Low-wear friction method and device for delivering raw materials by compressed air

A compressed air, low-wear technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as high maintenance costs, wear of high-speed rotating components, and reduced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

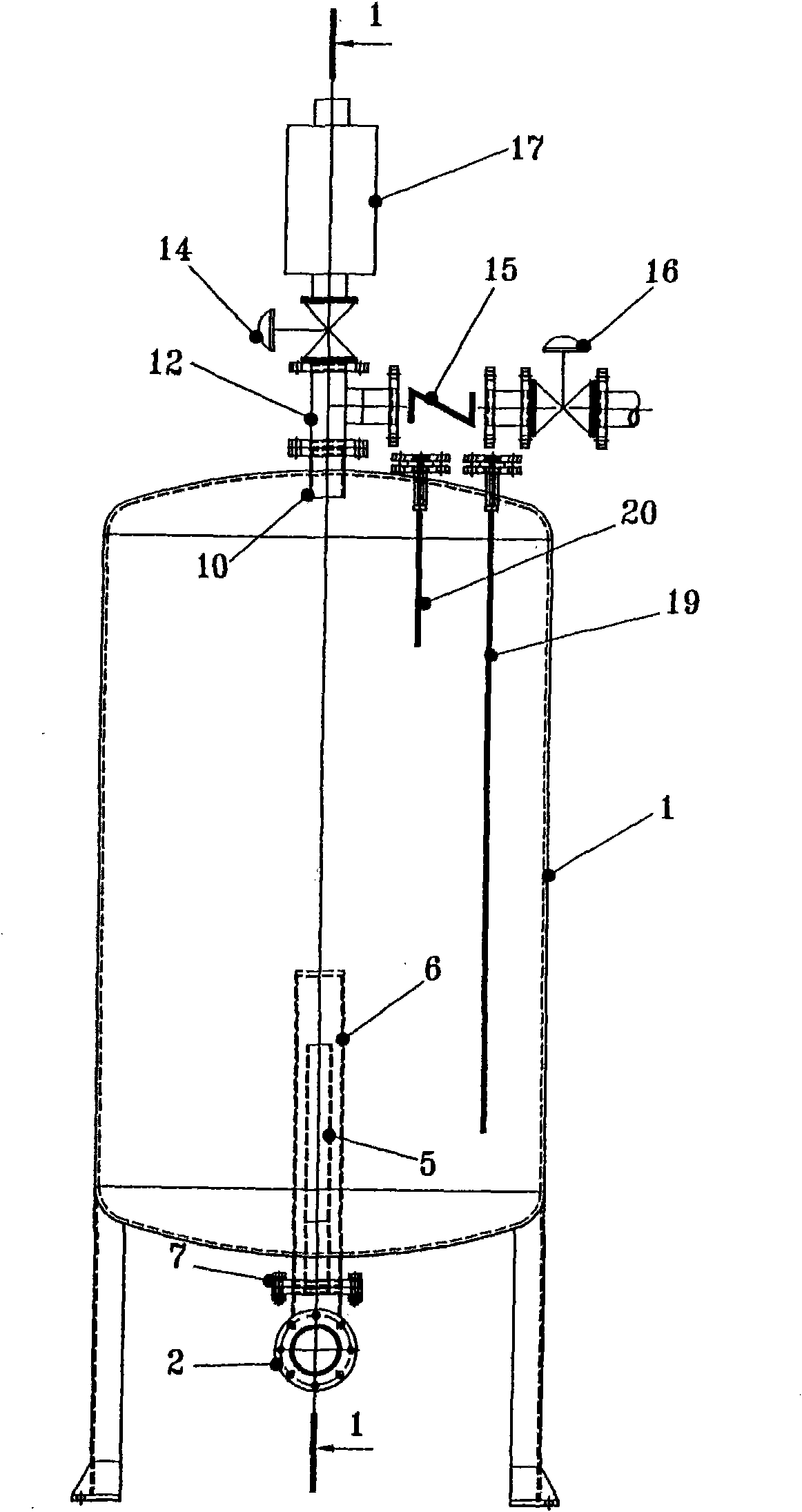

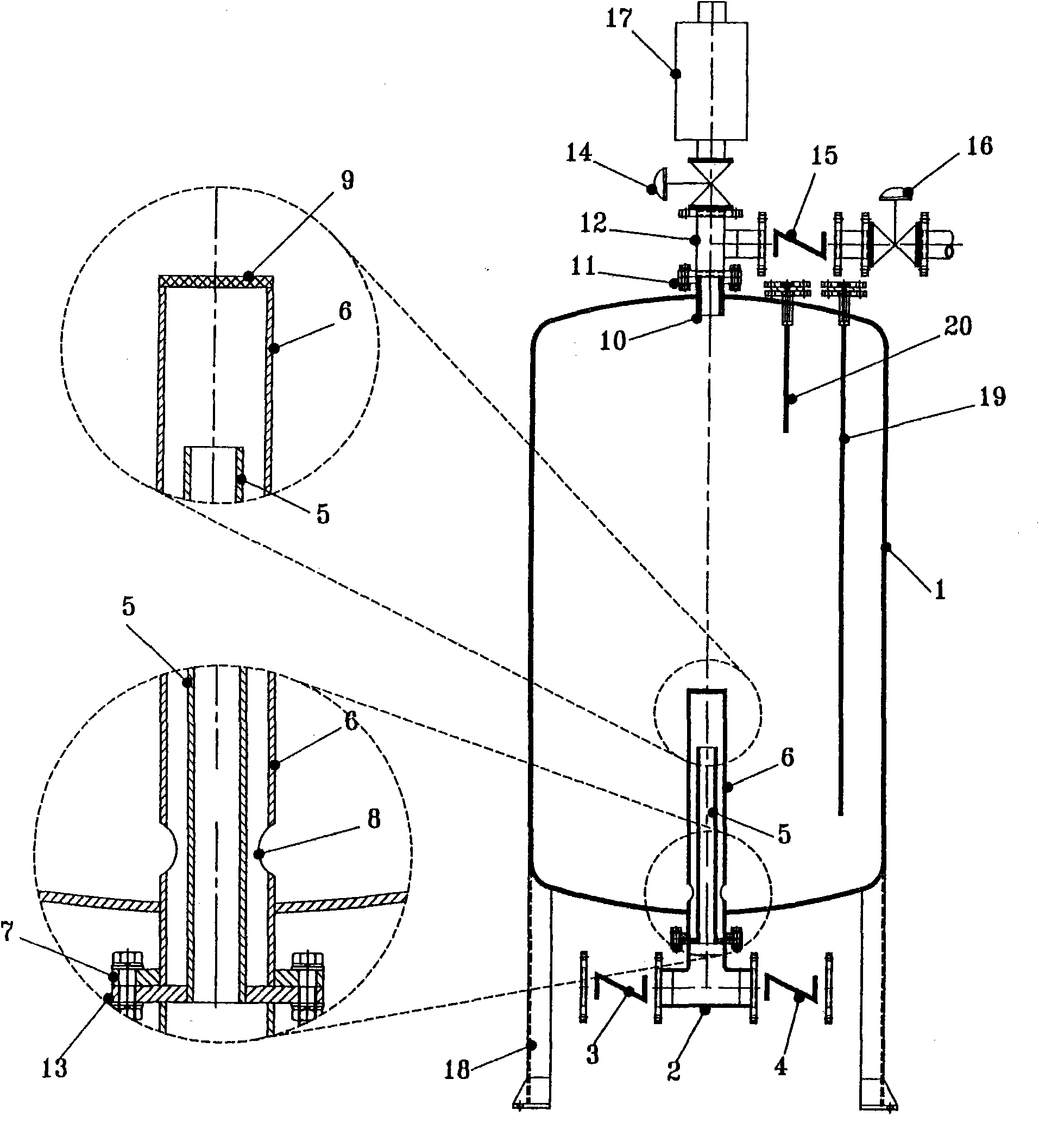

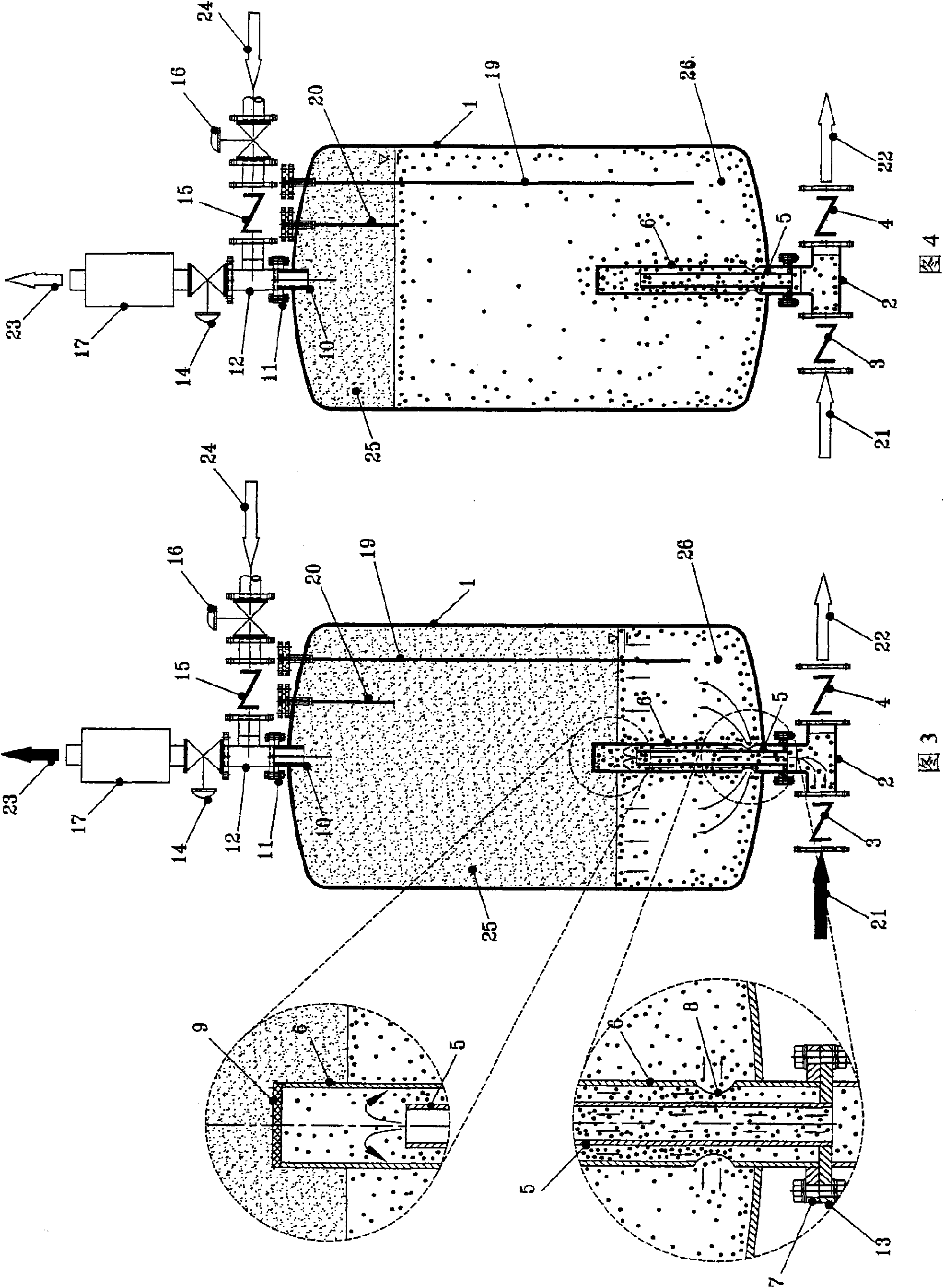

[0062] as attached image 3 to attach Figure 7 The shown method and device for pumping raw materials with compressed air with low wear and tear, the method includes an exhaust gas feeding step and an air intake discharging step. When the present invention pumps the raw material (26), first the intake valve (16) is closed, the exhaust valve (14) is opened, and the liquid raw material (26) is pushed along the mud inlet pipe group by its own weight or the pressurization of the electric pump (28). The feeding check valve (4) flows to the mud guide inner pipe (5) at the top of the mud inlet tee (2), and first along the annular gap between the mud guide inner pipe (5) and the mud guide outer pipe (6). After rectification, it is injected into the bottom of the closed tank (1), the liquid raw material (26) rises at a steady flow rate, and the air in the tank flows out of the closed tank (1) along the exhaust valve (14) during the rising process of the liquid level. When the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com