Integrated fiber F-P chamber pressure sensor

A pressure sensor, F-P technology, applied in the direction of instrumentation, force measurement, and measurement of the change force of the optical properties of the material when it is stressed, can solve non-linearity, reduce the accuracy of F-P pressure sensors, and reduce the accuracy of F-P pressure sensors, etc. problems, to achieve the effect of reducing thermal internal stress, avoiding additional stress, and facilitating pressure adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

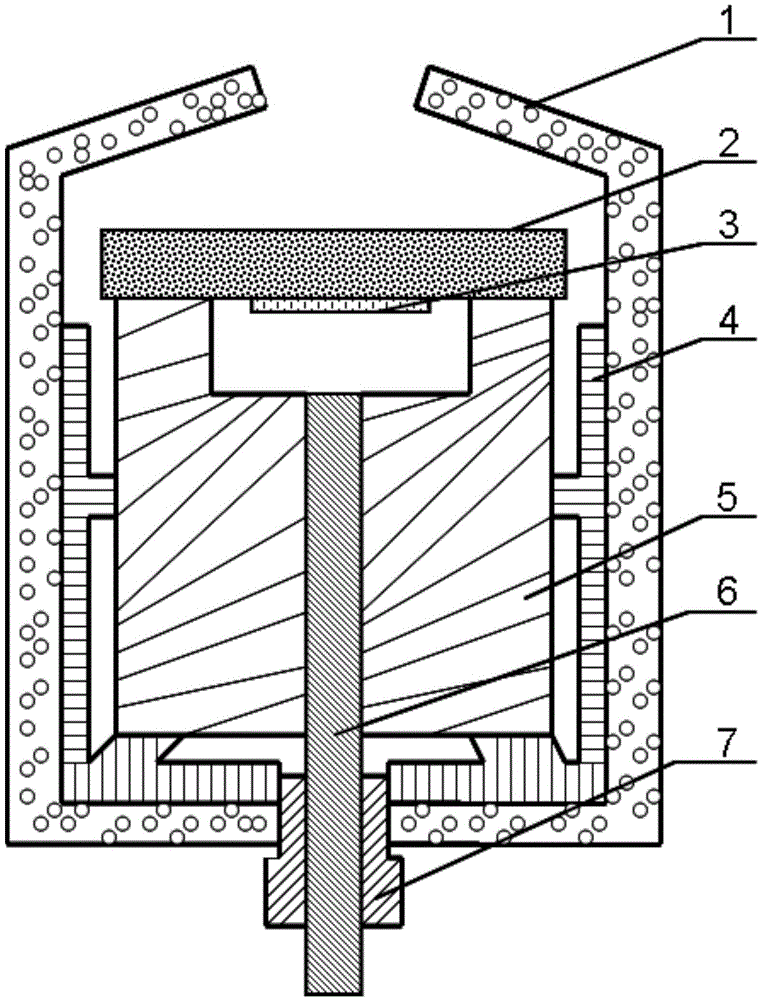

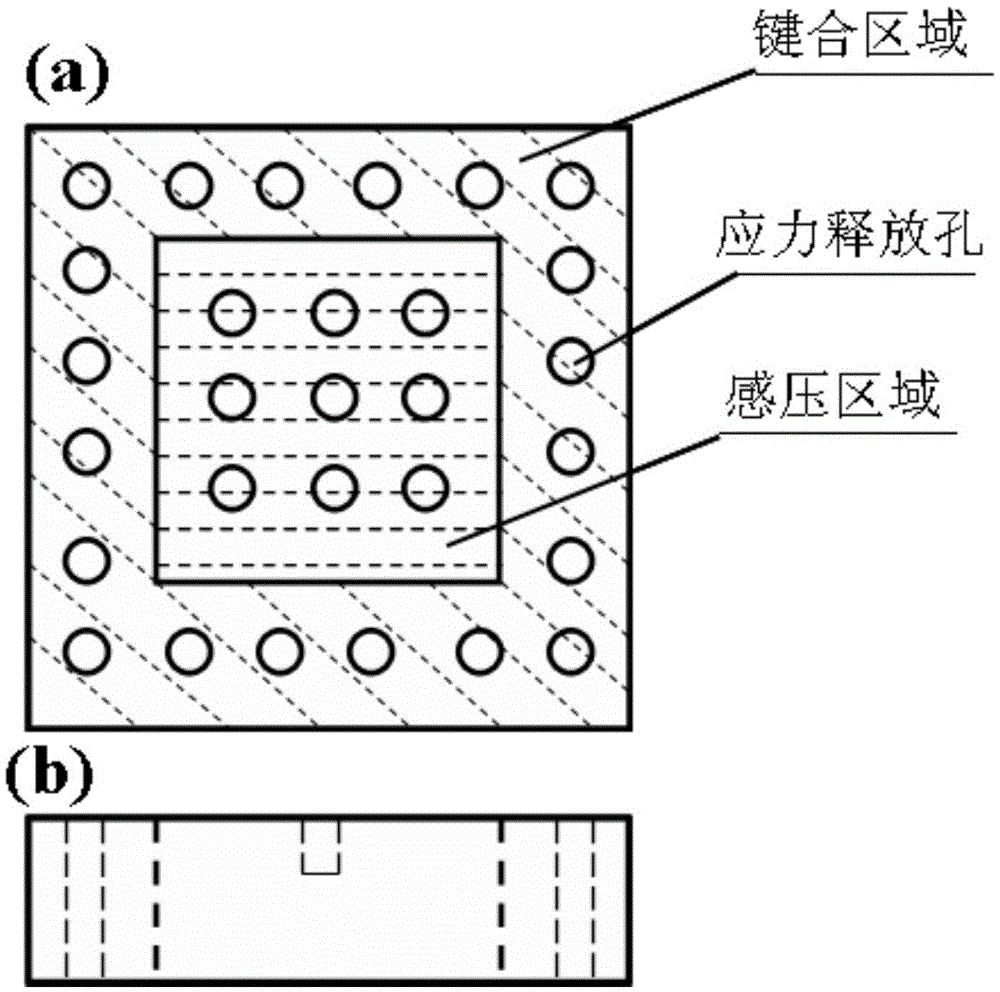

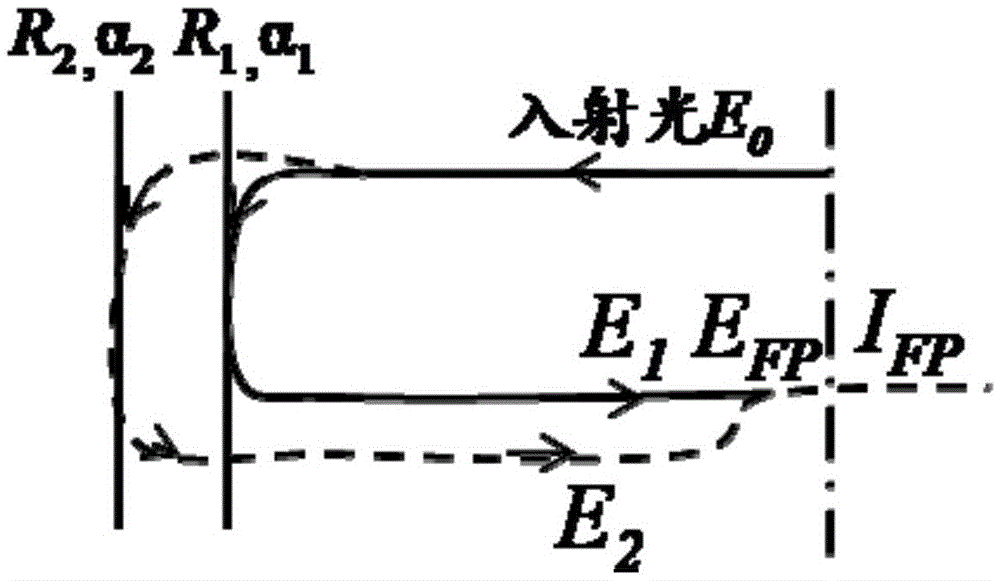

[0023] in as figure 1 In a preferred embodiment shown and described, the integrated optical fiber F-P cavity pressure sensor consists of a packaging shell 1, a pressure diaphragm 2, a composite dielectric film 3, a solid connection member 4, a ferrule 5, an optical fiber 6, and a fixed joint 7. It mainly includes a barrel-shaped packaging casing 1, a pressure diaphragm 2 arranged in the cylinder of the packaging casing 1, a composite dielectric film 3 fixedly connected under the end of the pressure diaphragm 2, and a groove at the end of the ferrule 5 The bottom plane is flush, and the optical fiber 6 protrudes out of the bottom of the packaging shell through the ferrule, and the optical fiber 6 protrudes out of the cylinder of the packaging shell 1 through the fixed joint 7 . The front end of the optical fiber 6 and the composite dielectric film 3 on the pressure diaphragm 2 form a pair of reflective surfaces and form interference fringes, and the external pressure is measure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com