Method for preparing low-smoke halogen-free flame-retardant cable material containing plastic compatilizer

A technology of flame retardant cable material and compatibilizer, used in plastic/resin/wax insulators, organic insulators, etc. Application range and other issues, to achieve the effect of improving the physical and mechanical properties of tensile strength and elongation at break, reducing interfacial energy, and ensuring tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

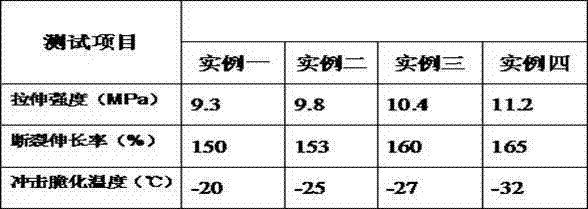

Examples

Embodiment Construction

[0008] 1. Production of compatibilizer

[0009] 1. Prepare a maleic anhydride acetone solution with a mass percentage concentration of 50%:

[0010] Dissolve 2kg of maleic anhydride in 2kg of acetone to form 4kg of maleic anhydride acetone solution with a concentration of 50% by mass.

[0011] 2. Preparation of grafting mixture:

[0012] Put 0.04 kg of bis-dipenta vulcanizing agent into 4 kg of maleic anhydride acetone solution with a concentration of 50% by mass, mix well to form a grafted mixture, and set aside.

[0013] 3. Preparation of compatibilizer:

[0014] Use a vented twin-screw extruder to plasticize 100kg of EVA resin, and use a stainless steel injection pump to drive the above grafted mixture into the third barrel of the extruder to make the maleic anhydride acetone solution and EVA resin plastic To carry out the grafting reaction. And control the reaction temperature of the 13 zones of the extruder respectively: 95℃, 110℃, 115℃, 120℃, 120℃, 125℃, 125℃, 130℃, 130℃, 135℃, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com