Screen printing machine scraper control mechanism

A screen printing machine and control mechanism technology, applied in the field of component structure, can solve problems such as unintuitive, inconvenient pressure adjustment, and the influence of air pressure instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

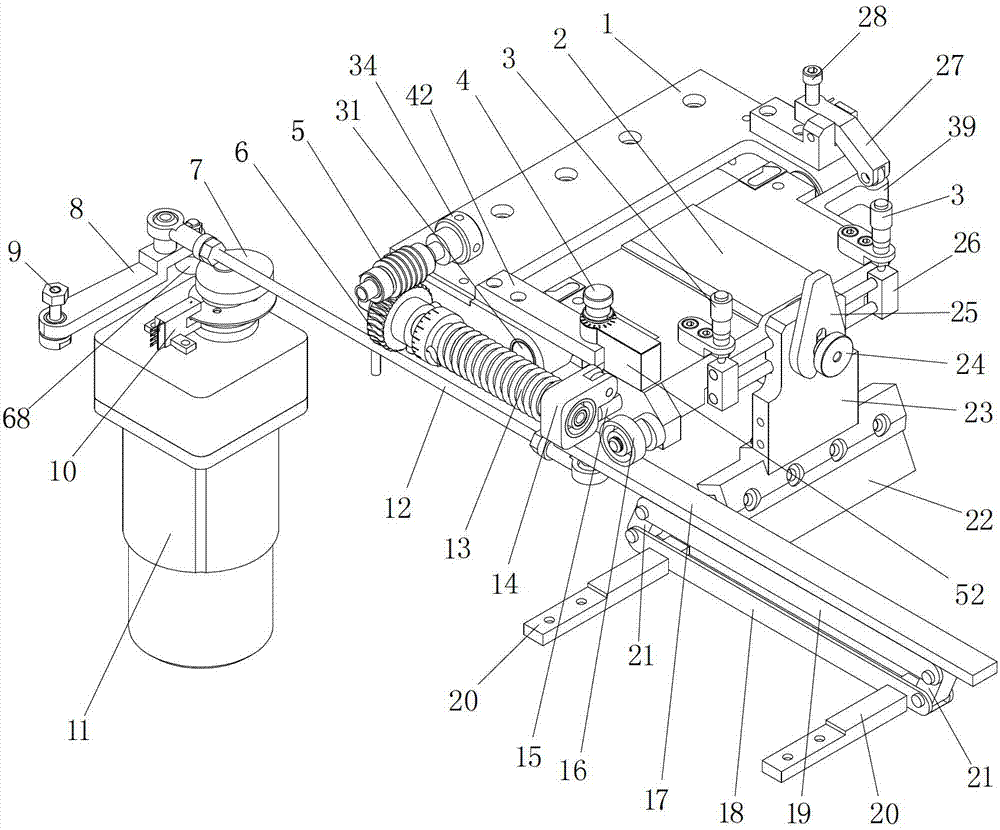

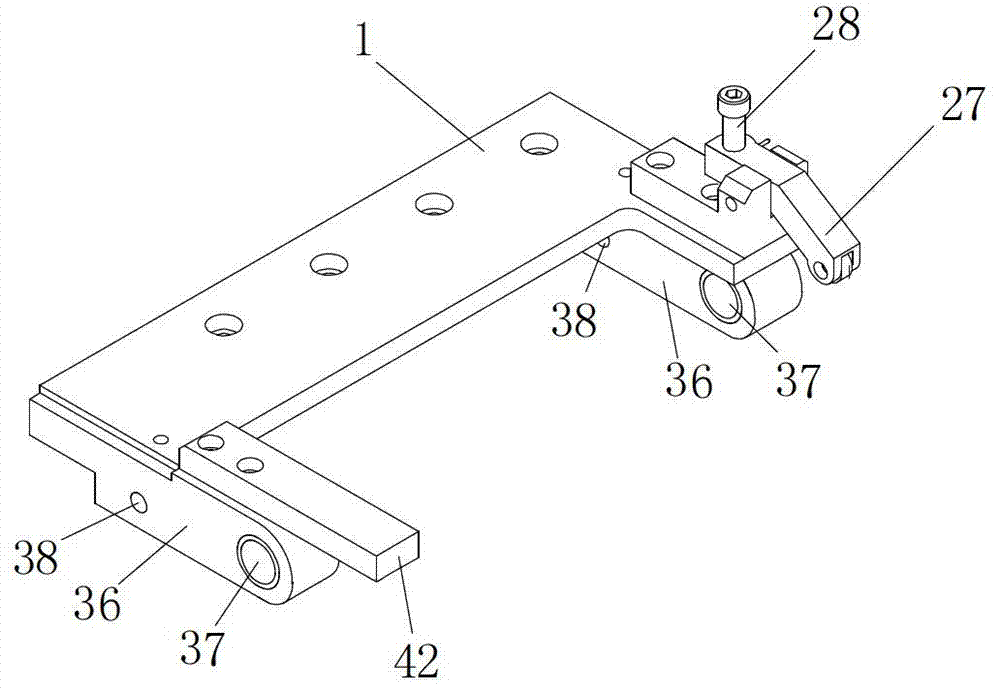

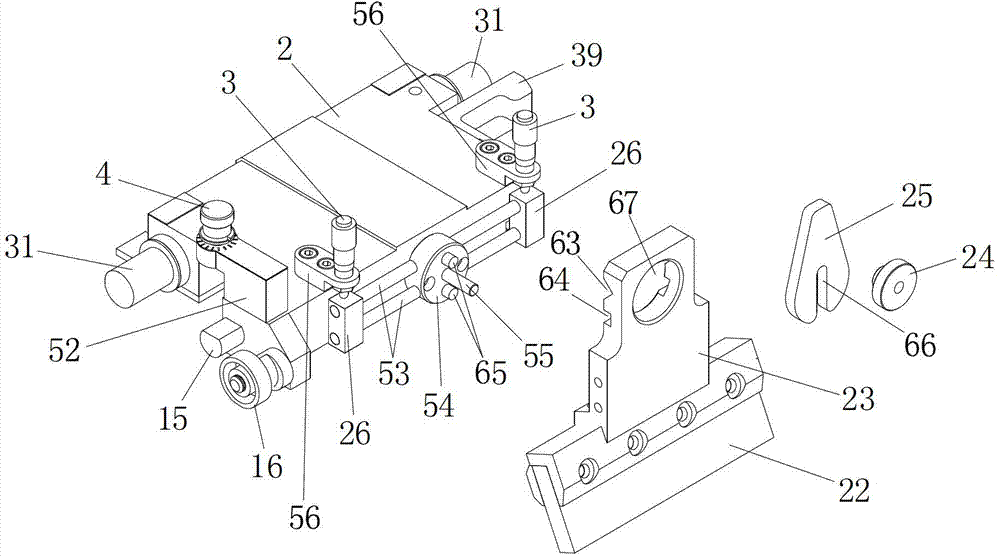

[0020] Such as figure 1 As shown, the scraper control mechanism of the screen printing machine includes a base 1, a scraper assembly, an ink flooding blade assembly, a scraper lifting mechanism and a scraper pressing mechanism. Such as figure 2 As shown, the left and right sides of base 1 respectively have an arm 36 protruding forward, the front portion of these two arms respectively has a scraper shaft hole 37, and the rear portion of these two arms respectively has a flooding knife shaft hole 38 . Such as figure 1 with image 3 As shown, the scraper assembly includes a scraper swing body 2 and a scraper 22 . The scraper is fixed on the front end of the scraper oscillating body. There is a scraper rotating shaft 31 at the rear of the scraper oscillating body. There are a roller 16 and a pressure rod 15 at the front of the left side. Such as Figure 5 As shown, the flood knife assembly includes a flood knife shaft 40 , a flood knife 32 and two side bars 41 . The shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com