Storage tank pressure balancer

A balancer and pressure technology, applied in pressure vessels, non-pressure vessels, balance valves, etc., can solve problems such as pressure increase, open welding of storage tanks, and collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

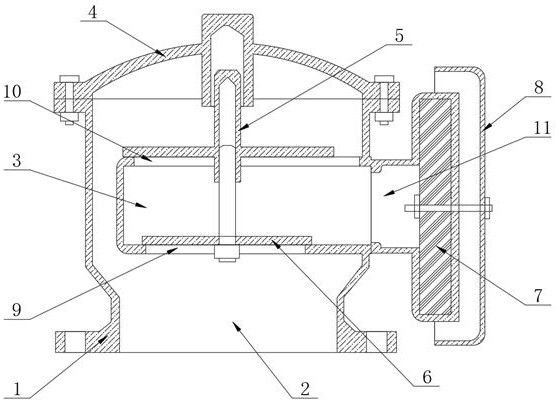

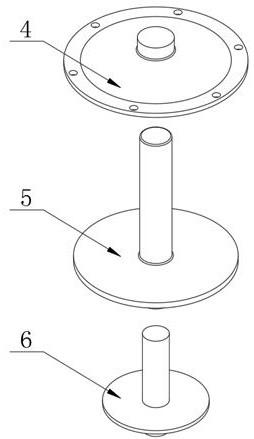

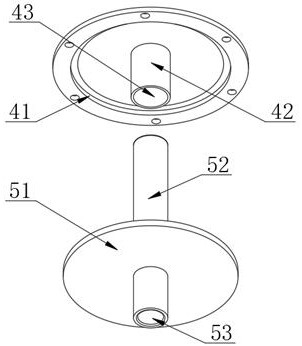

[0024] The present invention provides a tank pressure balancer includes a valve body 1, inside the valve body 1 2 is provided with a first chamber and a second chamber 3, the valve body 1 movably connected with a removable top bonnet 4, the valve cover 4 is connected between the active and negative pressure chamber 2 a first valve disk 5, the disk 5 is connected to the negative pressure valve 3 activity between the second chamber has a positive pressure valve disc 6, the a valve element movably connected with a detachable a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com