Unloading one-way valve applied to back flushing and dust cleaning system of dust collector

A technology of one-way valves and vacuum cleaners, which is applied in the direction of machines/engines, liquid displacement machinery, variable displacement pump components, etc. It can solve the problems that the unloading pressure cannot be adjusted, the compressed air cannot be discharged, and the motor and compressor are damaged. , to achieve the effect of reliable work, simple structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

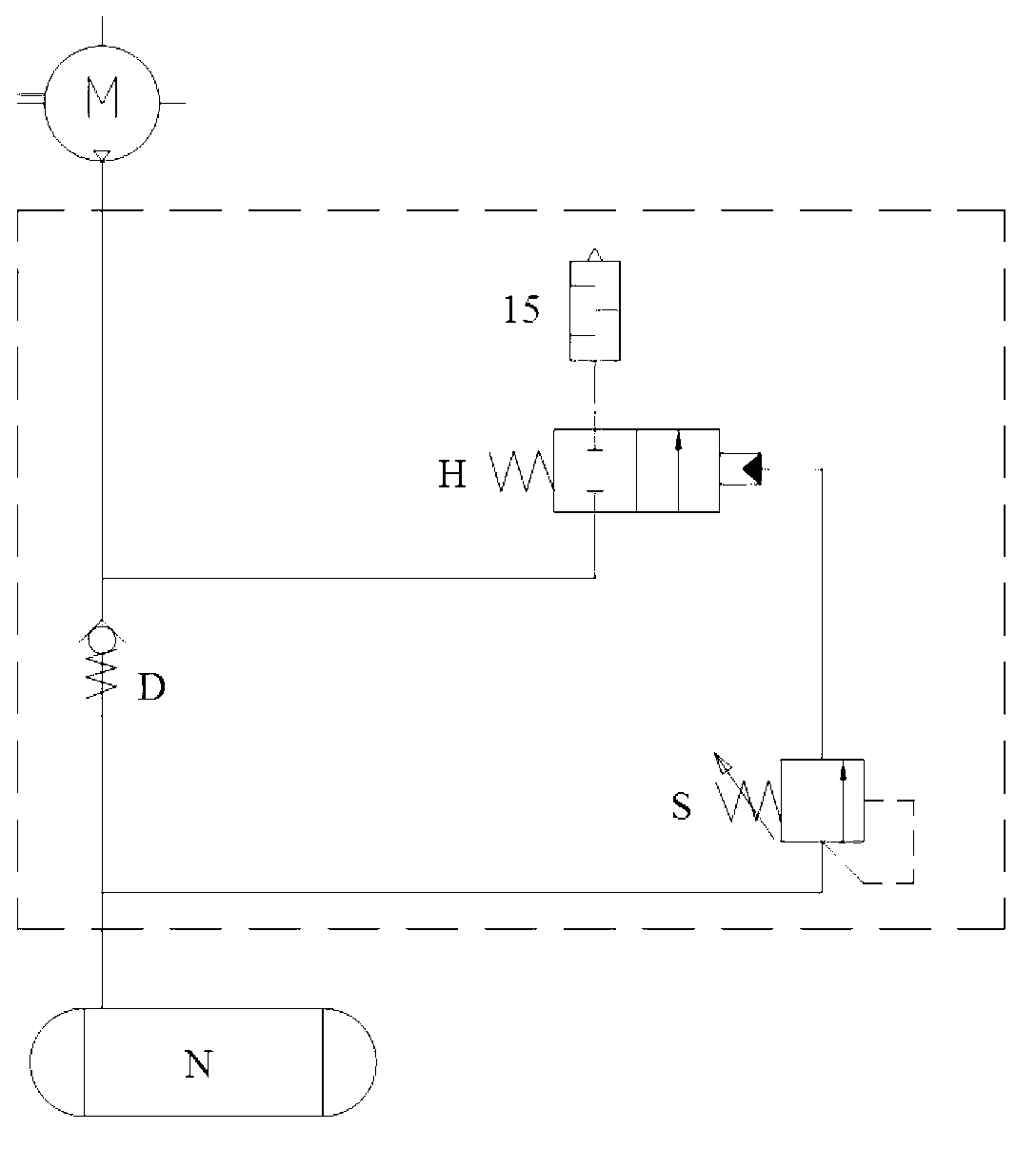

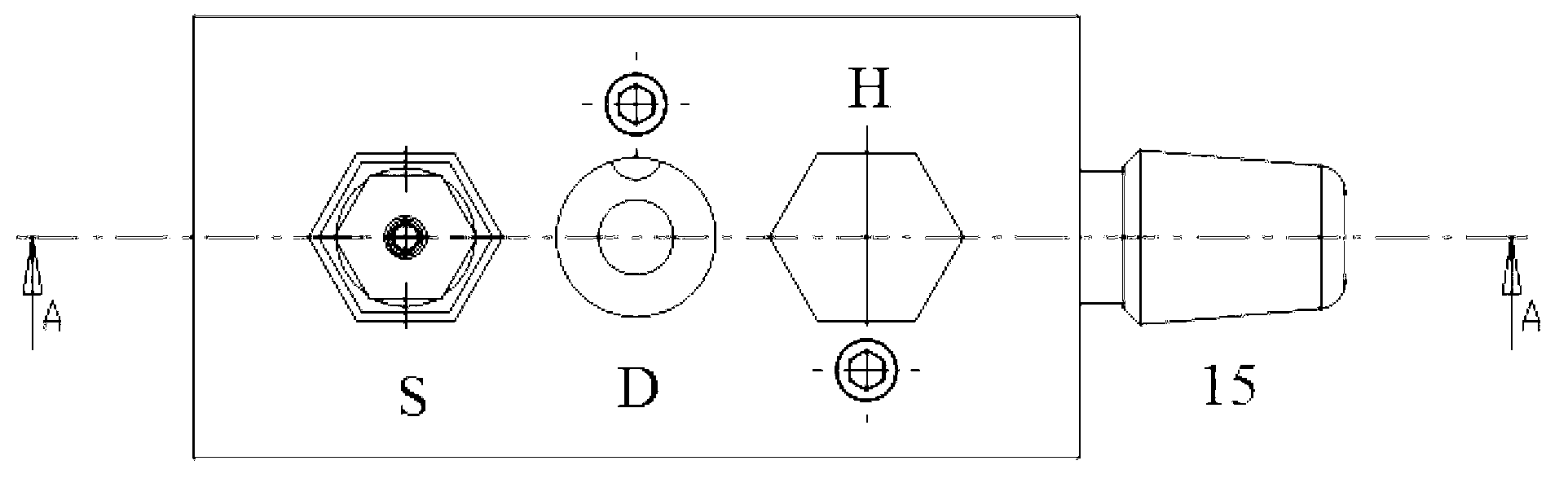

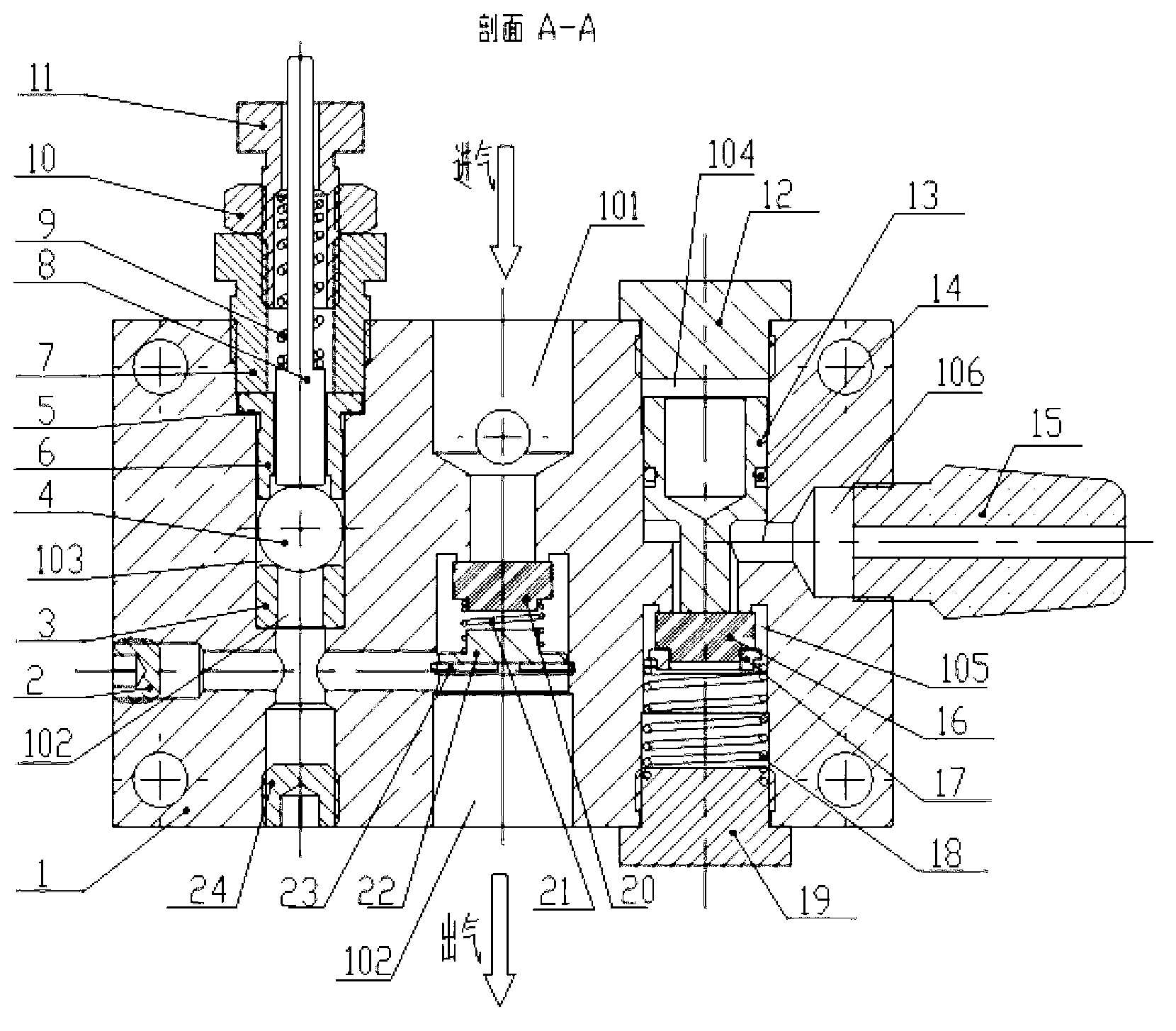

[0028] Such as figure 1 As described above, an unloading check valve applied to the dust cleaning system of a vacuum cleaner, the unloading check valve includes a valve body 1, and a check valve D, a sequence valve S and a reversing valve integrated on the valve body H, one end of the one-way valve D is connected to the air compressor M through the inlet pipe, and the other end is connected to the air tank N through the outlet pipe. The sequence valve S is respectively connected to the one-way valve D and the reversing valve H, and The valve H is connected to the muffler 15. When working, the pressure is set through the sequence valve S. This pressure is the working pressure required by the compressed air of the air storage tank N. When the compressed air output by the air compressor M makes the compressed air in the air storage tank N When the working pressure is reached, the sequence valve S is opened, and the air flow activates the reversing valve, so that the air is direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com