Forming guide device for tubular belt conveyor

A tubular belt-type, guiding device technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of conveyor belt tearing, jamming, damage to conveyor belts and idlers, etc., to achieve convenient adjustment and improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

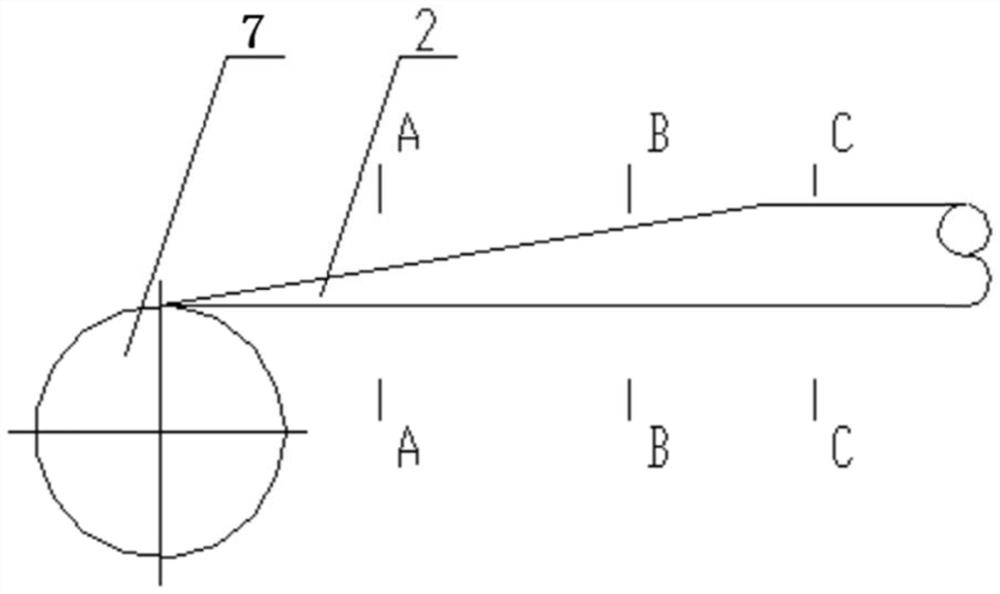

[0023] When the conveyor belt transitions from a flat shape to a round tube shape, due to the tension of the conveyor belt and the uncertainty of the transition length, the shape of the conveyor belt in the transition section is uncertain when it is formed, resulting in the contact between the guide roller device and the conveyor belt Therefore, this example provides a forming guide device for a tubular belt conveyor, which can solve the above problems through the mutual cooperation of the guide roller assembly and the transition roller group.

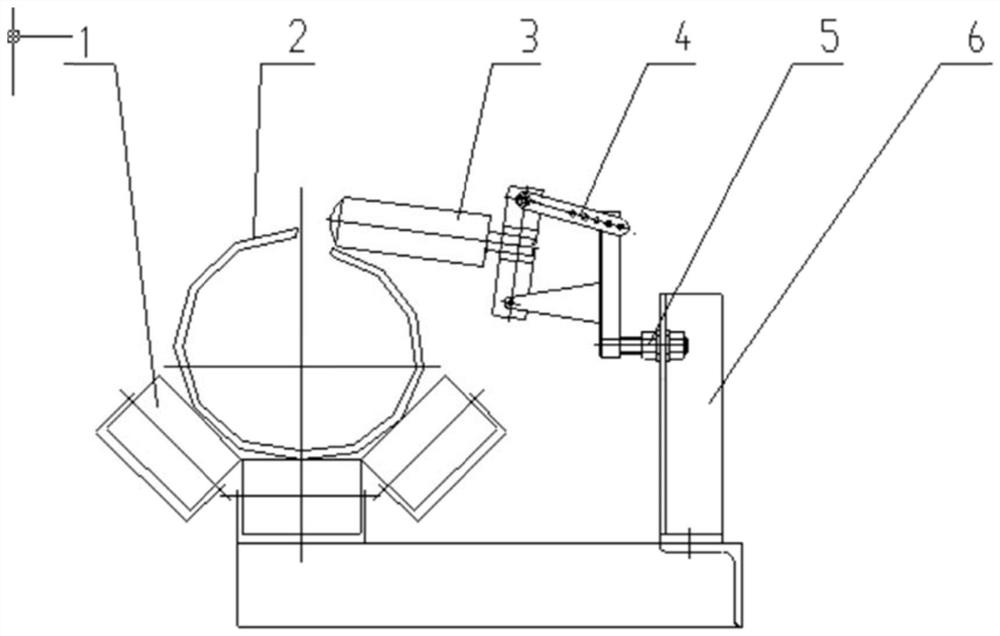

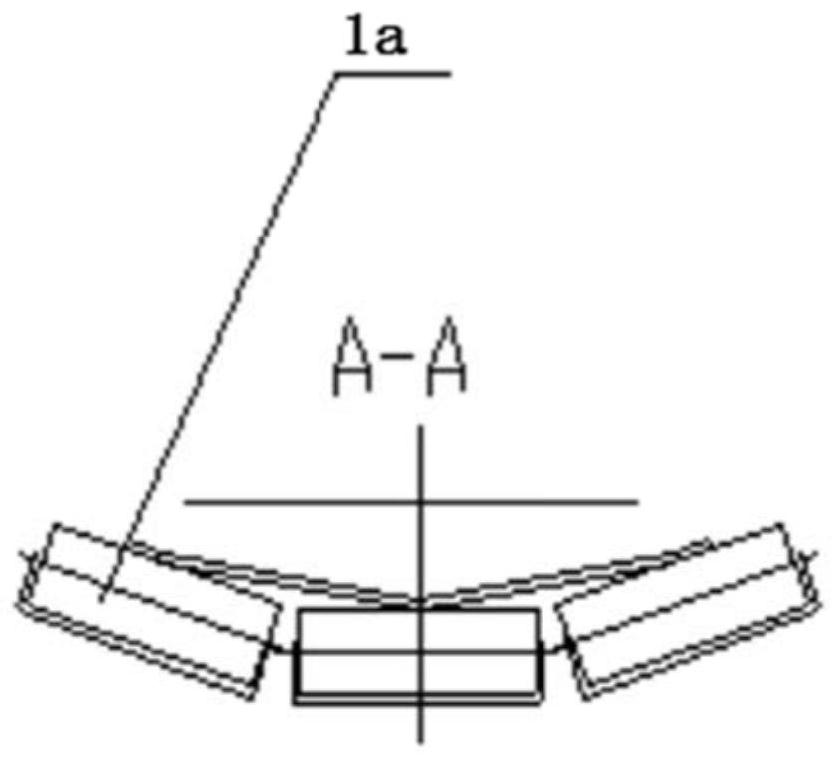

[0024] Such as figure 1 As shown, the forming guiding device of the tubular belt conveyor provided in this example includes: a transition idler roller set 1 and a guide roller assembly 3, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com