Biomass gasification power generation apparatus

A power generation device and biomass technology, applied in gasification process, manufacture of combustible gas, petroleum industry, etc., can solve problems that need to be improved, achieve high energy conversion efficiency, avoid environmental pollution, and stabilize pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

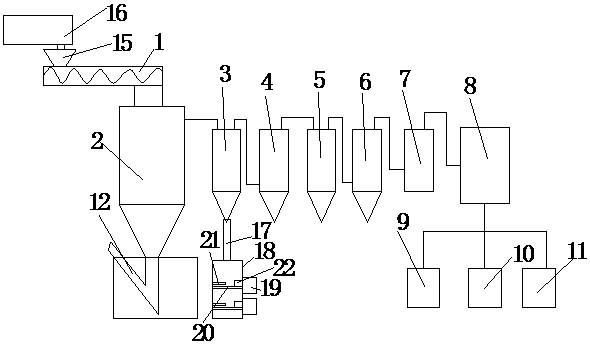

[0016] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

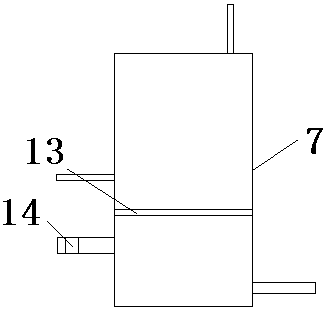

[0017] As shown in the figure, the biomass gasification power generation device of the present invention includes a screw feeder 1, a biomass gasification furnace 2, a cyclone dust collector 3, a filter 4, a condenser 5, and a hydrocyclone 6 connected in sequence , the balance tank 7 and the gas storage tank 8, the gas storage tank 8 is connected to the gas boiler 9 or the gas generator set 10, or directly connected to the gas supply user 11, and an automatic slagging system 12 is set under the biomass gasifier 2, and the cyclone dust removal A dry ash collection device is arranged below the device 3, and a buffer diaphragm 13 is arranged inside the balance tank 7. The upper part of the buffer diaphragm 13 is a gas chamber, and the lower part is a liquid chamber. A liquid pressure regulating device 14 is arranged at the liquid inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com