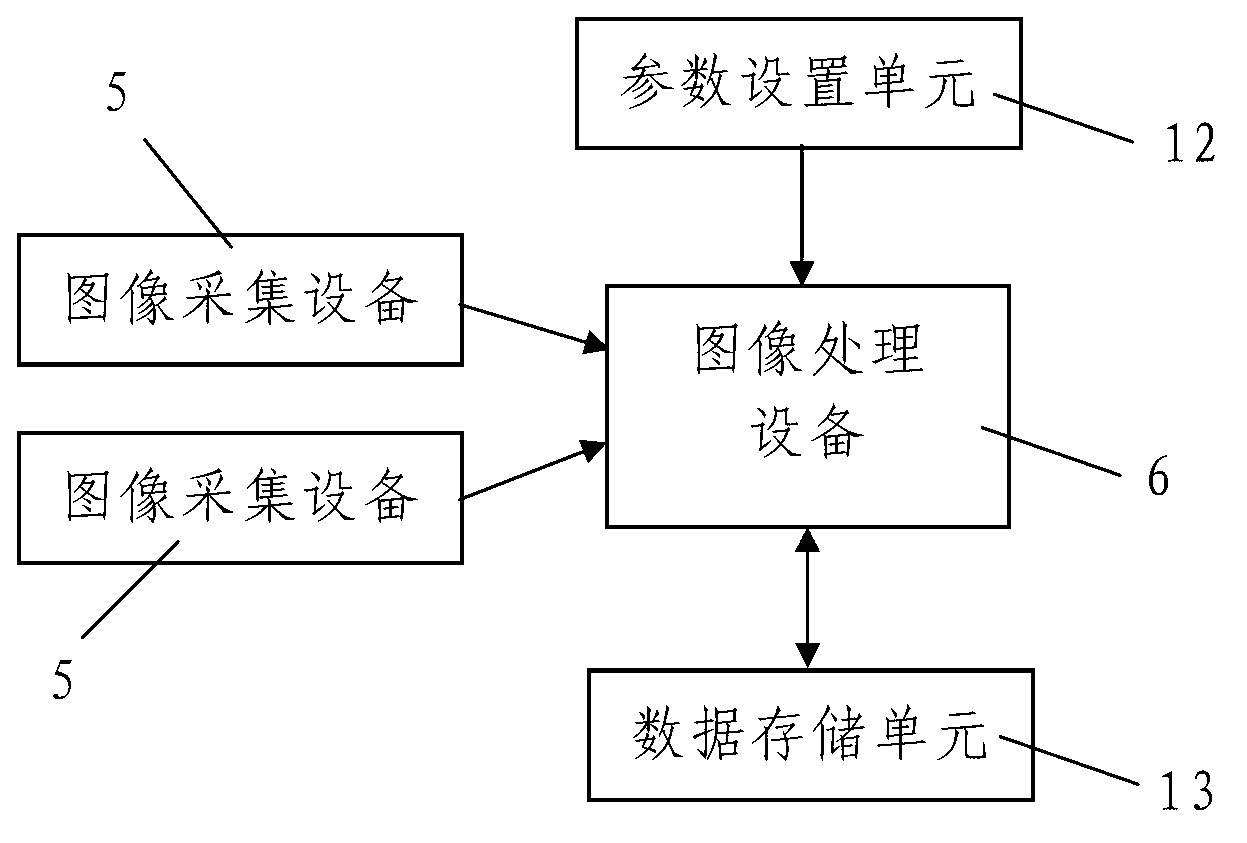

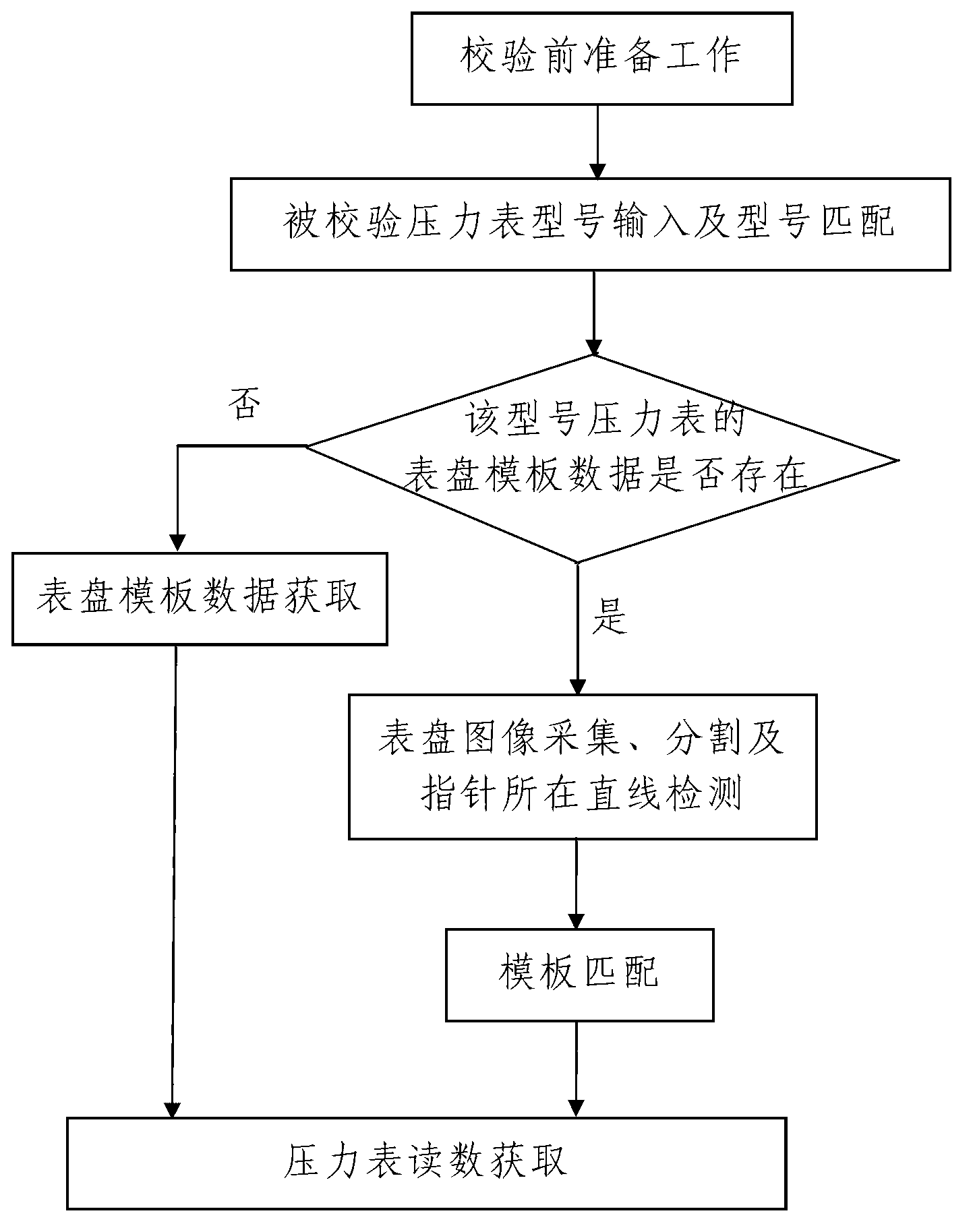

Batch calibration equipment and batch calibration method for intelligent pointer-type pressure gages

InactiveCN102840948ASimple structureEasy installation and layoutFluid pressure measurementTemplate matchingImaging processing

The invention discloses batch calibration equipment and a batch calibration method for intelligent pointer-type pressure gages. The batch calibration equipment comprises a horizontal calibration platform, a horizontal testing pipe, a plurality of quick connectors for being installed on a plurality of calibration pressure meters respectively, two image acquisition devices which are located in front of the horizontal calibration platform, an image processing device, a pressurization device and a pressure regulation device which regulates pressure in the horizontal testing pipe. The batch calibration method comprises the following steps of: firstly, doing a preparation work before calibration; secondly, inputting and matching models of the pressure gages to be calibrated; thirdly, obtaining data of dial plate templates; fourth, acquiring and dividing images of dial plates, and detecting straight lines at which pointers are located; fifth, matching the templates; sixth, obtaining numberical reading of the pressure meters, and the numberical reading obtaining process comprises the following steps of: obtaining dial plate image information to be processed, matching binocular stereo-vision images and processing the data. The batch calibration equipment disclosed by the invention is reasonable in design, simple and convenient in use and operation, has a good use effect, and calibration efficiency and calibration accuracy of the pointer-type pressure gages are greatly improved.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU +1

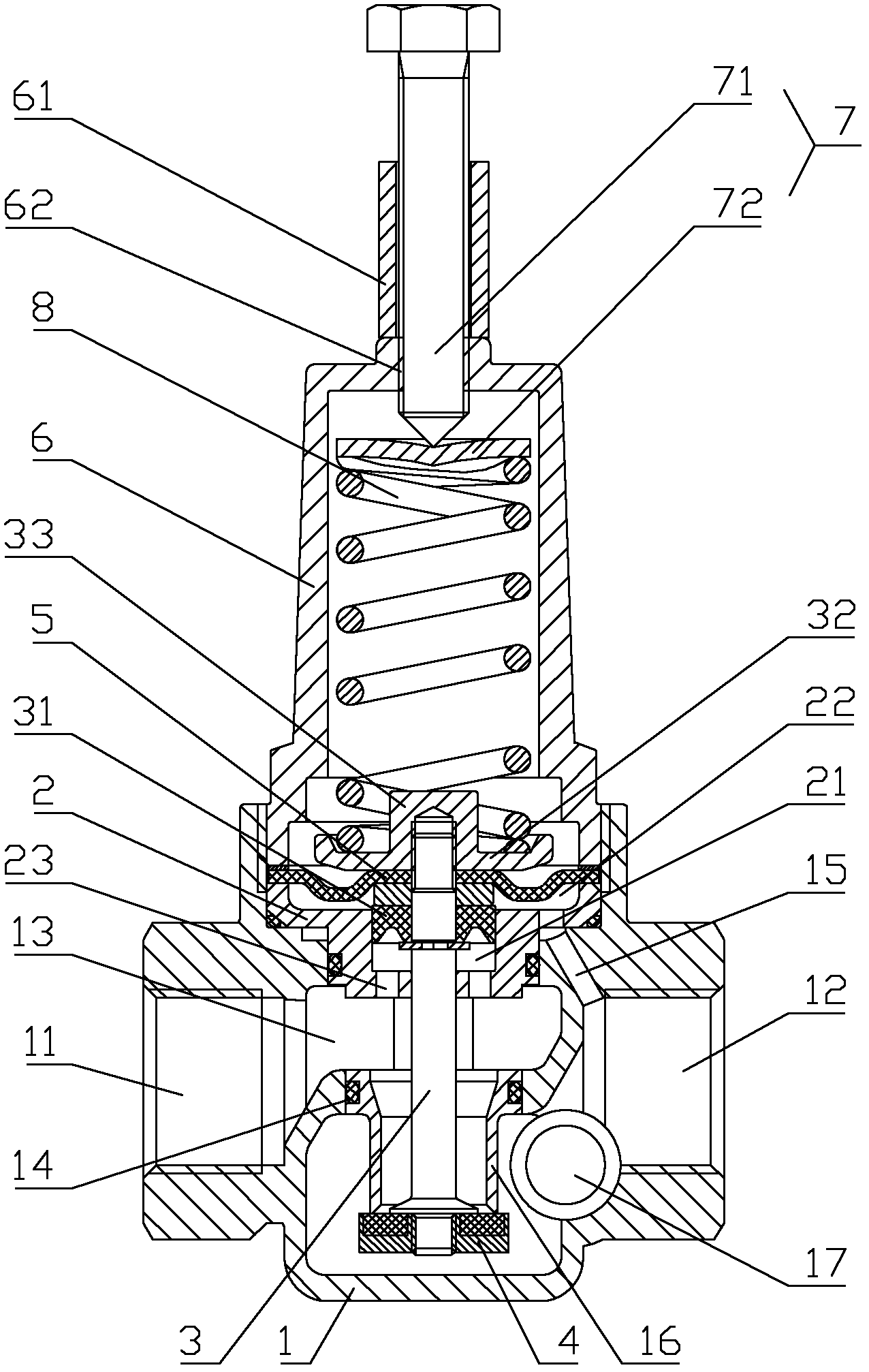

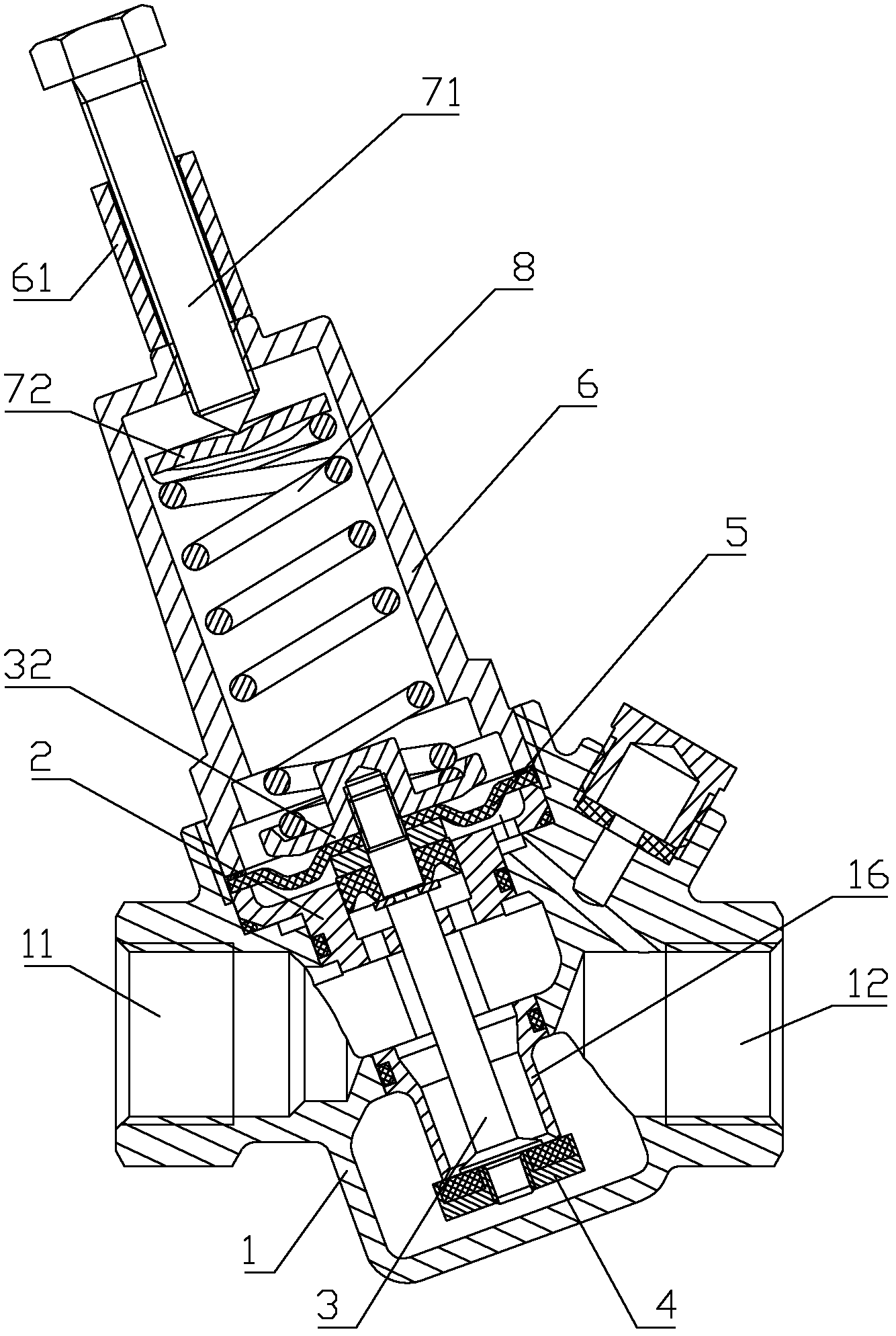

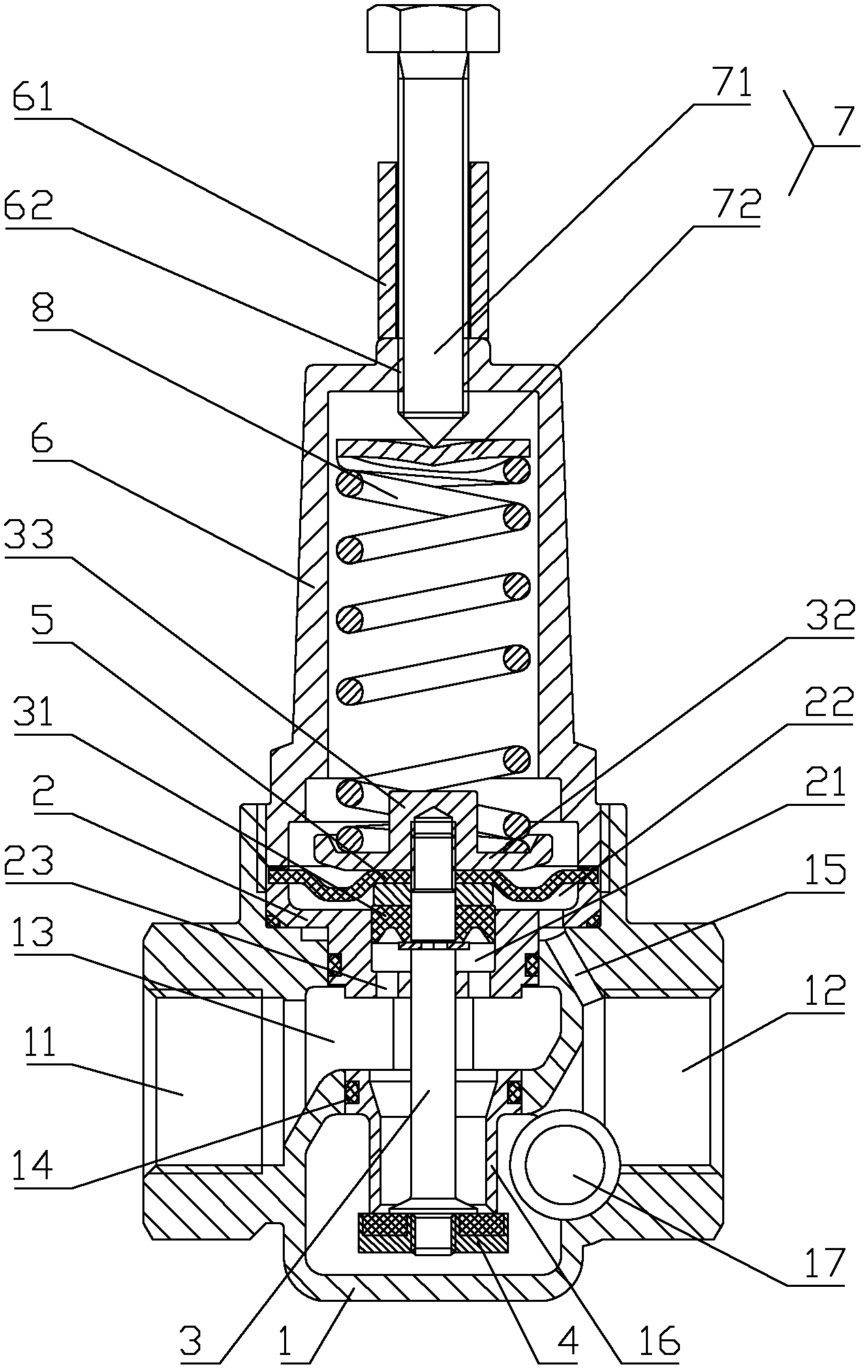

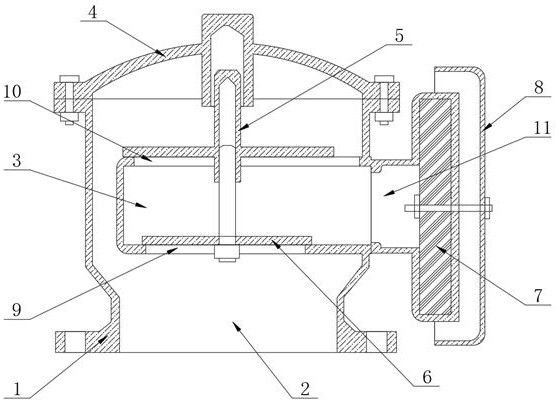

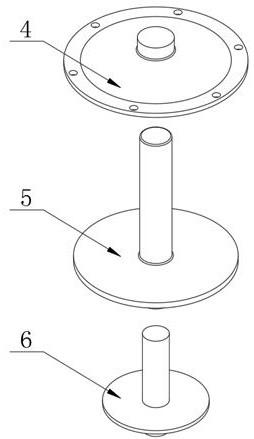

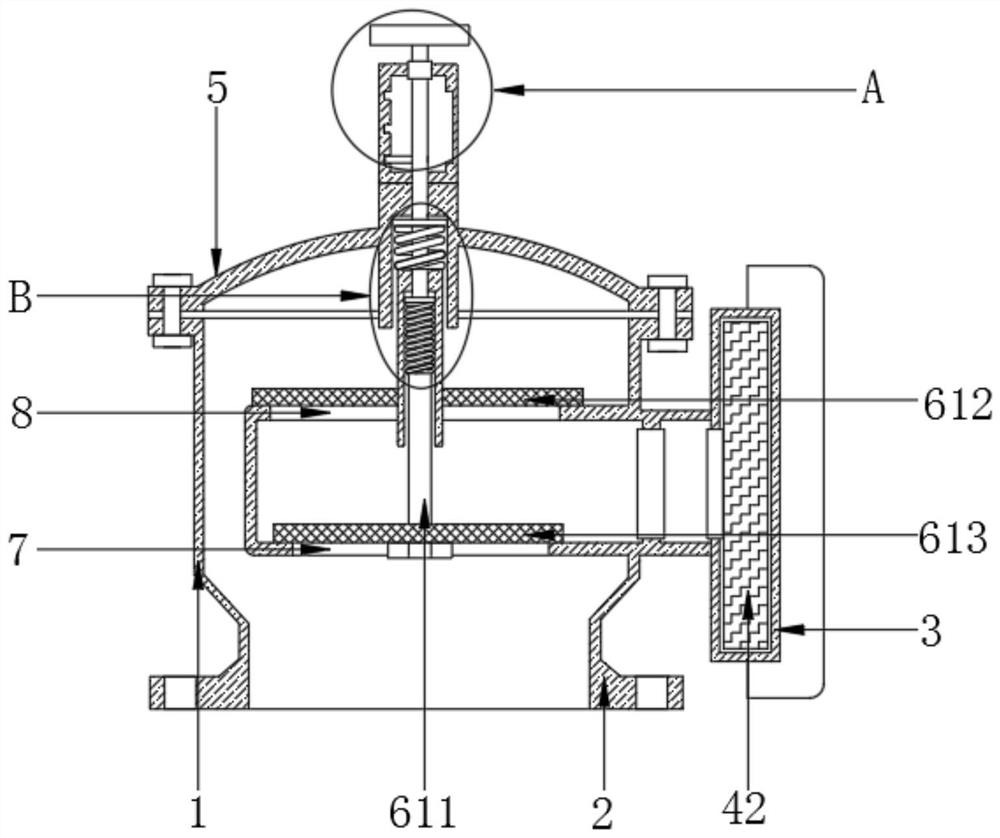

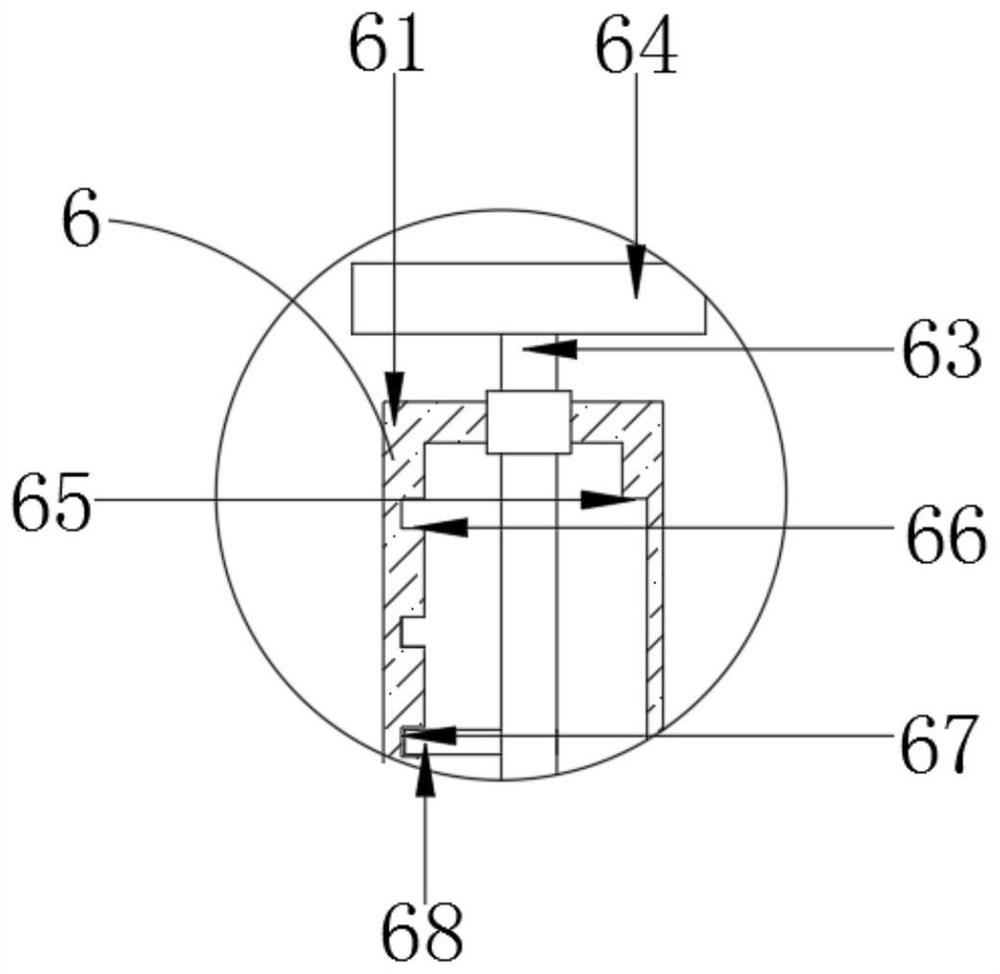

Adjustable high-flexibility low-pressure and stable-pressure pressure reducing valve

InactiveCN102425693ASimple structureReduce volumeEqualizing valvesSafety valvesCore componentEngineering

The invention discloses an adjustable high-flexibility low-pressure and stable-pressure pressure reducing valve, which comprises a valve body and a valve core component, wherein the valve body is provided with an inlet and an outlet; the valve core component is arranged in the valve body; a medium passage for communicating the inlet with the outlet is formed in the valve body; a throttling port is formed in the medium passage; the valve core component corresponds to the throttling port and is used for changing the medium pressure in front of and behind the throttling port; the valve core component comprises a valve core rack, a valve rod and a valve flap; the valve core rack is fixedly arranged in the valve body; the valve rod is arranged in the valve core rack; the valve flap is arranged at the lower end of the valve rod to change the flow rate of the medium passage; a sealing device is arranged between the valve rod and the valve core rack to isolate the upper part of the valve core rack from the lower part of the valve core rack; a pressure chamber in front of the valve is formed between the lower part of the valve core rack and the sealing device; the upper end of the valve core rack has a thin film structure, and a pressure chamber after the valve is formed between the upper end of the valve core rack and the upper part of the valve core rack; and a pressure adjusting structure is also arranged above the thin film structure. The valve has a simple and rational structure, is convenient to manufacture and mount, has high flexibility in pressure adjustment and has certain pressure stability, and the pressure adjustment range is adjustable.

Owner:ZHEJIANG DUNAN INTELLIGENT CONTROL TECH CO LTD

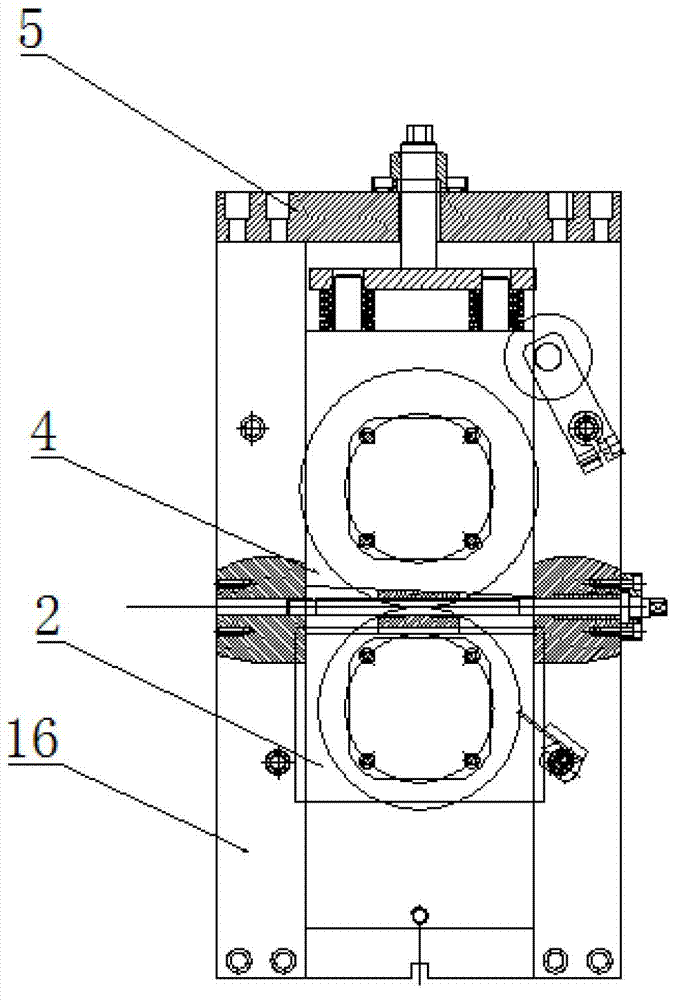

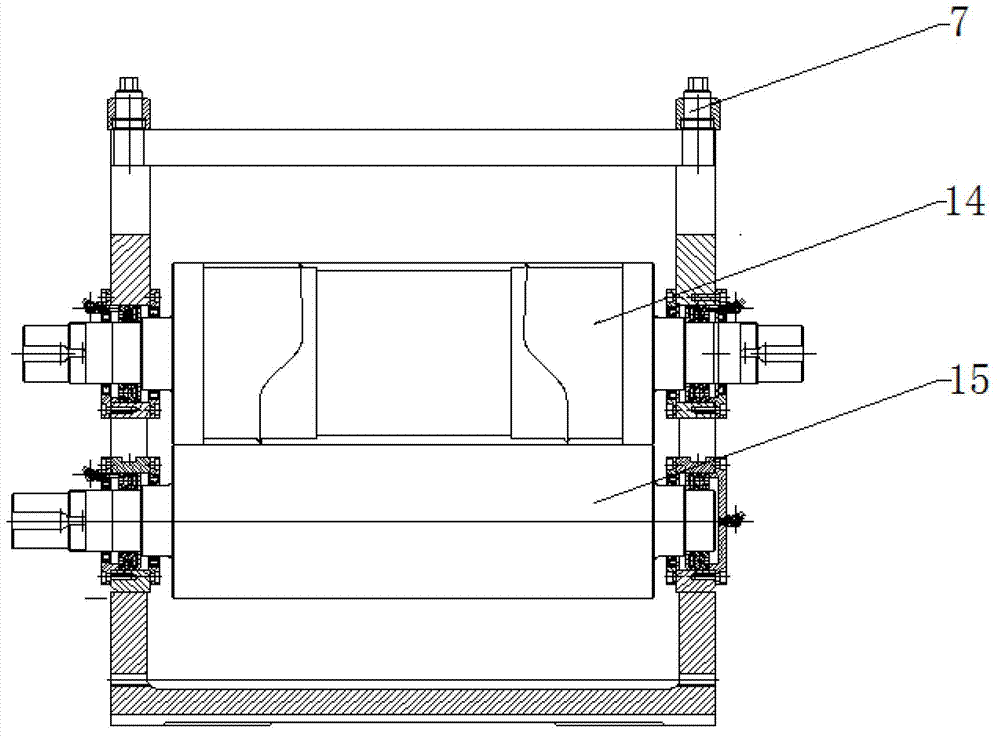

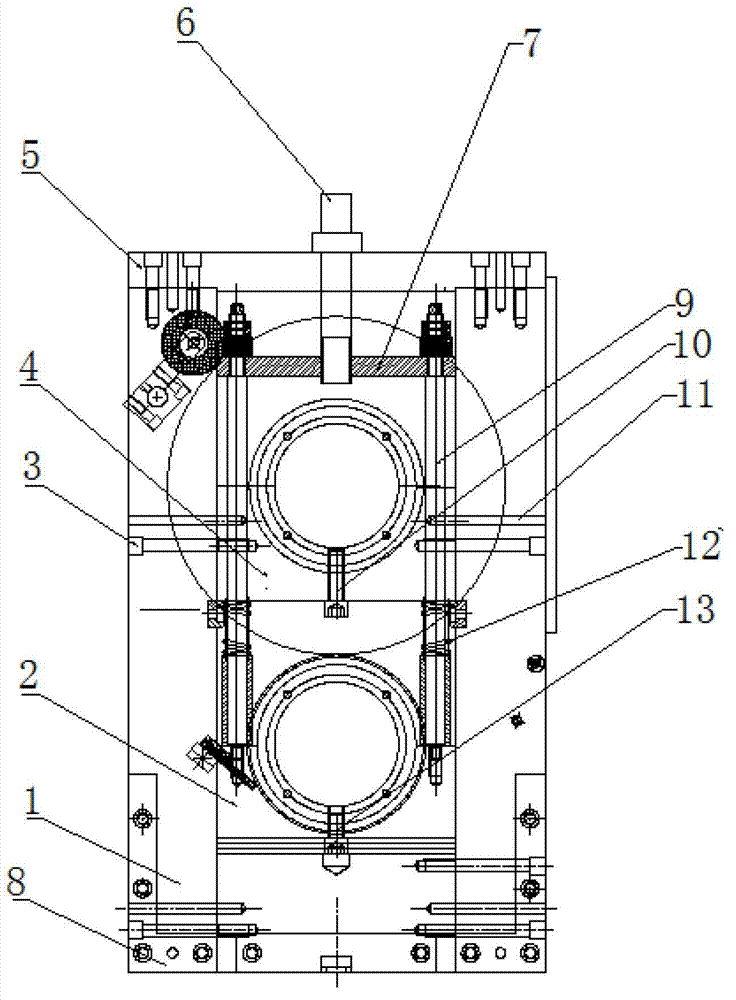

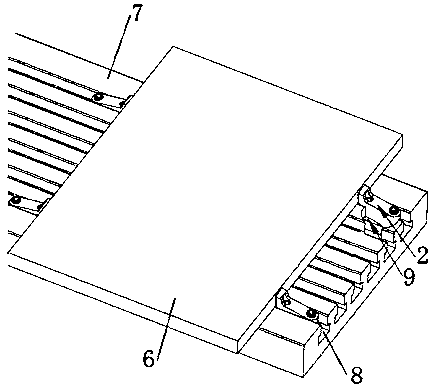

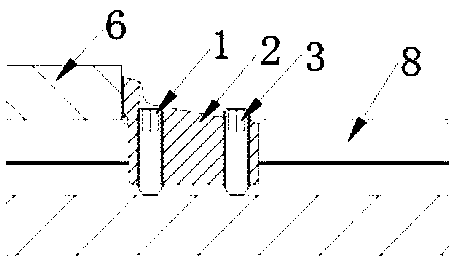

High-speed roll-pressing die-cutting rule mould frame

ActiveCN102825630AEliminate the possibility of vibrationImprove the use effectMetal working apparatusSelf weightEngineering

The invention discloses a high-speed roll-pressing die-cutting rule mould frame, which comprises a frame structure, two upper bearing pedestals, two lower bearing pedestals, an upper main cutter roll, a lower anvil roll and a pressurization mechanism, wherein the frame structure consists of two side plates, a top plate and a base; the two side plates are correspondingly provided with longitudinal chutes; the two upper bearing pedestals are fixedly arranged on the two side plates; the lower bearing pedestals are arranged on the side plates and can slide along the chutes under the driving of the pressurization mechanism; the upper main cutter roll is arranged between the two upper bearing pedestals; and the lower anvil roll is arranged between the two lower bearing pedestals. On the contrary with the traditional cutter mould frame, the high-speed roll-pressing die-cutting rule mould frame is characterized in that an interval between an upper roll and a lower roll is controlled by regulating the lower anvil roll assembly to achieve the use requirement, so that the vibration possibility of the upper main cutter roll in the high-speed production process is eliminated, and the purposes of improving the use effect and prolonging the service life are achieved. Meanwhile, pressure brought by the condition that a cutter point bears the self weight of the main cutter roll can be automatically eliminated, the user situation of the cutter point can be further improved, and the service life is prolonged.

Owner:三明市普诺维机械有限公司

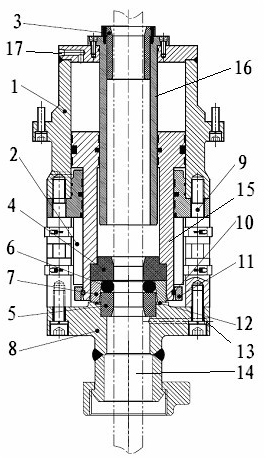

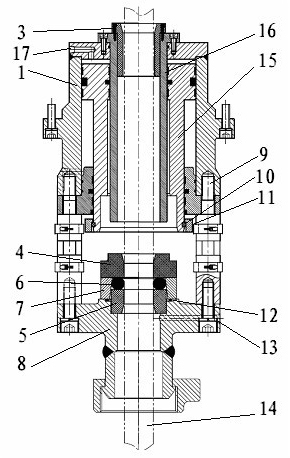

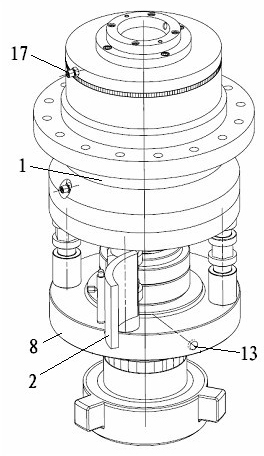

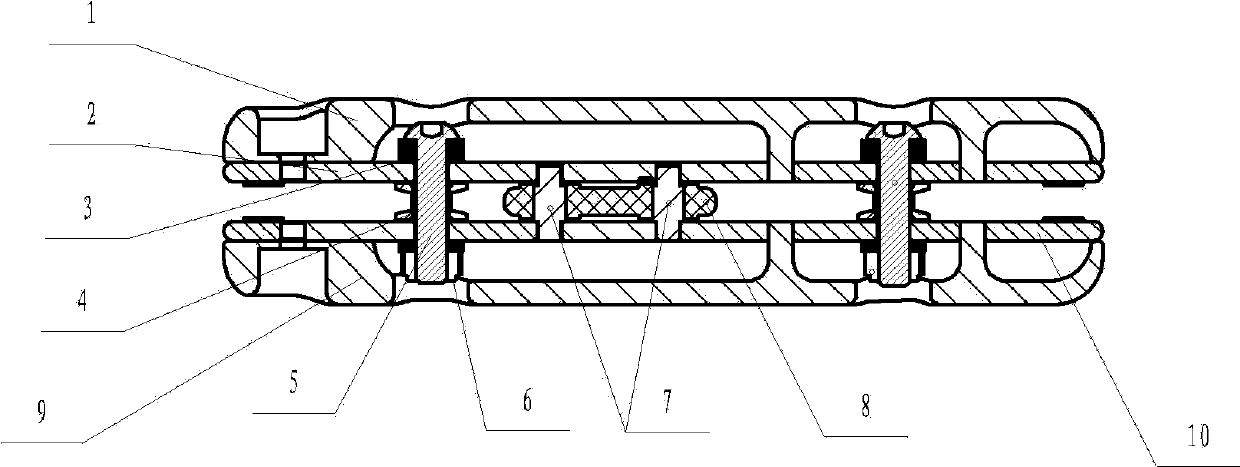

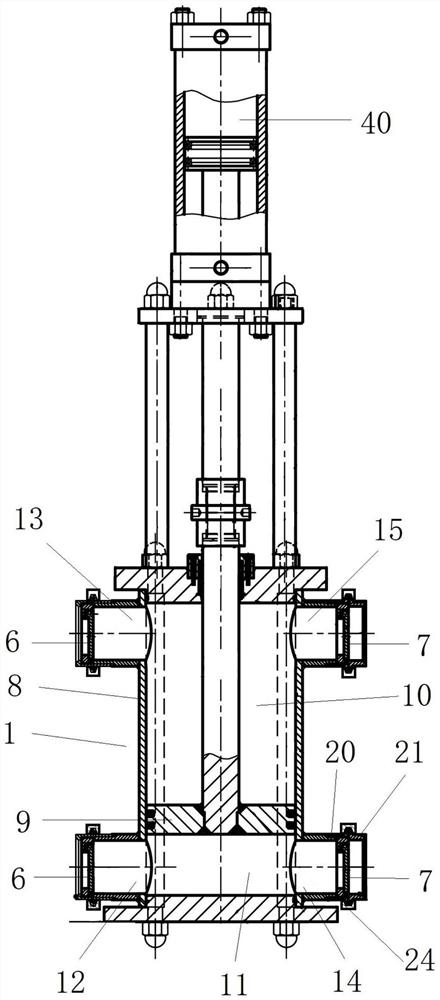

Blowout preventing box of continuous oil pipe and drill rod

The invention discloses a blowout preventing box of a continuous oil pipe and a drill rod. The blowout preventing box comprises a hollow hydraulic cylinder and a flange union connected through connecting rod bolts, and a set of valve assembly is arranged on the two connecting rod bolts opposite in the diameter direction respectively; the hollow hydraulic cylinder is arranged at a hydraulic inlet / outlet; a fixed sleeve is arranged in the cavity of the hollow hydraulic cylinder, an upper guide sleeve is sleeved at the upper end of the inner wall of the fixed sleeve, the upper guide sleeve and the interior of the flange union axially pass through the continuous pipe, a piston rod is arranged between the fixed sleeve and the hollow hydraulic cylinder, and the inner circumference of the lower section of the piston rod is provided with a seam allowance; and a middle guide sealing pressing sleeve and an inner cone guide spacing ring are sleeved on the inner circumference of the seam allowance, the inner circumference of the middle guide sealing pressing sleeve is sleeved with the continuous pipe, a main sealing ring and a lower guide sealing pressing sleeve are arranged between the inner cone guide spacing ring and the continuous pipe, and a hydraulic detection port is bypassed in the radial direction of the flange union. The pressure adjustment of the sealing cavity is convenient; time and labor are saved when the sealing ring is replaced; and the pressure of a wellhead can be detected in real time.

Owner:BAOJI PETROLEUM MASCH CO LTD

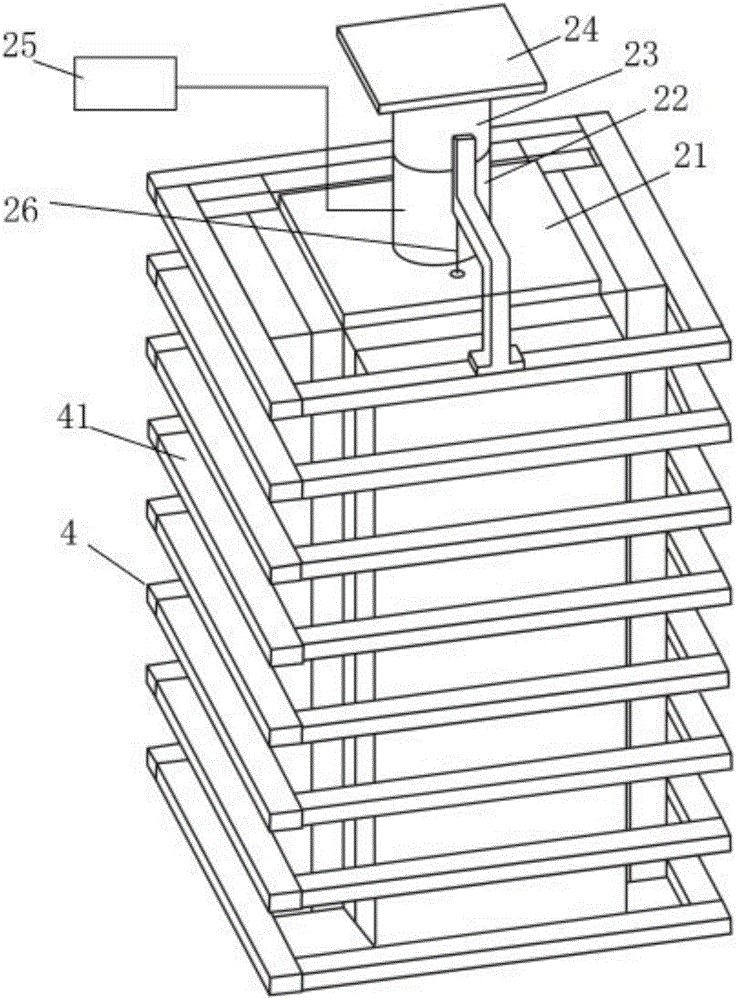

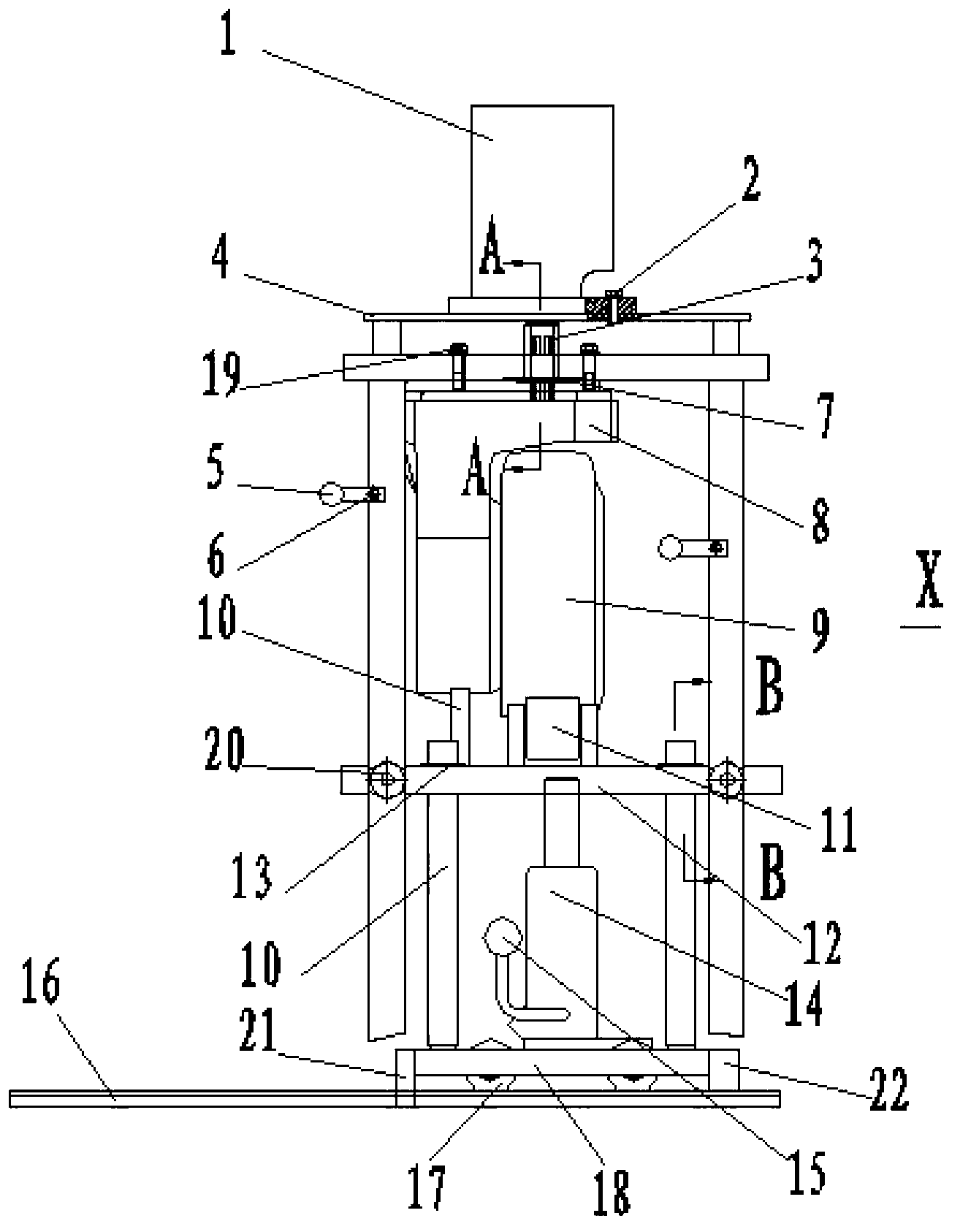

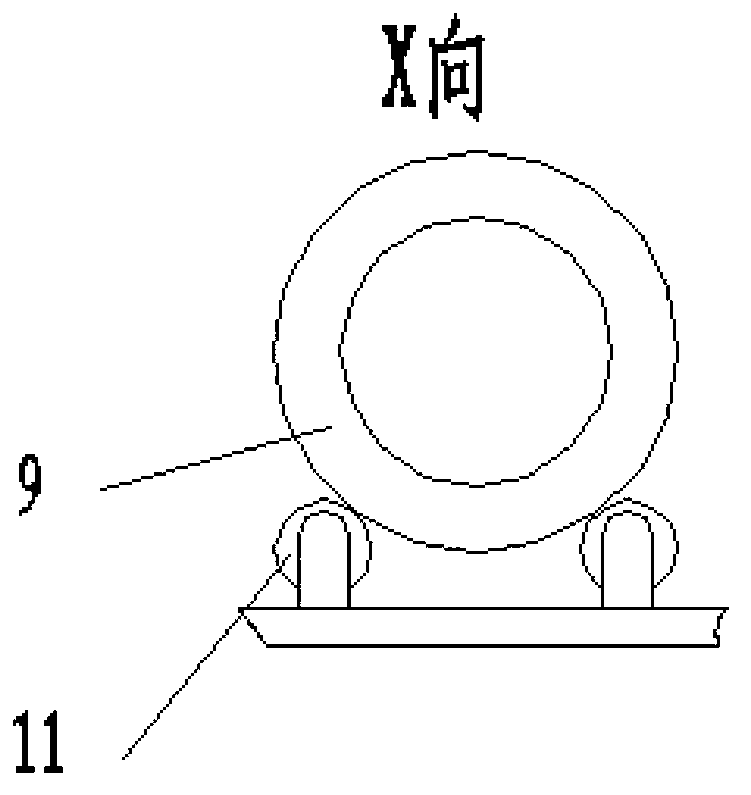

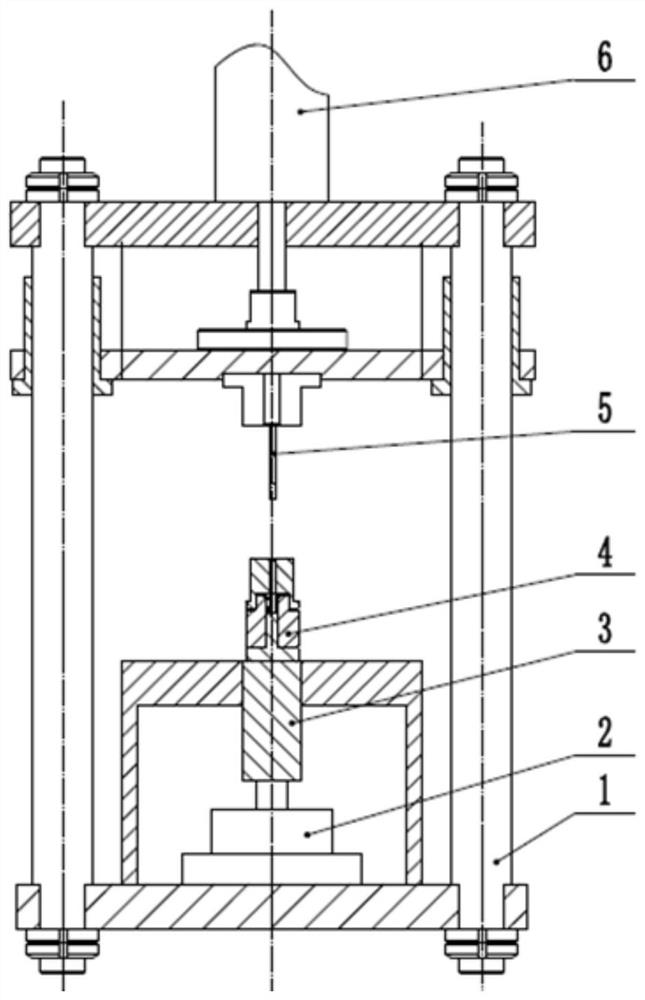

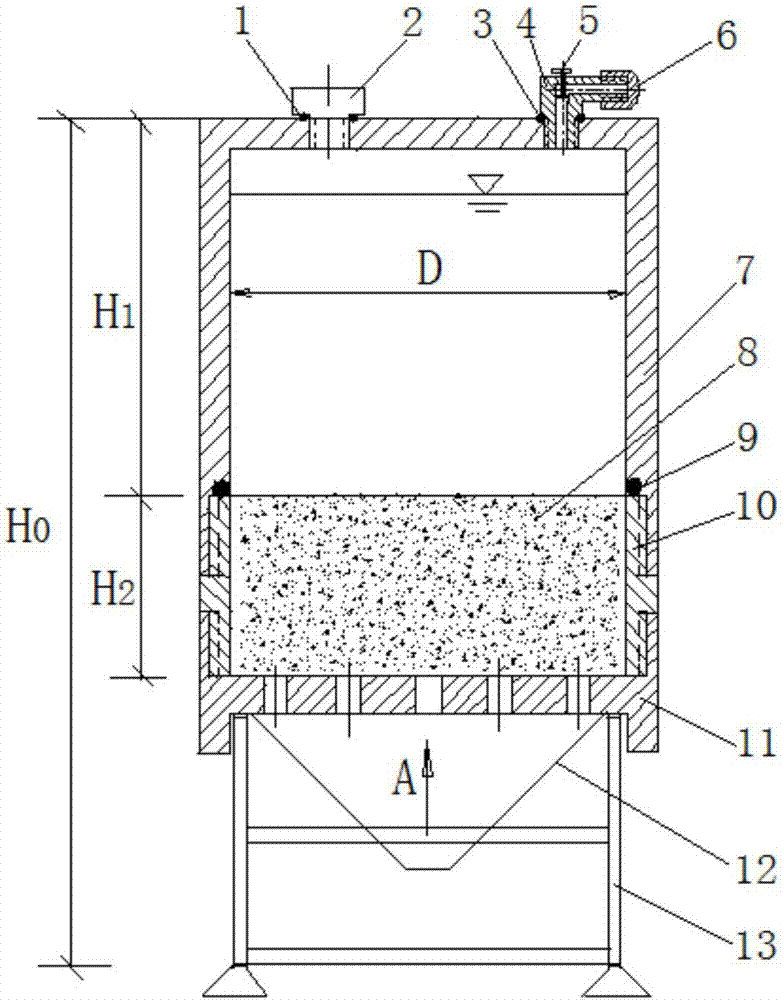

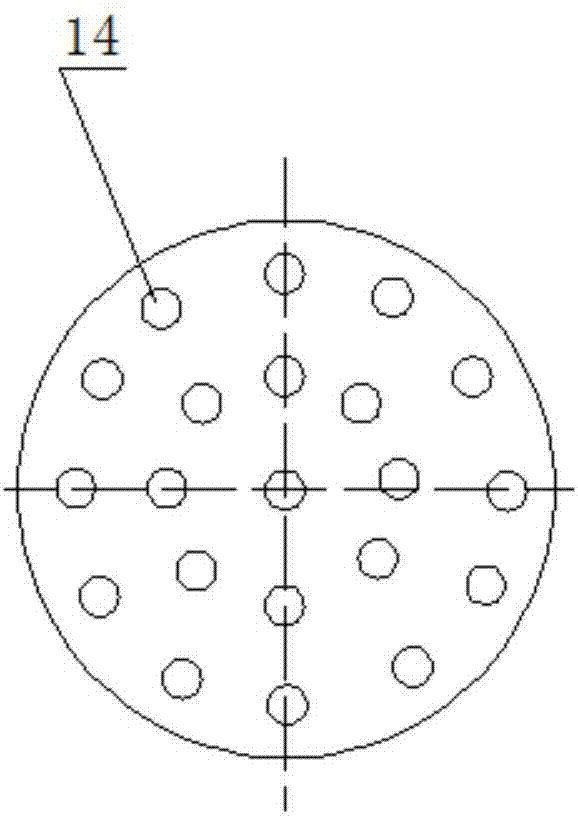

Rock-soil mass large size in-situ triaxial creep test system

InactiveCN106546492ASufficient room for deformationStable confining pressurePreparing sample for investigationMaterial strength using tensile/compressive forcesSoil massAxial pressure

The invention relates to a rock-soil mass large size in-situ triaxial creep test system. The system includes an axial pressure loading subsystem, confining pressure loading subsystems and a background control computer. The axial pressure loading subsystem is disposed at the top of a to-be-tested cylindrical rock-soil mass test block and has a first displacement meter, and the axial pressure loading subsystem and the first displacement meter are connected to the background control computer respectively through a line; the side wall of the to-be-tested cylindrical rock-soil mass test block is wrapped with a rubber layer, the confining pressure loading subsystems disposed on the outer surface of the rubber layer and have a plurality of second displacement meters internally, and the confining pressure loading subsystems and the plurality of second displacement meters are connected to the background control computer respectively through a line; and the confining pressure loading subsystems are externally sleeved with a counter-force fixation frame module. The system provided by the invention has the advantages of simple structure and convenient use, in the test process, the rock-soil mass test block has sufficient deformation space and stable confining pressure, at the same time rock-soil mass creep deformation wholeness can be monitored in real time, and the measurement structure is accurate.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

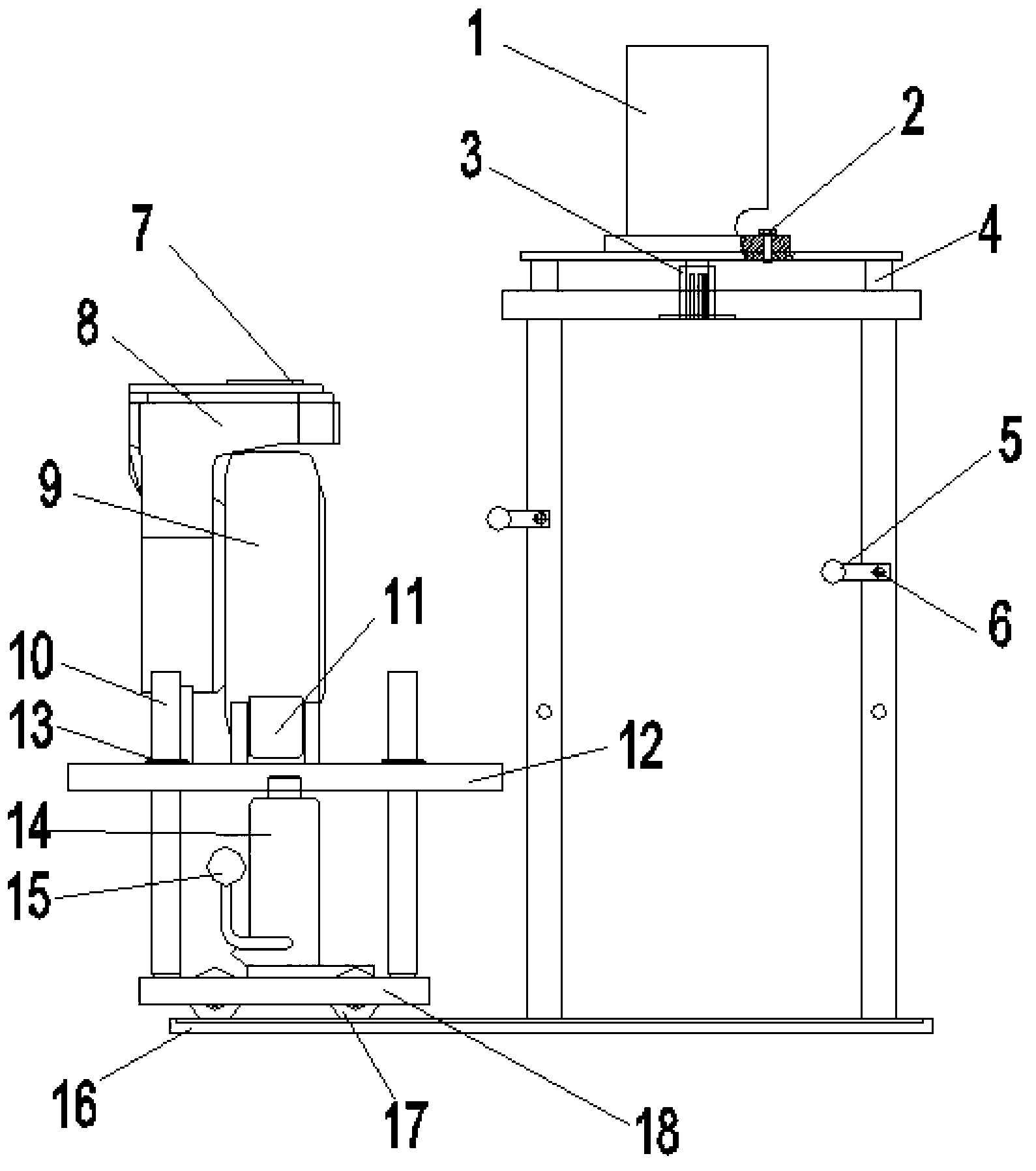

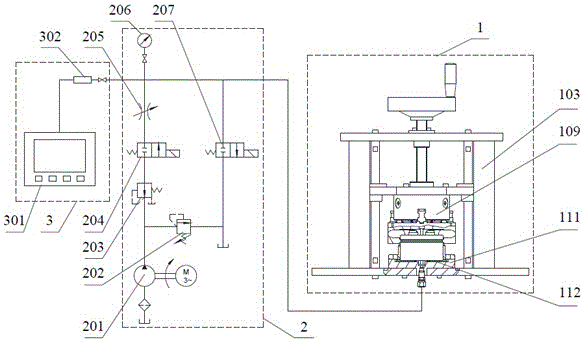

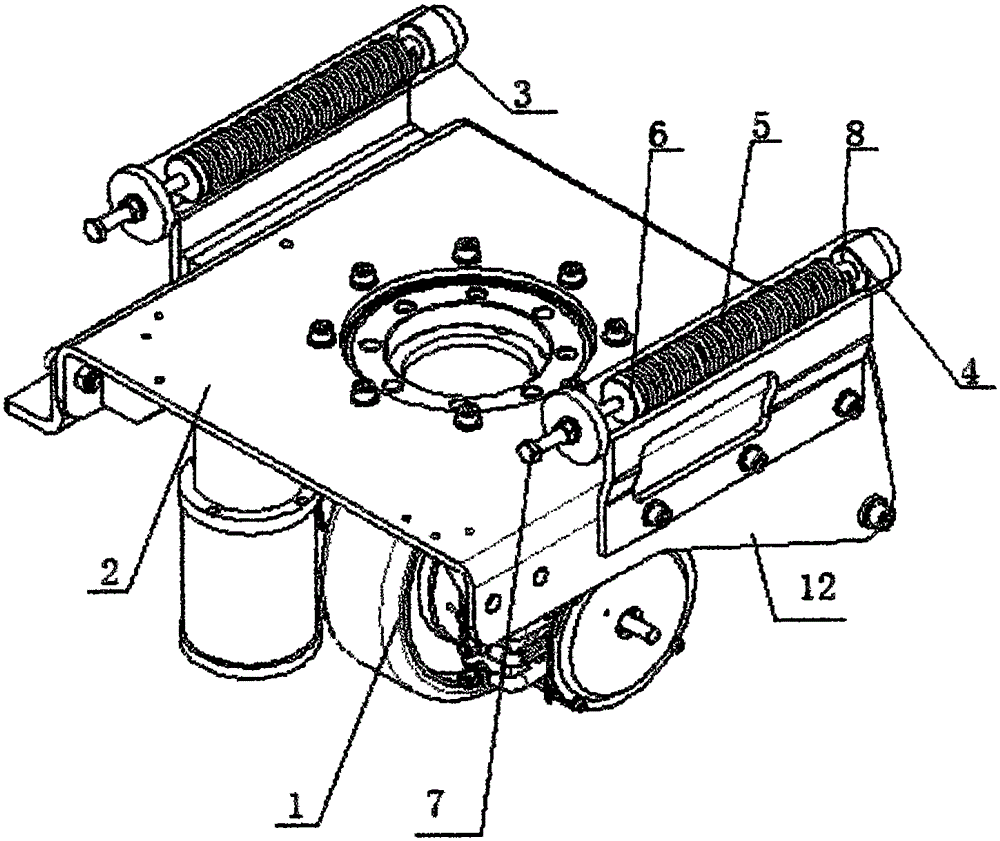

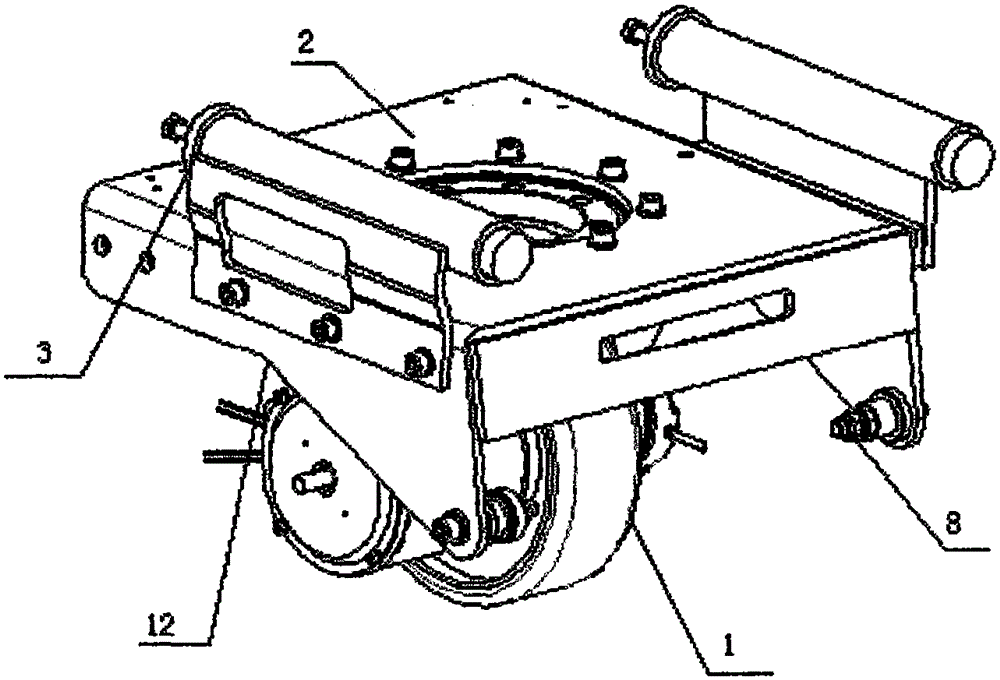

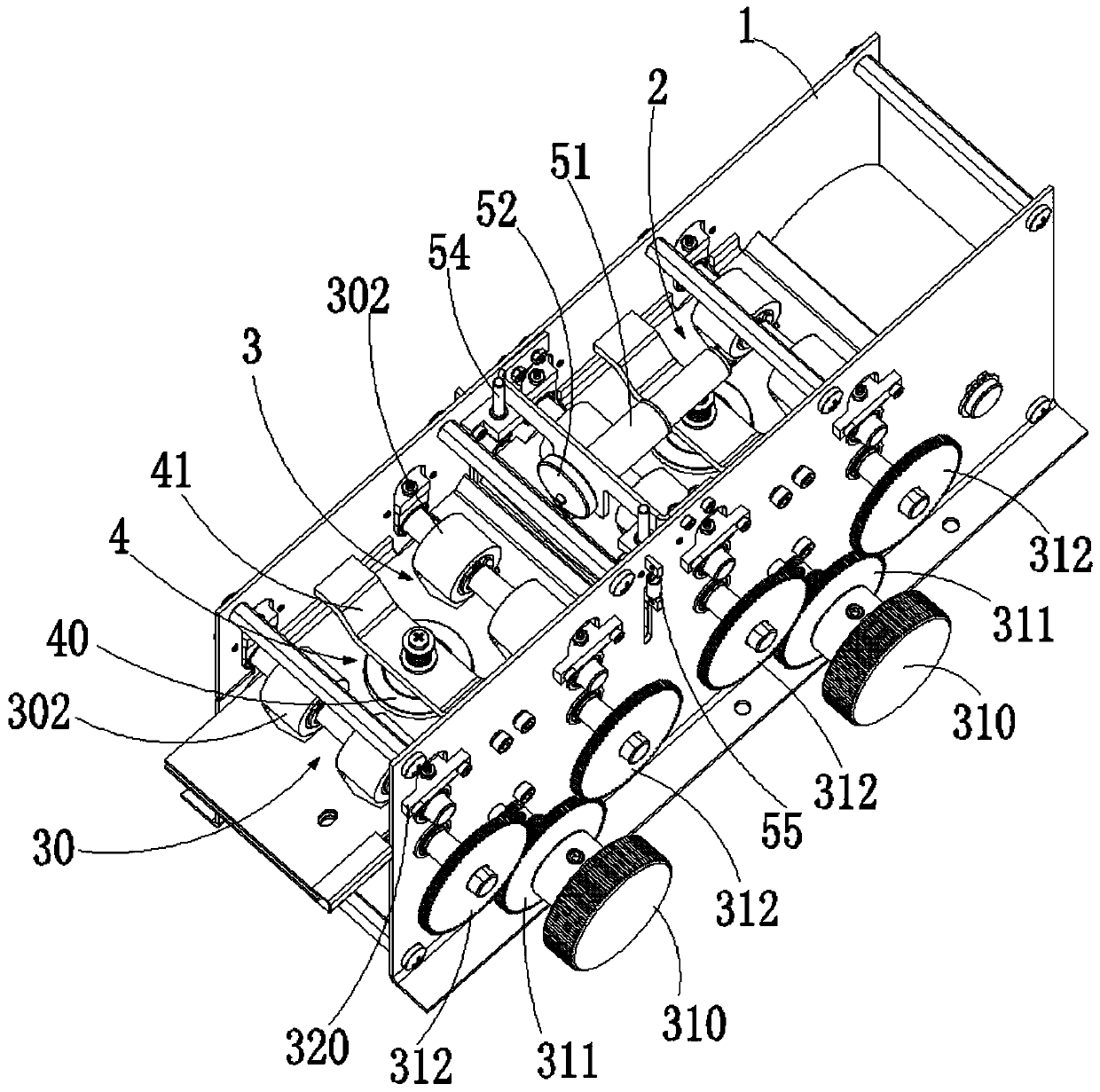

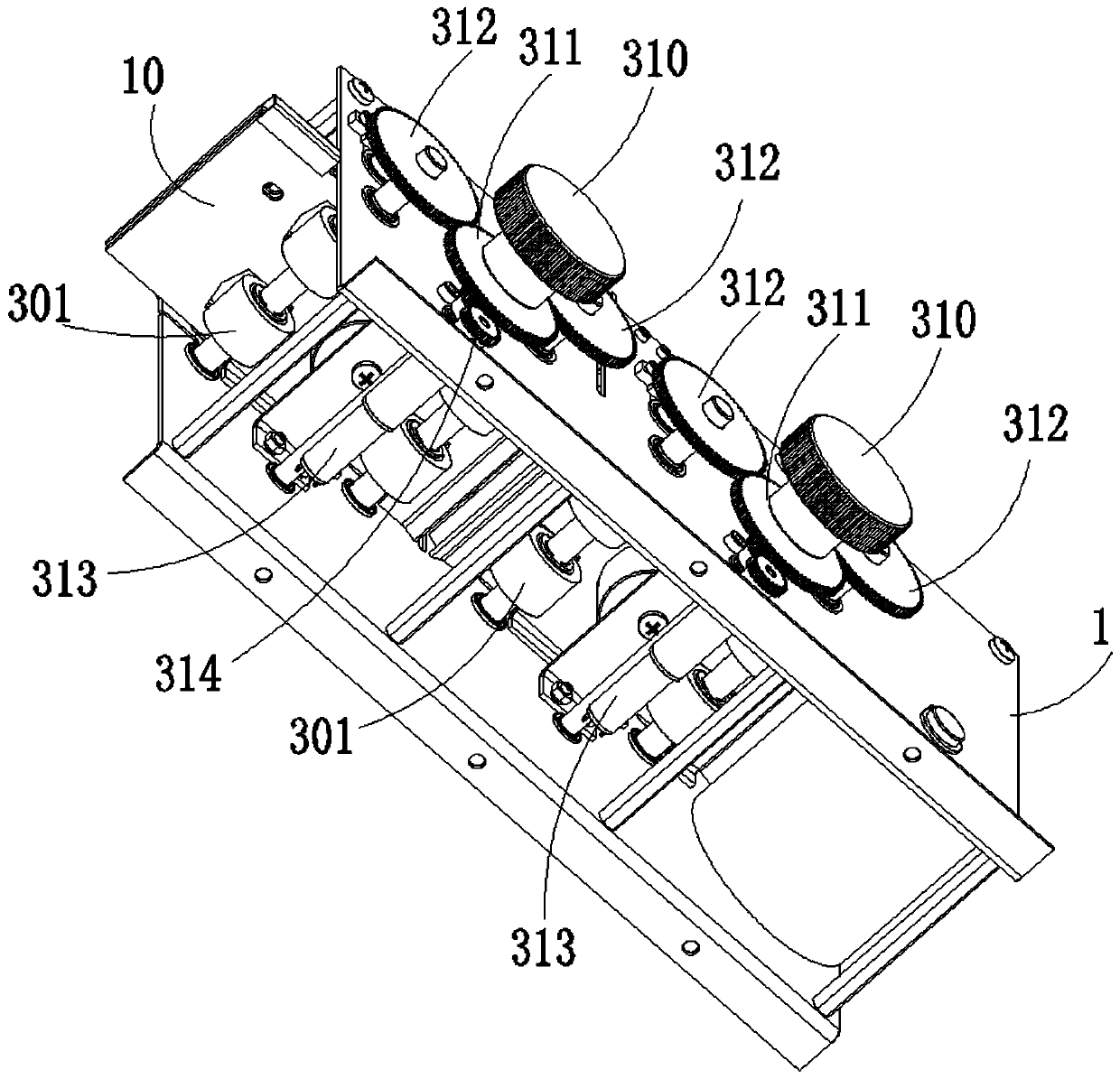

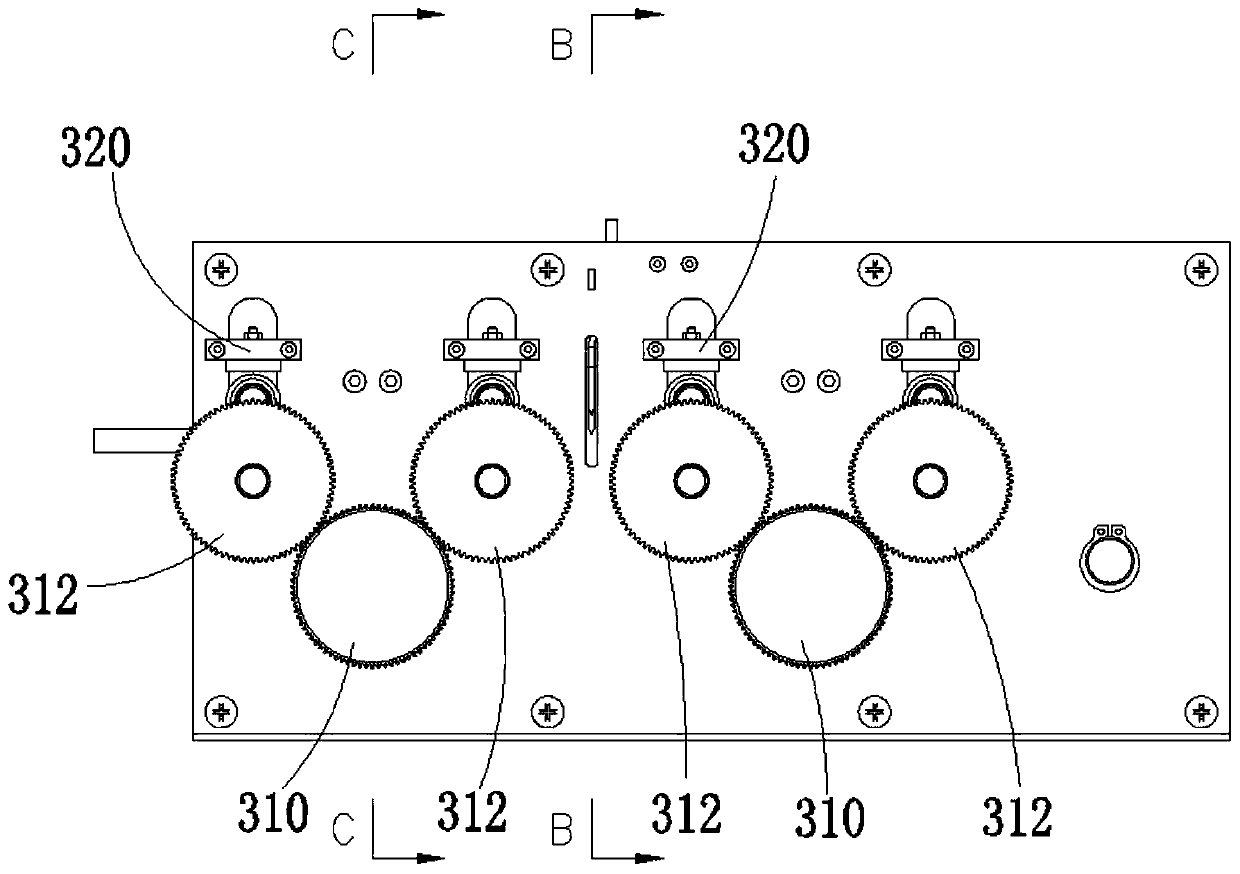

Gearbox detection device

ActiveCN103018036AQuick installationEasy pressure adjustmentSubsonic/sonic/ultrasonic wave measurementMachine gearing/transmission testingDrive wheelElectric machinery

The invention relates to a detection device, and in particular relates to a gearbox detection device. The gearbox detection device comprises an inner rack and an outer rack, wherein a driving motor is fixedly arranged above the outer rack through a fastener; a spline housing is arranged below the driving motor, and a gearbox is connected with the driving motor through the spline housing; a hydraulic jack is arranged on the inner rack; a horizontal supporting plate is arranged above the hydraulic jack; the horizontal supporting plate can be fixed on the outer rack; a guide post is also welded on the inner rack; the guide post penetrates through the horizontal supporting plate; two load rollers are arranged on the horizontal supporting plate; the two load rollers are tangential to a driving wheel; and the driving wheel is positioned below the gearbox.

Owner:ZHEJIANG MAXIMAL FORKELEVATOR

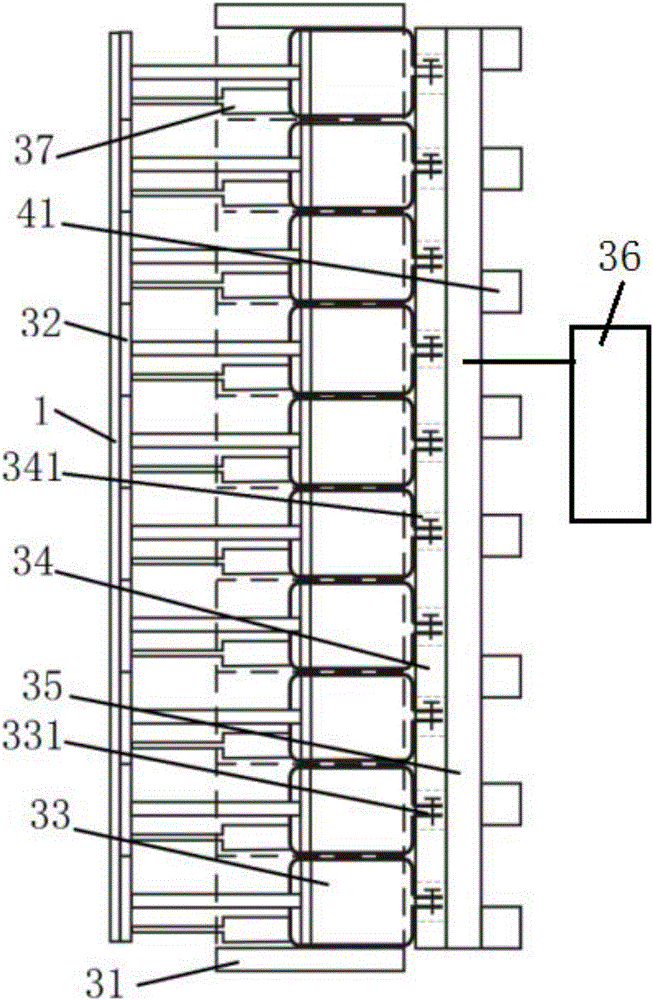

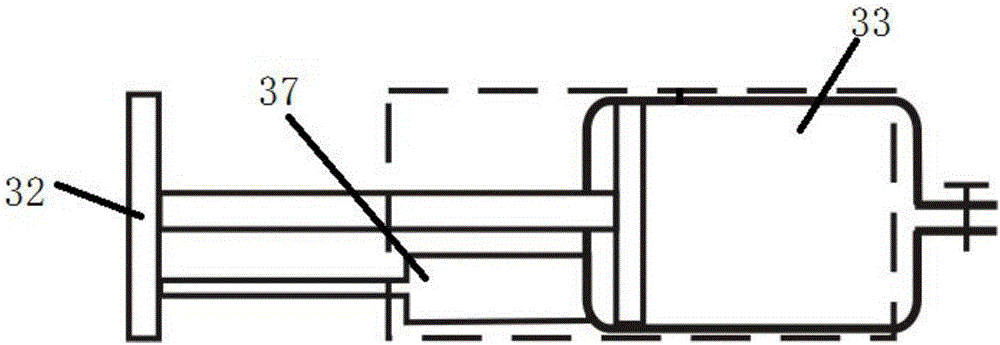

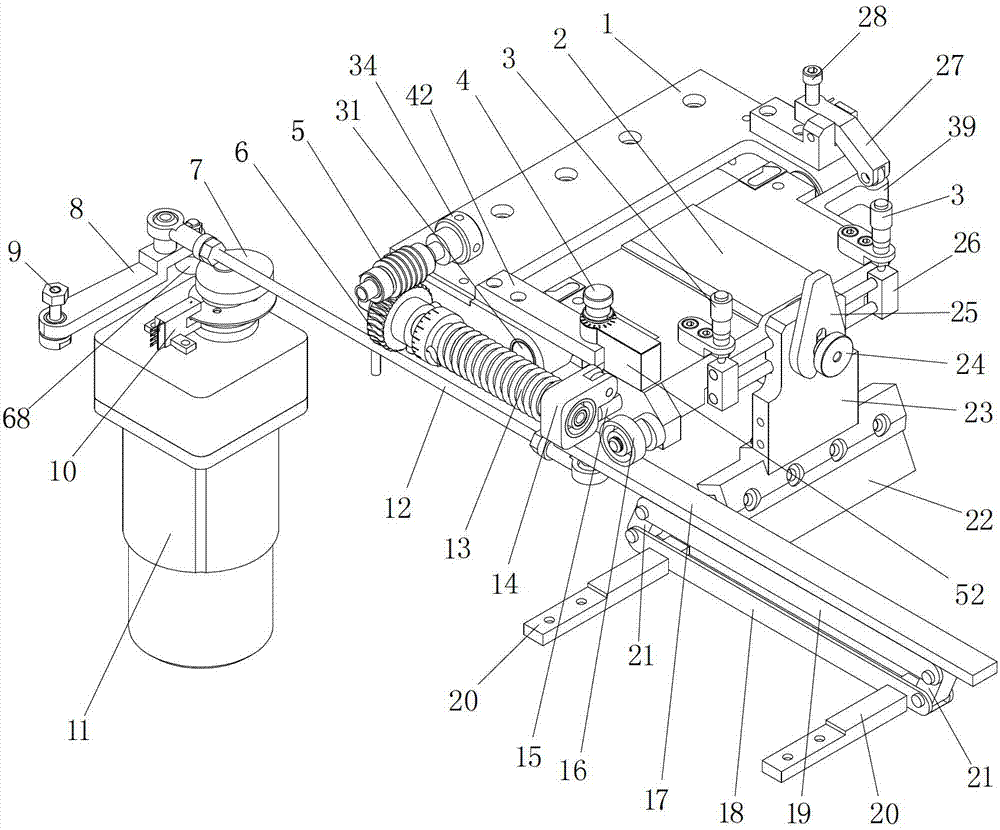

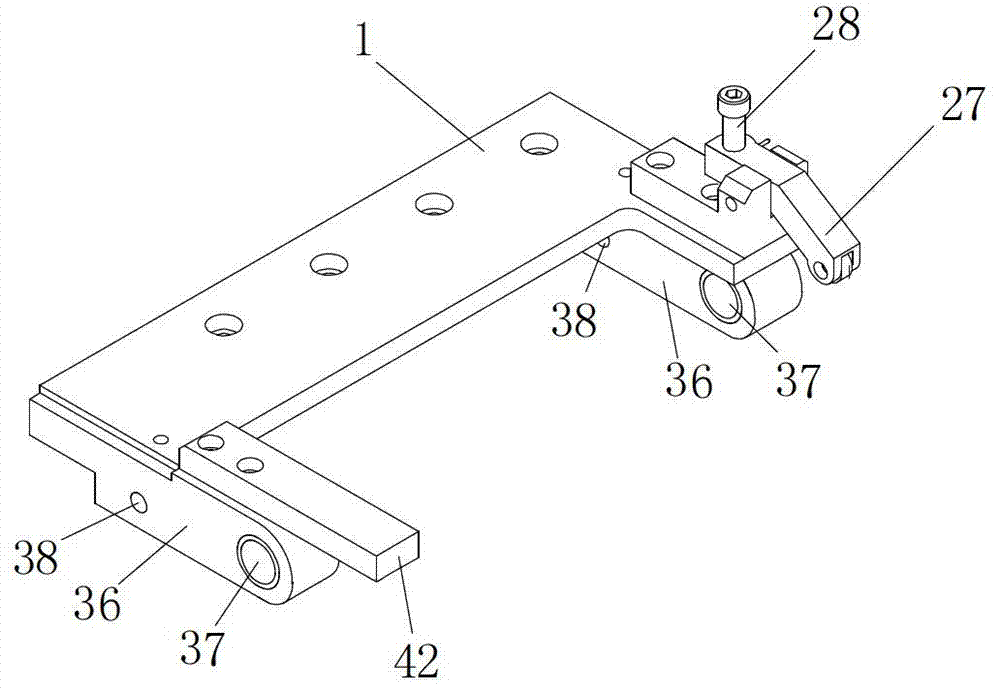

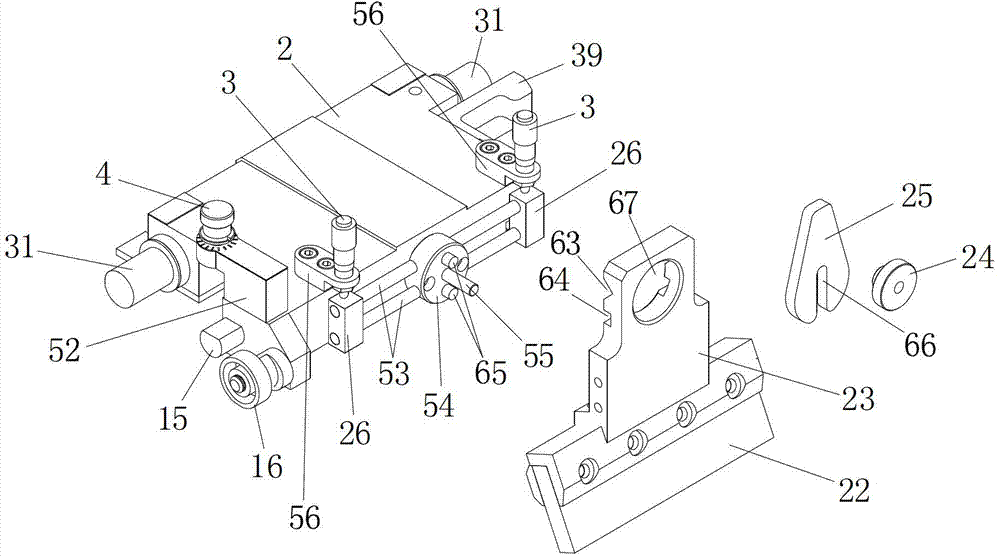

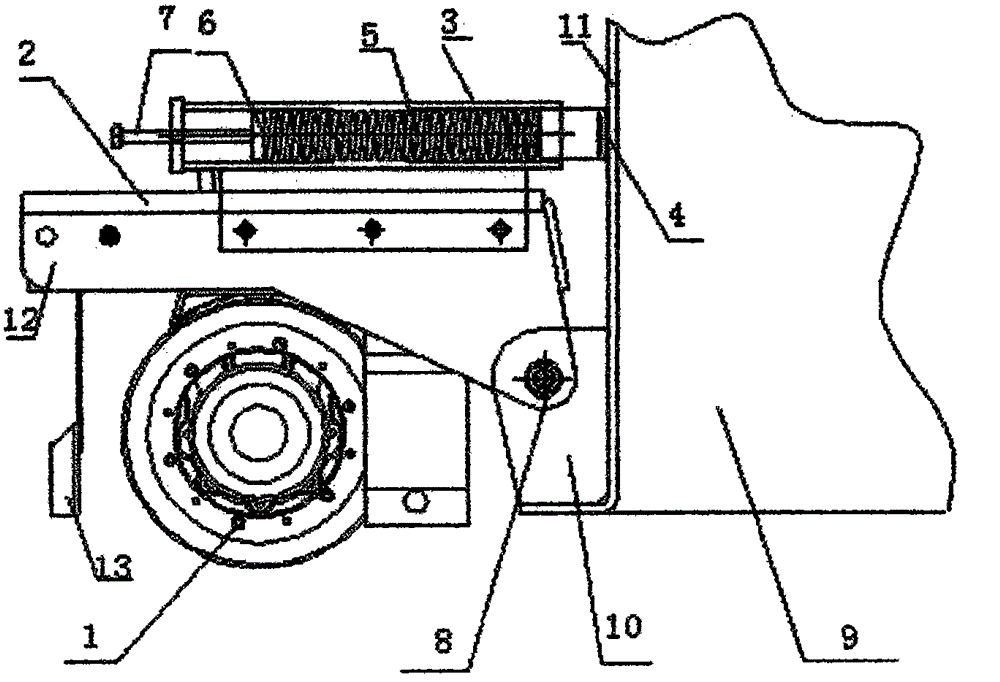

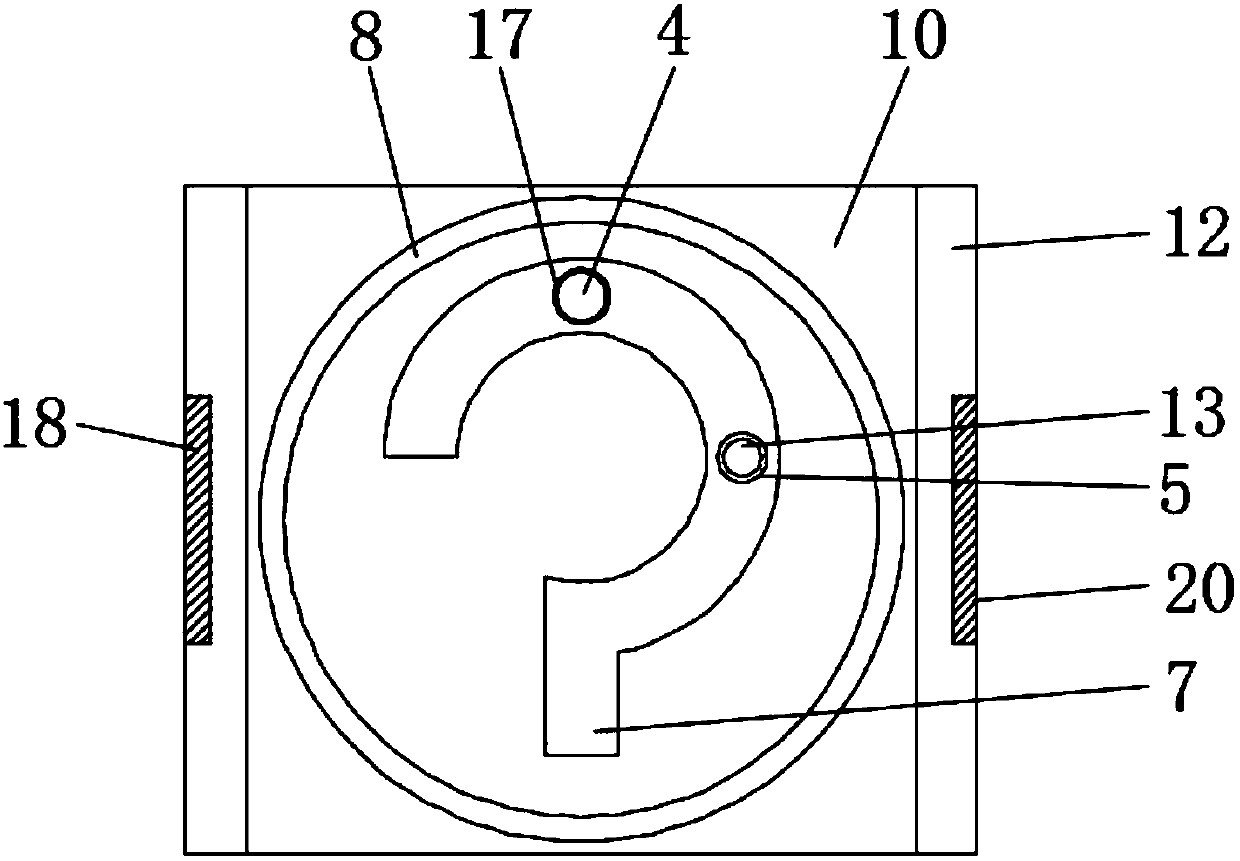

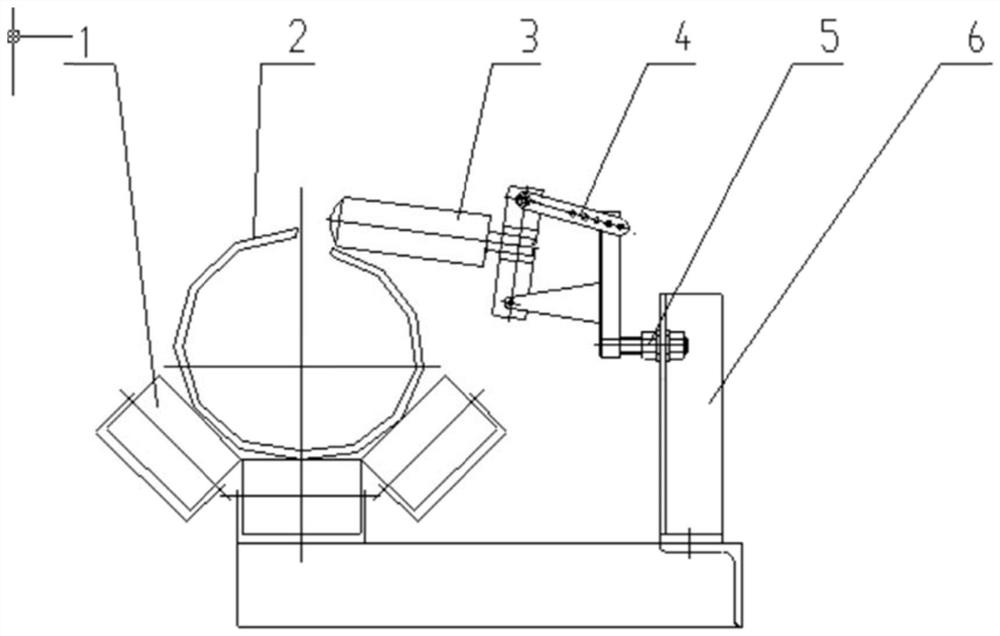

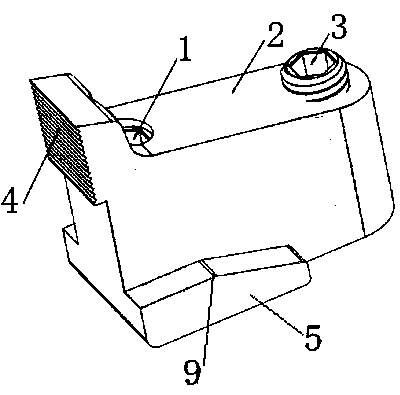

Screen printing machine scraper control mechanism

ActiveCN103072370AStrong controllabilityEasy pressure adjustmentScreen printersPressure transmissionElectric machine

The invention discloses a screen printing machine scraper control mechanism, which comprises a substrate (1), a scraper assembly, a covering ink blade assembly, a scraper lift mechanism and a scraper pressing mechanism. The scraper assembly comprises a scraper swing body (2) and a scraper (22); the covering ink blade assembly comprises a covering ink blade rotating shaft (40), a covering ink blade (32) and two side rods (41); the scraper lift mechanism comprises four-bar links (18, 19 and 21), a slide rail (17), a pull rod (12), an oscillating rod (8), a cam (7) and an electromagnetic brake motor (11); and the scraper pressing mechanism comprises a torsional spring (13), a worm wheel (6), a worm (5) and a pressure transmission seat (14). Two mechanisms are used for lifting motion of the scraper and pressure transmission, a worm and worm wheel mechanism drives the torsional spring for pressure adjustment, the pressure is convenient to adjust, the printing pressure stability is improved, the resistance of the lifting motion of the scraper cannot influence the printing pressure, and the mechanism controlled capacity is improved.

Owner:JIAXING WISDOM ELECTRONICS

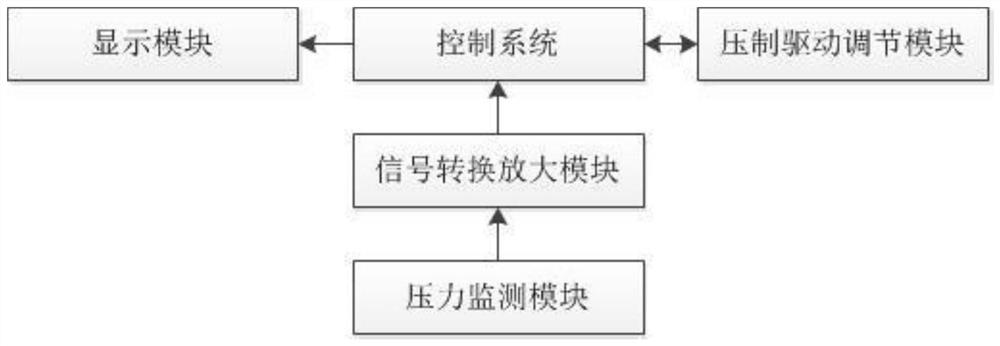

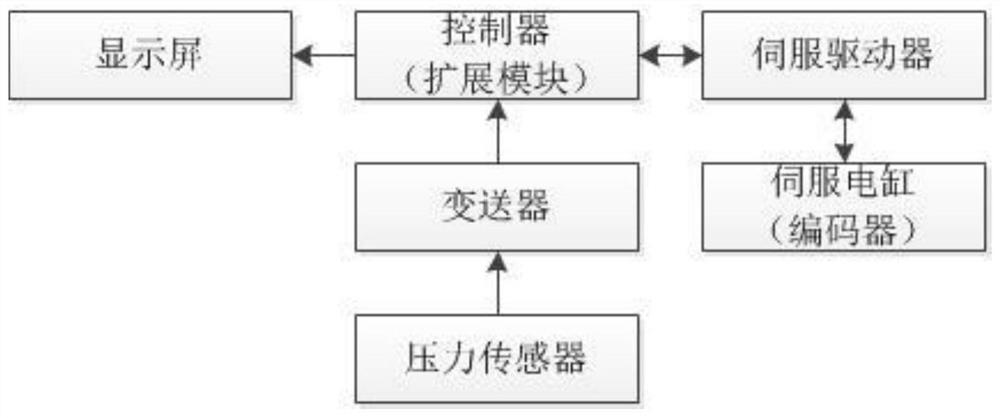

Initiating explosive device pressing system and method

The invention discloses an initiating explosive device pressing system and method, and the system comprises a punch which is used for pressing an initiating explosive device; a pressing driving adjusting mechanism which is connected with the punch; a pressure monitoring module which is used for measuring pressure information of pressing of the initiating explosive device; and a control system which receives the pressure information and controls the operation speed of the pressure driving adjusting mechanism according to the pressure information. The pressure monitoring module is arranged below the initiating explosive device, so that the magnitude of pressing force borne by the initiating explosive device can be obtained in real time and fed back to the control system; the control system controls the servo electric cylinder executing pressing according to pressure information, the operation speed of the servo electric cylinder is adjusted, and different pressing forces are applied to the initiating explosive device, so that the pressing force borne by the initiating explosive device reaches the target pressing force, and accurate pressure control in the pressing process is achieved; and the pressure adjusting process is simple, and automatic integration can be achieved.

Owner:中国兵器装备集团自动化研究所有限公司

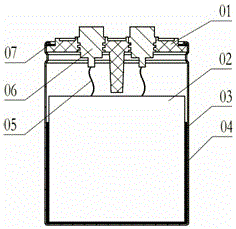

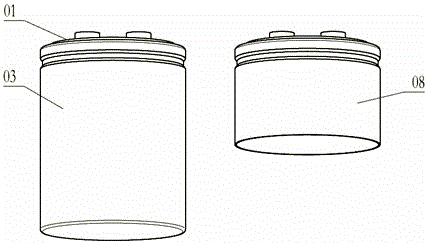

Capacitor seal strength detection device and detection method thereof

ActiveCN105928792AImprove sealingEasy pressure adjustmentMaterial strength using tensile/compressive forcesHydraulic pumpEngineering

The invention discloses a capacitor seal strength detection device and a detection method thereof. The detection device comprises a test piece clamping and sealing mechanism, a hydraulic system, and a pressure detection storage system; wherein the test piece clamping and sealing mechanism comprises a guide shaft, a linear bearing, a frame, a chuck installation plate, a nut, a screw rod, a hand wheel, a snap ring, a three-claw chuck assembly, a jack catch, an oil way connection disc, a rubber sheet, a filling member, and an expansion stopping ring. The hydraulic system comprises a hydraulic pump station, an overflow valve, a pressure reducing valve, a first electromagnetic valve, a throttle valve, a pressure meter, and a second electromagnetic valve. The pressure detection storage system comprises a recorder and a pressure transmitter. The provided detection device uses oil pressure to detect the capacitor seal strength, the pressure adjustment is convenient, the detection results are accurate, and the dynamic data during the detection process can be completely stored for following analysis.

Owner:NANTONG HICON ELECTRONICS

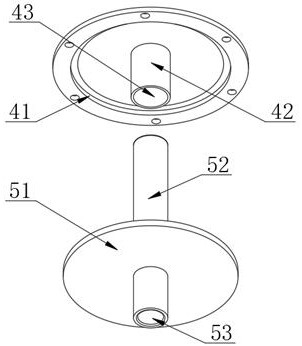

Automatic guided vehicle drive suspension device and automatic guided vehicle

ActiveCN106494257ACompact sizeLarge adjustable rangeSpeed controllerElectric vehicle charging technologyVehicle framePressure regulator

The invention discloses an automatic guided vehicle drive suspension device suspended below a vehicle frame; the automatic guided vehicle drive suspension device comprises a drive wheel set and a mount plate; the drive wheel set is fixed below the mount plate; two side edges of the mount plate are respectively fixedly provided with a side guard plate; the lower side angle of the side guard plate is hinged to the vehicle frame; a pressure regulator is transversely fixed on the mount plate, and can adjust the pressure applied to the vehicle frame. The invention also discloses an automatic guided vehicle having the drive suspension device; the pressure of the drive wheel set can be adjusted, thus effectively utilizing the vehicle frame chassis space.

Owner:GUANGZHOU JINGYUAN MECHANO ELECTRIC EQUIP

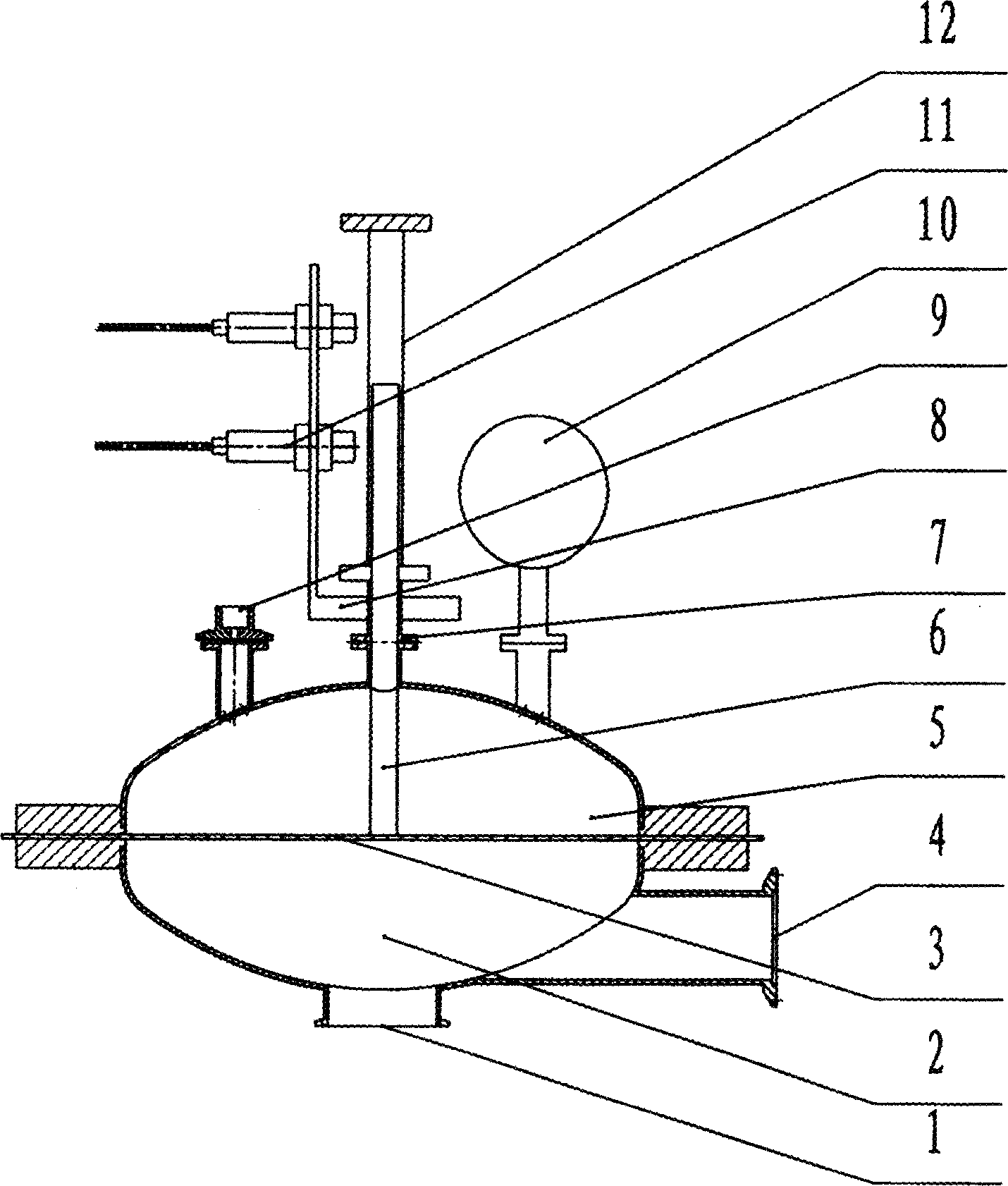

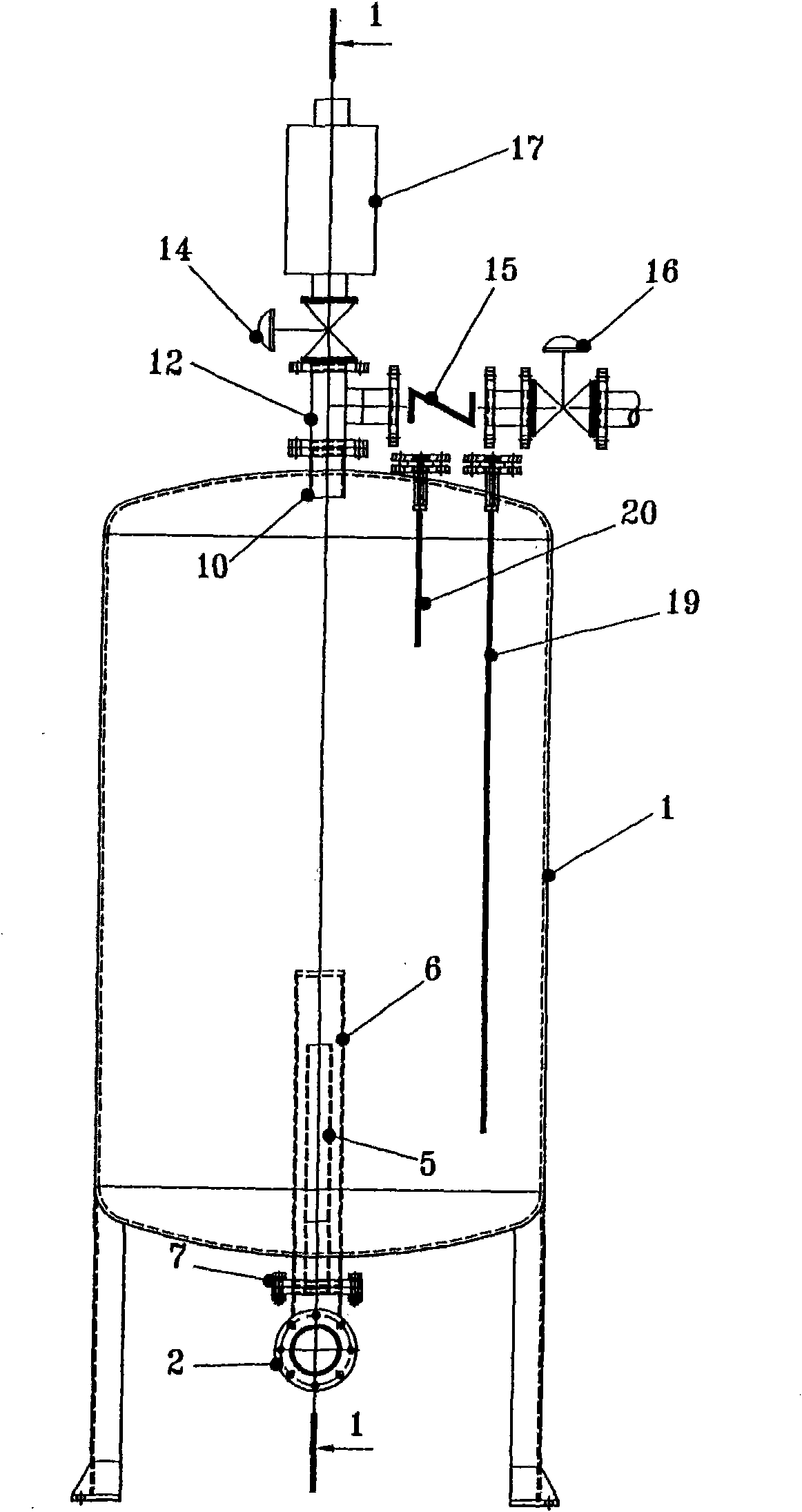

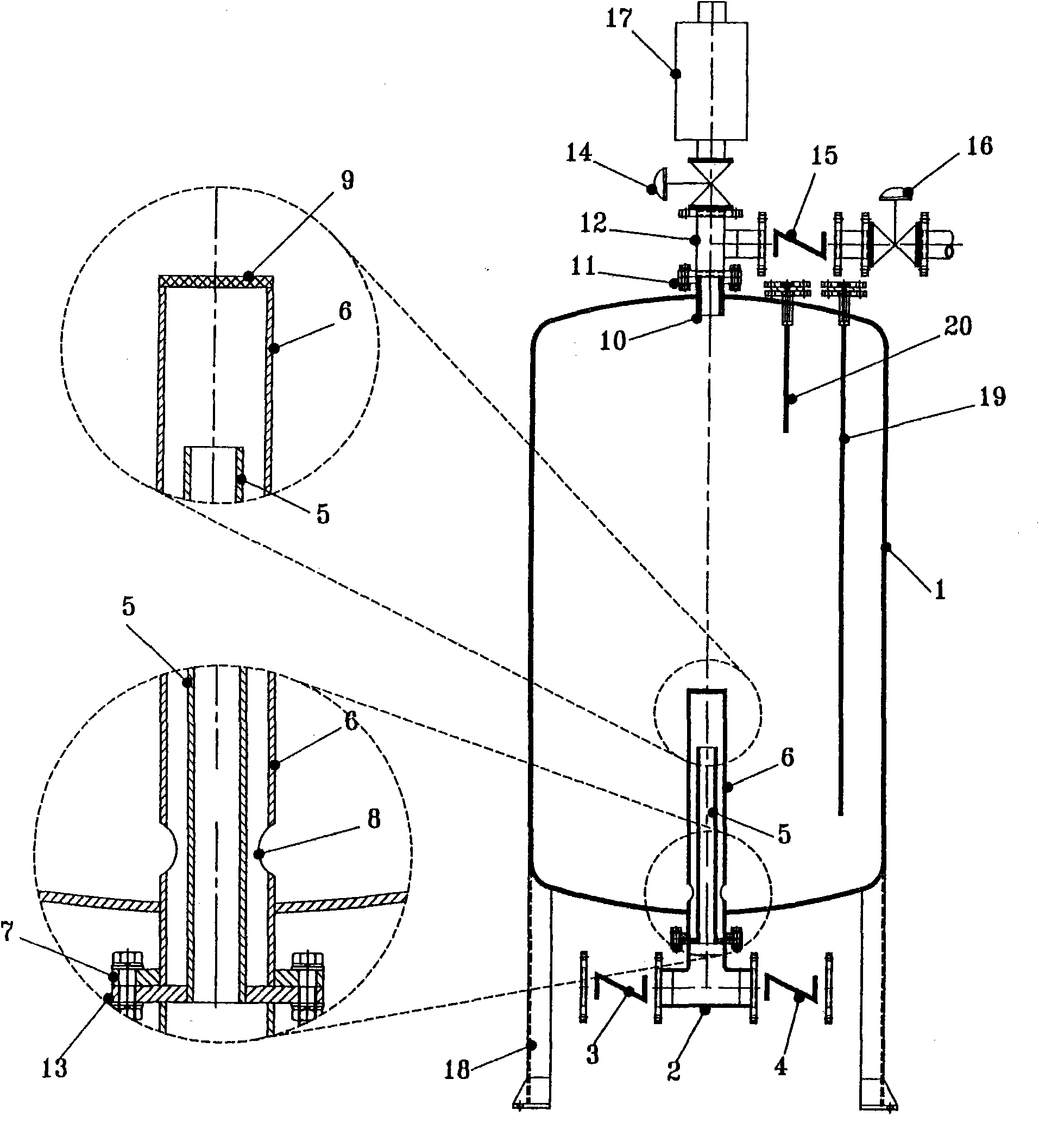

Pressure balancing tank

InactiveCN1868858AEasy pressure adjustmentLarge adjustment rangeLiquid bottlingEngineeringPressure balance

A pressure balanced tank with stable pouring pressure for the liquid contained in it features that a buffer membrane is used to divide the internal cavity of tank body into an upper gas cavity with gas inlet and outlet having relative gas valves, and a lower liquid cavity with liquid inlet and outlet, and a membrane position indicating column with a lower end in contact with said buffer membrane passes through said gas cavity. It can quickly compensate the pressure loss caused by pouring liquid.

Owner:SHINVA MEDICAL INSTR CO LTD

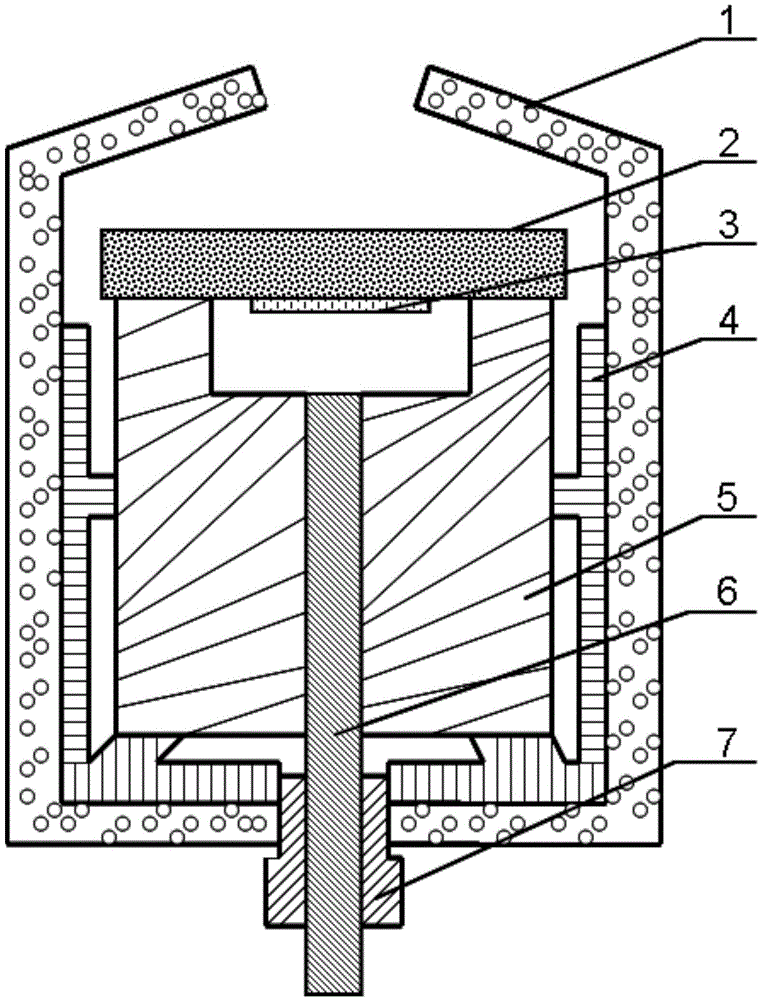

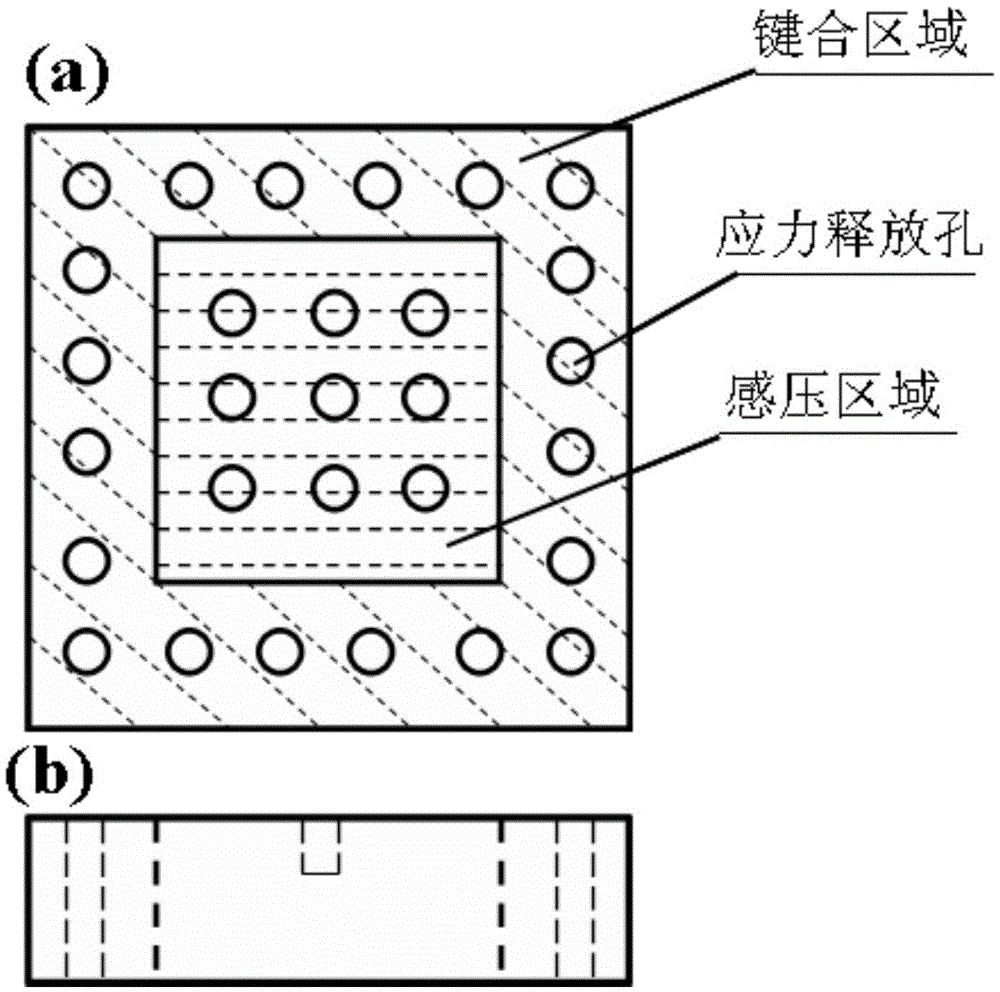

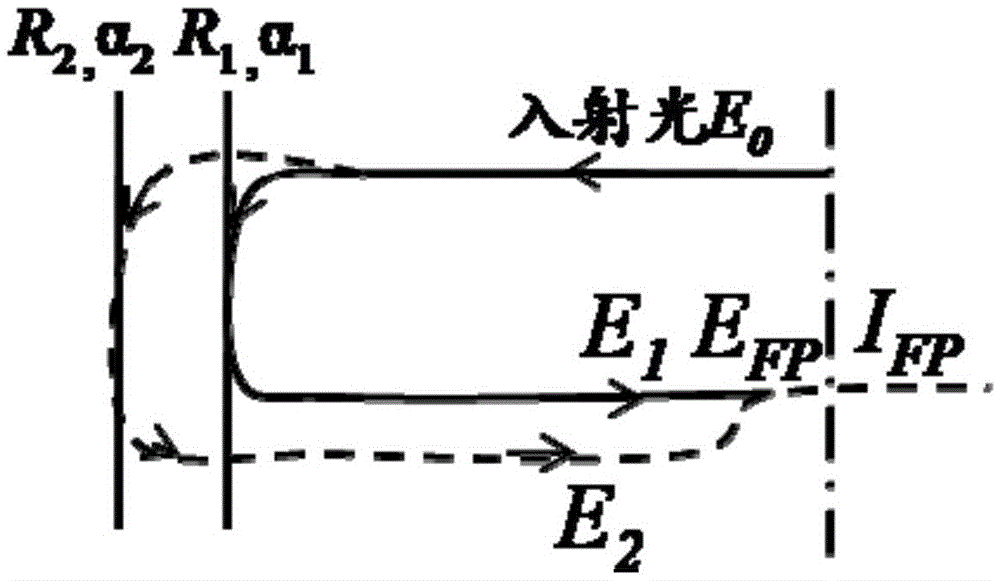

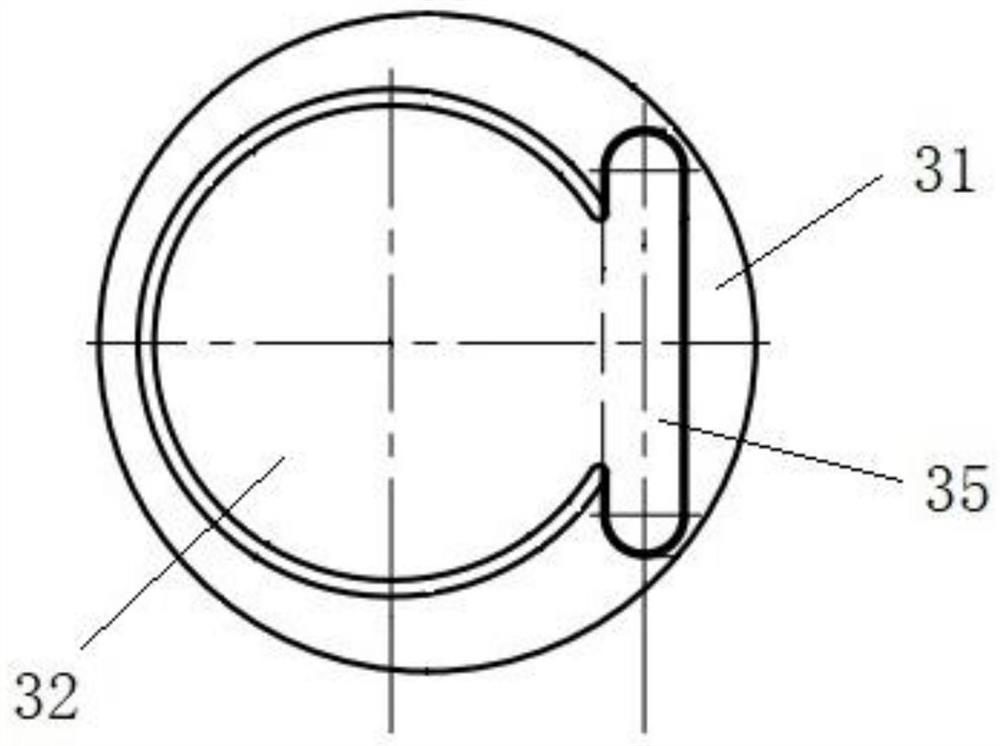

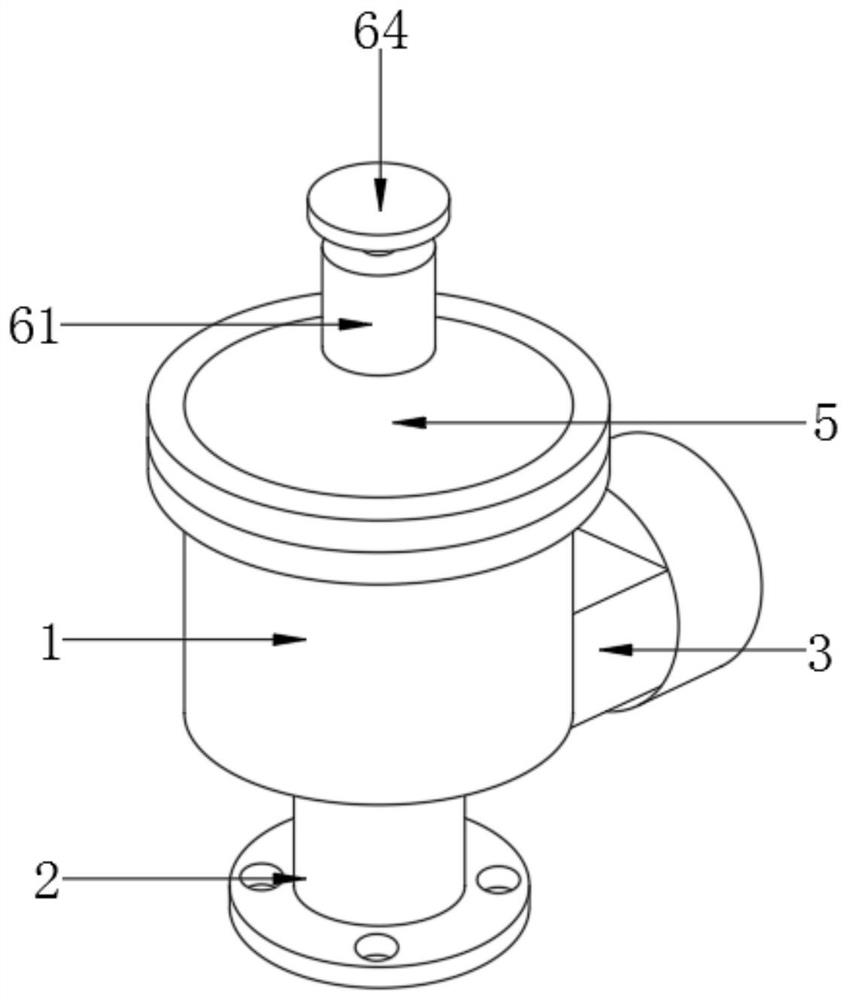

Integrated fiber F-P chamber pressure sensor

PendingCN105606277AEasy pressure adjustmentHigh precisionForce measurement by measuring optical property variationFiberComposite media

The invention discloses an integrated fiber F-P chamber pressure sensor. The integrated fiber F-P chamber pressure sensor comprises a barrel-like packaging casing (1), a pressure diaphragm (2) arranged in a packaging casing cylinder, a composite medium film (3) fixedly connected with the bottom end of the pressure diaphragm, and a fiber (6) which is level with a bottom plane of an end portion groove of an insertion core (5) and penetrates through the insertion core to stretch out of the bottom portion of the packaging casing, wherein the composite medium film (3) is just opposite to the top end groove of the insertion core axially, the pressure diaphragm (2) provided with a stress release hole structure is used for packaging the insertion core groove through the bonding technology to form an F-P resonant chamber, the insertion core and the pressure diaphragm are fixedly connected to form an integrated structure, and a circumferential connection fixedly-connected member (4) is assembled on the cylinder of the packaging casing (1) in an integrated mode. According to the integrated fiber F-P chamber pressure sensor, the insertion core provided with the top end groove and the pressure diaphragm are combined with the integrated F-P chamber through the bonding technology, subsequent laser welding and adhesive gluing technologies are saved, the thermal internal stress of a system is further reduced, and performance of the F-P chamber pressure sensor is improved.

Owner:CHENGDU KAITIAN ELECTRONICS

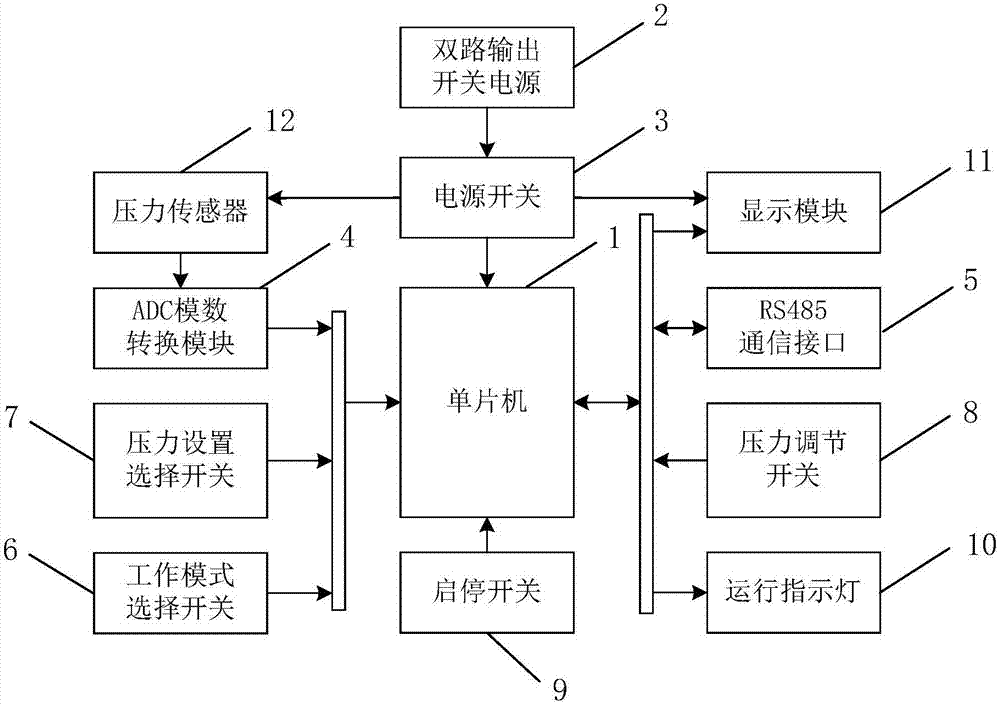

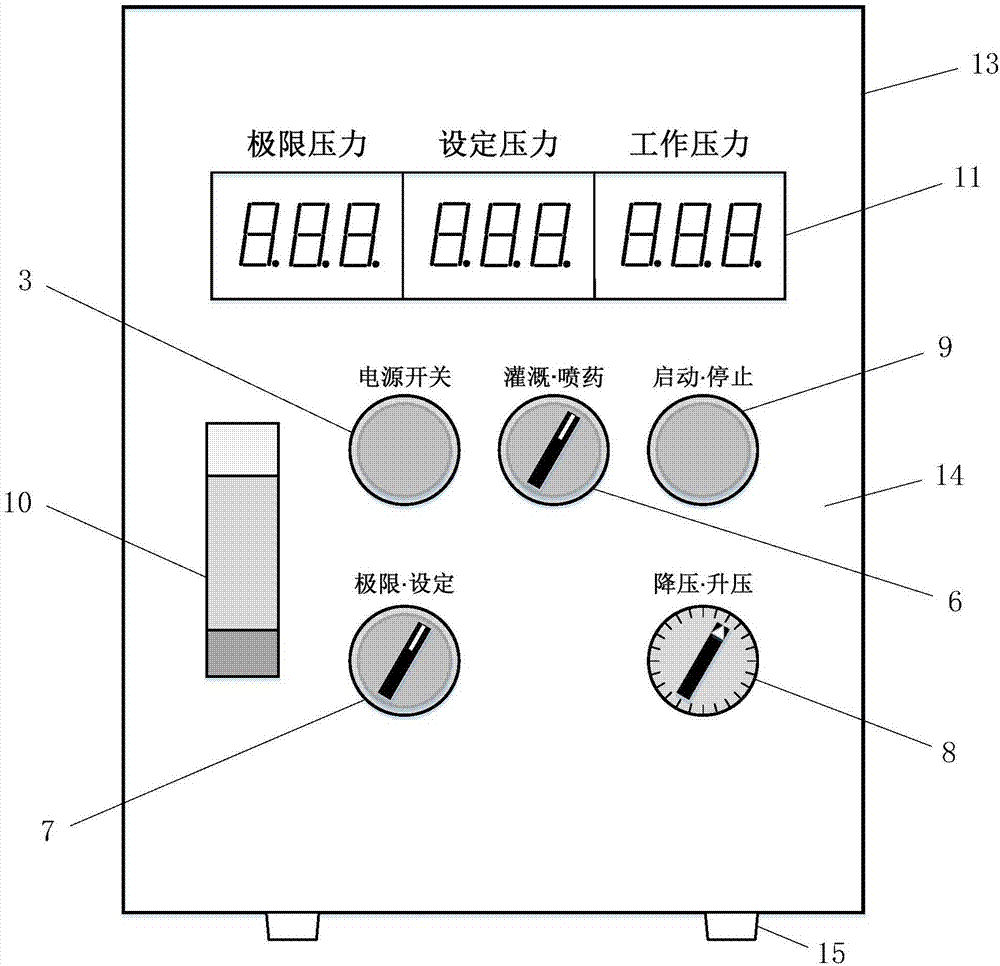

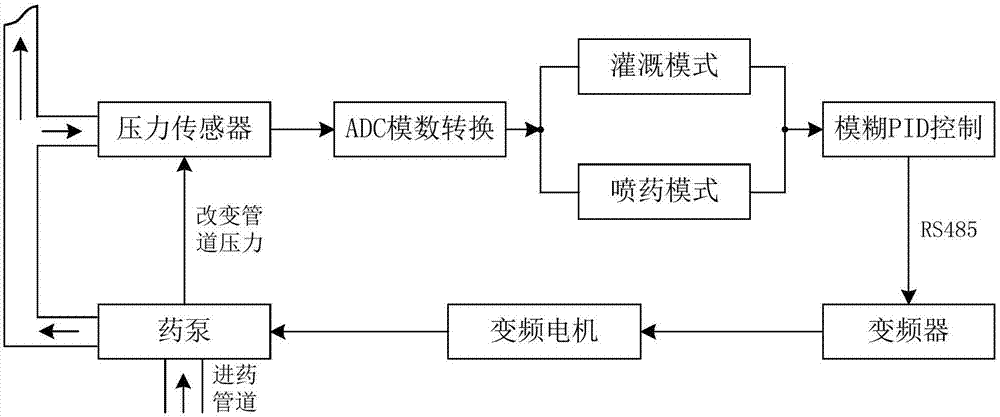

Pipeline liquid pressure controller and control method thereof

ActiveCN107272759AWork reliablyLong communication distanceFluid pressure control using electric meansMicrocontrollerFrequency changer

The invention discloses a pipeline liquid pressure controller and a control method thereof. The controller comprises a single-chip microcomputer (SCM), a dual output switching power supply, a power supply switch, an ADC analog-digital conversion module, an RS485 communication interface, a working mode selection switch, a pressure setting selection switch, a pressure adjustment switch, a start-stop switch, an operation indicator light and a display module. The SCM is connected with a frequency converter through the RS485 communication interface. The frequency converter is connected with a variable frequency motor. The variable frequency motor controls the rotational speed of a medicine pump. A water outlet of the medicine pump is connected with a pressure sensor and a liquor pipeline separately. The pressure sensor is used to detect the pressure of the liquor in the liquor pipeline. An input end of the dual output switching power supply is connected with a single-phase power supply, and an output end of the dual output switching power supply is connected with the power supply switch. The power supply switch is connected with the pressure sensor and the SCM separately. The pressure sensor is connected with the SCM through the ADC analog-digital conversion module. According to the invention, the RS485 communication interface is used to control the work of the frequency converter, the communication distance is farther, the anti-interference ability is stronger, and the controller works more reliably.

Owner:SOUTH CHINA AGRI UNIV

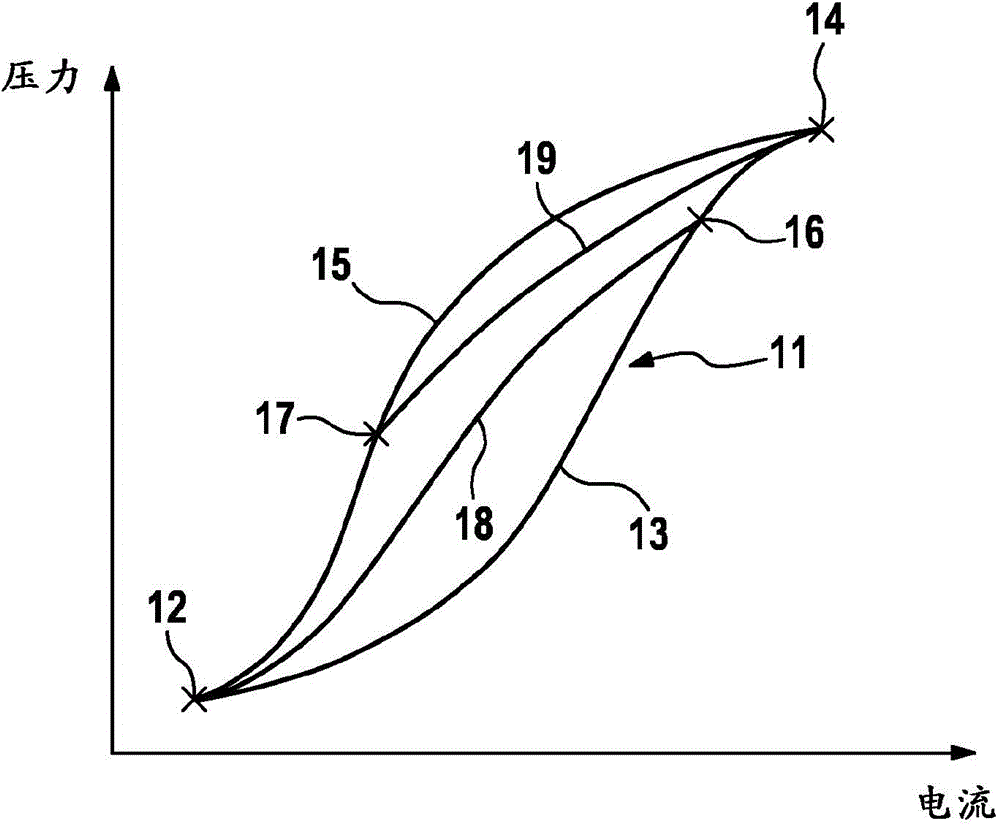

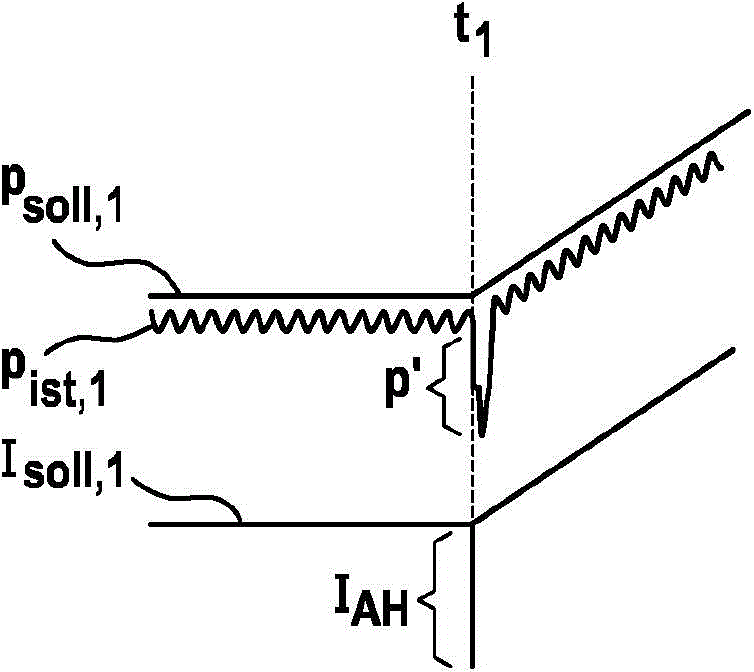

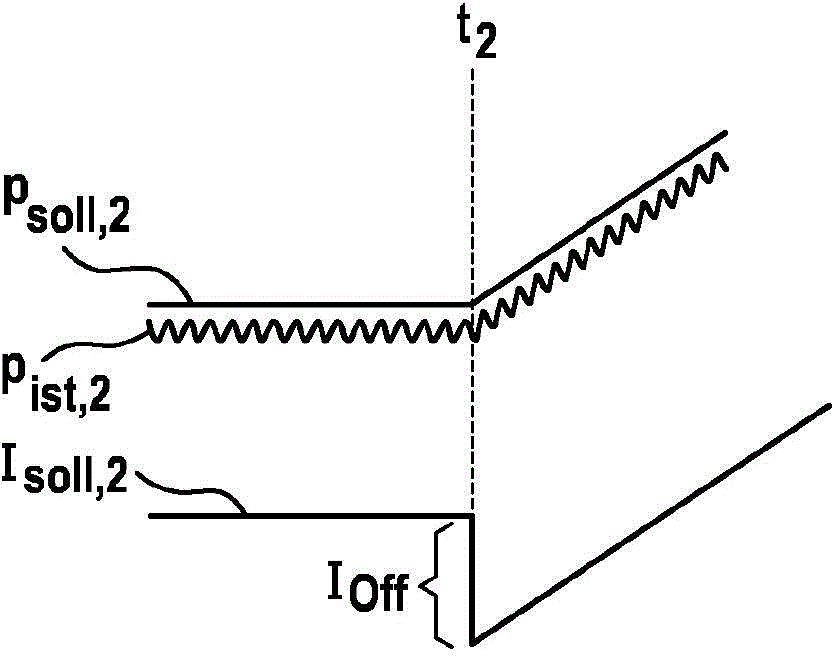

Switchover method for a solenoid valve operated in analogized form, electrohydraulic brake system, and use of the electrohydraulic brake system

InactiveCN104583033AEffective and quick setupEffective and fast pressure regulationOperating means/releasing devices for valvesBraking systemsElectricityHysteresis

The invention relates to a switchover method for a solenoid valve (52, 42), operated in analogized form, in an electrohydraulic brake system (30), in which method the solenoid valve (52, 42) can assume a closed position, an open position and a multiplicity of intermediate positions in accordance with electrical actuation or regulation, and wherein the actuation or regulation is performed as a function of a known current-pressure characteristic curve of the solenoid valve (52, 42). The switchover method according to the invention is characterized in that, upon a switchover of the solenoid valve (52, 42), a pressure-dependent and / or current-dependent magnetic hysteresis characteristic of the solenoid valve (52, 42) is compensated directly without prior modification of the present hysteresis characteristic. The invention also relates to an electrohydraulic brake system (30) and the use of the brake system (30).

Owner:CONTINENTAL TEVES AG & CO OHG

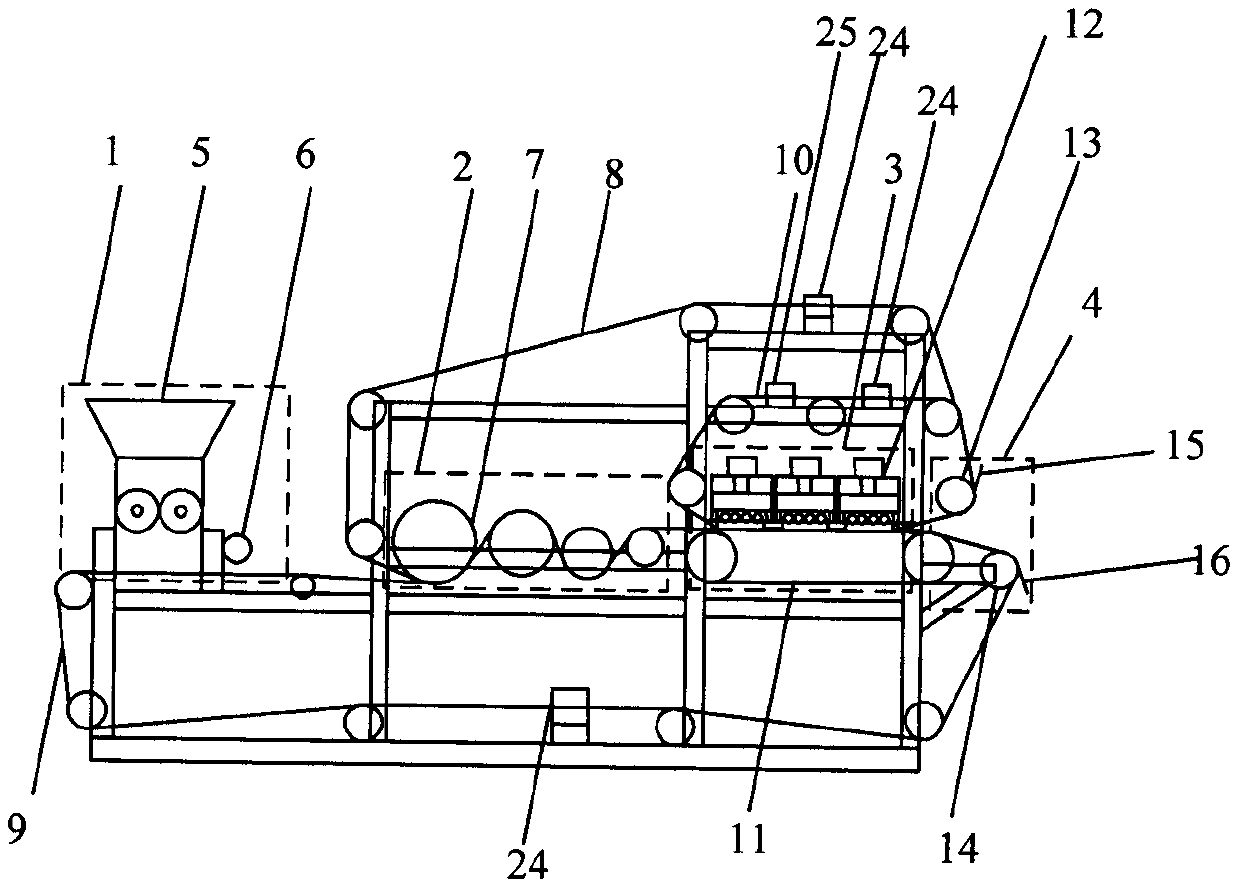

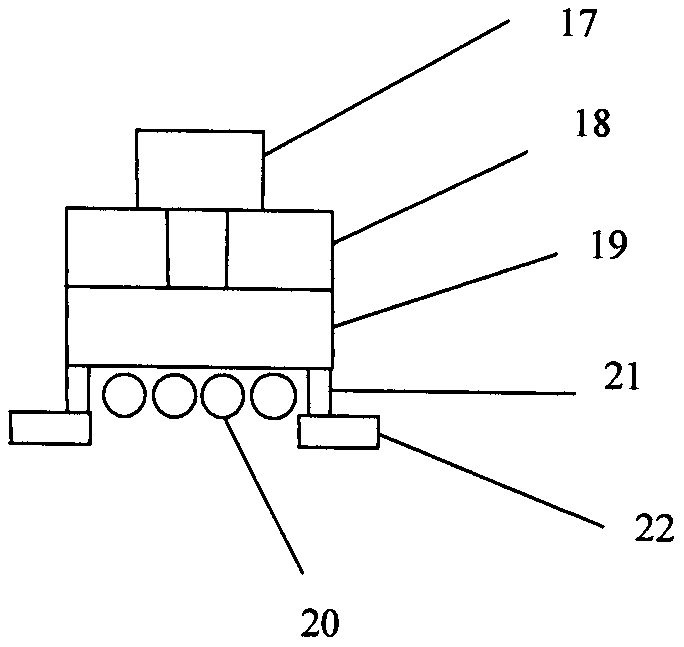

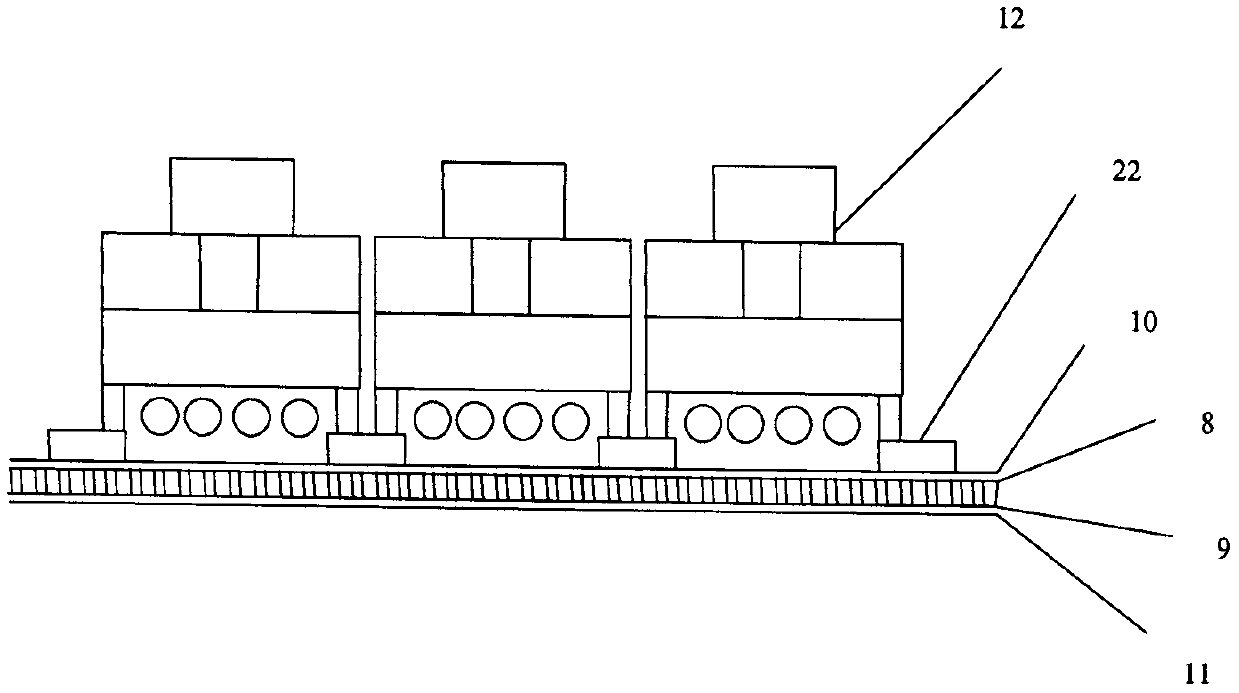

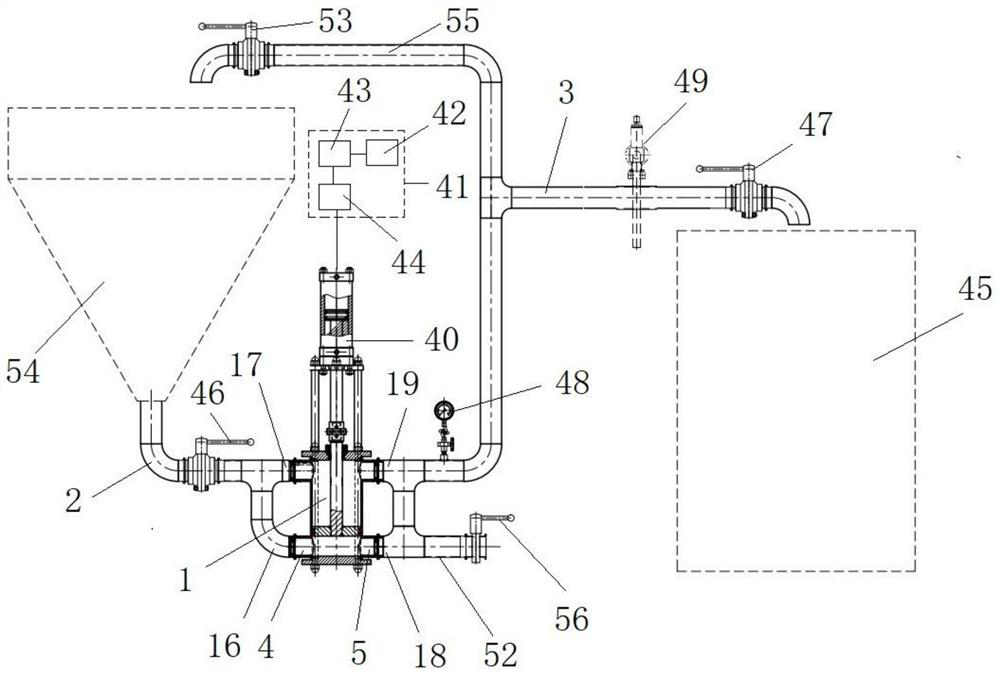

Continuous deep dewatering equipment

PendingCN110117147AAdaptableReasonable and flexible way of stepped pressurizationSludge treatmentSewage treatmentDistributor

The invention relates to continuous deep dewatering equipment. The equipment is mainly applied to situations, needing solid-liquid separation, such as sewage treatment plants, paper mills, chemical plants and pharmaceutical factories and particularly applied to continuous deep dewatering for sludge. The equipment is mainly composed of a distribution area, a pre-pressing area, a squeezing area anda discharging area, the distribution area comprises a distributor and an evening roller, and the pre-pressing area is composed of an upper filter screen, a lower filter screen and a dewatering roller;the squeezing area is composed of an upper filter screen, a lower filter screen, an upper liner band, a lower liner band and a pressurization assembly which are operated circularly, the upper and lower filter screens and the upper and lower liner bands overlap in the squeezing area to form a squeezing face similar to a plane, and the pressurization assembly vertically acts on the liner bands andprovides squeezing pressure of 10-60 kilograms; the discharging area is composed of discharging rollers and scrapers, and a mud cake is continuously and automatically discharged under the function ofthe filter screens and the scrapers. After squeezing, the water content of the mud cake is lower than 50%, and the equipment is automatically and continuously operated.

Owner:吕文彬

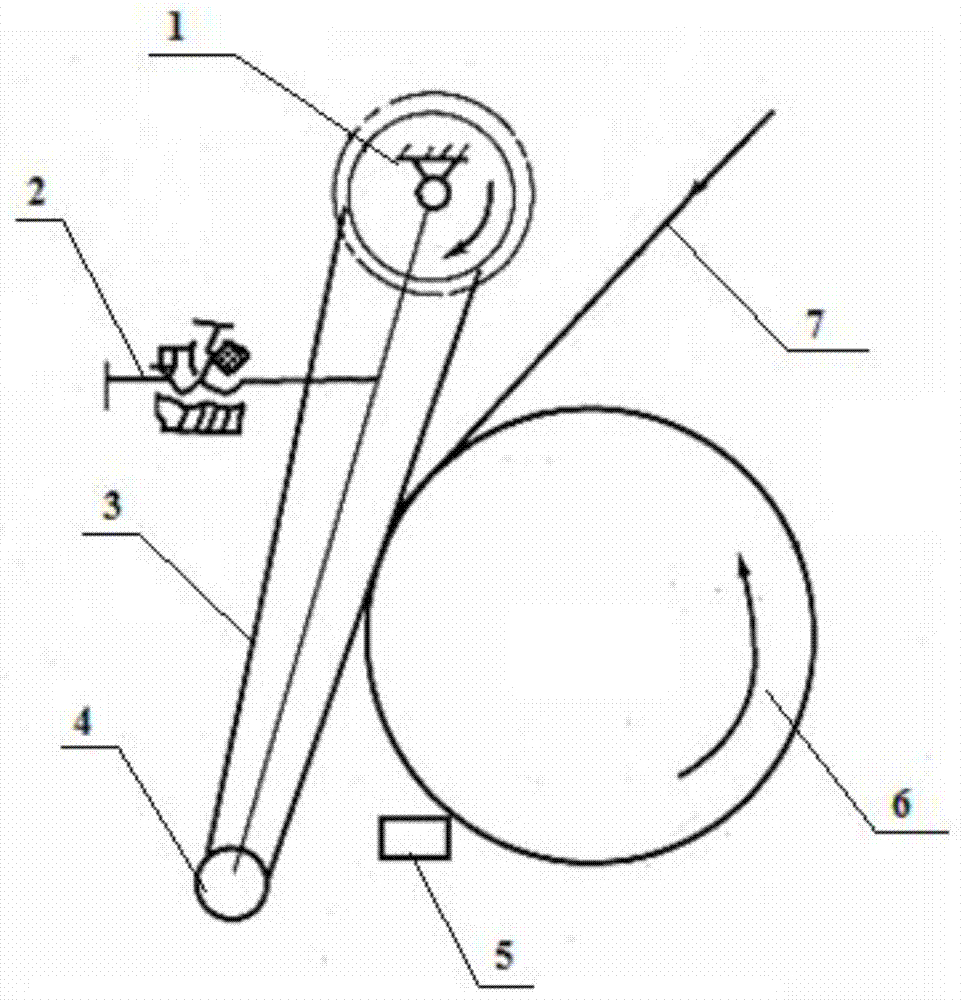

Dedusting and rewinding device

The invention discloses a dedusting and rewinding device which comprises a rewinding roller, wherein the rewinding roller is driven by a motor to rewind a paper belt, one end of a belt connected with the motor is fixed on a pulley, the belt is in contact with the surface of the rewinding roller, and a dedusting device is arranged below the rewinding roller. According to the invention, the motor is used to drive the rewinding roller to rewind the paper belt, the rewinding is stable, the pressure is conveniently regulated, and the paper belt is guaranteed to be smoothly rewound, and the dedusting and rewinding device is provided with the dedusting device to remove the dust adhered to the surface of the paper belt, so that the secondary dust pollution caused by the dust floating in the air is avoided, and the good health of staff is protected.

Owner:ANHUI PRINTING MECHANICAL & ELECTRICAL

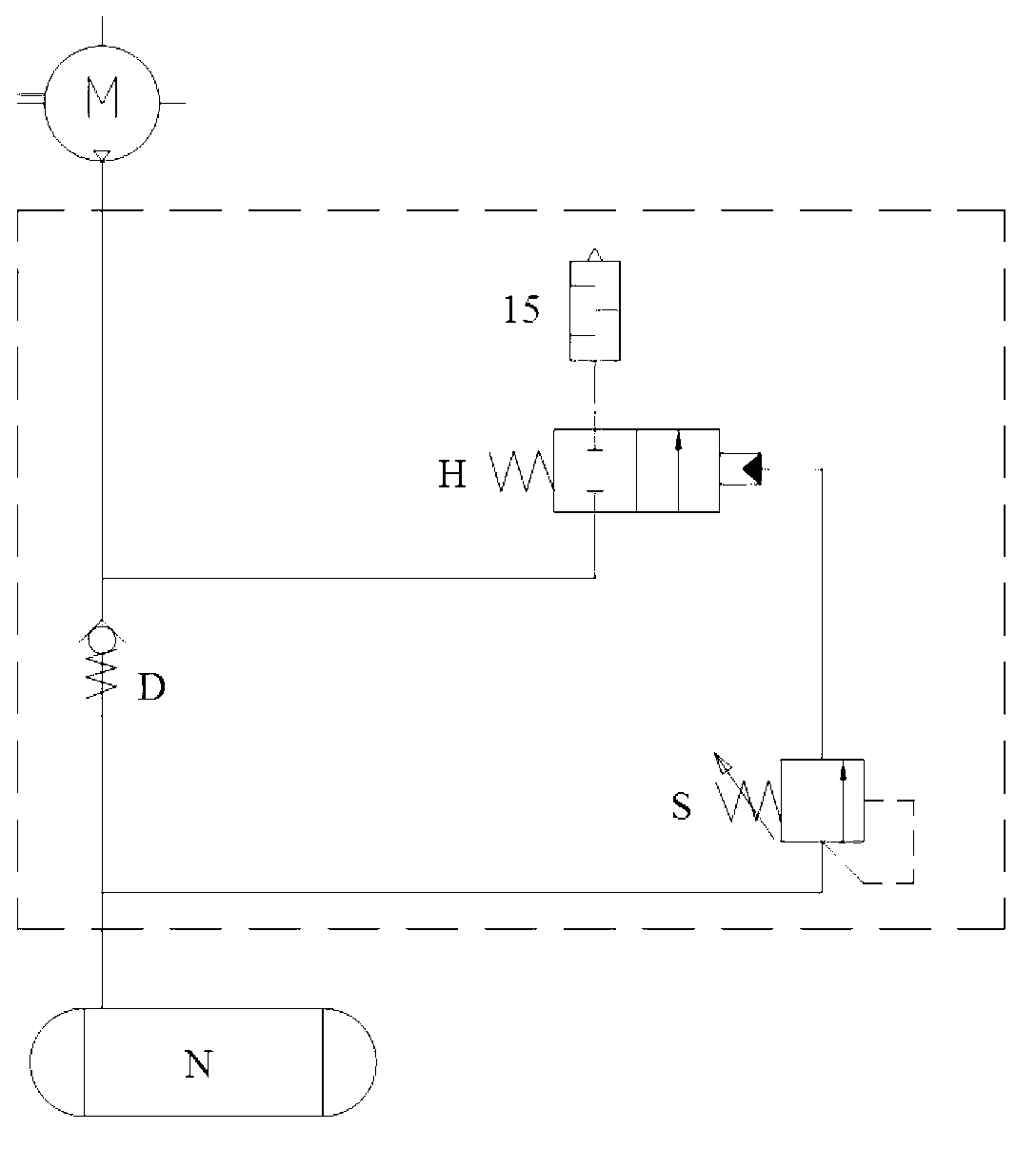

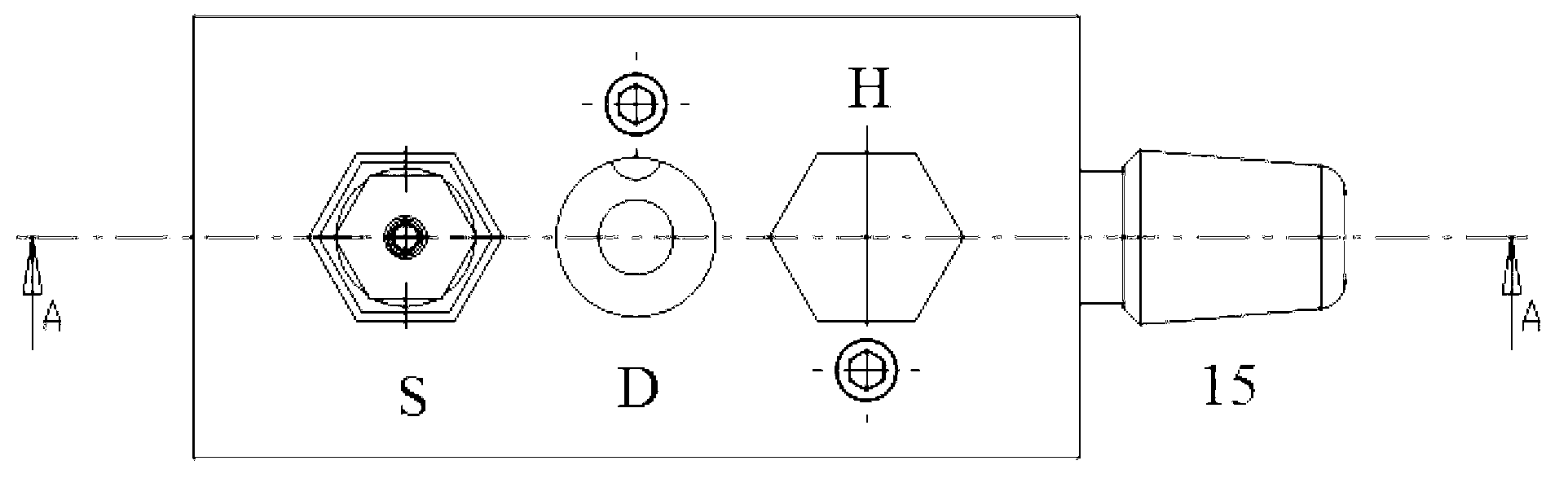

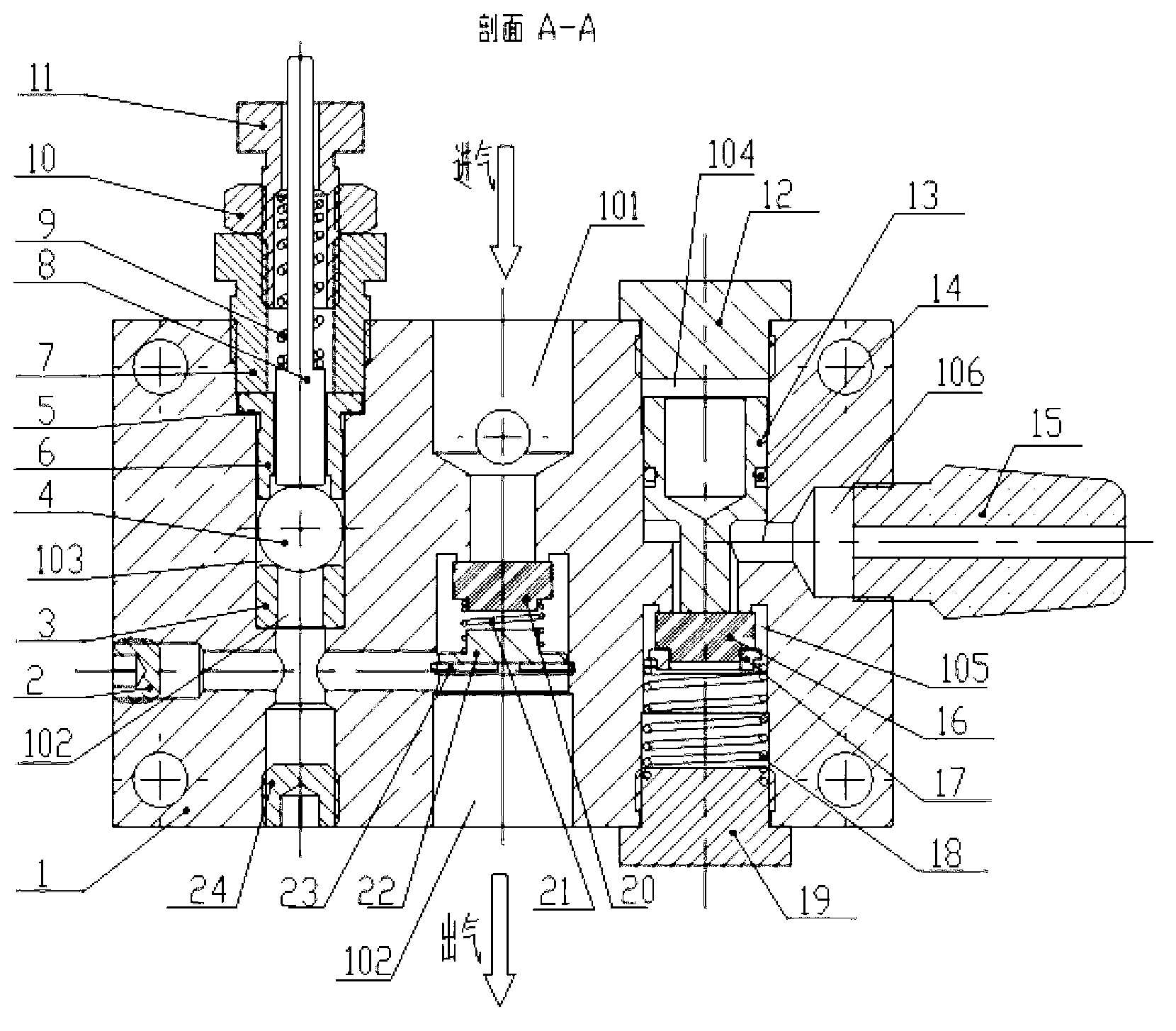

Unloading one-way valve applied to back flushing and dust cleaning system of dust collector

ActiveCN103016311ASimple structureEasy to processPositive displacement pump componentsPositive-displacement liquid enginesWorking pressureEngineering

The invention relates to an unloading one-way valve applied to a back flushing and dust cleaning system of a dust collector. The unloading one-way valve comprises a valve body as well as a one-way valve, a sequence valve and a reversing valve which are integrated on the valve body, wherein one end of the one-way valve is connected with an air compressor through an air intake pipe, and the other end of the one-way valve is connected with an air storage tank through an air exhaust pipe; the sequence valve is respectively communicated with the one-way valve and the steering valve; the reversing valve is connected with a silencer; when the unloading one-way valve works, the sequence valve sets pressure, namely the working pressure required for compressed air of the air storage tank; and when the compressed air output by the air compressor enables the compressed air in the air storage tank to reach the working pressure, the sequence valve is opened, the reversing valve is started by air flow, so that air is exhausted directly by the silencer, and air inflation to the air storage tank is stopped, and at the moment, the one-way valve is closed. Compared with the prior art, the unloading one-way valve disclosed by the invention has the advantages of simple structure, easy machining, high integration degree, small size, reliability, convenience for maintenance and the like.

Owner:HUSQVARNA AB

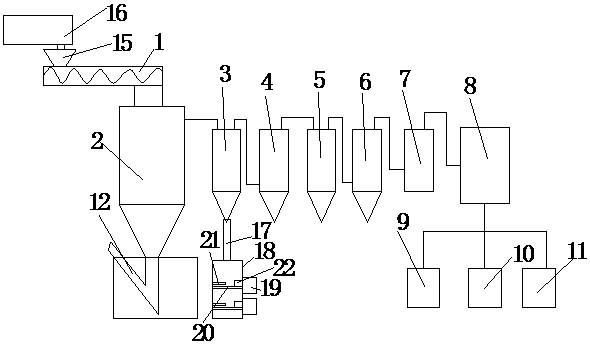

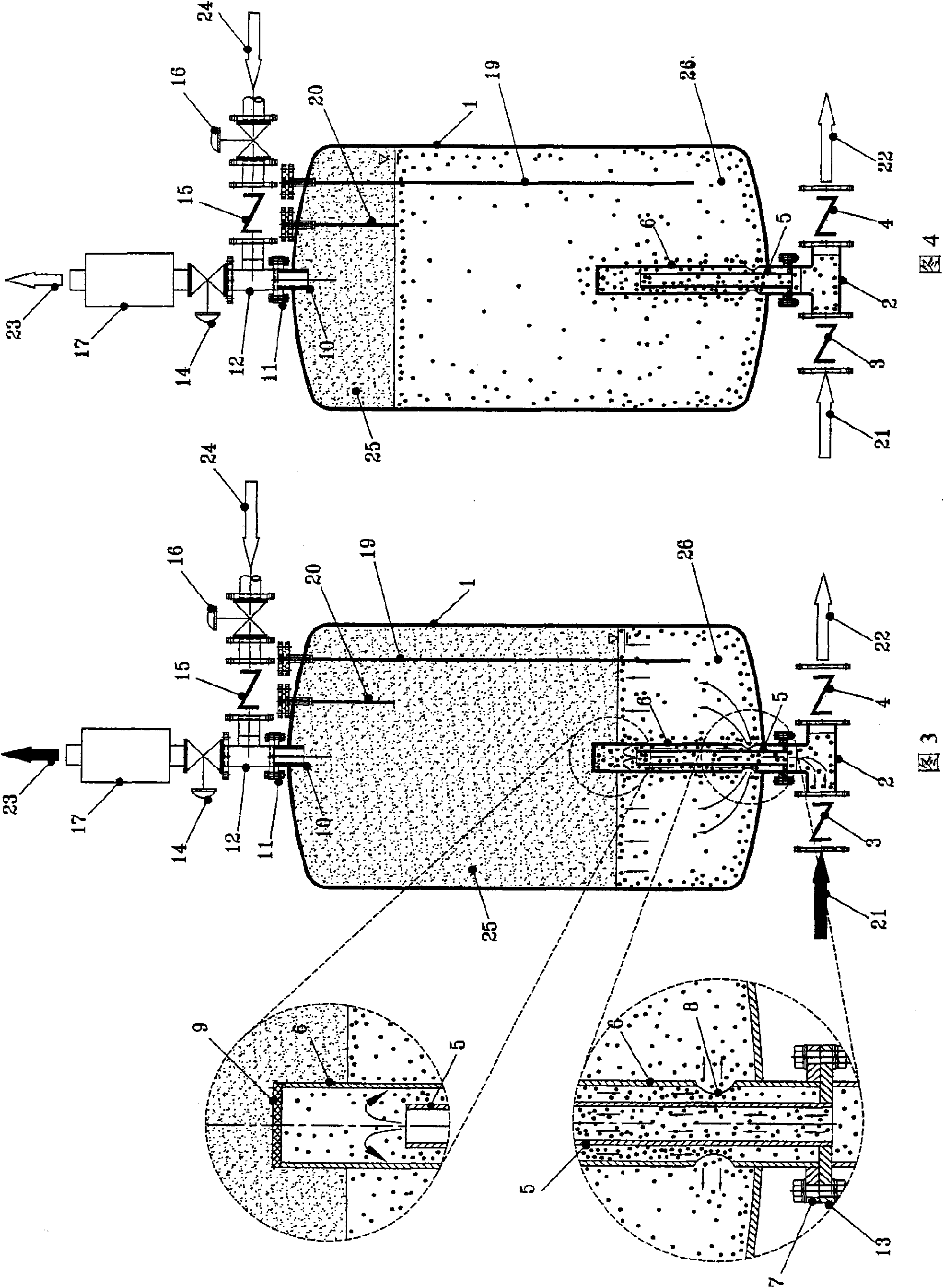

Biomass gasification power generation apparatus

InactiveCN108048134ASimple structureReasonable designGasification processes detailsCombustible gas productionProcess engineeringBiomass gasifier

The invention discloses a biomass gasification power generation apparatus, which comprises a screw feeder, a biomass gasification furnace, a cyclone dust removing device, a filter, a condenser, a hydrocyclone separator, a balance tank and a gas storage tank, wherein the screw feeder, the biomass gasification furnace, the cyclone dust removing device, the filter, the condenser, the hydrocyclone separator, the balance tank and the gas storage tank are sequentially connected, the gas storage tank is connected to a gas-fired boiler or a gas-fired generator set, or is directly connected to a gas supply user, an automatic residue discharge system is arranged below the biomass gasification furnace, a dry ash collection device is arranged below the cyclone dust removing device, a buffer membrane sheet is arranged inside the balance tank, a gas cavity is arranged above the buffer membrane sheet, a liquid cavity is arranged below the buffer membrane sheet, and the liquid inlet position of the liquid cavity is provided with a liquid pressure adjustment device. According to the present invention, various components are sequentially connected, the structure is simple and reasonable, and the balance tank is additionally arranged in front of the gas storage tank to balance the gas pressure in the gas storage tank, such that the gas input and output is ensured.

Owner:唐勇成

Low-wear friction method and device for delivering raw materials by compressed air

The invention relates to a low-wear friction device for delivering raw materials by compressed air, belonging to machinery and being a positive displacement pump. Firstly, the invention is provided with no runner assembly, a liquid raw material is pressurized and sent to the point of use by compressed air by a closed container, as the liquid raw material has slight friction with slot wall and the rotating element contacted with the liquid raw material is only provided with a material feeding check valve and a material discharging check valve, the maintenance of parts is easy and convenient. Secondly, the outlet pressure of the pump can be adjusted simply, the outlet pump lift of the material is equal to the pressure of the compressed air in a closed slot body, the pressure of the compressed air can be adjusted by an air compressor arbitrarily, the procedure is simple and the pressure can be changed without the need of other extra sensors. Thirdly, the materials of the invention features wide range and good practicability, namely, the raw materials capable of flowing into the closed container of the air pump can be sent to the point of use by compressed air, the raw material being used has wide range. And finally, the invention has simple structure and can be manufactured by ordinary materials, thus no special wear material is needed; most of the parts are universal products and can be obtained easily, therefore the interchangeability is high, the maintenance is easy and the manufacturing cost is low.

Owner:张日养

Air-pressure type percolation instrument for municipal solid waste landfill and use method of percolation instrument

ActiveCN106908366ACompact structureEasy and flexible operationPermeability/surface area analysisInlet valveSlurry

The invention discloses an air-pressure type percolation instrument for municipal solid waste landfill and a use method of the percolation instrument and belongs to the field of environmental geotechnical engineering. The percolation instrument comprises a liquid storage chamber, a sample chamber, a base and a support, wherein a liquid inlet hole and an air inlet hole are formed in the top of the liquid storage chamber respectively, a nut is arranged in the liquid inlet hole in a sealed manner, an air inlet valve is arranged in the air inlet hole in a sealed manner, and an adjusting lever is arranged on the air inlet valve; an opening is formed in the lower part of the liquid storage chamber and is in sealed connection with the upper end of the sample chamber, the lower end of the sample chamber is connected with the base provided with water holes, the lower end of the base is arranged on the support, a conical barrel located below the water holes is arranged on the support, and a percolate container is arranged at the bottom of the conical barrel. The percolate is pressurized through air pressure, so that percolation time of the percolate is substantially shortened, besides, the percolation instrument is simple and compact in structure, flexible to operate and good in air impermeability, adsorption blocking rate of anti-seepage slurry can be tested more accurately, and the anti-seepage effect of vertical anti-seepage walls all around the municipal solid waste landfill is checked.

Owner:CHANGZHOU INST OF TECH

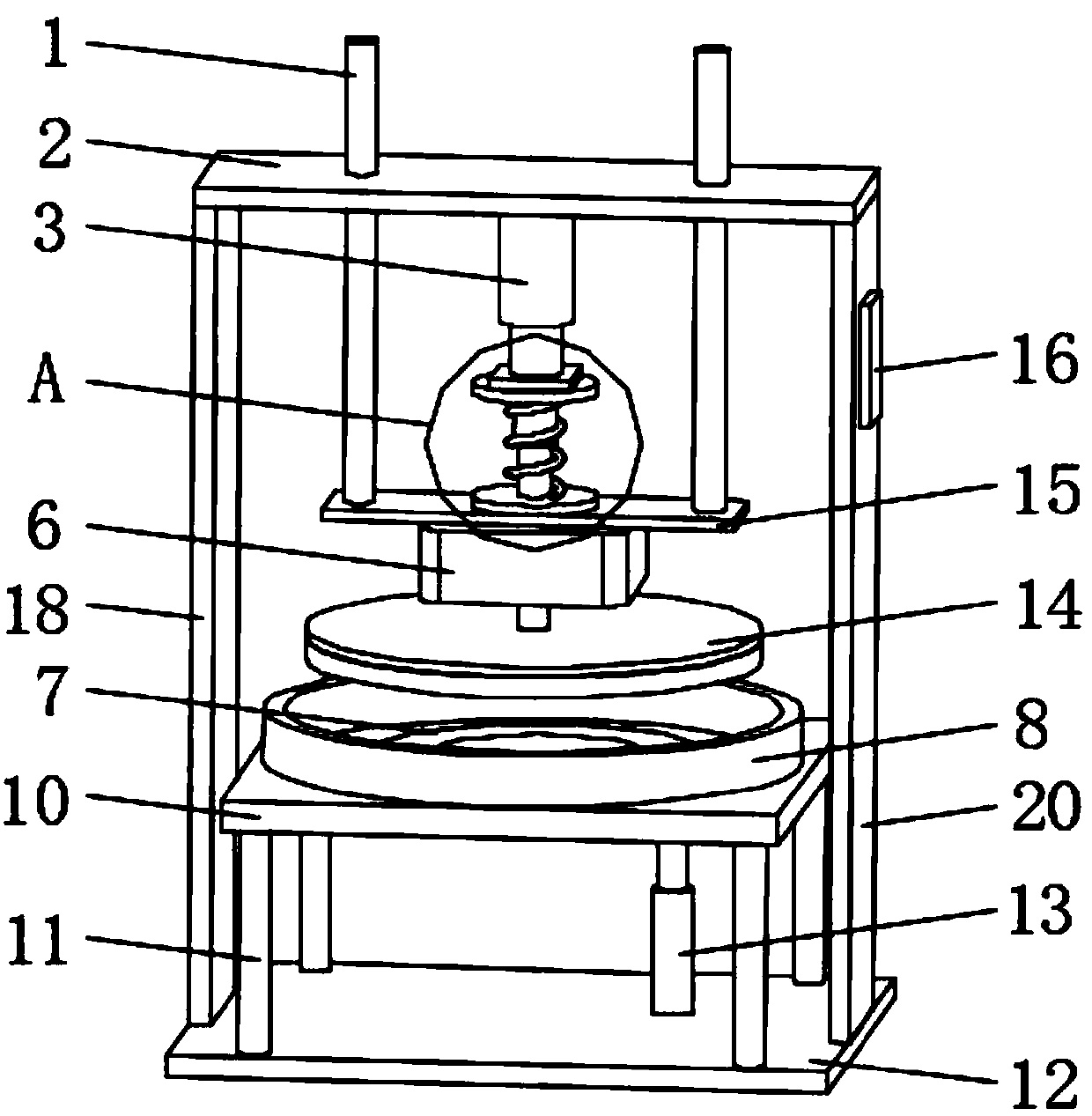

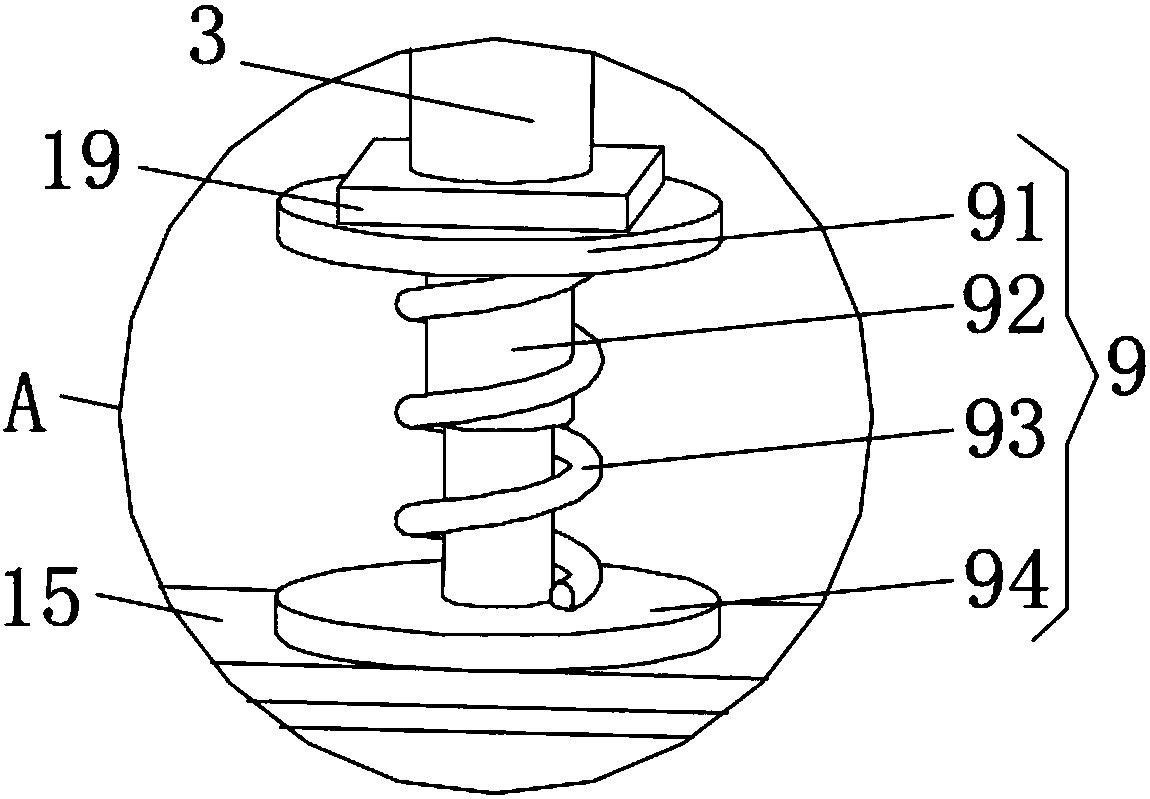

Grinding device of automobile muffler lifting hook

InactiveCN109968151AEasy pressure adjustmentGuaranteed grinding effectEdge grinding machinesGrinding drivesFixed frameEngineering

The invention discloses a grinding device of an automobile muffler lifting hook. The grinding device comprises a bottom plate, wherein a left vertical plate and a right vertical plate are arranged atthe left end and the right end of the upper surface of the bottom plate in parallel, the upper ends of the left vertical plate and the upper end of the right vertical plate are fixedly connected withthe left end and the right end of the lower surface of a transverse plate respectively, the middle position of the lower surface of the transverse plate and the upper end of an electric cylinder are fixedly connected through a fixing frame, a pressure sensor is fixed at the lower end of the electric cylinder, the side surface of the pressure sensor is connected with an elastic device, the lower end of the elastic device is fixedly connected with the middle position of the upper surface of the mounting plate, the elastic device enables a polishing disc to adjust the pressure of the automobile muffler lifting hook conveniently, and the grinding effect of the automobile muffler lifting hook is guaranteed; a fixing ring is used for preventing grinding powder from splashing, and the health of workers is guaranteed; and guide rods are used for preventing torque generated by a servo motor from damaging the electric cylinder and the elastic device, so that the grinding device of the automobilemuffler lifting hook is ensured to be used normally.

Owner:刘海平

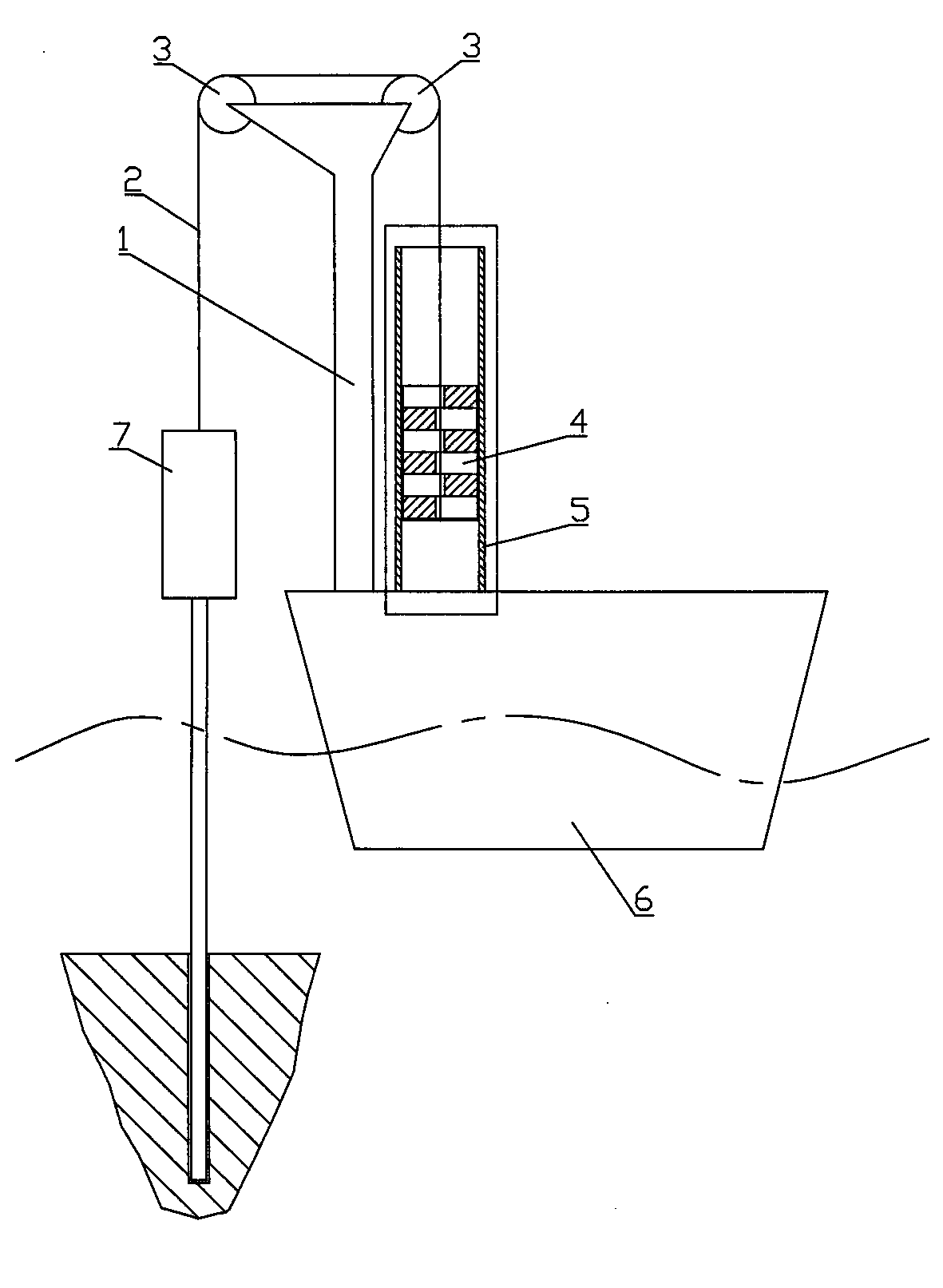

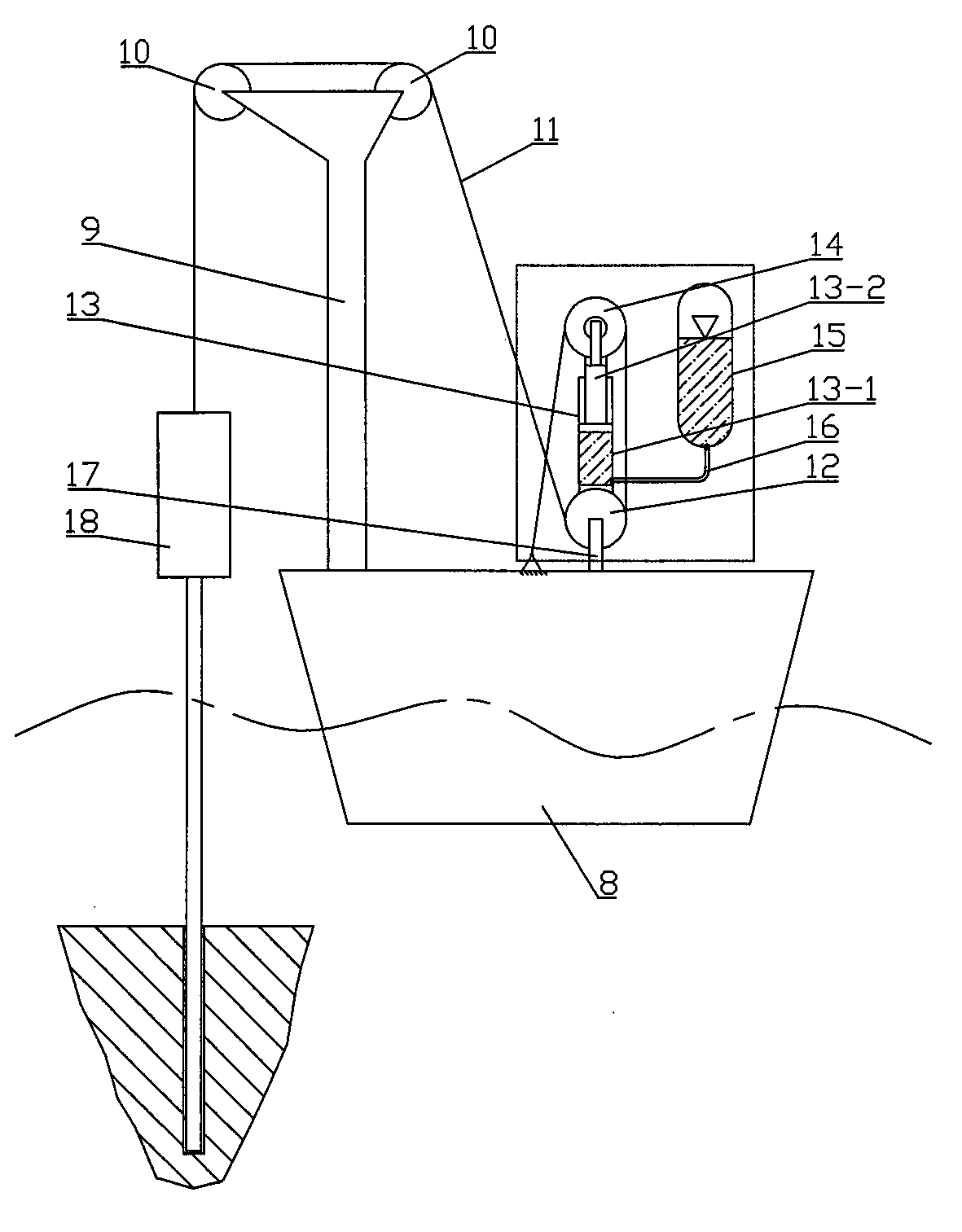

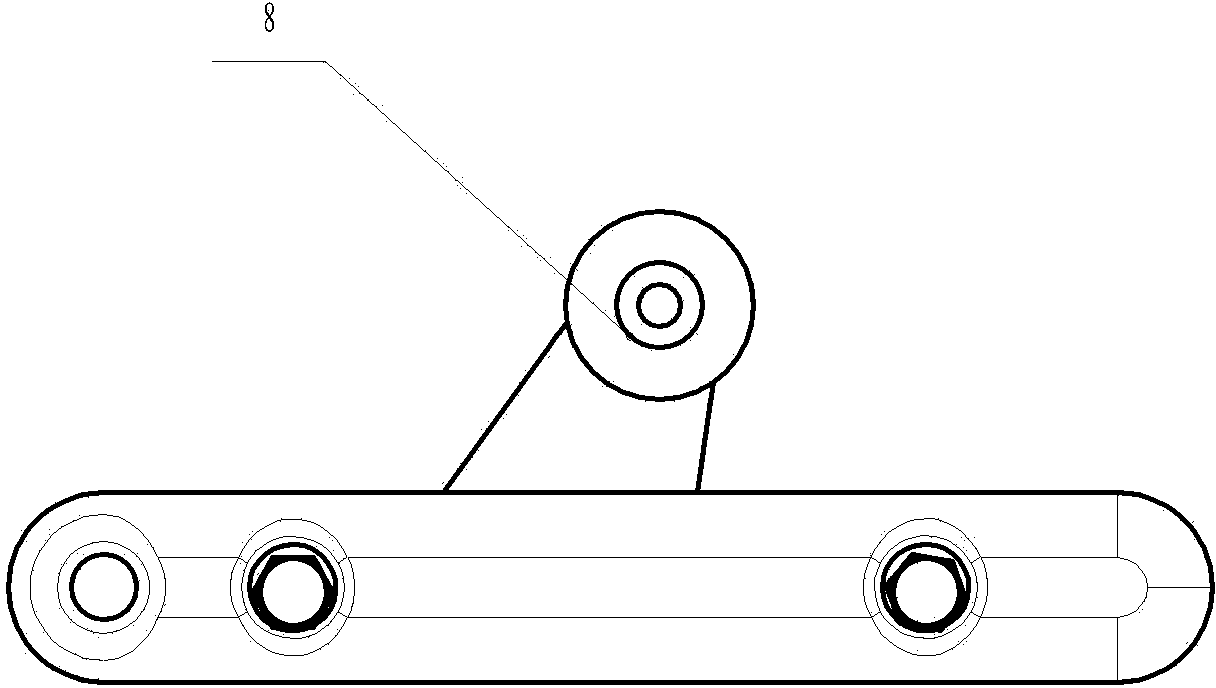

Marine rig hydraulic wave compensation device

InactiveCN103939033AEasy pressure adjustmentSimple structureDrilling rodsDrilling casingsTowerPiston rod

A marine rig hydraulic wave compensation device comprises a drill tower fixedly arranged on a drilling vessel, a tower top pulley, a steel wire rope and a hydraulic wave compensation mechanism, wherein the tower top pulley, the steel wire rope and the hydraulic wave compensation mechanism are arranged at the top end of the drill tower. The hydraulic wave compensation mechanism comprises an oil cylinder fixed wheel, an oil cylinder, an oil cylinder movable wheel, a sealed oil storage device and an oil pipe. The oil cylinder fixed wheel is fixedly arranged on the drilling vessel, the oil cylinder comprises a cylinder body and a piston rod, the lower end of the sealed oil storage device is provided with hydraulic oil, the upper end of the sealed oil storage device is provided with compressed gas, the hydraulic oil in the sealed oil storage device is communicated with hydraulic oil in an inner cavity of the cylinder body through the oil pipe, one end of the steel wire rope is connected with a drill bit part, and the other end of the steel wire rope sequentially winds around the tower top pulley, the oil cylinder fixed wheel and the oil cylinder movable wheel and is fixed to the drilling vessel. Quick and accurate compensation to balance of the drill bit part can be achieved, the marine rig hydraulic wave compensation device is simple in structure and stable and reliable in compensation and is not influenced by shaking of the drilling vessel, and safety hidden hazards do not exist.

Owner:HENGYANG ZHONGDI EQUIP PROSPECTING ENG MACHINERY

Movable switch knife

InactiveCN103367019AHigh dielectric strengthReduce distanceAir-break switch detailsEngineeringHigh pressure

The invention discloses a movable switch knife, relating to the manufacturing technical field of middle-high voltage electrical appliances. The movable switch knife comprises a left movable knife voltage balancing element, a right movable knife voltage balancing element, a left movable knife, a right movable knife, a movable knife supporting element, a movable knife pin, a movable knife connecting lever, a connecting bolt, a fastening nut and a disk spring, wherein the left and right movable knife voltage balancing elements are in hemispherical structures and have a plurality of holes, a plurality of holes in one-to-one correspondence to the left and right movable knife voltage balancing elements are formed in the left movable knife and the right movable knife, the movable knife supporting element is installed between the left movable knife and the right movable knife, and the movable knife connecting lever is used for connecting the left movable knife with the right movable knife through the movable knife pin; and the connecting bolt, the fastening nut and the disk spring are arranged in the left and right movable knife voltage balancing elements. The disk spring is composed of a plurality of pieces; and the left and right movable knife voltage balancing elements are riveted into a whole with the left movable knife and the right movable knife. The movable switch knife can be used for solving the problems of liable insulation flashover, bad insulation strength, poor environmental adaptability and severe partial discharge.

Owner:BEIHAI GALAXY SWITCH DEVICES

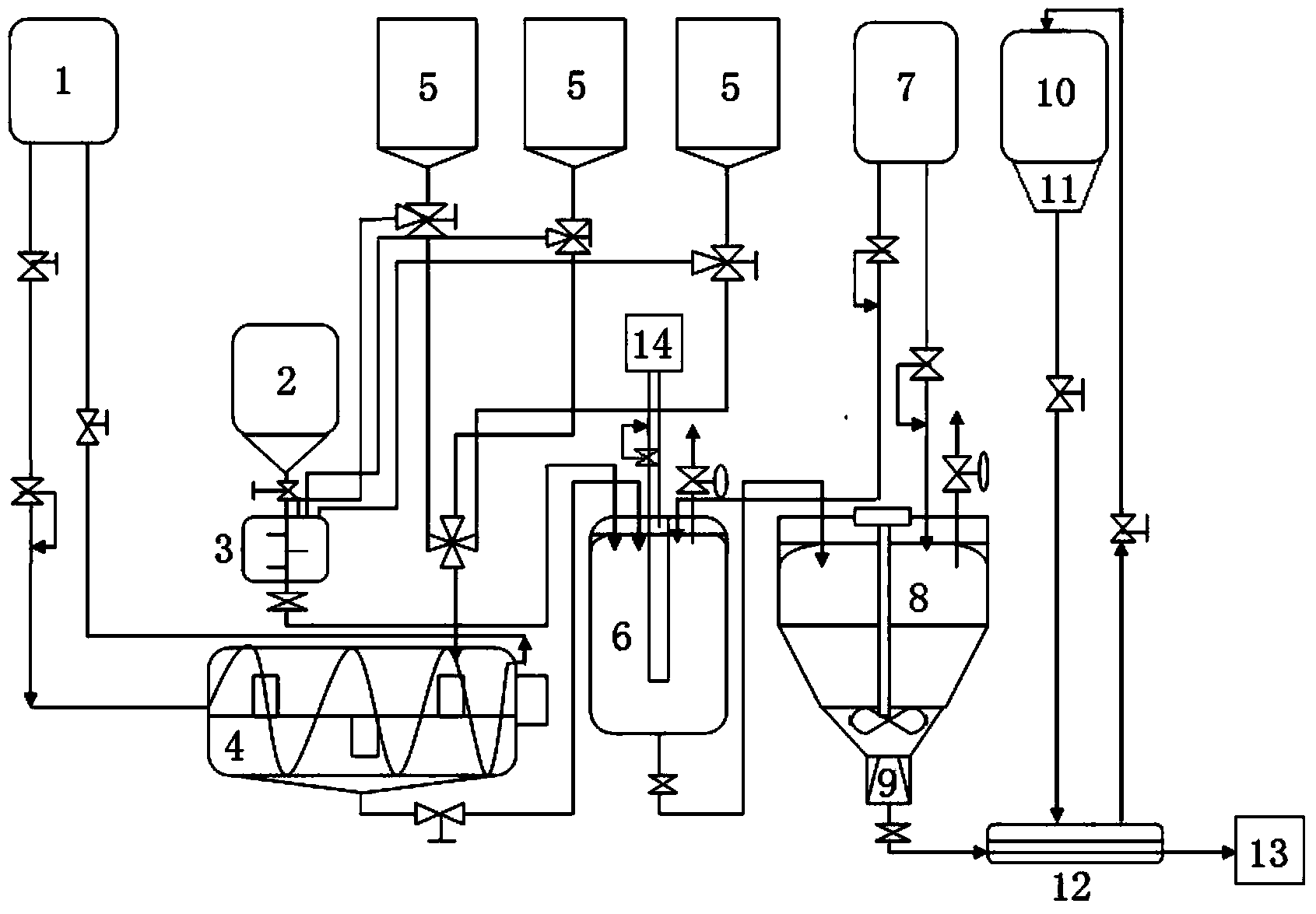

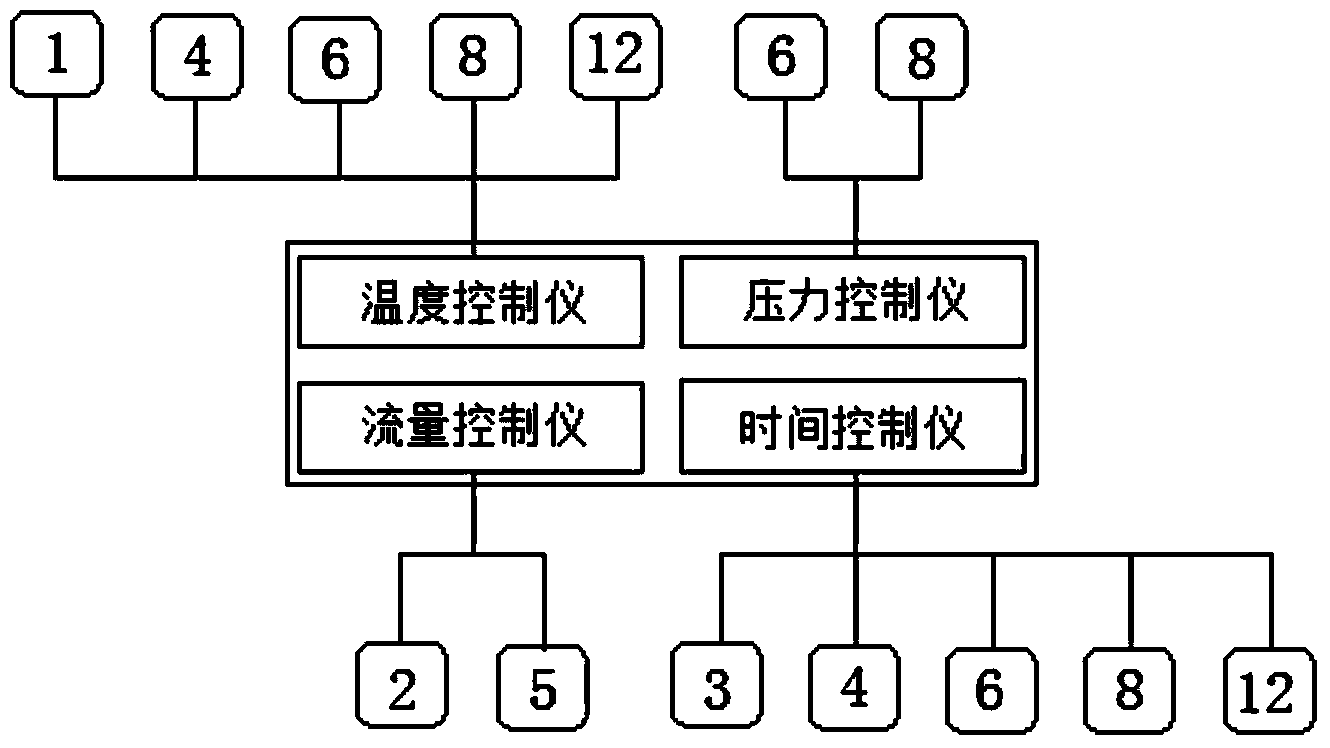

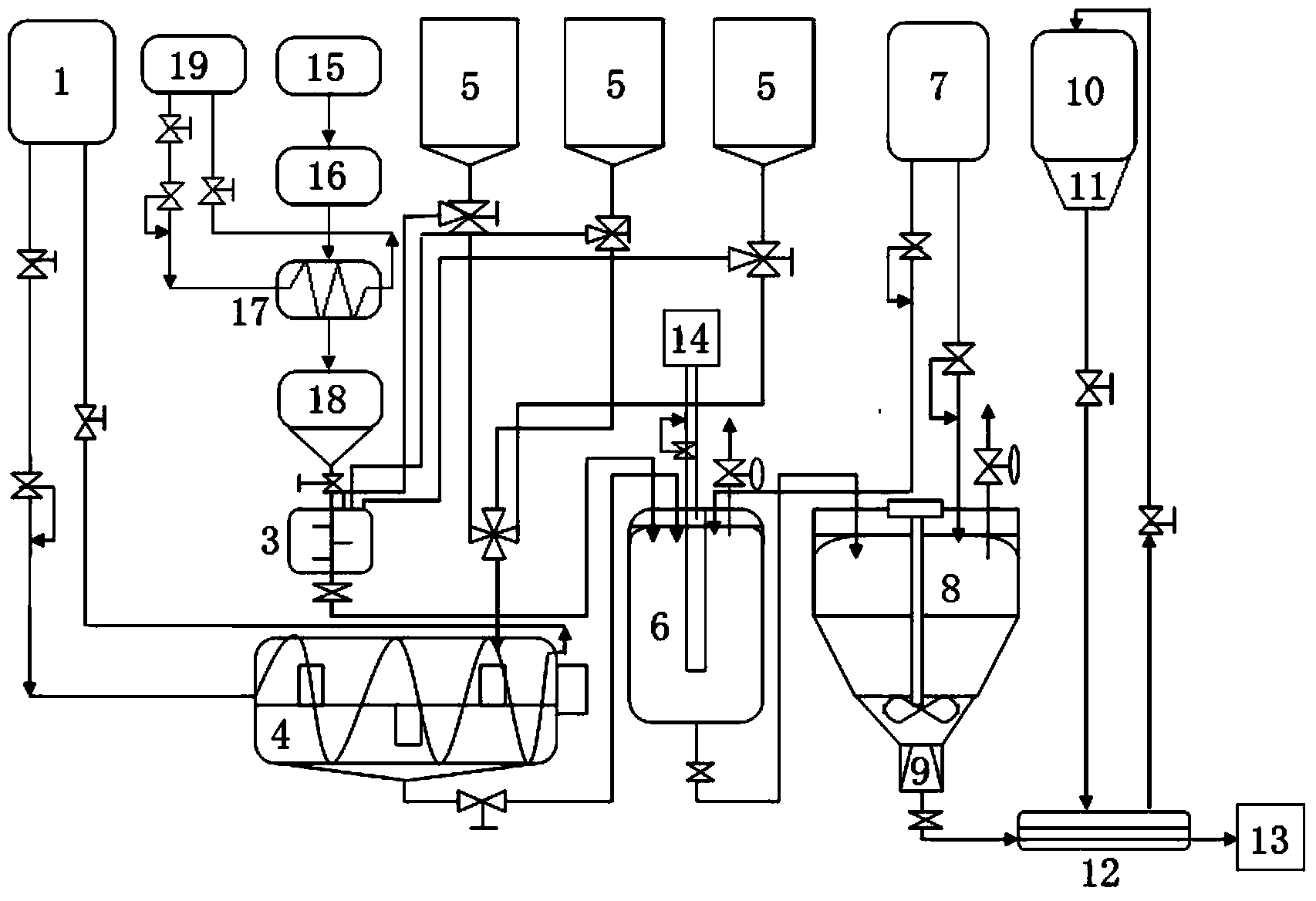

Production method and production system for health-protection lycopene oil

The invention discloses a production method and a production system for health-protection lycopene oil, belonging to the field of edible oil production. The production method comprises the following steps of (1) preheating part of raw oil, and preliminarily mixing the rest raw oil and lycopene powder or a lycopene extract; (2) mixing the preheated raw oil and the preliminarily mixed mixture again, and performing pressure vibration and pressure stirring; (3) extracting the mixture; (4) separating the extracted mixture to obtain the health-protection lycopene oil; (5) cooling the obtained health-protection lycopene oil and conveying the health-protection lycopene oil into a filling line. The invention also discloses the production system for the lycopene health-protection oil. The production method and the production system are simple in technology, high in production efficiency, safe and reliable; the physical characteristics that the lycopene is easy to oxidize, needs to be kept in a dark place and is low in heat stability are fully considered, so that the loss of the lycopene during processing is reduced to the maximum extent.

Owner:华康能仁(天津)生物科技有限公司

Intelligent conveying system of particle pump and test run method of intelligent conveying system

PendingCN112879259ALarge capacityGood volumetric efficiencyPump testingPositive displacement pump componentsPhysicsElectric machinery

The invention provides an intelligent conveying system of a particle pump. The intelligent conveying system is characterized by comprising a piston pump, a liquid inlet pipeline, a liquid outlet pipeline, a material receiving barrel and a hydraulic system, wherein the piston pump is provided with at least one liquid inlet and at least one liquid outlet, the liquid inlet pipeline communicates with the liquid inlet of the piston pump, one end of the liquid outlet pipeline communicates with the liquid outlet of the piston pump, and the other end of the liquid outlet pipeline stretches into the material receiving barrel; a first switch is arranged on the liquid inlet pipeline, and a pressure detection device, a throttling valve and a second switch are arranged on the liquid outlet pipeline; and the hydraulic system comprises a hydraulic cylinder and a hydraulic station, the hydraulic station comprises a PLC, a variable frequency motor and a hydraulic pump, the PLC is electrically connected with the variable frequency motor, the variable frequency motor is electrically connected with the hydraulic pump, the hydraulic pump is connected with the hydraulic cylinder, and the hydraulic cylinder is connected with the piston pump. By means of the intelligent conveying system of the particle pump, materials can be effectively protected and conveyed without damage, and the intelligent level is high. The invention further provides a test run method of the intelligent conveying system of the particle pump.

Owner:宁波得利时泵业有限公司

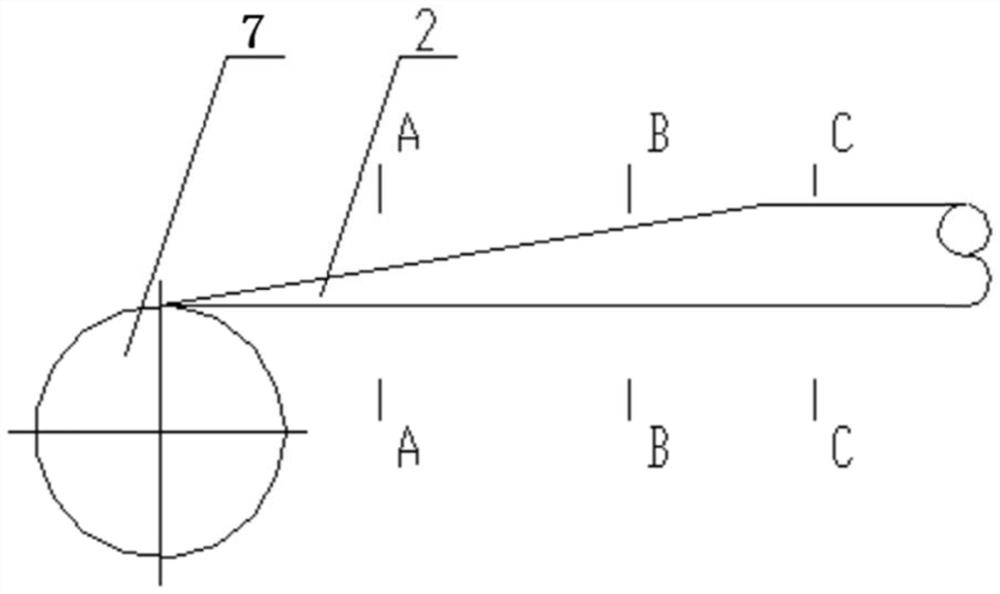

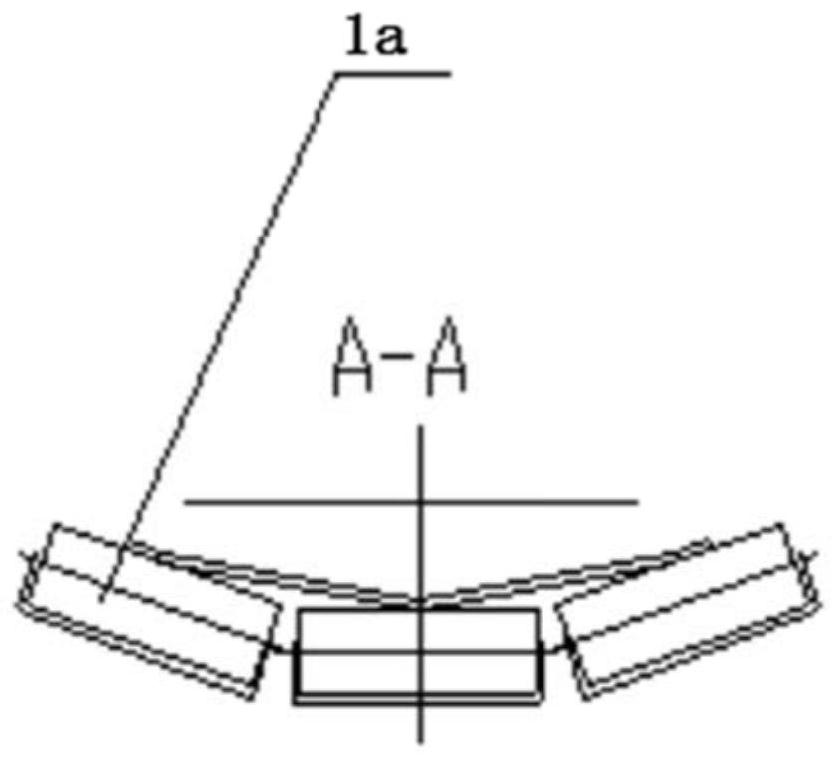

Forming guide device for tubular belt conveyor

PendingCN112357450AImprove reliabilityAdjust contact distanceConveyorsRollersConveyor beltBelt conveyor

The invention discloses a forming guide device for a tubular belt conveyor. The forming guide device comprises a transition idler set and at least one guide compression roller component, wherein the guide compression roller component and the transition idler set are arranged in a matched mode, so that a conveyor belt passing through a transition section can be formed step by step; the transition idler set is formed by a plurality of transition idlers and the guide compression roller component comprises a guide compression roller component, a connecting rod mechanism, a transverse adjusting mechanism and a longitudinal height adjusting support. According to the forming guide device for the tubular belt conveyor, the mechanical connecting rod mechanism is arranged, so that the guide compression roller and the conveyor belt can be in front-face contact, and the pressure of the conveyor belt can be adjusted conveniently; through the arrangement of the transverse adjusting mechanism, the contact distance between the guide compression roller and the conveyor belt can be conveniently adjusted; and through the arrangement of the longitudinal height adjusting support, the vertical positionrelation between the guide compression roller and the conveyor belt can be conveniently adjusted, and the reliability of the forming guide device for the tubular belt conveyor is improved.

Owner:CHINA COAL TECH & ENG GRP SHANGHAI

Storage tank pressure balancer

PendingCN113389924AAchieve voluntary pressure regulationEasy maintenanceContainer filling methodsEqualizing valvesEngineeringPressure balance

The invention discloses a storage tank pressure balancer, and particularly relates to the field of chemical equipment accessories. The storage tank pressure balancer comprises a valve body, wherein a first cavity and a second cavity are arranged in the valve body, the top of the valve body is detachably and movably connected with a valve cover, a negative pressure valve disc is movably connected between the valve cover and the first cavity, a positive pressure valve disc is movably connected between the negative pressure valve disc and the second cavity, a fire retardant plate is detachably and movably connected to one side of the valve body, a rainproof cap is arranged on one side of the fire retardant plate, and the rainproof cap, the fire retardant plate and the valve body are fixedly connected through bolts and nuts. The invention solves the problems that only an opening or one-way breathing mode is adopted in the prior art, is mainly applied to volatile liquid or storage tanks with large temperature difference change or certain requirements on sealing performance, has great benefits, and achieves the purposes of autonomous pressure regulation, is convenient to repair and maintain, and is safe and reliable; and the sealing performance is relatively poor as most storage tanks in the prior art are in opening or one-way breathing modes or rupture disks are mounted. The pressure regulation of the storage tank pressure balancer is relatively good.

Owner:DALIAN JIANHUA SLUDGE TREATMENT CO LTD

Industrial label shearing system

PendingCN109720679AEasy pressure adjustmentEasy to control delivery forceLabelling machinesIndustrial engineering

The invention relates to the technical field of industrial label shearing and provides an industrial label shearing system which comprises a rack. The rack is provided with a channel for industrial labels to pass through. A feeding side and a discharging side of the rack are arranged on the head side and the tail side of the channel. The system further comprises a first conveying mechanism, a second conveying mechanism, an electromagnetic pressing mechanism and a shearing mechanism, wherein the first conveying mechanism is used for guiding the industrial labels to be shorn into the channel from the feeding side, the second conveying mechanism is used for guiding the shorn industrial labels out of the channel from the discharging side, the electromagnetic pressing mechanism is used for stabilizing the industrial labels in the shearing process, and the shearing mechanism is used for shearing the two connected industrial labels. The first conveying mechanism, the shearing mechanism and the second conveying mechanism are sequentially arranged in the direction from the head side to the tail side of the channel. According to the system, the first conveying mechanism, the second conveyingmechanism, the electromagnetic pressing mechanism and the shearing mechanism cooperate to cut the industrial labels, the working efficiency is improved, and the labor cost is further reduced.

Owner:WISDRI ENG & RES INC LTD

Novel lateral positioning clamping device

PendingCN110539188AEasy to adjust the positionIngenious designPositioning apparatusMetal-working holdersMachine toolMachining

The invention provides a novel lateral positioning clamping device. The device is installed in a T-shaped groove of a machine tool workbench in a matched mode, and comprises a lever type clamping block, wherein a locking screw hole and an adjusting screw hole are formed in the middles of the left end and the right end of the lever type clamping block in the vertical direction correspondingly, a clamping tooth surface is arranged outside the upper portion of the left end of the lever type clamping block, rotating supporting blocks are symmetrically arranged at the bottoms of the front side andthe rear side of the lever type clamping block, and a locking screw and a pressure adjusting screw are in threaded connection with the locking screw hole and the adjusting screw hole respectively. Compared with the prior art, the device has the beneficial effects that the side surface of a plate type workpiece can be quickly and effectively fixed and locked, the surface machining of the plate workpiece is not affected, the machining working efficiency and the machining surface quality of the plate workpiece are improved, and the labor intensity is alleviated.

Owner:SUZHOU VOCATIONAL UNIV

Integrated fire-retardant breather valve capable of adjusting pressure of breather valve

PendingCN114673816AAvoid disassembly and replacement stepsEasy pressure adjustmentEqualizing valvesFire rescuePhysicsEngineering

The invention discloses an integrated fire-retardant breather valve capable of adjusting breather valve pressure, which comprises a breather valve body, the bottom of the breather valve body is fixedly communicated with a flange, one side of the breather valve body is communicated with a fire-retardant element, a replacement mechanism is arranged in the fire-retardant element, and the top of the breather valve body is fixedly connected with a valve cover through a bolt. The top of the valve deck and the interior of the breather valve body are provided with pressure adjusting mechanisms. According to the integrated fire-retardant breather valve capable of adjusting the pressure of the breather valve, the pressure adjusting mechanism is arranged, a pressing plate is rotated to be pressed downwards, so that an adjusting plate is rotated from a first adjusting groove to a pressing groove and slides downwards till a second adjusting groove is clamped, and adjustment of the pressure of the breather valve through external operation is achieved; according to the breather valve, the traditional step of disassembling the valve disc is avoided, so that the pressure is more convenient to adjust, and the step of stopping the work of the breather valve is reduced, so that the use efficiency of the breather valve is improved.

Owner:江苏复森特种阀门有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com