Blowout preventing box of continuous oil pipe and drill rod

A technology of coiled tubing and blowout preventer, which is applied in the fields of drill pipe blowout preventer and coiled tubing tubing. It can solve the problems of inconvenient pressure adjustment in the sealed cavity, inability to detect wellhead pressure in real time, and many parts to be disassembled. Lightweight, novel structure and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

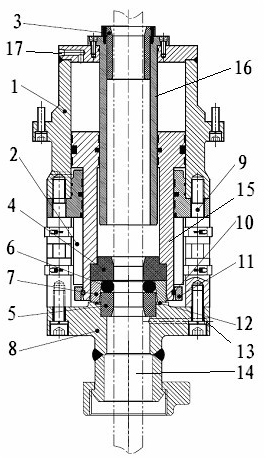

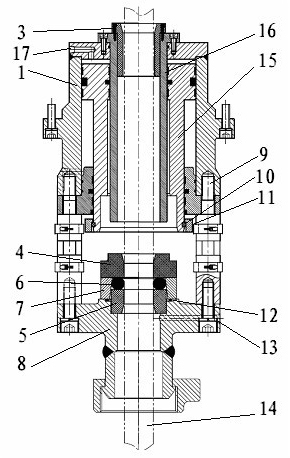

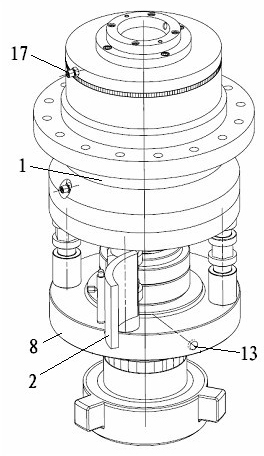

[0019] refer to figure 1 , figure 2 , the structure of the blowout prevention box of the present invention is to include a hollow hydraulic cylinder 1 and a flange union 8, the outer circumference of the hollow hydraulic cylinder 1 is provided with a flange, and the outer circumference of the flange union 8 is also provided with a corresponding flange, and the hollow hydraulic cylinder 1 is provided with a corresponding flange. The cylinder 1 and the flange union 8 are connected by a plurality of connecting rod bolts 9 evenly arranged along the circumference, and a set of valve assemblies 2 are respectively installed on the two connecting rod bolts 9 with opposite diameters, and each set of valve assemblies 2 The lugs are set on a connecting rod bolt 9; the top cover of the hollow hydraulic cylinder 1 is provided with a hydraulic inlet and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com