Continuous deep dewatering equipment

A deep dewatering and equipment technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of high requirements for equipment infrastructure, high labor intensity, intermittent operation of equipment, etc., to avoid The effect of excessive deformation, convenient pressure adjustment and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

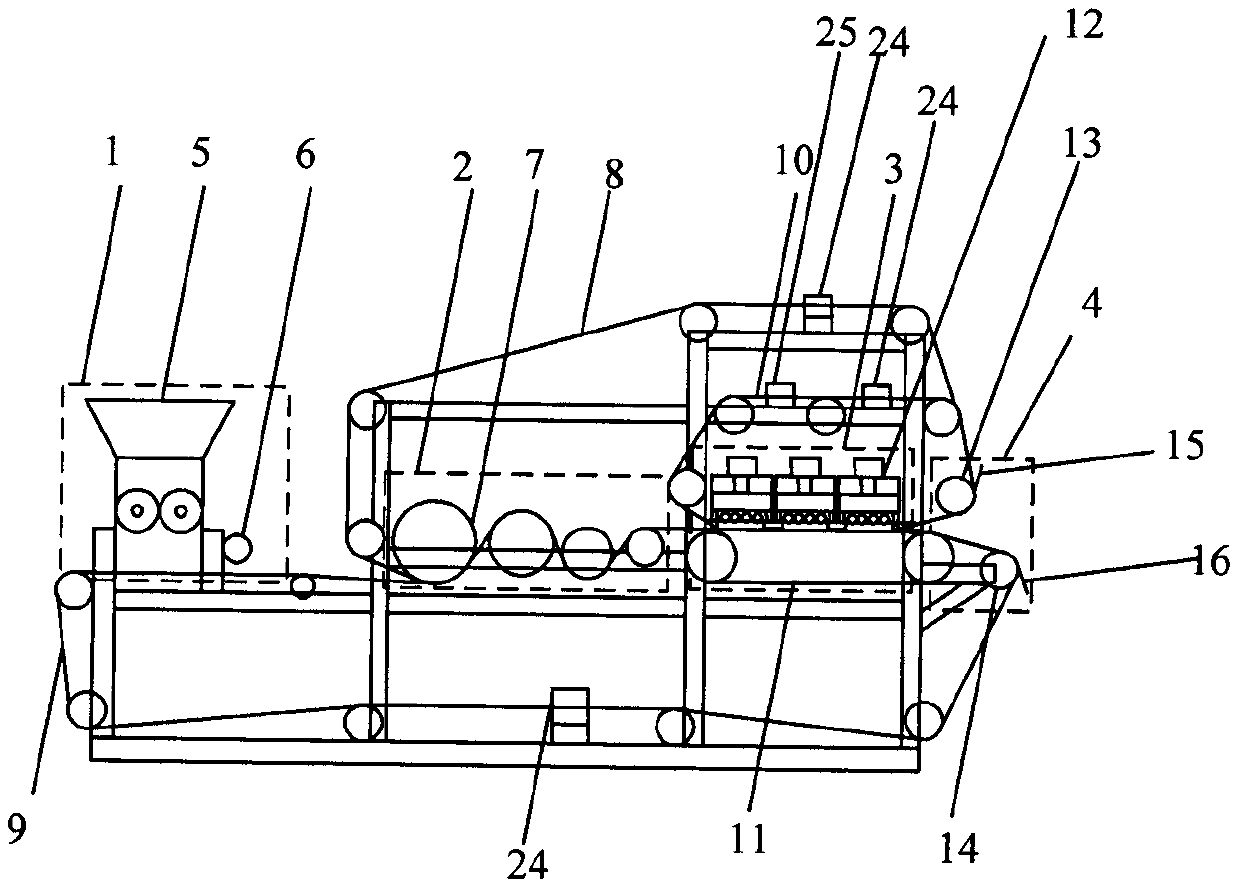

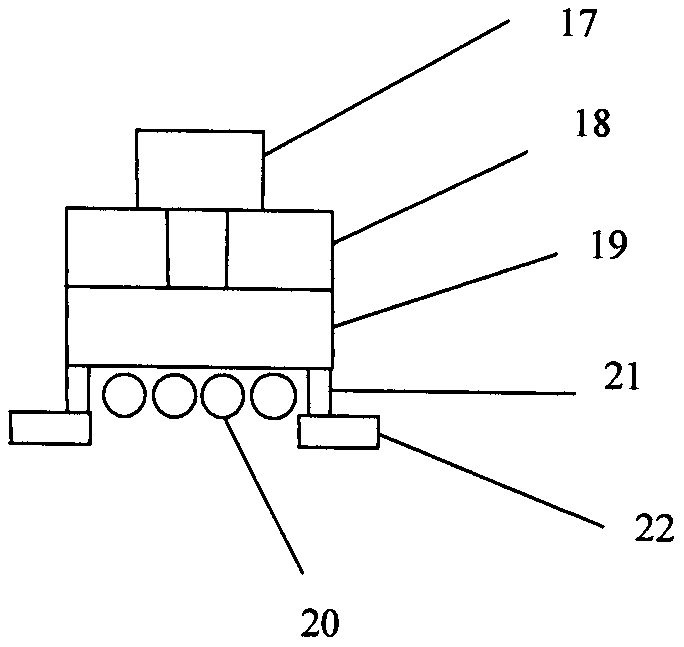

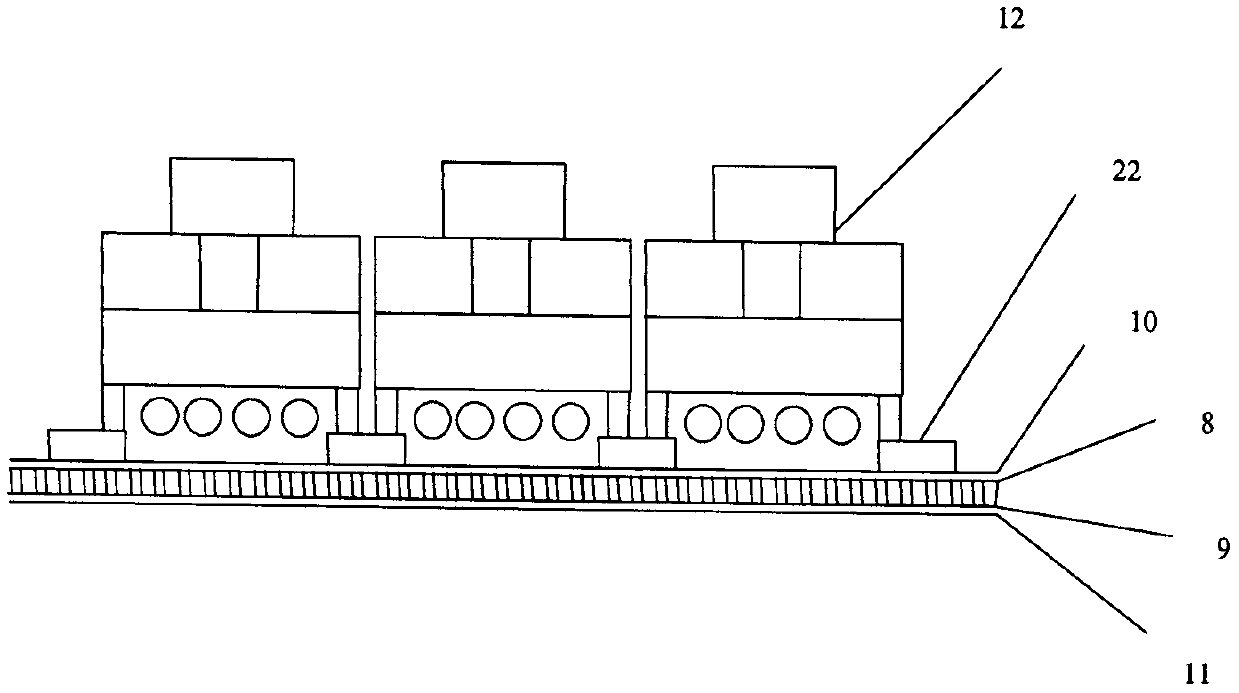

[0027] A continuous depth dehydration equipment mainly includes a distribution area 1, a pre-pressing area 2, a pressing area 3 and a discharge area 4. The material distribution area includes a distributor 5 and a leveling roller 6; the pre-pressing area is composed of a dewatering roller body 7, The upper filter screen 8 and the lower filter screen 9 are composed, and the upper filter screen 8 and the lower filter screen 9 are overlapped and wound in an S shape on the dewatering roller body 7; the pressing zone 3 is composed of the upper filter screen 8, the lower filter screen 9, the upper 10. The lower liner belt 11 and the pressurizing assembly 12 are composed of the upper filter screen 8, the lower filter screen 9, the upper liner belt 10 and the lower liner belt 11 which overlap in the pressing area to form a pressing surface close to the plane. The pressurization assembly 12 acts vertically on the pressing surface; the pressurizing assembly 12 is composed of a pressurizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com