Pipeline liquid pressure controller and control method thereof

A liquid pressure and controller technology, applied in fluid pressure control, electric fluid pressure control, non-electric variable control, etc., can solve problems such as low system reuse rate, short system life, interference and the impact of lightning weather. , to achieve the effect of strong anti-interference ability, long communication distance and convenient pressure adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

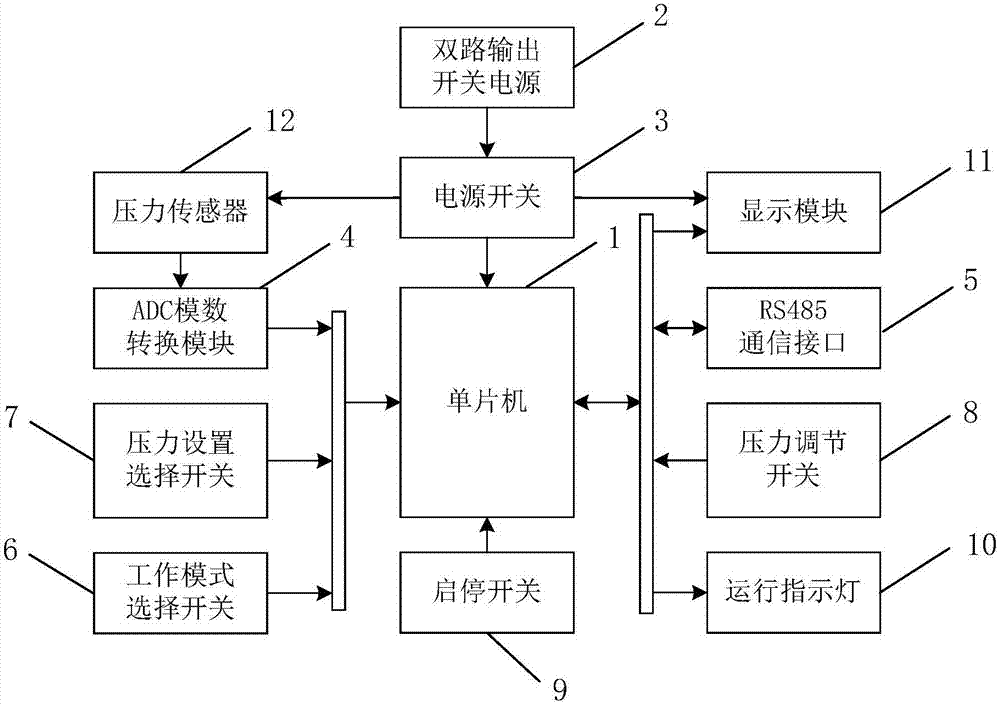

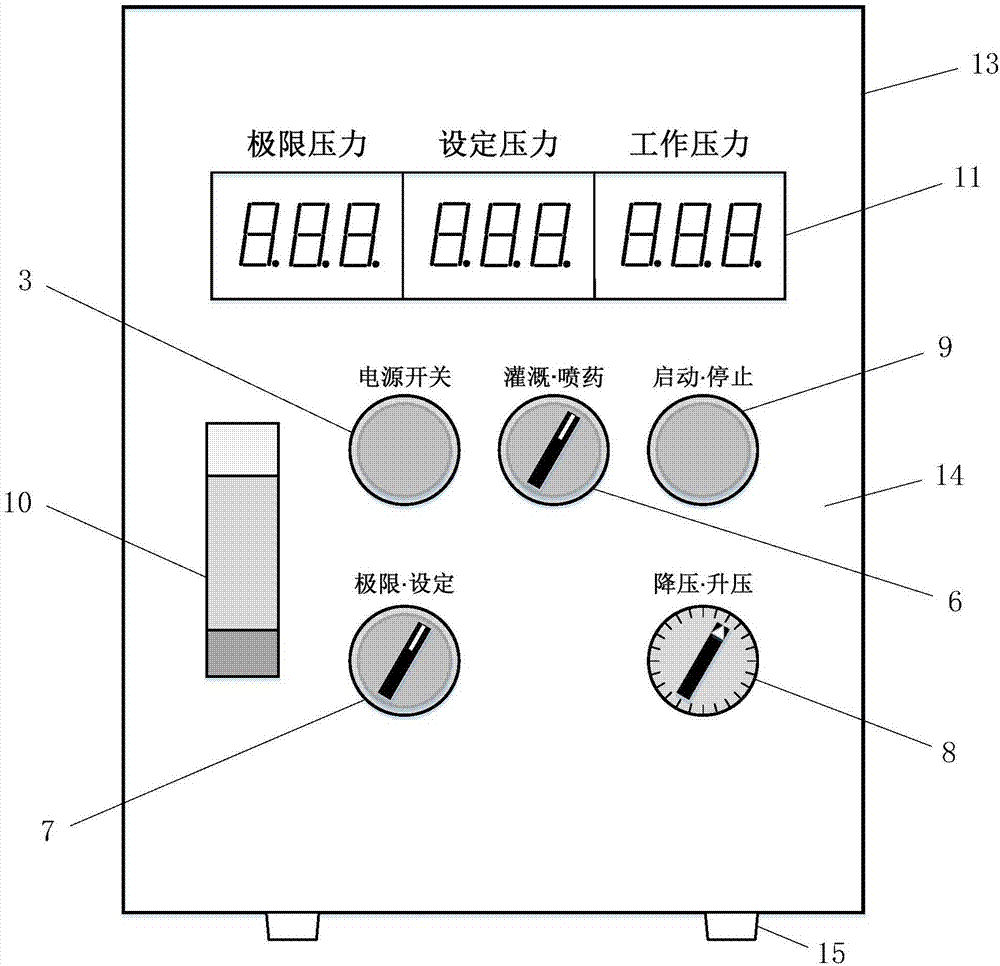

[0045] Such as figure 1 As shown, this embodiment provides a pipeline liquid pressure controller, which includes a single-chip microcomputer 1, a dual-output switching power supply 2, a power switch 3, an ADC analog-to-digital conversion module 4, an RS485 communication interface 5, and a working mode selection switch 6. Pressure setting selection switch 7, pressure adjustment switch 8, start-stop switch 9, running indicator light 10 and display module 11.

[0046] Described single-chip microcomputer 1 is the core of whole controller, and it adopts kernel to be cortex-M3 series single-chip microcomputer, is built-in with PID algorithm, single-chip microcomputer 1 is connected with frequency converter by RS485 communication interface 5, and described frequency converter is connected with frequency conversion motor, and frequency conversion motor is used In order to control the speed of the drug pump, the water outlet of the drug pump is respectively connected to the pressure se...

Embodiment 2

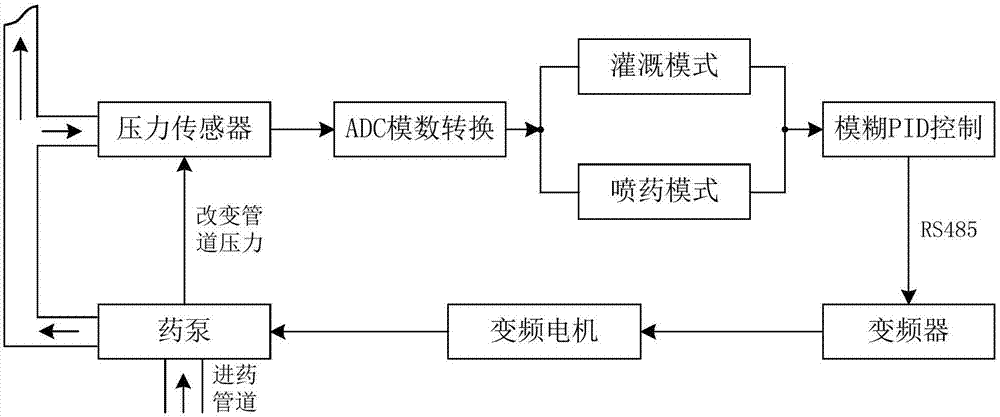

[0068] Such as Figure 4 As shown, the pipeline liquid pressure controller in this embodiment includes a single-chip microcomputer 1 , a dual-output switching power supply 2 , a power switch 3 , an ADC analog-to-digital conversion module 4 , and an RS485 communication interface 5 .

[0069] The single-chip microcomputer 1 is connected with the frequency converter through the RS485 communication interface 5, and the frequency converter is connected with the frequency conversion motor, and the frequency conversion motor is used to control the speed of the drug pump. It is used to detect the pressure of the liquid medicine in the liquid medicine pipeline.

[0070] The input terminal of the dual-output switching power supply 2 is connected to the single-phase power supply, and the output terminal is connected to the power switch 3. The power switch 3 is connected to the pressure sensor 12 and the single-chip microcomputer 1 respectively. When the power switch 3 is pressed, the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com