Production method and production system for health-protection lycopene oil

A technology of lycopene and a production method, which is applied in the field of production methods and production systems of health-care oil, can solve the problems of large loss of lycopene, easy oxidation of lycopene, low production efficiency, etc. The effect of full and uniform fusion, improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

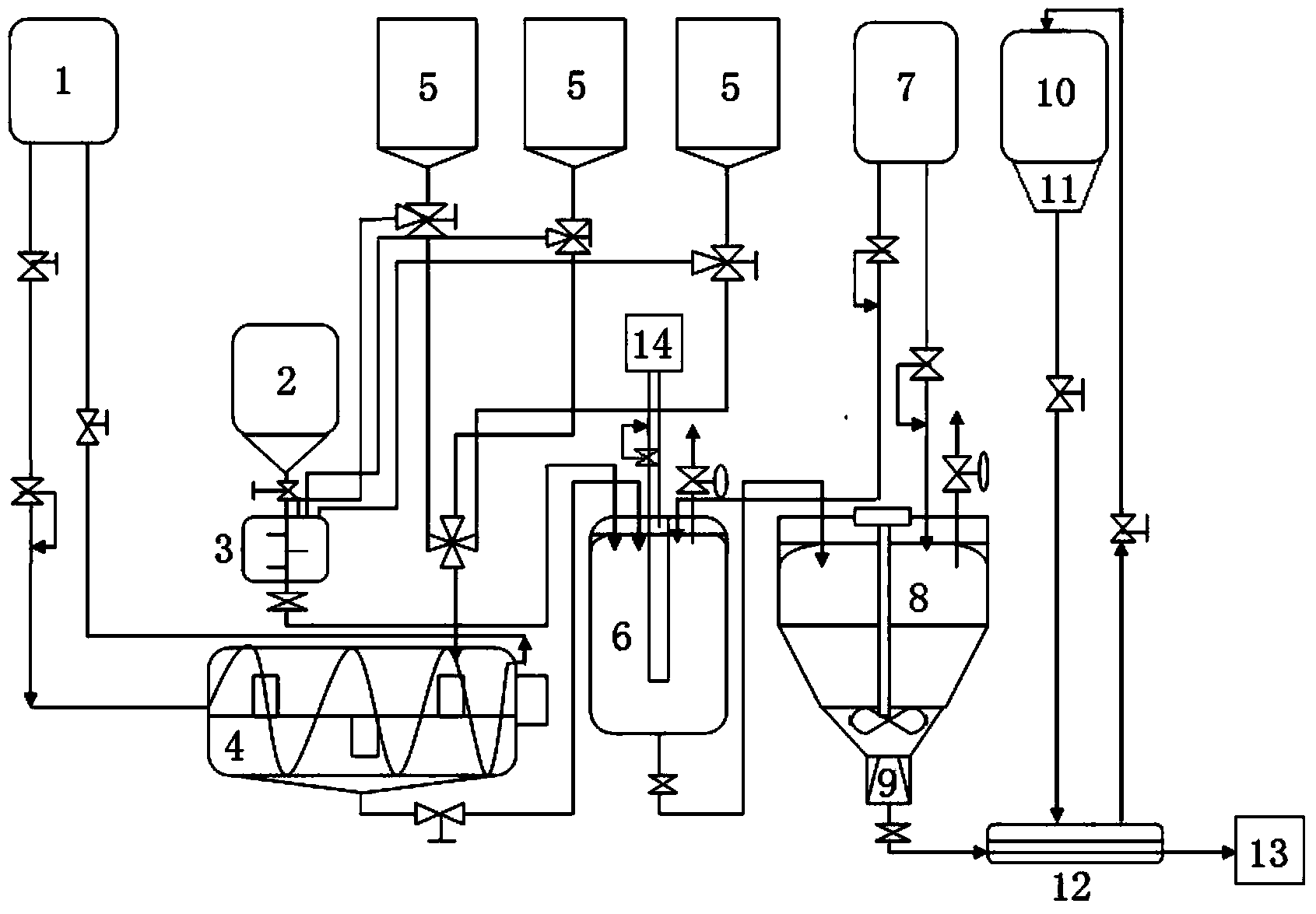

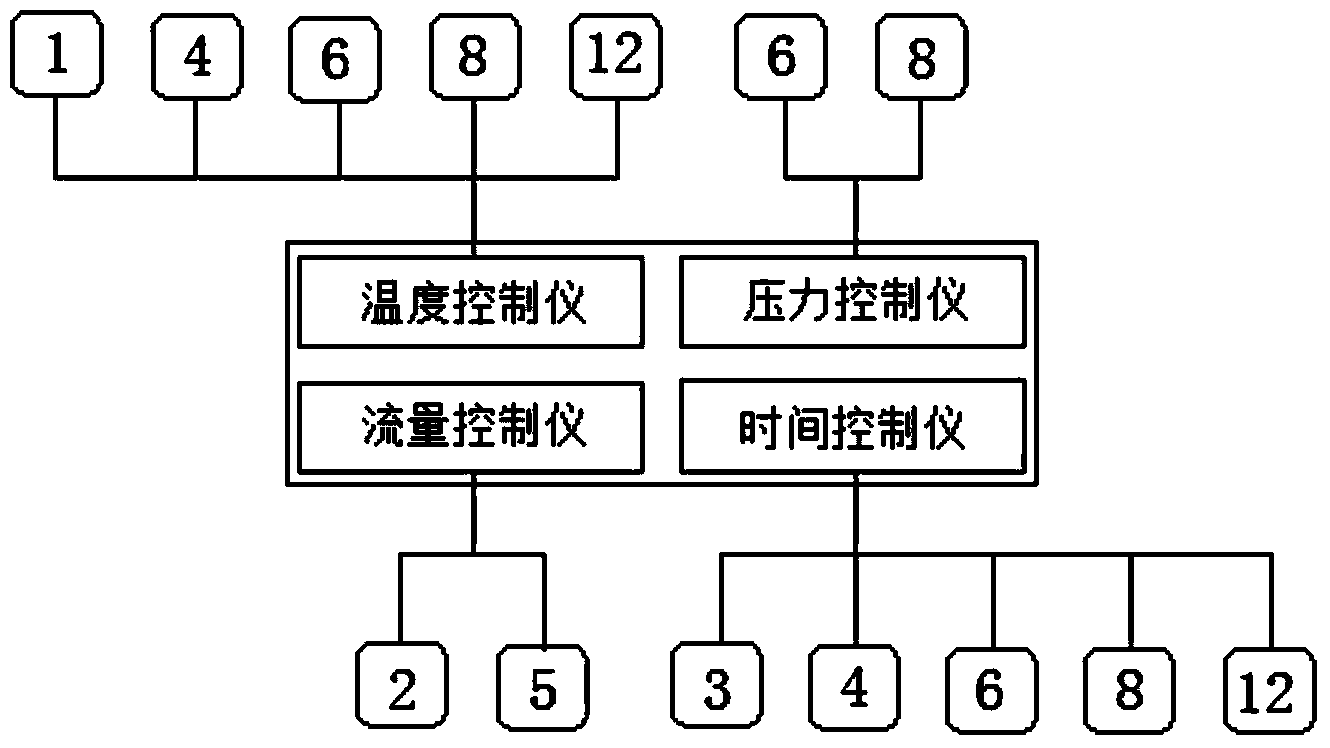

[0060] The production method of a kind of lycopene health-care oil of this embodiment adopts refined vegetable oil and lycopene extract as production raw materials, and the lycopene contained in the lycopene extract is usually 5% to 10%. The steps are:

[0061] (1) Preheat a part of the raw material oil with high-temperature heat transfer oil, and at the same time stir the raw material oil so that it can quickly and evenly reach the set temperature of 172°C. The preheating effect is better. The preheating temperature is based on the content of lycopene Melting point (in the case of 760mmHg, the melting point of lycopene is 172 ℃ ~ 173 ℃), so that the raw material oil and lycopene can be more fully fused; at room temperature, another part of the raw material without preheating Oil and lycopene extract are initially mixed, and the initial mixing of raw material oil and lycopene extract is completed instantaneously before entering the next step, which greatly shortens the residen...

Embodiment 2

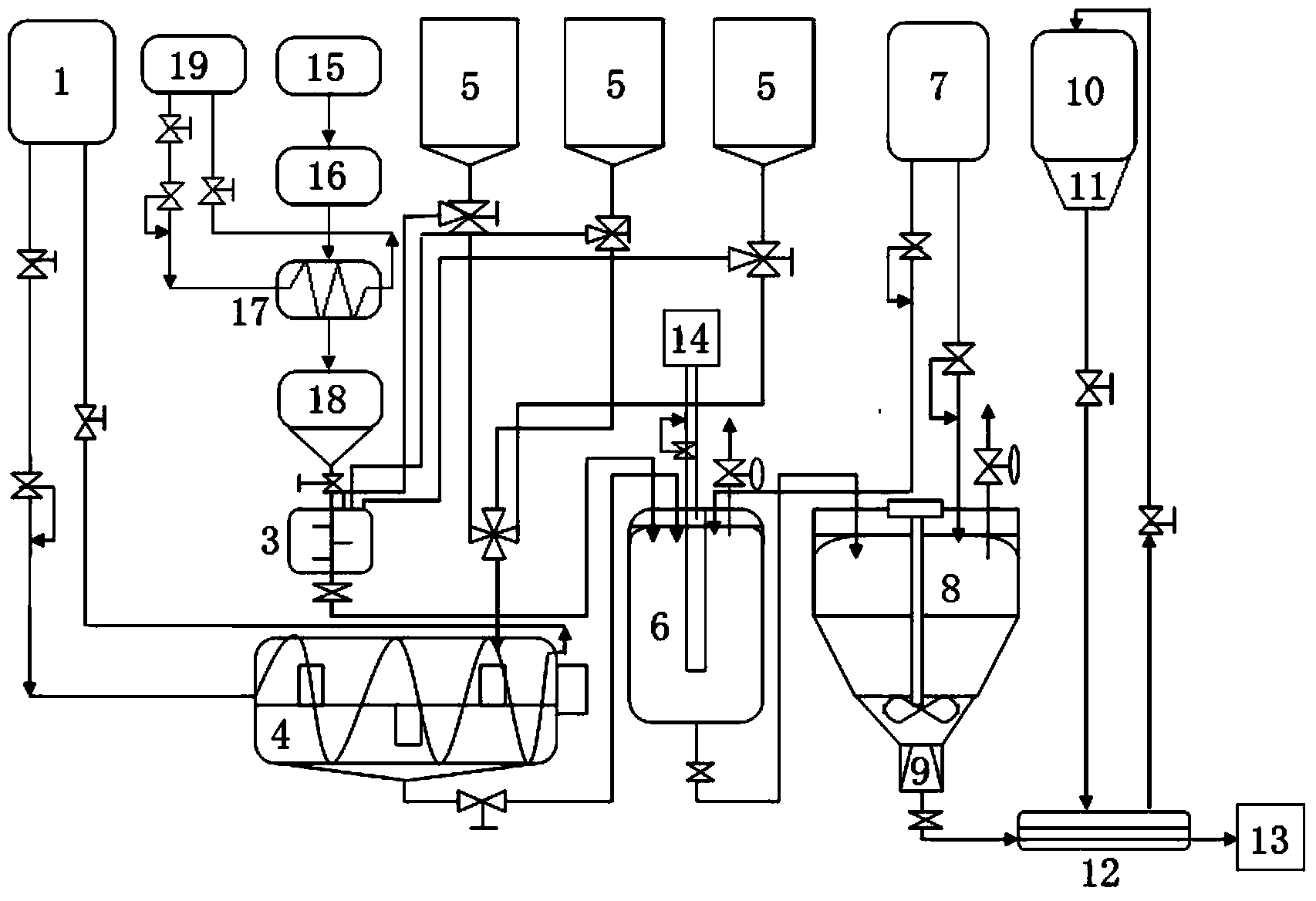

[0070] The production method and production system of a lycopene health-care oil in this embodiment are basically the same as in Example 1, except that in step (1), a part of the raw material oil is preheated by high-temperature heat transfer oil, and the preheating temperature is 174 °C; in step (2), the preheated raw material oil and the mixture after initial mixing are mixed again, and pressure vibration is performed, and the vibration frequency is 3300KHz; in step (3), the mixture is extracted, and the extraction time is 7.5min.

Embodiment 3

[0072] The production method and production system of a lycopene health-care oil in this embodiment are basically the same as in Example 1, the difference is that in step (1), a part of the raw material oil is preheated by high-temperature heat transfer oil, and the preheating temperature is 176 °C; in step (2), the preheated raw material oil and the mixture after initial mixing are mixed again, and pressure vibration is performed, and the vibration frequency is 5000KHz; in step (3), the mixture is extracted, and the extraction time is 5min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com