Switchover method for a solenoid valve operated in analogized form, electrohydraulic brake system, and use of the electrohydraulic brake system

A technology of brake system, conversion method, applied in the direction of brake, valve operation/release device, valve detail, etc., which can solve the problem of inaccuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

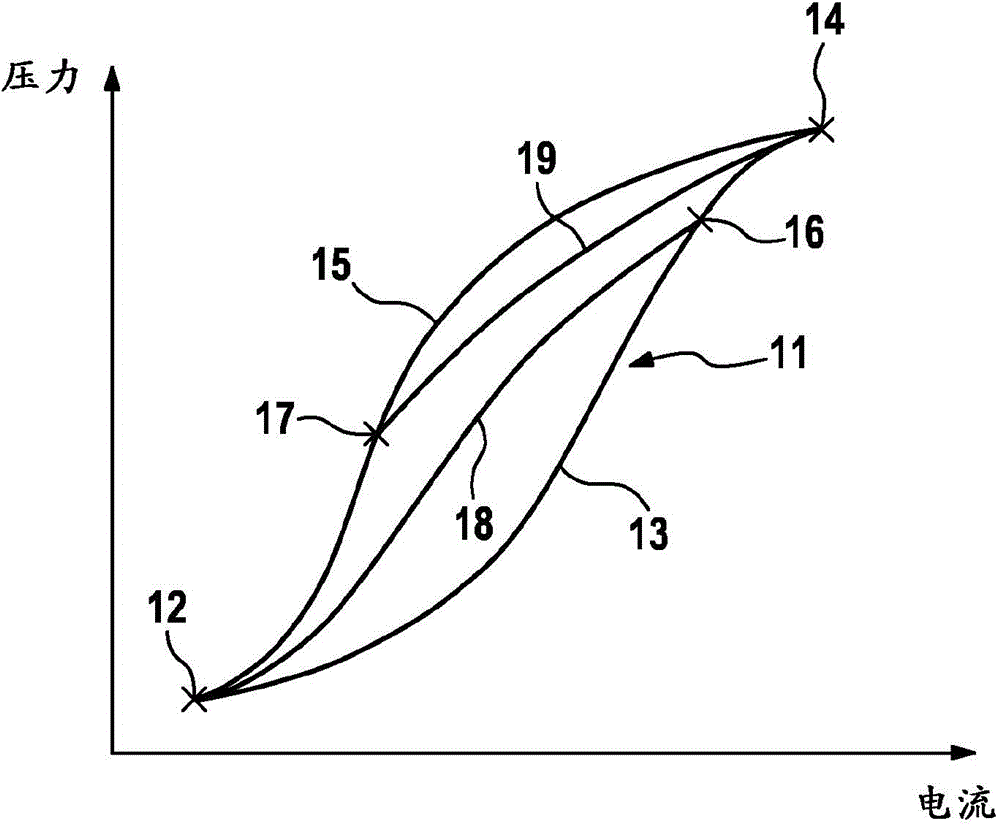

[0027] figure 1The current- and pressure-dependent hysteresis characteristic curve 11 of a solenoid valve is shown by way of example in . The x-axis represents the current applied to the solenoid valve, and the y-axis represents the pressure acting on the solenoid valve at which the solenoid valve is opened by applying a correspondingly set current. As the current loading increases from point 12 , the magnetic force on the solenoid valve, which according to the example keeps the solenoid valve closed, even if the valve stem remains in the closed position, changes to a higher pressure along line 13 . At point 14 the maximum magnetic force is reached. This corresponds to the maximum pressure the solenoid valve can withstand without opening. Now, starting from point 14 , if the current application is reduced again, the magnetic force, and thus the pressure, changes along line 15 with the solenoid valve open. As can be seen, hysteresis effects produce the phenomenon that two di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com