Automatic guided vehicle drive suspension device and automatic guided vehicle

A technology for automatic navigation vehicles and suspension devices, which is applied in the directions of motor vehicles, electric vehicles, and control drives, can solve the problem that the pressure cannot adjust the excessive space of the frame and chassis, and achieves a space saving, compact size, and reasonable layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

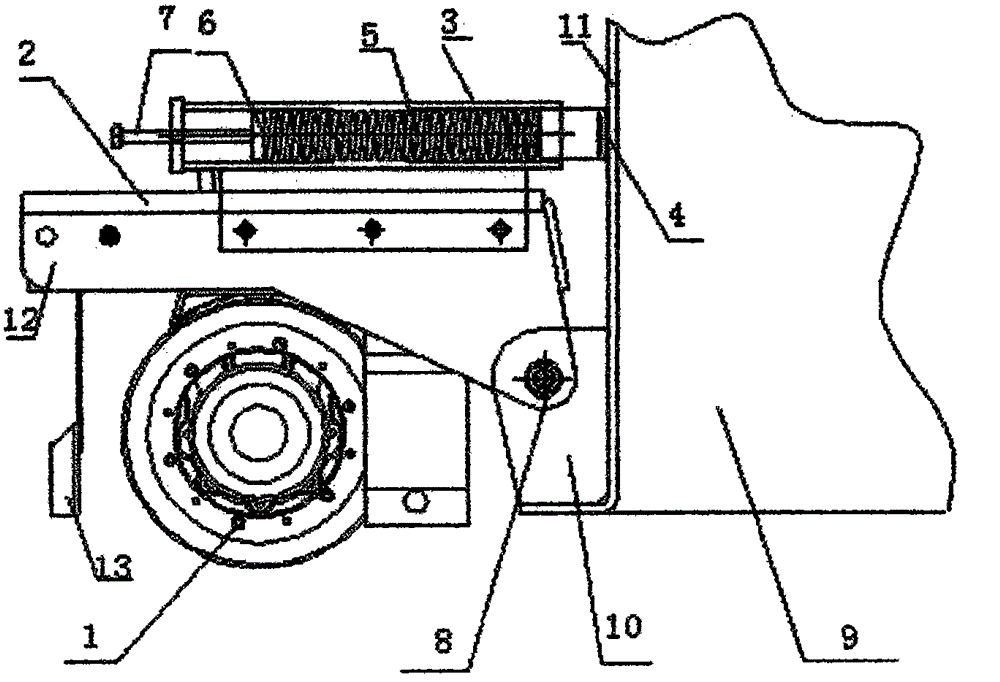

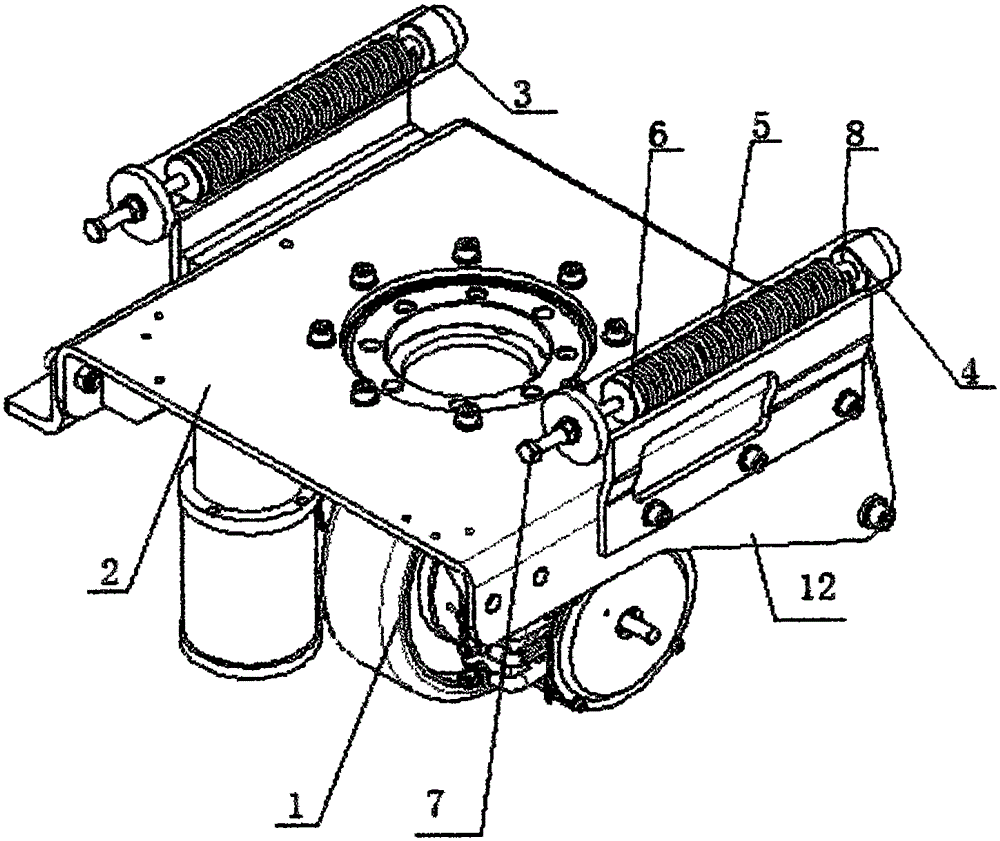

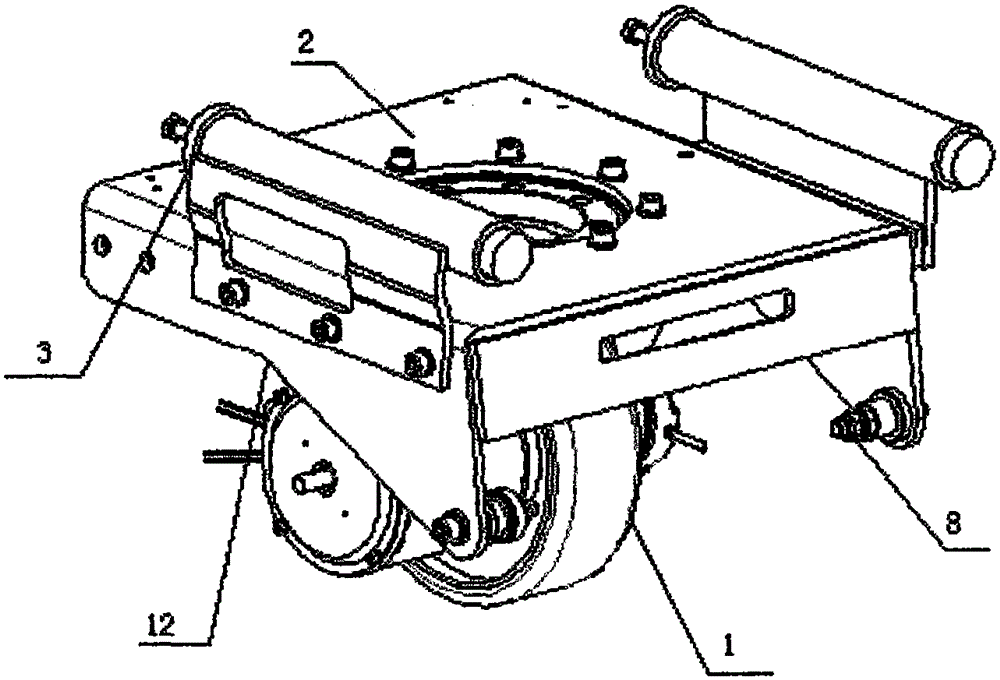

[0029] The drive suspension device of the automatic guided vehicle of the present invention can be used as the drive of the dollies such as logistics, handling, and this embodiment is applied to a kind of automatic guided vehicle, embodiment 1, as figure 1 , figure 2 and image 3 As shown, the automatic guided vehicle includes a vehicle frame 9 and a navigation sensor 13, and the vehicle frame is also provided with a drive suspension device for the automatic guided vehicle.

[0030] The driving suspension device of the automatic guided vehicle has a driving wheel set 1 suspended below the vehicle frame 9 and a mounting plate 2 for installing the driving wheel set 1 . On the actual automatic guided vehicle, in addition to the driving wheel set, there are also load-bearing wheel sets supporting the weight of the trolley. At present, four load-bearing wheels are installed on the four corners of the vehicle frame 9, and the driving wheel set 1, The navigation sensor 13 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com