Marine rig hydraulic wave compensation device

A wave compensation and hydraulic technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of inaccurate balance compensation response, counterweight stuck in the casing, slow response of balance compensation, etc., to achieve flexible response, Convenient pressure adjustment, stable and reliable compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

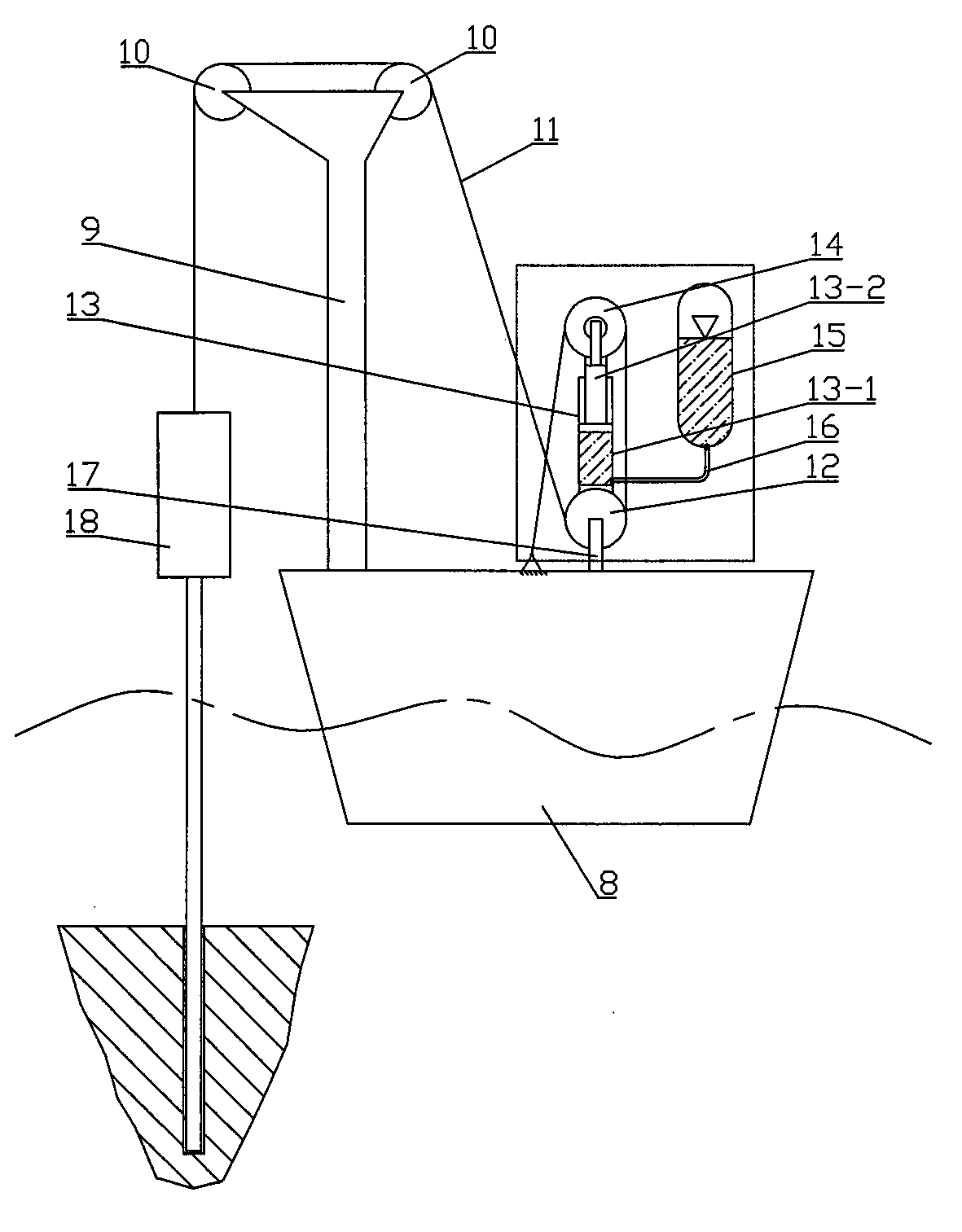

[0015] like figure 2 Shown: a hydraulic wave compensation device for an ocean drilling rig, including a drilling tower 9 fixedly installed on a drilling ship 8, a tower top pulley 10 installed on the top of the drilling tower 9, a steel wire rope 11 and a hydraulic wave compensation mechanism, the hydraulic wave compensation The mechanism includes oil cylinder fixed wheel 12, oil cylinder 13, oil cylinder movable wheel 14, sealed oil reservoir 15 and oil pipe 16, oil cylinder fixed wheel 12 is fixedly installed on the drilling ship 8 through bracket 17, oil cylinder 13 includes cylinder body 13-1 and piston rod 13-2, the cylinder body 13-1 is welded and fixed on the fixed wheel 12 of the oil cylinder, the end of the piston rod 13-2 is connected with the axle of the movable wheel 14 of the oil cylinder, the lower end of the sealed oil reservoir 15 has hydraulic oil, and the upper end has compressed gas, The hydraulic oil at the lower end of the sealed oil reservoir 15 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com