Condensation-controllable split type testing tank

A test box, split-type technology, applied in the field of environmental test equipment, can solve the problems of low temperature of the sample test box, condensation on the outer wall of the sample test box, reduction of the insulation thickness of the test box, etc., to achieve compact size and small footprint , lightweight effect

Active Publication Date: 2016-10-12

NAT INST OF METROLOGY CHINA +1

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The test box usually needs to be designed separately according to the customer's requirements, and due to the limitation of the customer's use site, the size of the sample test box is also limited. In many cases, under the condition of ensuring the normal use of the test sample, it is necessary to reduce the insulation thickness of the test box , w

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

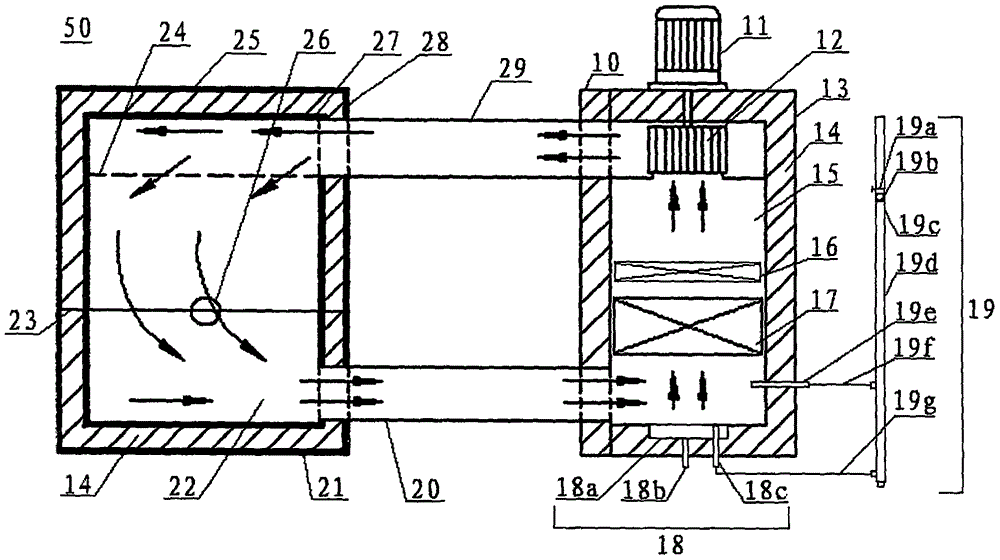

The invention provides a condensation-controllable split type testing tank. The condensation-controllable split type testing tank comprises a control box, a sample testing tank body and at least one set of ventilation pipelines located between the control box and the sample testing tank body. The control box comprises a humidifying system, a heating system and a refrigerating system. The sample testing tank body comprises at least two assembling structures capable of being disassembled and assembled, and pipeline holes penetrating through the a main part of the sample testing tank body are formed in the joints of the assembling structures. At least one temperature control assembly is arranged on the wall of the sample testing tank body, and the control box and the sample testing tank body form a circulation system through connection of the ventilation pipelines.

Description

technical field [0001] The invention relates to the field of environmental test equipment, in particular to a split test chamber with controllable condensation. Background technique [0002] The test box usually needs to be designed separately according to the customer's requirements, and due to the limitation of the customer's use site, the size of the sample test box is also limited. In many cases, under the condition of ensuring the normal use of the test sample, it is necessary to reduce the insulation thickness of the test box , which also creates additional problems: [0003] 1. During the damp heat test, condensation may occur on the inner wall of the sample test chamber and may damage the test sample. [0004] 2. During the low-temperature test, condensation may occur on the outer wall of the sample test box and may cause the sample test box to fail to reach the required low temperature. [0005] 3. Under one experimental condition, it is necessary to prevent conde...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01L1/00B01L7/00

CPCB01L1/00B01L7/00B01L2300/10B01L2300/18

Inventor 孟涛李晓鹏何军李波

Owner NAT INST OF METROLOGY CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com