Batch calibration equipment and batch calibration method for intelligent pointer-type pressure gages

The technology of a calibration device and calibration method, which is applied in the field of instrument calibration, can solve the problems of easy fatigue, low reliability, and low calibration efficiency when reading the dial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

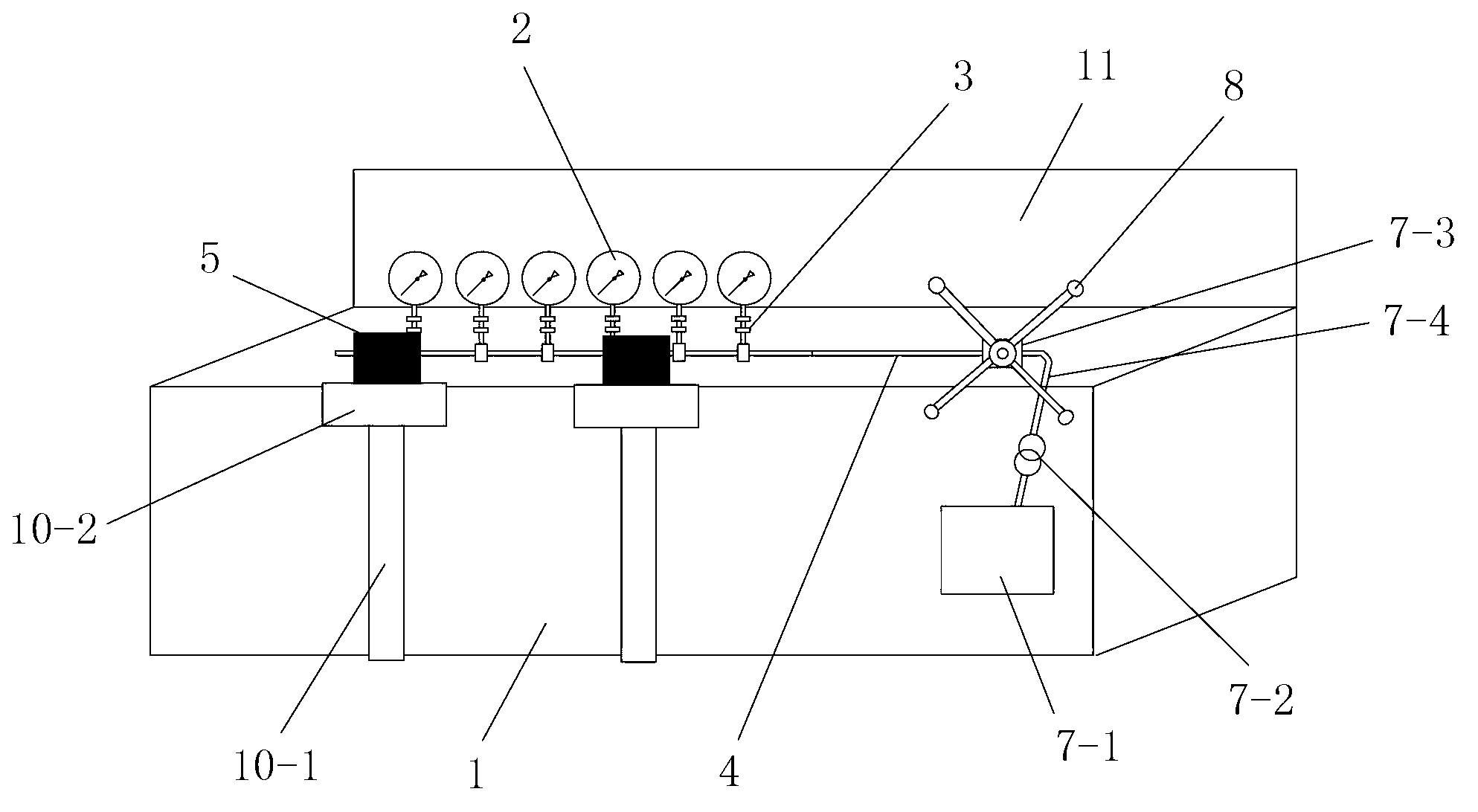

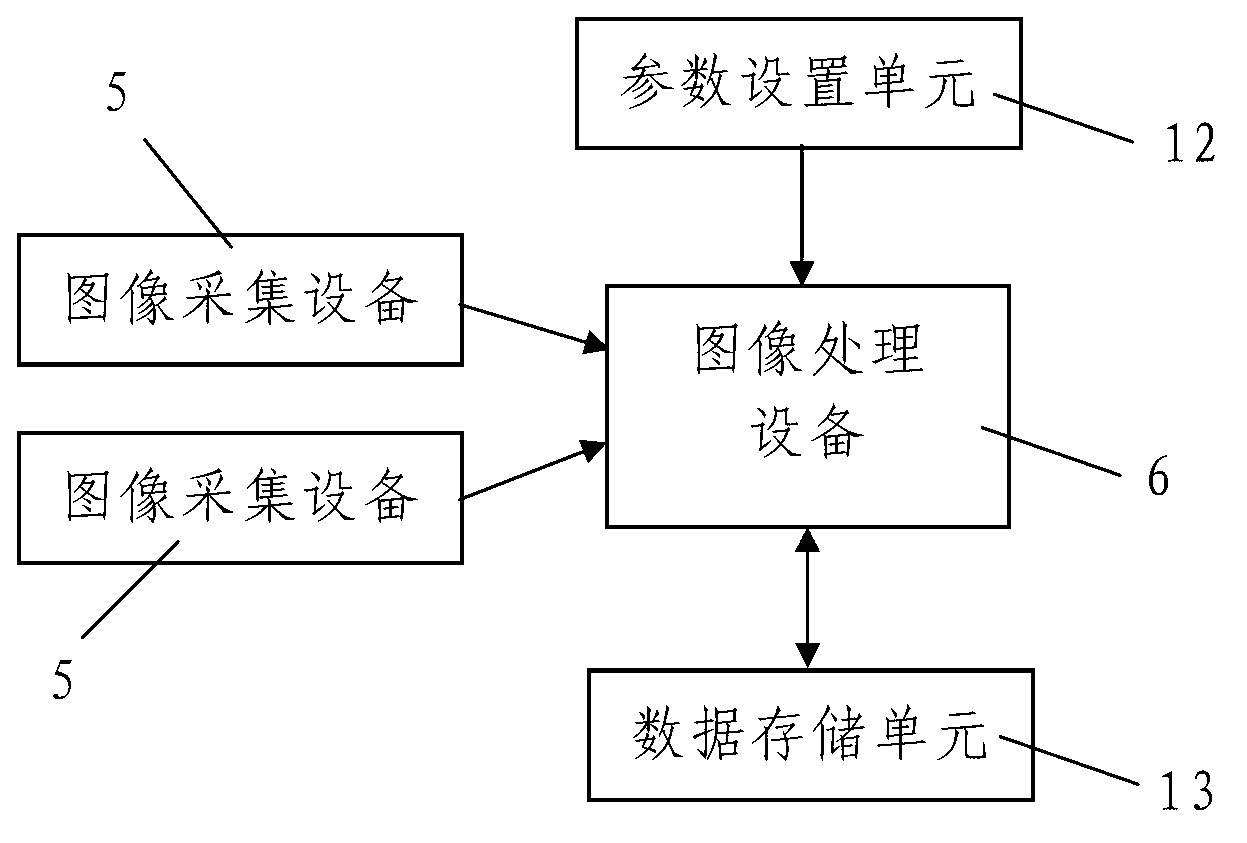

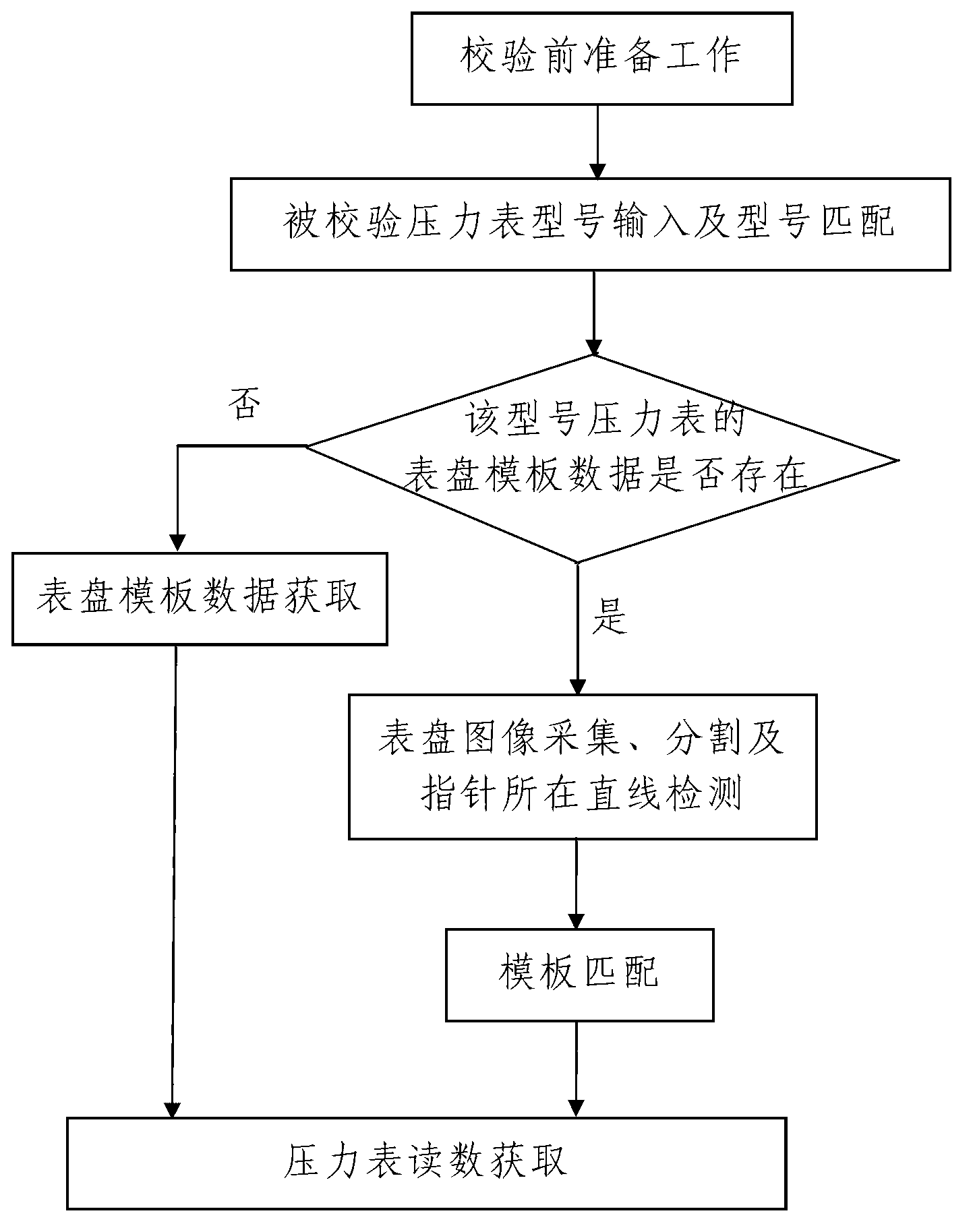

[0063] Such as figure 1 , figure 2 The batch calibration device for intelligent pointer pressure gauges shown includes a horizontal calibration platform 1, a horizontal test tube 4 installed on the horizontal calibration platform 1, and a plurality of pressure gauges 2 to be calibrated. A quick connector 3, two image acquisition devices 5 that are located in front of the horizontal calibration platform 1 and capture the dial images of a plurality of pressure gauges 2 to be verified, and images connected to the two image acquisition devices 5 Processing equipment 6, a pressurizing device for pressurizing the horizontal test tube 4 and a pressure regulating device for adjusting the internal pressure of the horizontal test tube 4 by controlling the pressurizing device, the pressurizing device connects the pipeline with the The horizontal test pipe 4 is connected, and the pressurizing device is connected to the pressure regulating device. The number of the multiple pressure gau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com